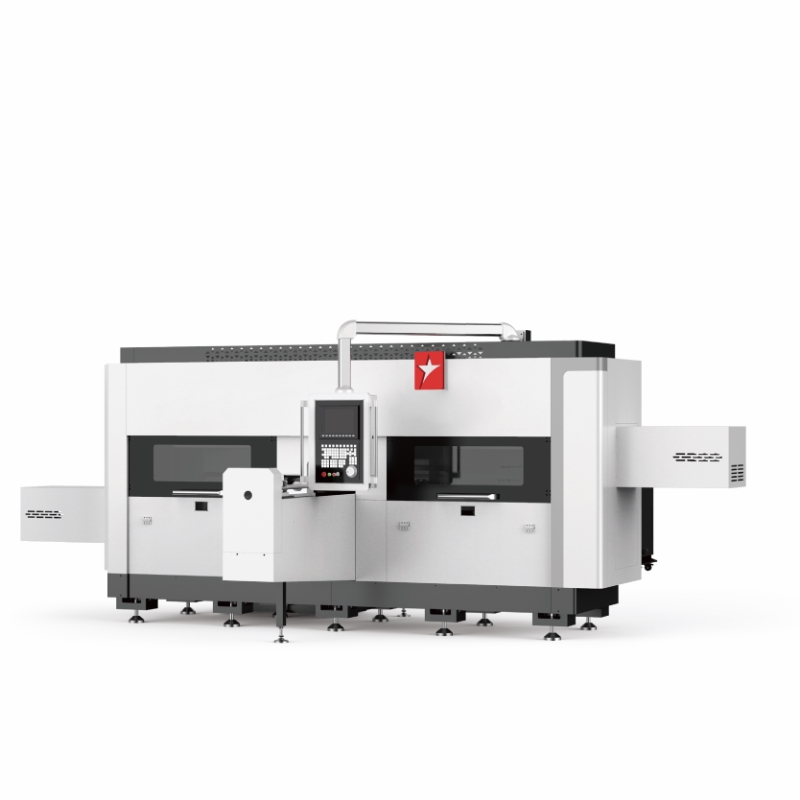

Cnc Gear Cutting Machine Manufacturer in China - Precision Engineering Solutions

As a manufacturer of high-quality CNC gear cutting machines in China, I understand the importance of precision and efficiency in your production processes. Our machines are designed to meet the demanding needs of various industries, ensuring that each gear is cut to perfection. With advanced technology and robust performance, they help you streamline your operations and increase productivity. I know how crucial it is to have reliable equipment that can handle complex gear designs without compromising on quality. That's why our CNC gear cutting machines come with user-friendly interfaces and customizable features to suit your specific requirements. Trust in our expertise and commitment to excellence, and take your manufacturing capabilities to the next level. Choose our CNC gear cutting machines for unmatched performance and durability, and experience the difference in your production line. Let’s work together to boost your efficiency and output!

Cnc Gear Cutting Machine Service Where Innovation Meets 2025

In the rapidly evolving world of manufacturing, the demand for precision and efficiency is higher than ever. As we approach 2025, innovative solutions in CNC gear cutting technology have emerged, transforming the way businesses approach component production. The CNC gear cutting machine service is revolutionizing industries by offering unparalleled accuracy and speed, ensuring that manufacturers can meet the diverse needs of their clients while maintaining high operational standards. Our cutting-edge machines utilize advanced technology to facilitate complex gear profiles and increase production rates significantly. With features designed for ease of operation and maintenance, these machines minimize downtime and maximize productivity. Additionally, they are equipped with intelligent automation systems that not only streamline the cutting process but also enhance the overall precision of each gear produced. As global buyers seek reliable partners for their manufacturing needs, embracing these innovations is crucial in staying competitive. Investing in state-of-the-art CNC gear cutting services positions businesses to take advantage of emerging trends in manufacturing. As industries become increasingly interconnected, having access to sophisticated machinery can open doors to new opportunities and partnerships. By harnessing the potential of modern technology, manufacturers can ensure they are well-prepared for the demands of the future, driving growth and success in a dynamic global market.

Cnc Gear Cutting Machine Service Where Innovation Meets 2025

| Feature | Description | Innovative Aspect | Expected Outcome |

|---|---|---|---|

| Precision Cutting | Advanced CNC technology for exact gear specifications. | Utilizes AI algorithms to enhance accuracy. | Reduced material waste and improved efficiency. |

| User-Friendly Interface | Intuitive controls for easy operation and quick training. | Touchscreen operation with real-time feedback. | Decreased learning curve for new operators. |

| Automated Workflows | Fully automated processes reduce manual intervention. | Integration with industry 4.0 technologies. | Increased production rates and consistency. |

| Energy Efficiency | Designed to minimize energy consumption during operation. | Smart power management systems. | Lower operational costs and a smaller carbon footprint. |

| Real-time Monitoring | Continuous data collection for performance tracking. | Cloud connectivity for remote access and analysis. | Proactive maintenance and minimized downtime. |

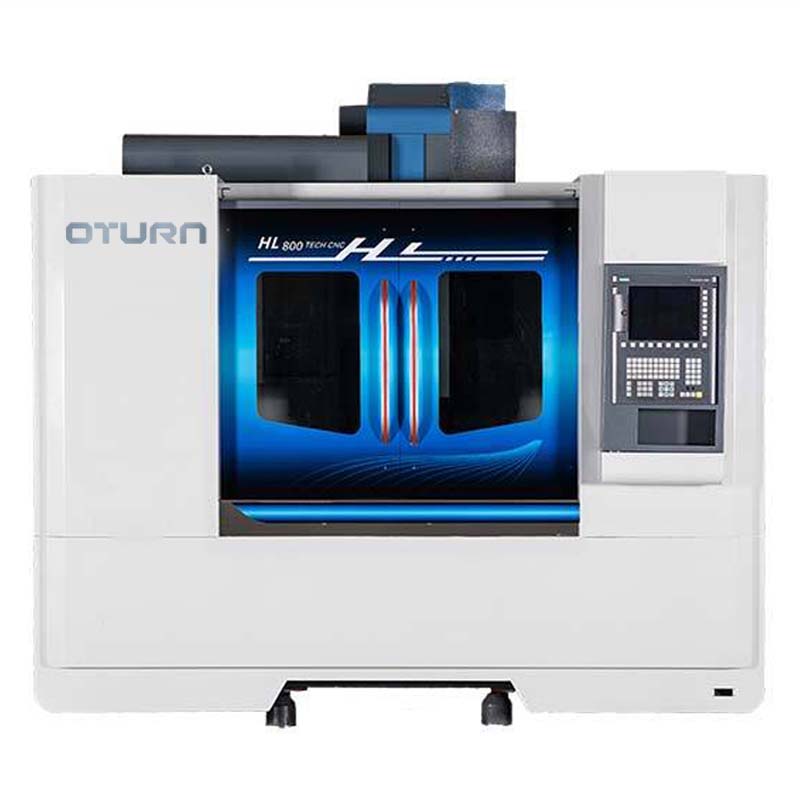

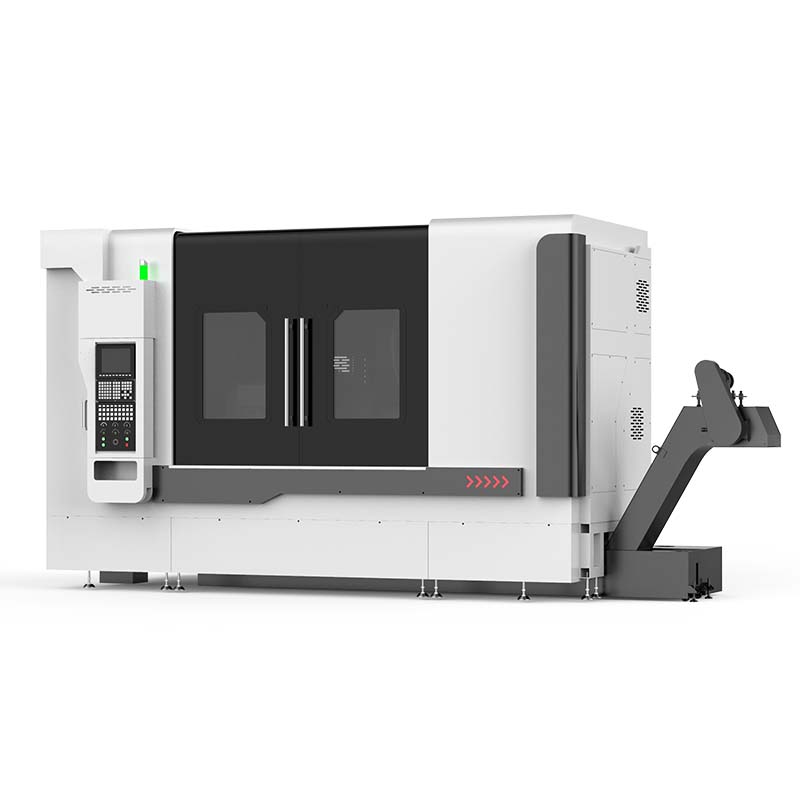

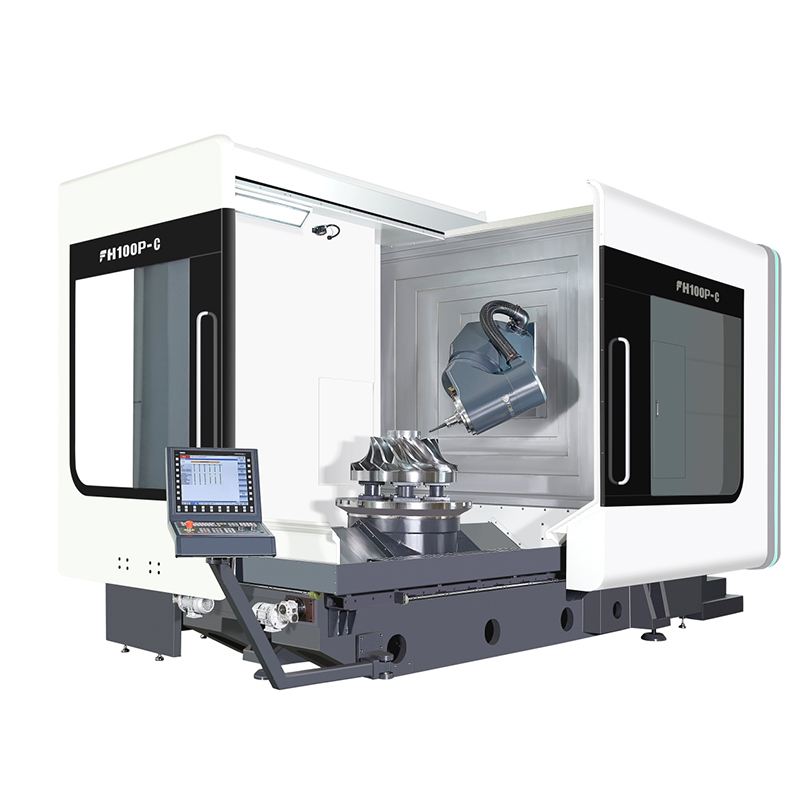

Related Products