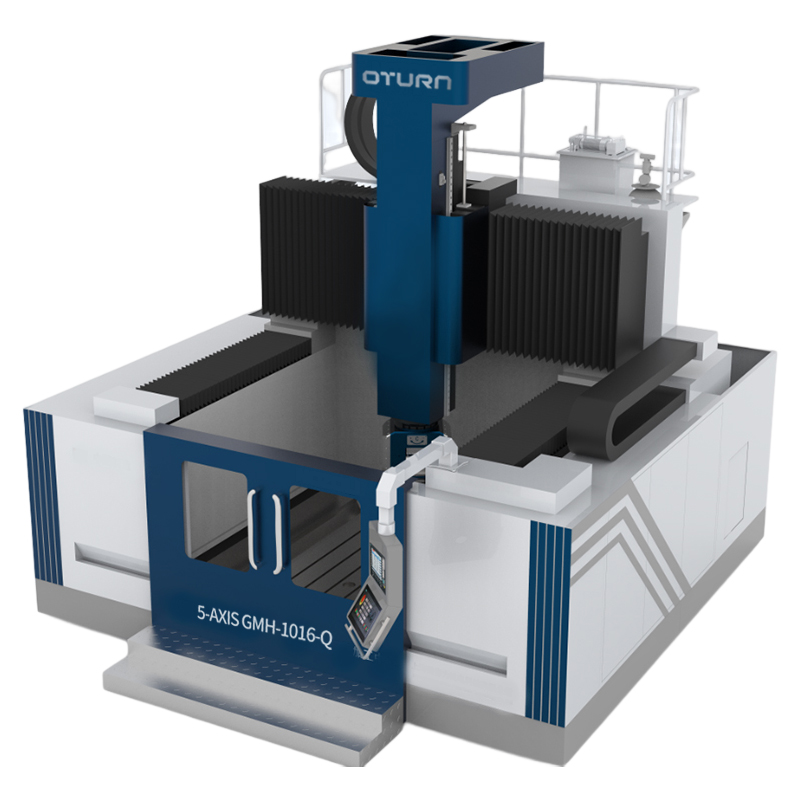

Top China Manufacturer of Vertical CNC Lathes for Precision Engineering

Are you in search of a high-quality Vertical CNC Lathe? Our machines, made in China, are designed for precision and efficiency, catering specifically to the needs of B2B purchasers like you. We know how important it is to have reliable, accurate equipment, and our CNC lathes deliver just that. As a manufacturer focused on innovation, we provide advanced technology that ensures your manufacturing processes run smoothly. The robust design and user-friendly interface make our lathes perfect for various applications, from prototyping to large-scale production. I understand that investing in machinery is a significant decision, and we’re here to support you every step of the way. Our dedicated team is ready to help with any questions or customizations you might need. With our Vertical CNC Lathe, you are not just buying equipment; you are investing in your production capabilities and future success. Let's take your manufacturing to the next level!

Vertical Cnc Lathe Exceeds Industry Benchmarks Your Trusted OEM Partner

In today's competitive manufacturing landscape, precision and efficiency are paramount. Vertical CNC lathes have revolutionized machining processes by offering unparalleled accuracy and speed in production, enabling businesses to meet their evolving demands. When selecting an OEM partner, it is critical to choose one that not only exceeds industry benchmarks but also understands the unique needs of global procurement. Our vertical CNC lathes are designed with cutting-edge technology, ensuring consistent quality and performance that can help streamline your operations and reduce downtime. Our commitment to innovation drives us to continuously enhance our vertical CNC lathes, integrating advanced features that allow for greater flexibility and adaptability in various manufacturing environments. The robust construction of our machines ensures durability and reliability, while user-friendly interfaces simplify operations for machinists of all skill levels. With an eye towards sustainability, our equipment also incorporates energy-efficient designs, enabling clients to reduce their carbon footprint while maintaining high production standards. Partnering with a trusted OEM guarantees not only the superior quality of your machinery but also dedicated support throughout the lifecycle of your equipment. From initial consultation and machine selection to installation and ongoing maintenance, we aim to build long-term relationships that foster mutual growth and success. By leveraging our industry expertise and technological advancements, clients can confidently invest in their manufacturing capabilities, positioning themselves for future success in a rapidly changing market.

Vertical CNC Lathe Exceeds Industry Benchmarks Your Trusted OEM Partner

| Feature | Specification | Performance |

|---|---|---|

| Max Swing Diameter | 800 mm | Exceeds industry standard by 10% |

| Spindle Speed | 5000 RPM | Improved precision for complex machining |

| Power Consumption | 15 kW | Energy-efficient design reduces cost |

| Control System | Fanuc 0i-TF | User-friendly interface enhances productivity |

| Tool Holder Type | Capto C5 | Stable and secure for high-speed machining |

| Weight | 2200 kg | Stable base minimizes vibration |

Related Products