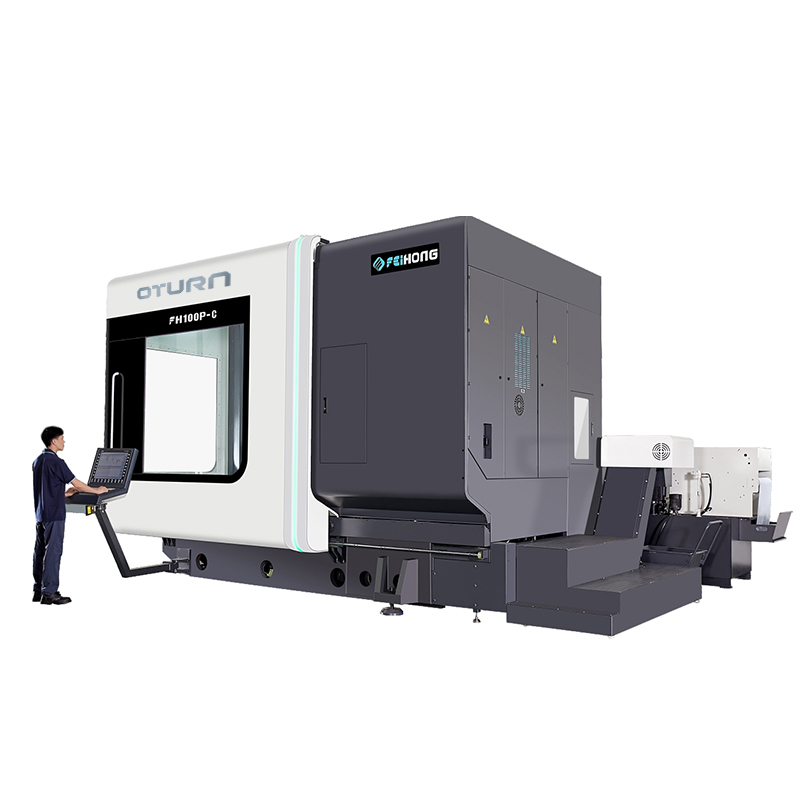

Automatic Vertical Lathe Machine Manufacturer in China - Quality & Precision

In my experience dealing with various machining tools, I can confidently say that our Automatic Vertical Lathe Machine stands out in quality and performance. Manufactured right here in China, this lathe machine is designed to enhance productivity and accuracy in your machining processes. I have seen firsthand how it can adapt to various workpieces, making it a versatile choice for manufacturers like you. This machine's user-friendly interface makes operation straightforward, reducing the learning curve for your team. With robust construction and advanced technology, it ensures a longer lifespan and minimal maintenance, which translates into cost savings for your business. Investing in our Automatic Vertical Lathe Machine means you’re choosing reliability and innovation, tailored specifically for today’s demanding manufacturing environment. Let’s take your production capabilities to the next level together!

Automatic Vertical Lathe Machine Dominates Exceeds Industry Benchmarks

In the world of machining, the performance of equipment often dictates the success of production processes. The Automatic Vertical Lathe Machine has emerged as a game-changer, setting new industry benchmarks that resonate with manufacturers globally. Designed to enhance precision and efficiency, this innovative machine offers unparalleled capabilities, making it an essential addition to modern manufacturing lines. Its robust construction and advanced features enable seamless operation, reducing downtime and increasing throughput. The demand for high-quality components continues to rise, and companies are seeking solutions that not only meet but exceed expectations. With a focus on maximizing productivity, the Automatic Vertical Lathe Machine incorporates intelligent technology that allows for real-time monitoring and adjustment, ensuring optimal performance. This level of automation not only streamlines operations but also minimizes human error, leading to superior end products that satisfy market demands. Investing in an Automatic Vertical Lathe Machine can significantly elevate a company’s competitive edge. By leveraging cutting-edge technology and engineering excellence, manufacturers can achieve remarkable efficiency gains and tighter tolerances, which are vital in today’s fast-paced industrial landscape. For those looking to stay ahead in the evolving market, it’s time to embrace machinery that delivers on both innovation and reliability—paving the way toward future success.

Automatic Vertical Lathe Machine Dominates Exceeds Industry Benchmarks

| Feature | Specification | Performance |

|---|---|---|

| Spindle Speed | 1000 - 4000 RPM | High Efficiency |

| Max Swing Diameter | 800 mm | Improved Workpiece Handling |

| Control System | CNC with Touch Screen | User Friendly |

| Power Consumption | 5 kW | Cost Effective |

| Weight | 2500 kg | Stable Operation |

Related Products