Big Spindle Bore Lathe Manufacturer in China: Top Quality Equipment

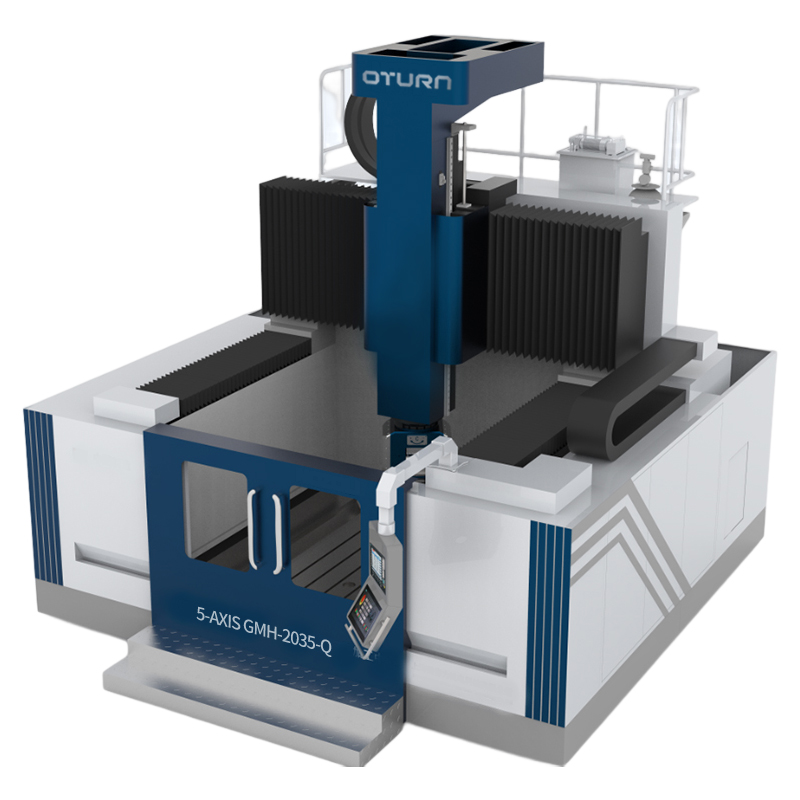

When it comes to precision and productivity, my Big Spindle Bore Lathe is here to transform your manufacturing experience. As a reliable choice from a leading manufacturer in China, this lathe offers remarkable versatility for various machining tasks. With a spacious spindle bore, it easily accommodates large workpieces, enabling you to enhance your operational efficiencies. I’ve designed this machine keeping your needs in mind, ensuring durability and performance that you can count on. Whether you're tackling complex components or simple turns, the user-friendly controls allow for seamless operation. Moreover, the robust construction means it can withstand the demands of any busy workshop. Collaborating with me means you not only get superior machinery but also the promise of dedicated support and expert insights tailored to elevate your production. Investing in a Big Spindle Bore Lathe isn't just purchasing equipment; it's about partnering for growth and precision in your business. Let's elevate your manufacturing together!

Big Spindle Bore Lathe Delivers Unmatched Quality Manufacturers You Can Rely On

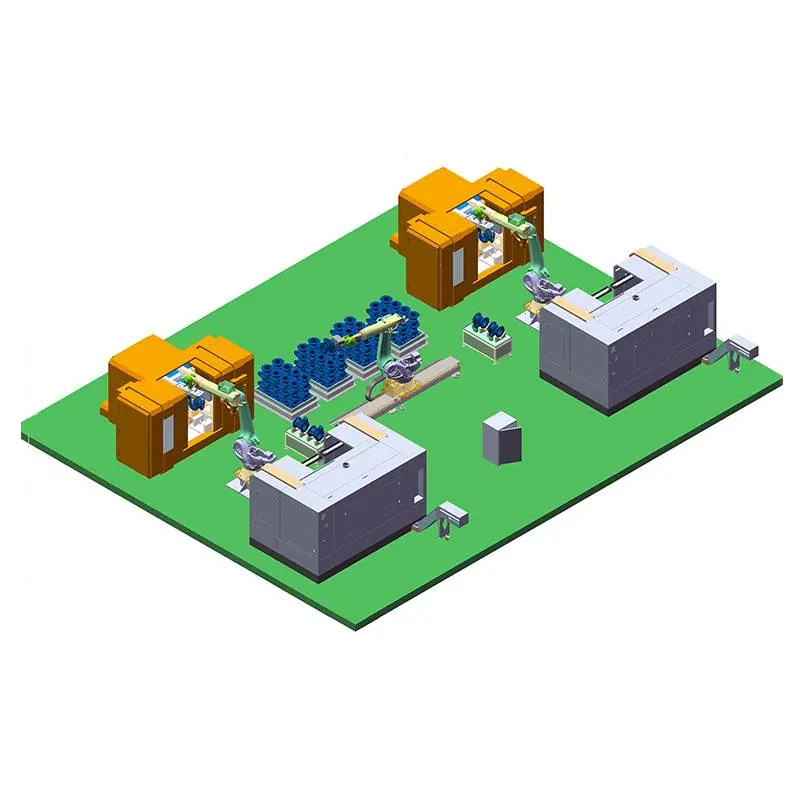

When it comes to precision machining and turning large workpieces, big spindle bore lathes stand out for their exceptional capabilities. These machines are engineered to accommodate larger bar stock and components, ensuring efficient production without compromising on quality. Manufacturing businesses around the globe are increasingly relying on big spindle bore lathes to enhance their operational efficiencies, reduce cycle times, and meet the strict demands of high-quality standards. Not only do these lathes provide superior performance in heavy-duty applications, but they also feature advanced technological integration that facilitates ease of use and monitoring. Industries such as aerospace, automotive, and heavy machinery benefit significantly from the reliability and durability that come with investing in top-tier spindle bore lathes. By choosing a manufacturer that is known for unmatched quality and innovation, businesses can ensure that their production processes are smooth, efficient, and capable of meeting the most challenging requirements. In a competitive global market, it is crucial for manufacturers to partner with suppliers who prioritize quality and customer satisfaction. Investing in big spindle bore lathes from reputable manufacturers not only guarantees superior machining results but also fosters long-term relationships built on trust and reliability. As companies seek to elevate their production capabilities, the right spindle bore lathe can become an invaluable asset in achieving operational excellence and ensuring a competitive edge in the industry.

Big Spindle Bore Lathe Delivers Unmatched Quality Manufacturers You Can Rely On

| Manufacturer | Model | Spindle Bore Diameter (mm) | Max Swing (mm) | Max Turning Length (mm) | Weight (kg) |

|---|---|---|---|---|---|

| Manufacturer A | Model X1 | 120 | 600 | 1500 | 2000 |

| Manufacturer B | Model Y2 | 150 | 800 | 1800 | 2500 |

| Manufacturer C | Model Z3 | 170 | 900 | 2000 | 3000 |

| Manufacturer D | Model W4 | 200 | 1000 | 2200 | 3500 |

Related Products