CNC turning centers are indispensable for precision shaft machining due to their unparalleled accuracy, repeatability, and automation capabilities. These features are critical for meeting modern manufacturing’s stringent demands. A CNC Turning Center offers significant advantages over other methods. These machines ensure consistent quality, reduce errors, and optimize production. This directly translates into practical benefits for manufacturers. An Automated CNC Lathe provides enhanced efficiency. Manufacturers often seek a strong CNC turning center price performance ratio. Many Industrial CNC lathe suppliers in China offer competitive solutions. The Lathe Machine Precision achieved is exceptional.

Key Takeaways

- CNC turning centers make very precise parts. They create shafts with exact sizes and smooth surfaces. This helps machines work better and last longer.

- These machines work by themselves. They follow computer programs. This means fewer mistakes and faster work than old methods.

- CNC turning centers can cut many different materials. They work with common metals and special strong ones. This makes them useful for many industries.

- They have strong parts and smart sensors. These features stop vibrations and check sizes as they work. This keeps every part accurate.

- Using CNC turning centers saves money. They make fewer bad parts and finish jobs faster. This helps companies produce more with less effort.

The Demands of Precision Shaft Machining

Defining Precision in Shaft Machining

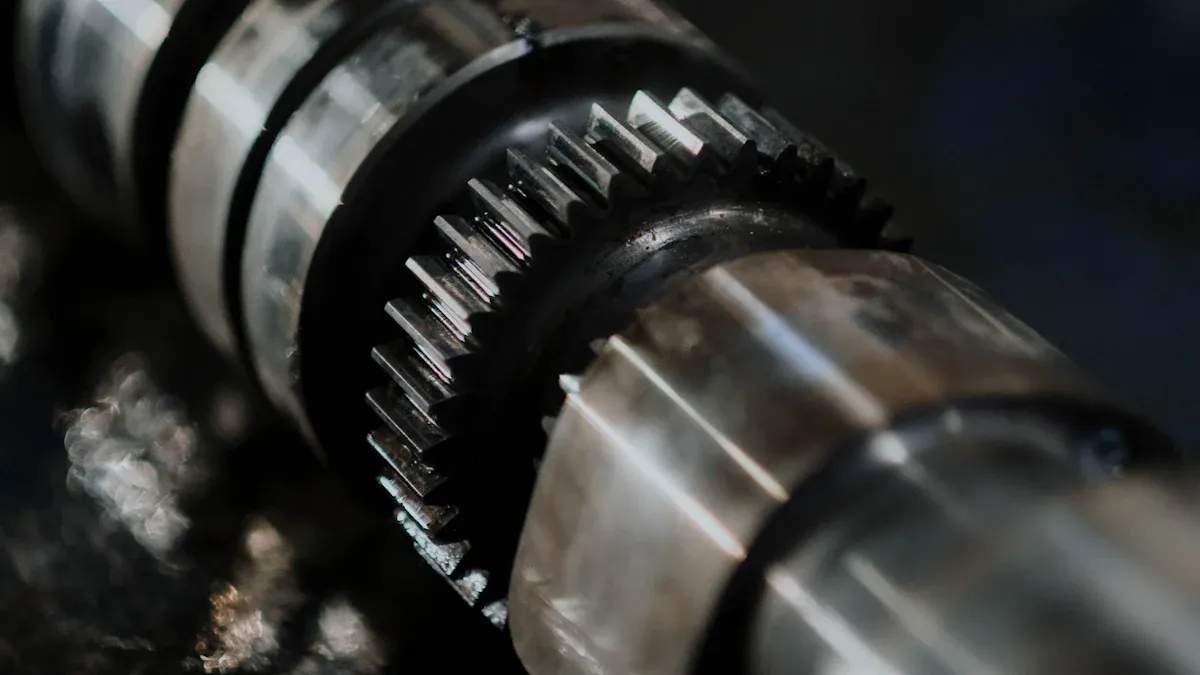

Precision in shaft machining means creating components with extremely tight tolerances and exact dimensions. Manufacturers measure precision by how closely a finished shaft matches its design specifications. This includes diameter, straightness, concentricity, and surface finish. Achieving high precision ensures parts fit together correctly and perform reliably.

Limitations of Traditional Methods

Traditional machining methods often struggle to meet modern precision demands. Manual turning or older semi-automated machines rely heavily on operator skill. This introduces variability and human error. These methods also lack the fine control needed for complex geometries and very tight tolerances. They often result in slower production times and higher scrap rates. This makes them less efficient for high-volume, high-precision manufacturing.

Why Shafts Require High Precision

Shafts are critical components in many machines, especially those with rotating parts. Their precise dimensions directly affect performance and longevity. For critical assets, manufacturers require tight alignment specifications. This is due to high RPMs or demanding conditions, which can amplify vibrations. Small misalignments stress components like bearings and seals, leading to premature wear. This increases the risk of catastrophic failures.

For example, centrifugal compressors in refineries and generators in power plants depend on highly precise shafts. Even small amounts of shaft misalignment can significantly reduce a bearing’s operational life. Some cases show up to a 50% loss of expected bearing life with as little as a 5 mil offset misalignment. Over 50% of rotating equipment breakdowns are primarily caused by shaft misalignment. A single coupling failure can lead to thousands of dollars in lost productivity due to downtime.

Manufacturers use specific ISO standards to ensure precision:

| Component Type | Application | Recommended ISO Standards | Purpose |

|---|---|---|---|

| Shafts and holes for rotating components | Components in rotating machinery requiring specific fits for proper function | ISO 2768 Fine and ISO 286 Grades 6 or 7 (IT6, IT7) | Ensures precise linear/angular dimensions (ISO 2768) and tight fits for rotational balance (ISO 286) |

| Cylindrical features (shafts and holes) | Where precise fits are essential | ISO 286 Grade 6 (IT6) | For very tight tolerances in high-precision applications where minimal deviation is critical |

These standards ensure shafts meet the exact requirements for their intended use, preventing costly failures and ensuring optimal machine operation.

Core Advantages of CNC Turning Centers

Unmatched Accuracy and Repeatability

CNC turning centers offer exceptional accuracy and repeatability, which are crucial for producing high-quality shafts. These machines precisely control tool movements and workpiece rotation. This ensures every shaft meets exact specifications. Modern CNC turning centers can achieve a concentricity of ±0.005 mm for cylindrical parts like shafts. This level of precision is vital for components operating at high speeds or under heavy loads.

Compared to conventional lathes, CNC turning centers provide superior consistency. Conventional lathes rely heavily on an operator’s skill, leading to variations between parts. CNC lathes, as computerized automated machines, use programming to produce accurate, reliable, and repeatable results. This significantly reduces the chance of human error.

| Machine Type | Accuracy Level |

|---|---|

| CNC Lathe | 0.001mm |

| Conventional Lathe | 0.01mm (operator-dependent) |

This table clearly shows the difference in achievable accuracy. CNC turning centers consistently deliver parts with tighter tolerances. This makes them ideal for industries demanding the highest precision.

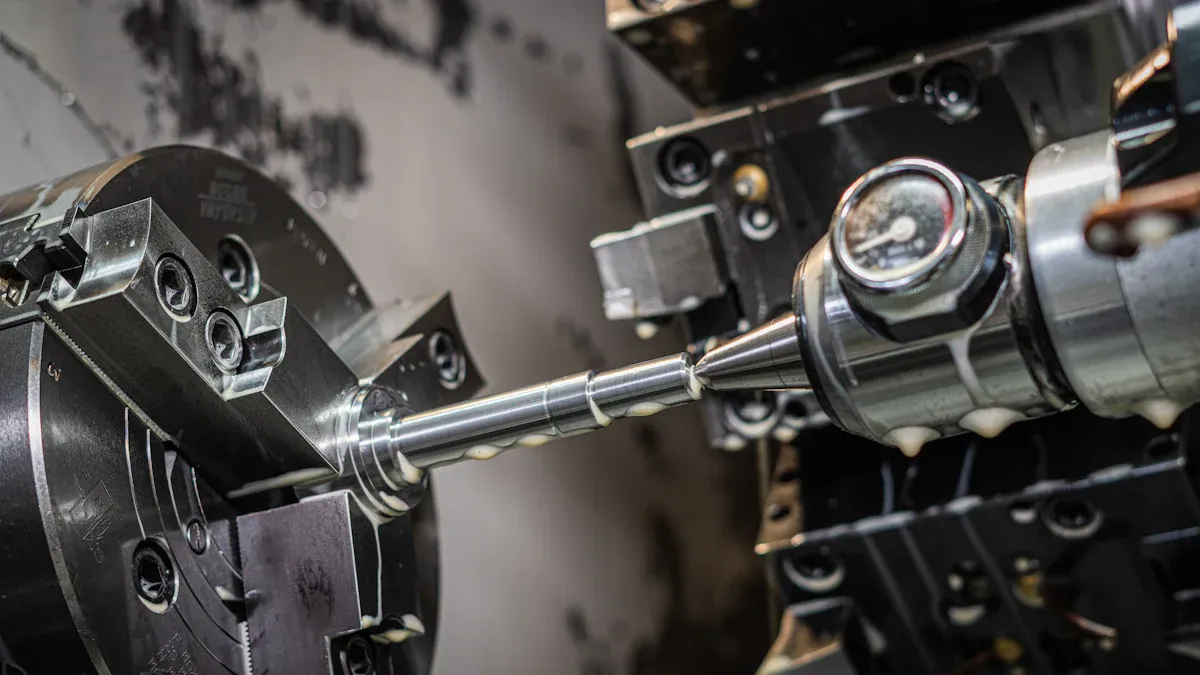

Advanced Tooling and Multi-Axis Capabilities

Advanced tooling and multi-axis capabilities greatly expand the functionality of CNC turning centers. These features allow for the creation of complex shaft geometries in a single setup. For example, a Y-axis mill-turn machine combines turning and milling operations. It includes an additional linear Y-axis, perpendicular to the X and Z axes. This enables sideways tool movement. This capability allows for true 3-axis interpolation with a spindle C-axis or live tool turret. Manufacturers can machine complex geometries in one setup.

Live tooling capability further enhances productivity. It provides full milling capabilities. This allows for fast and accurate turning of shafts, pinions, and close-tolerance components. This integration means the machine can perform drilling, tapping, and contouring without moving the part to another machine.

Multi-axis CNC turning centers, especially 5-axis lathes, introduce rotational movement (A and B axes). This is in addition to the conventional X, Y, and Z axes. This capability allows the cutting tool to approach the workpiece from nearly any angle. This eliminates the need for multiple setups. It directly reduces setup times and machining time. This also enhances consistency, which is crucial for high-volume, high-performance parts. Most features can be completed in a single setup. This leads to reduced secondary operations. The ability to machine complex parts in one go eliminates the need for expensive jigs, fixtures, and secondary operations. This further reduces costs.

Automation and Reduced Human Error

Automation is a cornerstone advantage of CNC turning centers. It significantly reduces human error in the manufacturing process. Once programmed, the machine executes operations with consistent precision. This minimizes the variability that human intervention can introduce. Automated processes ensure each shaft is machined identically. This leads to uniform product quality across entire production runs.

The reduction in human error also translates to less material waste and fewer rejected parts. This improves overall efficiency and cost-effectiveness. Operators can oversee multiple machines or focus on other critical tasks. This optimizes labor utilization. The automated nature of these machines also allows for continuous operation. This increases production output and meets demanding schedules.

Material Versatility of CNC Turning Centers

CNC turning centers demonstrate remarkable material versatility. They effectively machine a broad spectrum of materials. This capability allows manufacturers to produce shafts for diverse applications. These machines handle common industrial metals with ease. They also process advanced and challenging materials.

Manufacturers frequently machine carbon steels, stainless steels, and alloy steels like 4140 and 4340. They also work with non-ferrous metals such as aluminum, brass, and bronze. The robust construction and powerful spindles of a CNC Turning Center enable efficient material removal from these standard materials.

Beyond common metals, these machines excel with specialty and exotic alloys. They process materials like Inconel, Monel, Hastelloy, and Titanium. These materials are often difficult to machine due to their hardness or unique properties. CNC turning centers also handle hardened steels and various nickel-based alloys. This broad material compatibility makes them indispensable across many industries. They can even machine ceramics and plastics when required.

The advanced tooling options and rigid machine designs contribute to this versatility. High-performance cutting tools, often made from carbide or ceramics, withstand the stresses of machining tough materials. The machine’s stability minimizes vibration. This ensures precise cuts even on materials that resist deformation. This combination of power, precision, and tooling allows a CNC turning center to maintain tight tolerances across all these different material types.

Key Features of CNC Turning Centers for Precision

Rigid Construction and Vibration Dampening

The foundation of precision machining lies in the machine’s structural integrity. CNC turning centers feature exceptionally rigid construction. This robust design minimizes vibrations and deflections during the cutting process. A machine’s rigidity directly impacts the quality of the finished shaft. High spindle accuracy reduces vibration and chatter, leading to smoother surface finishes. High spindle rigidity ensures accuracy under real cutting loads. This prevents dimensional tolerances from drifting. A lack of sufficient spindle rigidity causes unstable tool-workpiece contact. This deteriorates surface finish and causes dimensional tolerances to drift.

| Machining Aspect | Influence of Spindle Accuracy |

|---|---|

| Dimensional Tolerance | Directly determines roundness & concentricity |

| Surface Finish | Reduces vibration and chatter |

Manufacturers build these machines with heavy, cast iron bases and robust components. This dampens vibrations effectively. This stability allows the cutting tool to maintain consistent contact with the workpiece. It ensures precise material removal and superior surface finishes. This rigid framework is crucial for achieving the tight tolerances required for critical shaft applications.

High-Resolution Encoders and Feedback Systems

High-resolution encoders and sophisticated feedback systems are vital for the unparalleled accuracy of CNC turning centers. Encoders are sensors that monitor the exact position and movement of the machine’s axes and spindle. They provide real-time data on the tool’s location relative to the workpiece. These systems continuously compare the actual position with the programmed position. If any deviation occurs, the feedback system immediately sends corrective signals to the machine’s controls. This ensures the tool follows the programmed path with extreme precision.

This continuous monitoring and adjustment process eliminates errors that could arise from mechanical play or minor environmental changes. It guarantees that each cut is executed exactly as specified. This closed-loop control system is fundamental to achieving the high repeatability and tight dimensional accuracy essential for precision shaft machining.

Thermal Stability Management

Maintaining thermal stability is a significant challenge in precision machining. Heat generated during cutting, from motor operation, or from ambient temperature fluctuations can cause machine components and workpieces to expand or contract. This thermal expansion can lead to dimensional inaccuracies. CNC turning centers employ several advanced strategies to manage these thermal effects.

One key approach involves operating within temperature-controlled environments. This includes insulating the machining area, installing sophisticated HVAC systems, and employing specialized thermal shields. These measures maintain a consistent ambient temperature. Precision-enhancing tool compensation and probing systems continuously monitor and fine-tune tool lengths during machining. They make instantaneous adjustments to counteract dimensional changes caused by temperature fluctuations.

Manufacturers also use effective coolant systems. Advanced cooling methods, such as cryogenic cooling, significantly improve temperature control and reduce thermal deformation. For example, cryogenic cooling achieved ±0.01 mm precision on Inconel disks for an aerospace firm. This showed a 58% improvement in temperature control compared to flood cooling. Strategic optimization of tool paths helps manage heat buildup distribution. This prevents concentrated heat and promotes a more controlled expansion pattern.

Other methods include:

- Deliberate Avoidance of Rapid Temperature Changes: Orchestrating controlled temperature transitions allows materials to acclimate gradually. This significantly reduces the risk of sudden shifts in dimensional integrity.

- Diligent Machine Calibration and Maintenance: Regular calibration routines accommodate potential thermal effects. This enables the machine to dynamically adjust operations and compensate for temperature-induced dimensional variations.

- Harnessing Simulation through Finite Element Analysis (FEA): FEA software simulates and comprehends the thermal behavior of materials. This allows manufacturers to predict and mitigate potential issues before actual machining.

- Thorough Post-Machining Inspection and Precise Compensation: Comprehensive inspections after parts cool to ambient temperature help identify and address subtle deviations introduced by thermal expansion and contraction.

- Adjust Feed Rates and Spindle Speeds: Balancing feed rates to enhance material removal while minimizing heat generation, and managing spindle speeds for optimal machining conditions, helps control thermal deformation and improve accuracy.

- Improve Clamping and Workholding Techniques: Using heavy-duty clamping systems, employing modular fixtures, and adding structural support elements ensure workpieces are securely held. This prevents movement and reduces thermal deformation.

- Implement Thermal Compensation Systems: These systems use advanced algorithms and strategically placed temperature sensors. They monitor heat changes and predict/correct thermal errors in real-time.

- Use Real-Time Monitoring and Sensors: Temperature-sensitive sensors provide insights into heat distribution. They detect minor fluctuations and allow immediate corrective actions.

- Invest in High-Precision Machine Components: Machines built with materials having low thermal expansion coefficients and high thermal conductivity, along with advanced designs featuring thermal barrier coatings, perform better under varying temperatures and dissipate heat effectively.

These comprehensive thermal management strategies ensure that CNC turning centers maintain their high precision even under varying operational conditions.

Integrated Measurement and Inspection

Integrated measurement and inspection systems are crucial features of modern CNC turning centers. These systems allow the machine to verify part dimensions directly on the machine tool. This capability significantly enhances precision and quality control. It minimizes the need for manual intervention and separate inspection stations.

CNC turning centers often incorporate sophisticated probing technologies. These include touch probes and laser probes. A touch probe physically contacts the workpiece. It records precise dimensional data. Laser probes use non-contact methods. They measure features with high accuracy. The machine uses these probes to perform several critical functions:

- Part Setup and Alignment: Probes accurately locate the workpiece on the machine. They establish the exact position of the part. This ensures correct machining operations from the start.

- In-Process Measurement: The machine takes measurements during the machining cycle. It checks critical dimensions as it cuts. This real-time data allows for immediate adjustments.

- Post-Process Verification: After machining, the probe performs a final inspection. It verifies that the finished part meets all specifications.

This integration creates a powerful feedback loop. If the probe detects a deviation from the programmed dimensions, the machine’s control system automatically adjusts tool offsets. This correction happens in real-time. It ensures subsequent cuts produce parts within tolerance. This closed-loop manufacturing process is vital for maintaining consistent quality. It also prevents the production of out-of-spec parts.

Consider the benefits of this integrated approach:

| Feature | Traditional Inspection | Integrated Inspection (CNC Turning Center) |

|---|---|---|

| Location | Separate inspection station | On-machine, in-process |

| Timing | After machining, batch-based | During or immediately after machining, real-time |

| Feedback Loop | Manual, delayed, prone to human error | Automated, immediate, closed-loop correction |

| Human Intervention | High (manual measurement, data entry) | Low (automated probing, software analysis) |

| Scrap/Rework | Higher (errors detected later) | Lower (errors corrected immediately) |

| Production Speed | Slower (due to separate inspection step) | Faster (seamless integration) |

| Data Collection | Manual recording, potential for inconsistencies | Automated, digital, consistent data logging |

Integrated measurement systems drastically reduce human error. They eliminate the need for operators to manually remove parts for inspection. This saves valuable time. It also reduces the risk of damaging the part during handling. The automated data collection provides comprehensive quality records. Manufacturers use this data for process improvement and traceability. This capability ensures every shaft produced meets the highest standards of precision and reliability.

Applications and Industry Impact of CNC Turning Centers

Aerospace Components

Aerospace manufacturing demands extreme precision and reliability. CNC turning plays a crucial role in producing critical components for this sector. Manufacturers use these machines to create various aerospace shaft components. These include transmission shafts, rotor shafts, pump shafts, and engine shafts. DPI CNC machines many critical aerospace parts, including shafts, connectors, and other cylindrical items. They achieve tight tolerance turning for these components. This ensures the safety and performance of aircraft and spacecraft.

Automotive Production

The automotive industry relies heavily on precision machining for powertrain components. Shaft-type precision parts, like crankshafts, are vital for optimal vehicle power and performance. Crankshafts are the ‘heartbeat’ of the assembly. They require inspection of many dimensional characteristics, making quality control challenging. CNC turning centers produce camshafts with lobes ground to ±5 μm accuracy. This ensures precise valve timing. Input/output shafts and intermediate gears also require precise fit tolerances, such as H7/k6, and circularity under five μm for their bearing journals. Custom transmission shafts achieve roundness within three μm for minimal radial runout. This ensures optimal high RPM operation.

Medical Device Manufacturing

Medical device manufacturing requires exceptional accuracy and sterility. CNC turning is a common method for creating shafts and other cylindrical parts with high accuracy. This principle applies directly to various medical applications. Medical CNC turning produces instrument shafts for robotic surgical instruments. It also creates shafts for minimally invasive surgical instruments. These shafts have diameter tolerances of ±0.025mm. They maintain concentricity within 0.05mm across lengths of 300-400mm. This precision ensures the instruments function flawlessly during delicate procedures.

Energy Sector Applications

The energy sector places immense demands on machinery, requiring components that withstand extreme conditions and operate with unwavering reliability. CNC turning centers are indispensable for producing the precision shafts vital for various energy applications. These machines manufacture critical parts for oil and gas, power generation, and renewable energy industries.

For the oil and gas industry, CNC turning centers produce shafts for drilling equipment. These shafts require extreme tolerances and fine surface finishes. Heavy-duty lathes, a specialized type of turning equipment, are ideal for these robust shaft productions. They accommodate large spindles and rotating fixtures, which are common in oil and gas machinery. This capability ensures the integrity and performance of drilling components operating deep underground or offshore.

In power generation, CNC turning centers create shafts for turbines and generators. These components must endure high rotational speeds and significant thermal stress. The precision achieved by CNC turning ensures optimal balance and minimal vibration, which extends the lifespan of expensive power generation equipment. For example, turbine shafts demand exceptional concentricity and surface finish to prevent premature wear and energy loss.

Renewable energy also benefits from CNC turning technology. Wind turbine main shafts, for instance, are massive components that require precise machining to ensure efficient power conversion. CNC turning centers handle the scale and precision needed for these large-diameter shafts. They guarantee the structural integrity and operational efficiency of wind energy systems. The ability of CNC turning centers to machine diverse materials, from specialized alloys to high-strength steels, makes them perfectly suited for the varied material requirements of the energy sector.

Cost-Effectiveness and Efficiency Gains with CNC Turning Centers

Reduced Scrap and Rework

CNC turning centers significantly reduce scrap and rework. Their high precision and repeatability minimize manufacturing defects. Machines follow programmed instructions exactly. This ensures each part meets exact specifications. Fewer errors mean less material waste. Manufacturers save money on raw materials. They also avoid the time and cost of re-machining faulty parts. This directly improves overall production efficiency and profitability.

Faster Production Cycles

These machines dramatically speed up production. Automation allows for continuous operation. Multi-axis capabilities complete complex parts in one setup. This eliminates time-consuming transfers between machines. CNC turning centers enable lights-out manufacturing. This means machines operate unattended for extended periods.

- Bar feeders continuously load lathes for unattended machining.

- Robotic arms palletize completed parts. Vacuum unloaders also assist.

- Systems check cutting tool inserts for breakage and wear. They confirm proper operation.

- Automatic tool setting with probes ensures accuracy. Load fault capacity stops the machine if issues arise.

- Extra cutting tools on standby allow continuous production.

- Chip and coolant management is also automated. This includes filling coolant reservoirs and clearing chips. Effective chip transport prevents blockages. Coolant filtration and pressure monitoring ensure reliability.

These features allow machines to run without constant human supervision. This boosts output significantly.

Lower Labor Costs

CNC turning centers reduce labor costs. Automation minimizes the need for direct human intervention. One operator can oversee multiple machines. This optimizes workforce utilization. Lights-out manufacturing further lowers costs. Machines operate unattended for extended periods. This reduces overtime expenses. It also allows staff to focus on higher-value tasks. The precision of these machines also reduces the need for extensive manual quality checks. This streamlines the entire production process.

CNC turning centers are not merely an option but an essential technology for precision shaft machining. They deliver the accuracy, repeatability, and efficiency modern industries demand. Their advanced capabilities directly address the challenges of producing high-quality shafts. This makes them indispensable for manufacturers aiming for excellence. A CNC Turning Center ensures superior product quality and optimized production processes.

FAQ

What is a CNC turning center?

A CNC turning center is a computer-controlled machine tool. It rotates a workpiece against a cutting tool. This process shapes cylindrical parts like shafts. It offers high precision and automation for manufacturing.

How do CNC turning centers ensure high precision?

They use rigid construction and advanced feedback systems. High-resolution encoders monitor tool position. Thermal management prevents dimensional changes. Integrated measurement systems verify accuracy in real-time. This ensures consistent, precise output.

What types of materials can CNC turning centers machine?

CNC turning centers handle a wide range of materials. These include:

- Steels (carbon, stainless, alloy)

- Aluminum

- Brass

- Titanium

- Exotic alloys like Inconel

This versatility supports diverse industry needs.

What are the main benefits of using CNC turning centers for shaft machining?

They provide unmatched accuracy and repeatability. Manufacturers experience reduced scrap and faster production cycles. Automation lowers labor costs. These machines ensure consistent quality for critical components.

Post time: Jan-07-2026