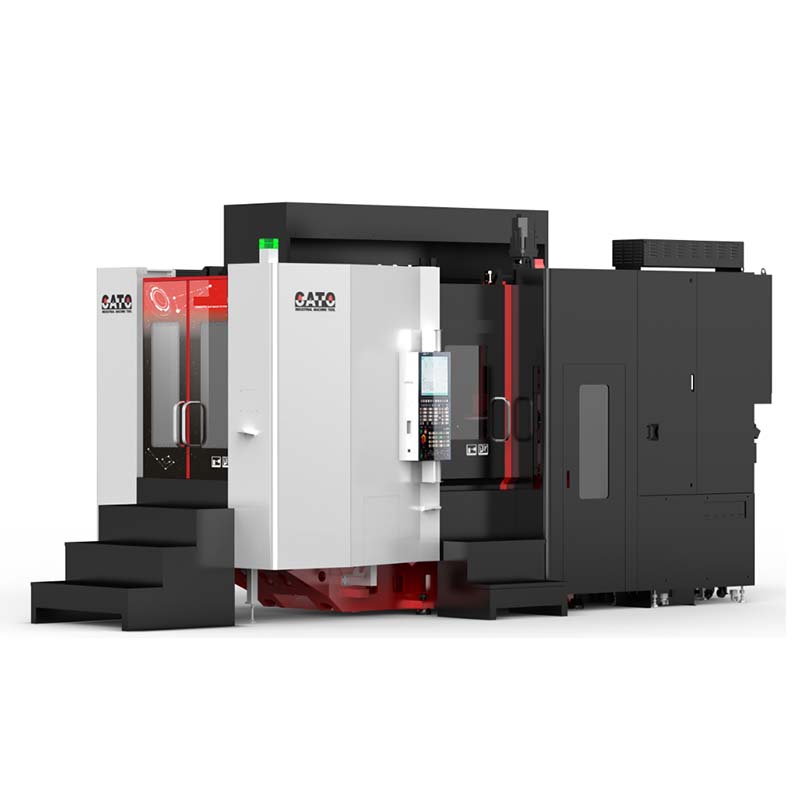

Cnc Automatic Lathe Manufacturer in China - Quality & Precision Machines

As a professional in the field, I understand the critical role a CNC automatic lathe plays in modern manufacturing. This precision-engineered machinery offers unmatched accuracy and efficiency, making it the perfect choice for businesses seeking to enhance production capabilities. Sourced from reputable manufacturers in China, these lathes are built to handle a variety of materials, ensuring you get the most out of your investment. I’ve seen firsthand how these machines streamline operations, allowing for shorter lead times and improved quality of finished products. The user-friendly interface and advanced technology make it easy to integrate into existing workflows. Whether you're scaling up production or embarking on new projects, this CNC automatic lathe can cater to your needs. If you're in the market for reliable, high-performance machinery, partnering with a trusted manufacturer in China can be your key to success. Don't miss out on the opportunity to elevate your business—let this automatic lathe be the game-changer you need!

Cnc Automatic Lathe Market Leader Winning in 2025

As we look towards 2025, the CNC automatic lathe market is set to experience remarkable growth, driven by advancements in technology, increased demand for precision manufacturing, and the integration of automation in production processes. Global procurement professionals are keenly interested in the benefits and capabilities that modern CNC lathes offer, including enhanced efficiency, reduced cycle times, and the ability to produce complex components with unparalleled accuracy. The evolution of CNC lathe technology has opened new avenues for industries ranging from aerospace to automotive, where precision components are pivotal. With cutting-edge features such as multi-axis machining, real-time monitoring, and user-friendly interfaces, manufacturers can optimize their workflows and minimize waste. This not only boosts productivity but also aligns with sustainability goals, as companies strive to reduce their environmental footprint while maintaining high-quality standards. To capitalize on these emerging opportunities, businesses must focus on investing in reliable partners who understand the global market dynamics and can offer comprehensive support. Looking ahead, strategic collaborations within the CNC sector will enhance supply chain efficiency and foster innovation, ensuring that companies remain competitive in an increasingly demanding landscape. As we approach 2025, staying informed about these trends will empower procurement professionals to make wiser decisions that align with their operational goals.

Cnc Automatic Lathe Market Leader Winning in 2025

| Region | Market Share (%) | Year-On-Year Growth (%) | Key Technologies | Competitive Edge |

|---|---|---|---|---|

| North America | 35 | 10 | Automation, Real-time Data Analytics | Advanced Manufacturing Techniques |

| Europe | 30 | 8 | Smart Machines, IoT Integration | Sustainability Practices |

| Asia-Pacific | 25 | 15 | AI-Driven Automation, Robotics | Cost Efficiency |

| Latin America | 5 | 5 | Flexible Manufacturing Systems | Local Adaptation Strategies |

| Middle East & Africa | 5 | 6 | CNC Technology, Digital Twin | Emerging Market Opportunities |

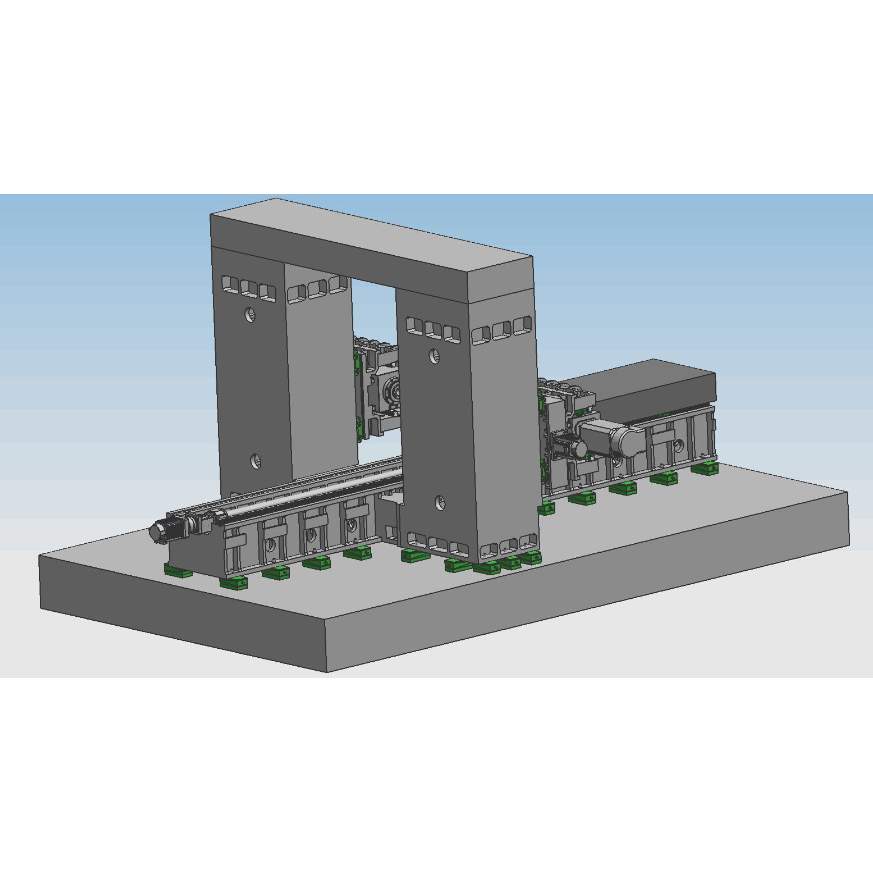

Related Products