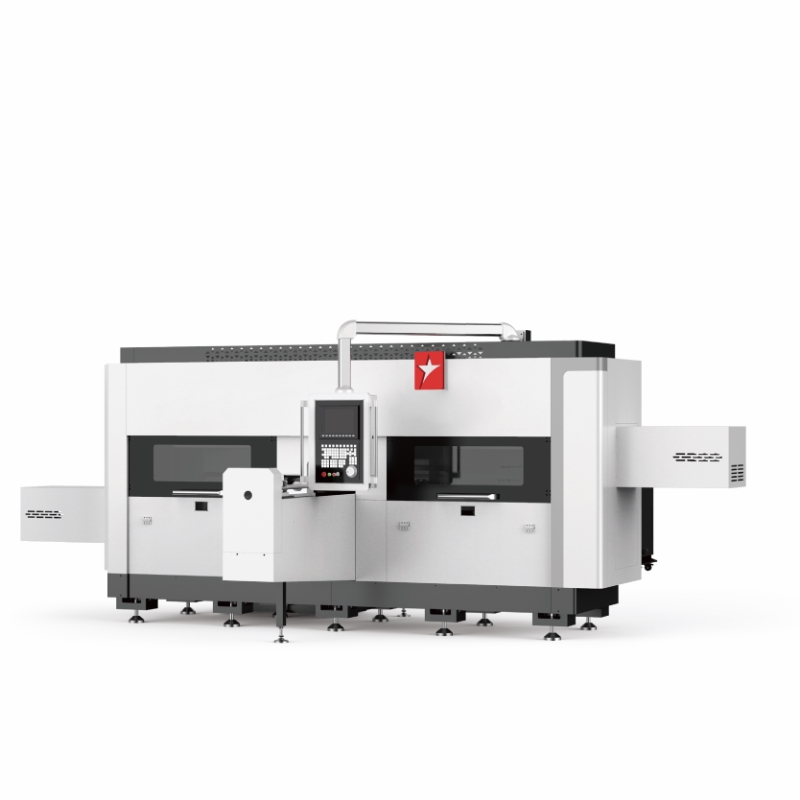

Top China CNC Turning Centers from Reliable Manufacturers

When it comes to precision machining, I trust the reliability of China CNC Turning Centers. With an impressive range of specifications, these machines cater to various industrial needs. Each center is crafted by top manufacturers in China, ensuring high quality and durability for your operations. I have seen firsthand how these centers enhance productivity, allowing for intricate designs and efficient production cycles that meet tight deadlines. The advanced technology incorporated in these CNC turning centers makes them not just user-friendly but also capable of handling complex tasks with ease. What impresses me the most is the competitive pricing offered by Chinese manufacturers, making it feasible for businesses of all sizes to enhance their machining capabilities without breaking the bank. If you're looking to elevate your machining processes with state-of-the-art equipment, China CNC Turning Centers are definitely an investment worth considering. Quality, affordability, and performance—it’s all here waiting for you!

China CNC Turning Centers Manufacturer Pioneers in the Field

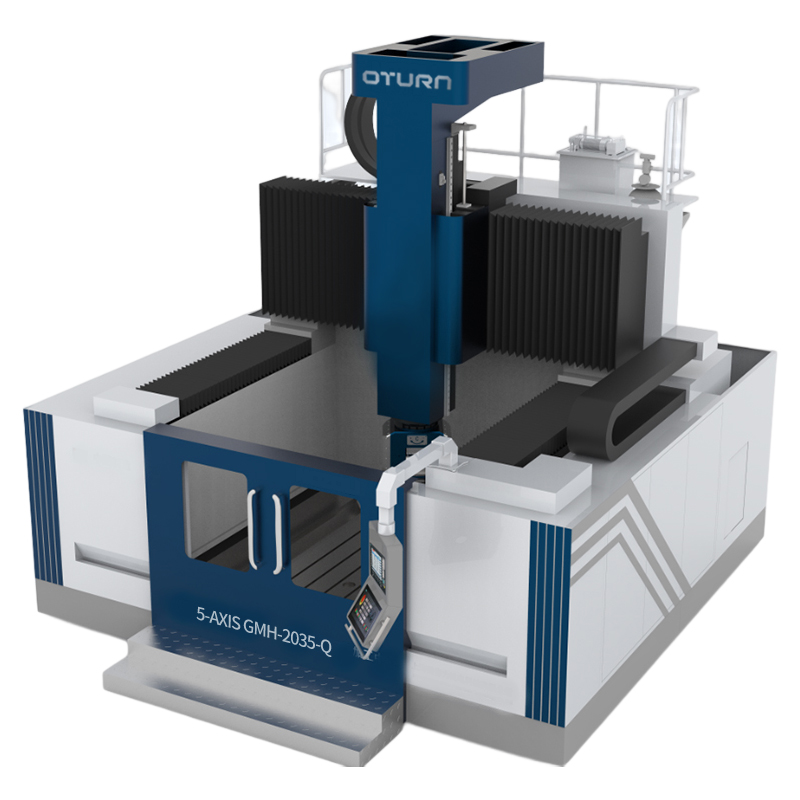

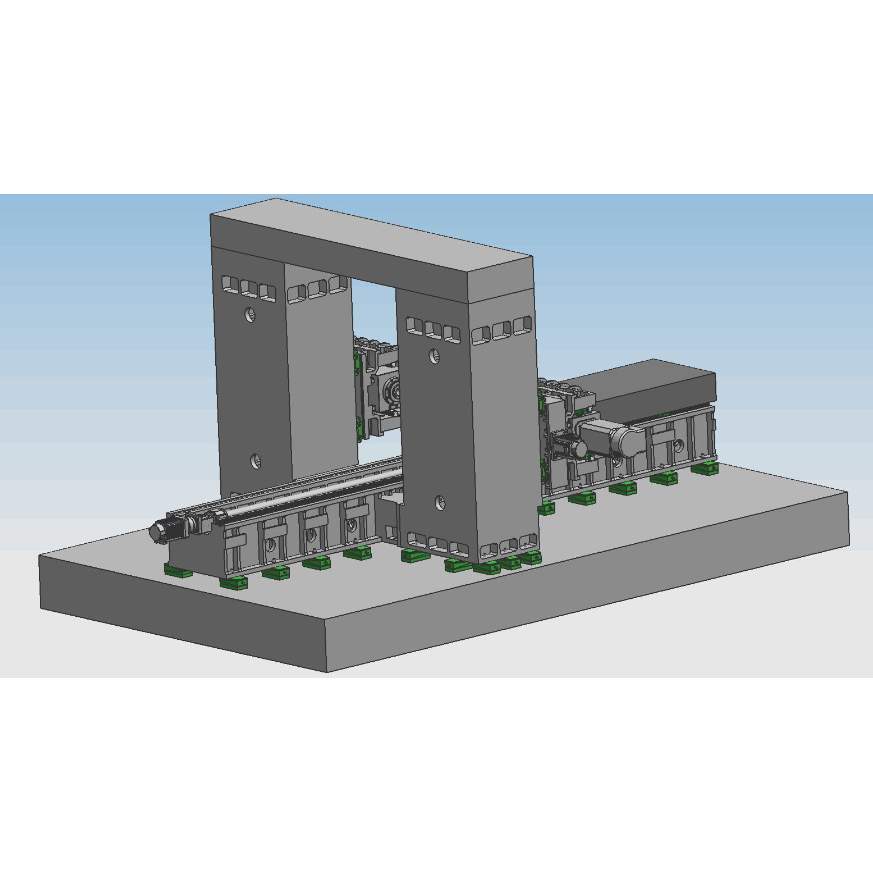

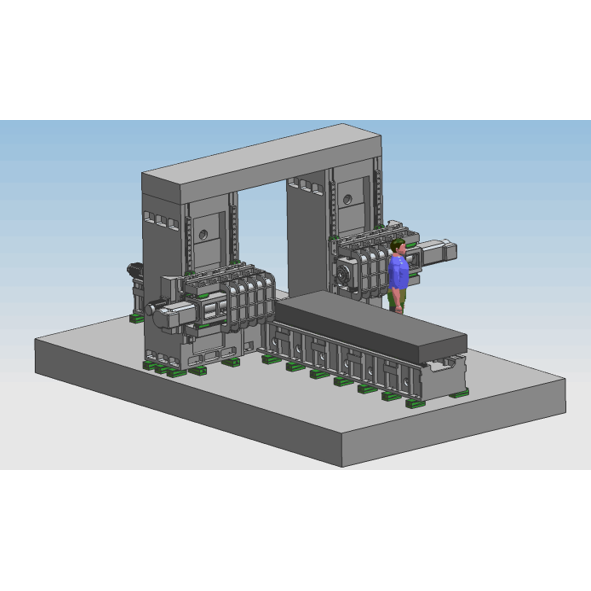

In the competitive landscape of manufacturing, the importance of precision engineering and reliable machinery cannot be overstated. As global demand for high-quality components rises, CNC turning centers have emerged as essential tools for many industries, including automotive, aerospace, and electronics. A leading manufacturer in this sector is dedicated to delivering state-of-the-art CNC turning centers that combine innovation with exceptional performance. Their advanced machinery is designed to meet the diverse needs of manufacturers worldwide, ensuring superior accuracy and efficiency in production processes. These CNC turning centers are equipped with the latest technology, enabling faster cycle times and improved productivity without compromising quality. With customizable features and a range of sizes, they cater to various applications, from small batch productions to large-scale manufacturing. The manufacturer emphasizes durability and reliability, providing clients with machines that withstand rigorous use while maintaining precision. Buyers can benefit from comprehensive support services, including installation, training, and maintenance, ensuring that their investment translates into long-term operational success. In an era where efficiency and sustainability are paramount, partnering with a trusted CNC turning center manufacturer opens doors to enhanced capabilities and competitive advantages. By leveraging advanced machining solutions, global buyers can not only optimize their operations but also position themselves for future growth in an ever-evolving market. Embrace the cutting-edge technology offered by a pioneer in the industry and elevate your manufacturing processes to new heights.

China CNC Turning Centers Manufacturer Pioneers in the Field

| Feature | Specification | Application |

|---|---|---|

| Max Spindle Speed | 6000 RPM | Precision machining of metals |

| Tool Storage Capacity | 20 tools | Complex part production |

| Control System | Fanuc 0i-TD | Automated machining |

| Max Turning Diameter | 250 mm | Turning of various materials |

| Weight | 1500 kg | Stable operation |

| Power Supply | 220V/380V | Industrial usage |

Related Products