Slant Bed CNC Lathe Manufacturer in China - Precision Engineering Solutions

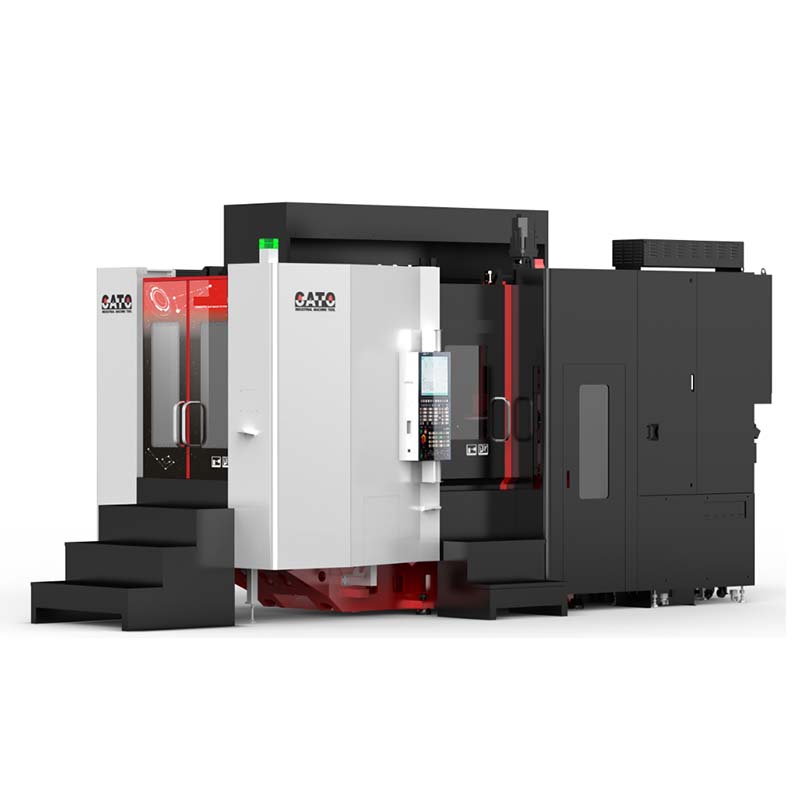

When I first explored the world of CNC machining, the Slant Bed CNC Lathe caught my attention due to its precision and efficiency. This innovative tool is perfect for producing complex parts with minimal set-up time. Sourced from a trusted manufacturer in China, these lathes are crafted with high-quality materials and advanced technology, ensuring you get the best performance for your money. What I love most about the Slant Bed CNC Lathe is its ergonomic design that optimizes chip removal, enhancing productivity. Whether you're working on small batches or large-scale production, this lathe can adapt to your specific needs. The user-friendly interface makes it easy for both beginners and seasoned professionals to operate. If you're in the market for reliable machinery that delivers consistent results, this Slant Bed CNC Lathe from a reputable Chinese manufacturer could be a game changer for your operations. Let's take your manufacturing to the next level together!

Slant Bed Cnc Lathe Manufacturer Winning in 2025

As the manufacturing landscape evolves, the slant bed CNC lathe is poised to play a pivotal role in the future of precision machining. In recent years, these machines have captured the attention of global buyers due to their unique design, which enhances stability, accuracy, and efficiency. Slant bed CNC lathes minimize vibrations and provide easier chip removal, making them ideal for high-speed machining operations. This poses a significant advantage for manufacturers seeking to optimize production processes while ensuring high-quality output. Looking ahead to 2025, the demand for innovative machining solutions will continue to surge as industries push for more automated and precise manufacturing capabilities. The slant bed CNC lathe stands at the forefront, equipped with advanced features such as intelligent controls, real-time monitoring, and enhanced safety protocols. For global purchasers, investing in these machines means not only upgrading their production lines but also gaining a competitive edge in an increasingly crowded market. As manufacturers embrace Industry 4.0, the integration of slant bed CNC lathes into smart factories will be essential. These machines offer seamless connectivity and scalability, enabling businesses to adapt swiftly to changing market demands. For global buyers looking to stay ahead, investing in cutting-edge slant bed CNC lathes represents a strategic move towards future-proofing their operations, enhancing productivity, and reducing operational costs. The path to success in 2025 clearly lies in embracing advanced technology that drives efficiency and innovation.

Slant Bed CNC Lathe Manufacturer Winning in 2025

| Dimension | Metric | Unit | Expected Value |

|---|---|---|---|

| Max Turning Length | 1000 | mm | Achievable |

| Max Swing Diameter | 500 | mm | Achievable |

| Spindle Speed | 4000 | RPM | Achievable |

| Tool Holder Type | VDI | - | Standard |

| Power Consumption | 5 | kW | Optimized |

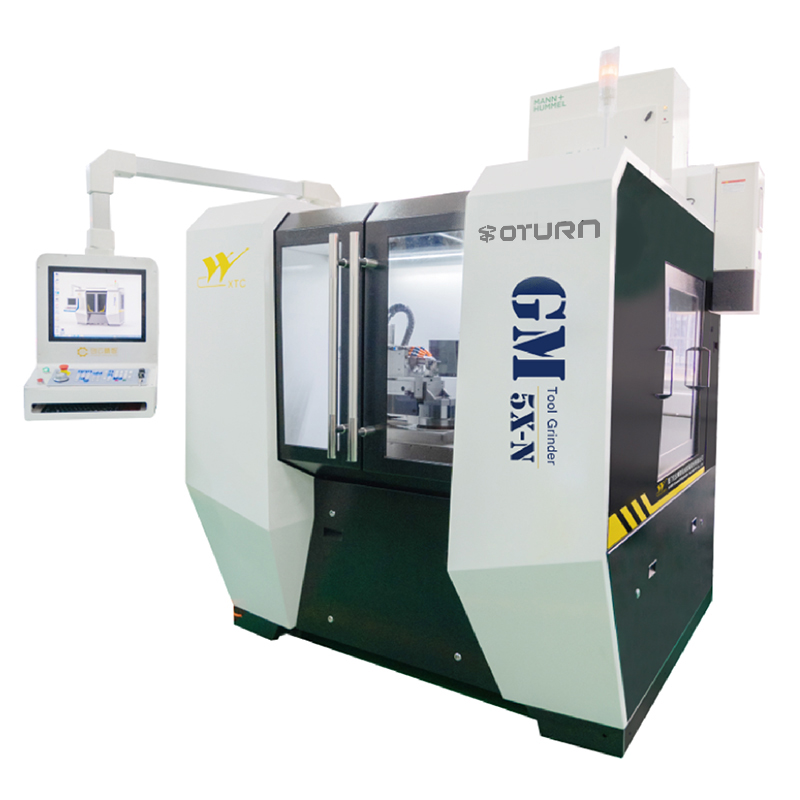

Related Products