CNC Double Column Lathe Manufacturers in China: Precision & Quality

As a seasoned buyer, I understand the importance of precision and reliability in machining. The Cnc Double Column Lathe from a top-notch manufacturer in China offers exactly that, combining advanced technology with exceptional durability. This machine is designed to handle large workpieces with ease, providing the stability and accuracy needed for high-quality production. Whether you're in the automotive, aerospace, or energy sectors, this lathe's performance can significantly enhance your manufacturing process. With multiple configurations and customizable options, it truly caters to specific production needs. Plus, its user-friendly interface means even operators with less experience can achieve professional results. Investing in our Cnc Double Column Lathe will not only improve efficiency but also ensure consistent output. Trust me, if you’re looking to elevate your machining capabilities and streamline operations, partnering with a reliable manufacturer from China is the way to go. Don't miss out on this opportunity to upgrade your shop with world-class equipment!

Cnc Double Column Lathe Stands Out For the Current Year

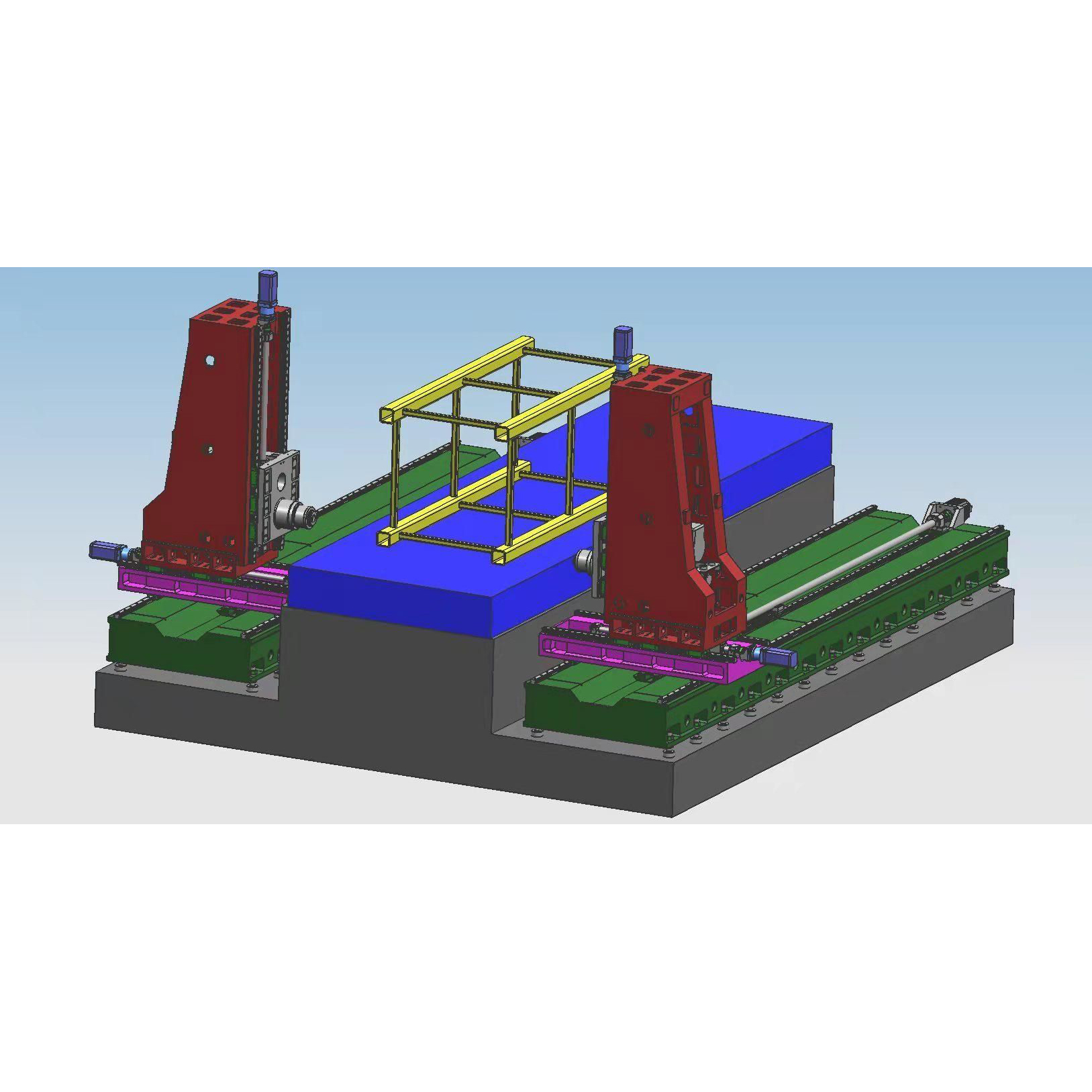

In the ever-evolving landscape of machining technology, the CNC double column lathe has emerged as a powerhouse, particularly for industries seeking precision and efficiency. This advanced machine tool is designed to handle complex machining tasks with unparalleled accuracy, making it an ideal choice for manufacturers aiming to enhance productivity. Its robust structure allows for larger workpieces, accommodating diverse materials while ensuring superior performance under heavy loads. One of the standout features of the CNC double column lathe is its ability to minimize vibrations during operation, leading to smoother cuts and improved surface finishes. This capability not only extends tool life but also reduces downtime, a critical factor for businesses looking to streamline their operations. Furthermore, the integration of advanced CNC technology allows for user-friendly programming and automation, enabling even complex designs to be produced with ease and consistency. As global demand for high-quality machined parts continues to rise, investing in a CNC double column lathe represents a strategic move for manufacturers seeking to maintain competitiveness in the market. With its combination of durability, precision, and efficiency, this machine stands out as an essential asset for factories aiming to meet diverse production needs while optimizing operational costs. Embracing this technology will undoubtedly pave the way for innovation and growth in the manufacturing sector.

Cnc Double Column Lathe Stands Out For the Current Year

| Feature | Description | Benefit | Applicability |

|---|---|---|---|

| Precision Machining | High accuracy and repeatability in machining processes. | Improves product quality and reduces waste. | Aerospace, automotive, and heavy machinery. |

| Large Work Capacity | Designed to handle large and heavy workpieces. | Enables machining of larger components. | Construction, oil and gas, and shipbuilding. |

| User-Friendly Interface | Intuitive control panel for easy operation. | Reduces training time for new operators. | General manufacturing. |

| Robust Construction | Built with high-strength materials to withstand heavy usage. | Enhances durability and decreases maintenance costs. | Heavy-duty industrial applications. |

| Advanced Cooling System | Integrated cooling mechanisms to prevent overheating. | Increases tooling life and enhances performance. | Metals and plastics machining. |

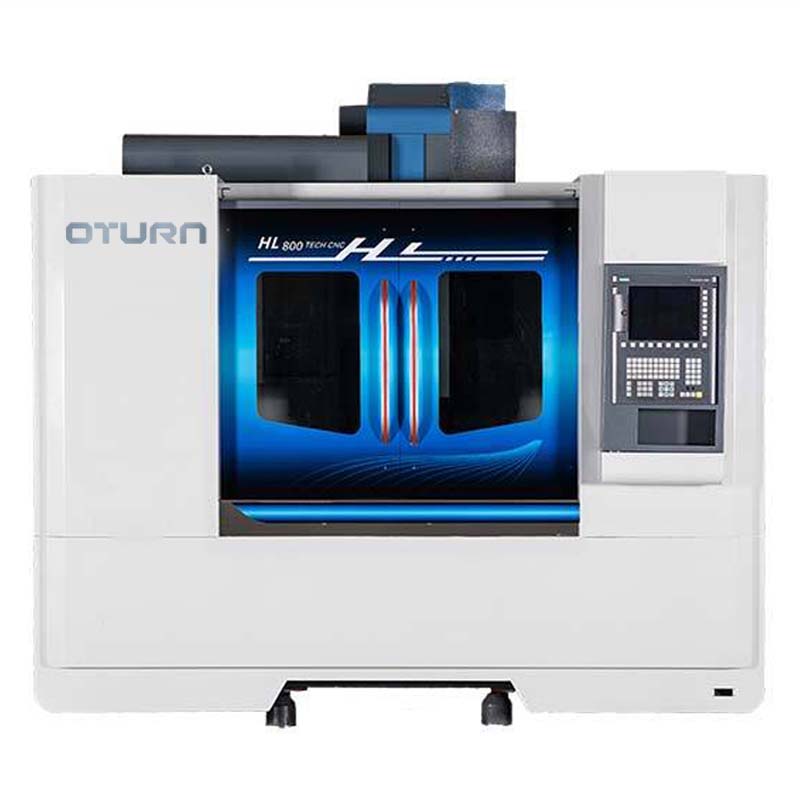

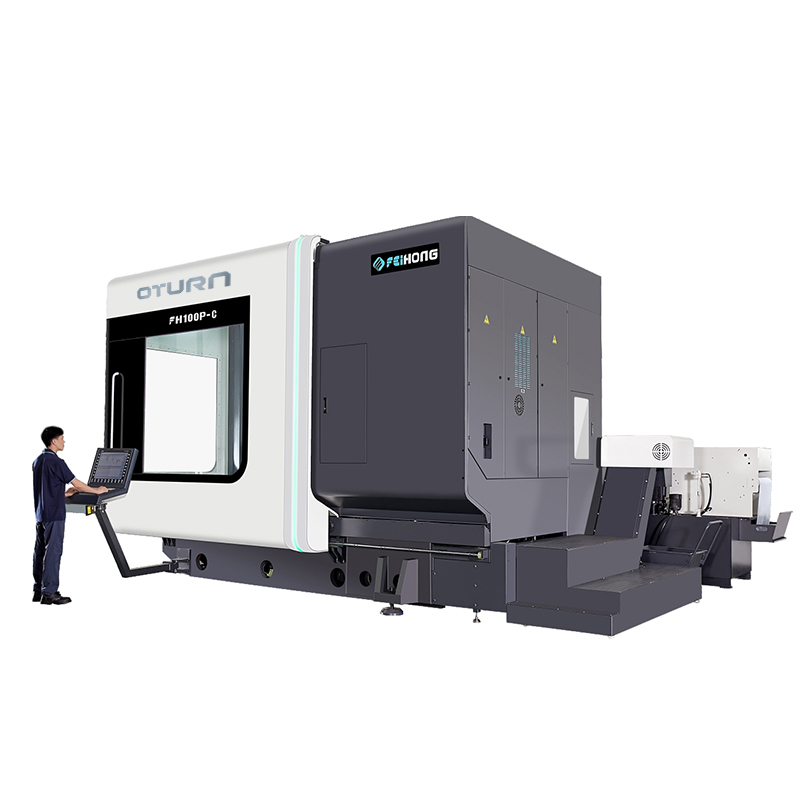

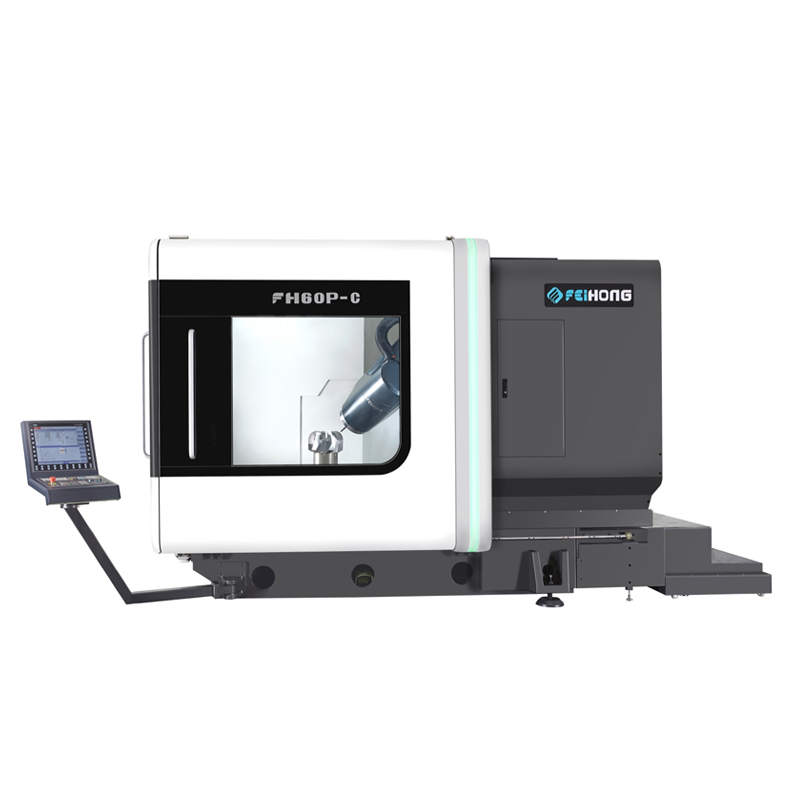

Related Products