5-Axis Horizontal Machining Center Manufacturer in China - High Precision Solutions

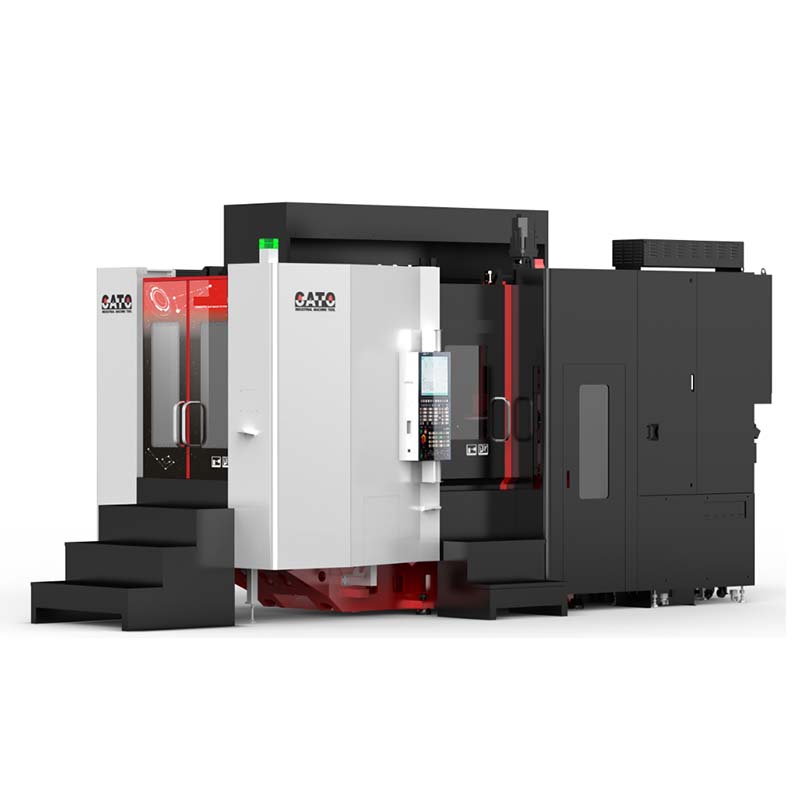

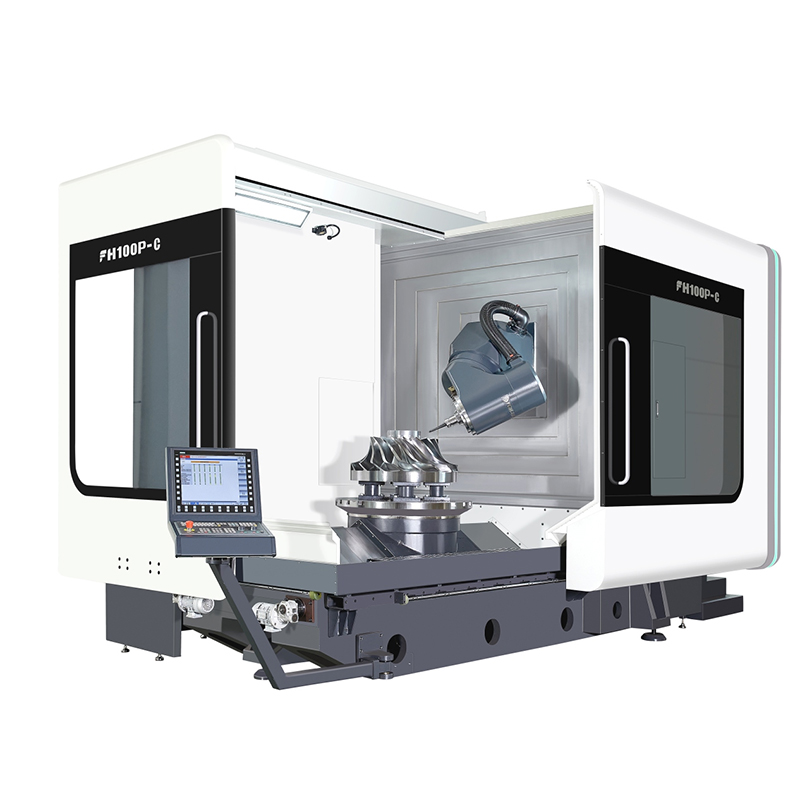

When it comes to precision machining, our 5-axis Horizontal Machining Center stands out as a game changer. This advanced machine, designed in China, offers flexibility and efficiency, enabling manufacturers to achieve complex geometries with ease. With its robust construction and user-friendly interface, even those new to machining will find it intuitive to operate. We understand that as a buyer, you’re looking for the best value for your investment. Our centers come equipped with state-of-the-art technology, ensuring high reliability and speed while maintaining accuracy. The performance is backed by our dedicated support team, ready to assist you throughout the process. Whether you're scaling up production or introducing intricate designs, our 5-axis Horizontal Machining Center is tailored to meet your needs. Choosing us means investing in quality and innovation—perfect for manufacturers who strive for excellence. Let’s transform your production capacity together!

5-axis Horizontal Machining Center Guarantees Peak Performance Supplies the World\u2019s Top Brands

The 5-axis horizontal machining center represents the pinnacle of precision engineering and productivity in the modern manufacturing landscape. This advanced technology allows for an unparalleled level of complexity in machining processes, enabling manufacturers to create intricate designs with remarkable accuracy. By incorporating simultaneous adjustments along multiple axes, these centers significantly reduce setup times and enhance operational efficiency, making them an ideal choice for businesses aiming for top-tier performance. In a world where quality and speed are paramount, the flexibility offered by 5-axis horizontal machining centers allows companies to cater to the varying demands of diverse industries. From automotive to aerospace, the ability to machine complex parts in a single setup streamlines production, minimizes waste, and improves overall output. Buyers seeking to elevate their production capabilities will find that investing in such sophisticated equipment not only meets but exceeds the expectations of global clientele. By choosing to equip your operations with cutting-edge 5-axis horizontal machining technology, you align yourself with the best in the industry. The high precision and reliability of these machines empower manufacturers to maintain stringent quality control while rapidly responding to market changes. As the demand for excellence continues to rise, integrating this advanced machining capability will position your business as a leader in a competitive global market, ready to meet the challenges of today and the opportunities of tomorrow.

5-axis Horizontal Machining Center Guarantees Peak Performance Supplies the World’s Top Brands

| Feature | Specification | Application | Material Compatibility |

|---|---|---|---|

| Spindle Speed | 20,000 RPM | Aerospace Component Machining | Aluminum, Titanium |

| Travel X/Y/Z | 1200 mm / 800 mm / 600 mm | Mold Making | Steel, Copper |

| Tool Change System | Automatic Tool Changer (ATC) | Precision Parts Manufacturing | Plastic, Composite Materials |

| Control System | CNC with Dynamic Graphical Interface | Medical Devices | Ceramics, Glass |

| Weight | 5,000 kg | Heavy-Duty Engineering | Alloys |

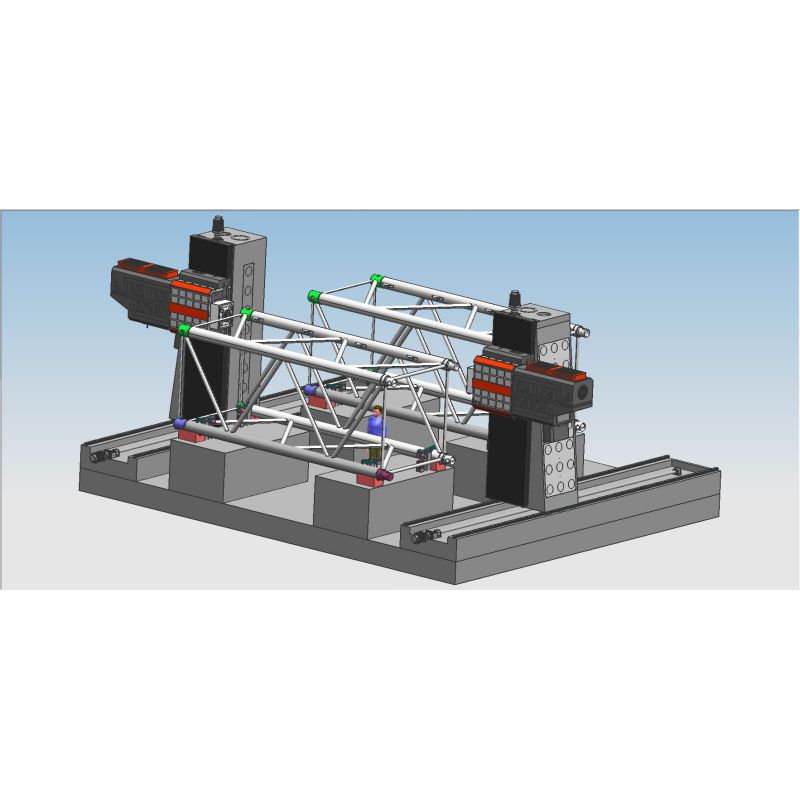

Related Products