The ideal CNC turning machine for 2025 depends entirely on your specific operational needs. Selecting the right CNC turning machine is a strategic investment for future efficiency and profitability. This ensures you produce High Precision Turning Parts effectively. A China CNC Turning Machine Manufacturer can offer diverse options for your production goals. This guide helps you navigate the choices to find your optimal CNC Turning Center. Consider a Smart Manufacturing CNC solution for advanced automation and data insights.

Key Takeaways

- Choose a CNC turning machine based on your specific needs, like the size of parts you make and the materials you use.

- Different machines, such as horizontal, vertical, Swiss-type, and multi-axis, each have special strengths for different kinds of jobs.

- Adding automation tools like bar feeders and robots helps machines run longer and make more parts without needing constant human help.

- Important machine details like spindle power, part size limits, and tool capacity affect how well the machine works for your tasks.

- Good chip and coolant systems are important to keep the machine running smoothly, make tools last longer, and keep parts looking good.

Categorizing CNC Turning Machine Types for Your Needs

Choosing the right CNC turning machine starts with understanding the different types available. Each machine offers unique strengths for various production demands.

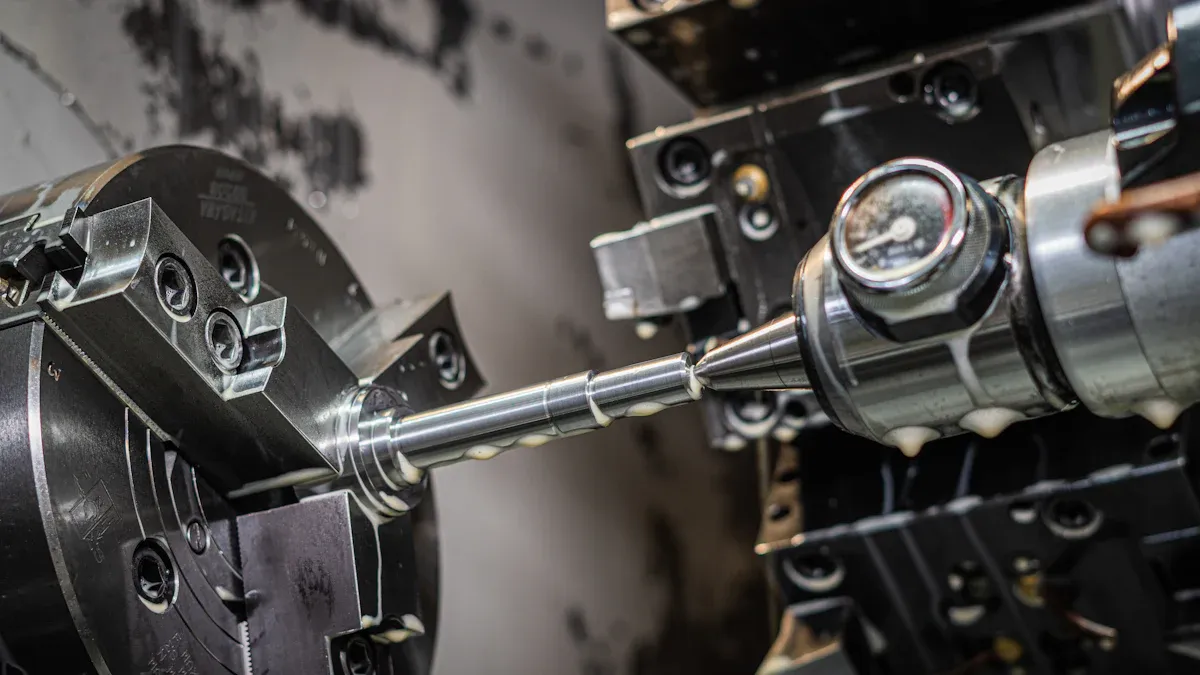

Horizontal CNC Turning Machines

Horizontal CNC turning machines are workhorses in many manufacturing environments. They excel at handling large diameter components like shafts and cylinders. Industries such as oil and gas, and heavy equipment manufacturing often use these machines. They are also great for batch production, efficiently processing many identical parts. This ensures consistent quality with minimal setup time.

These machines offer robust support for heavy workpieces. This rigidity enhances stability and reduces vibrations during machining. Operators also find easy access to the workpiece and tooling, which simplifies setup and maintenance. Horizontal CNC machines often come with larger Automatic Tool Changers (ATCs). Some machines start with 60-90 tools, and capacities can expand to 120 or even 240 tools. This allows for more jobs and less manual intervention. Horizontal machining centers are also very adaptable for pallet systems. While vertical machines can have pallet changers, horizontal machines are better suited for linear pallet systems. They can achieve higher efficiency, sometimes around 85% with a standard PC2, compared to 40% for a stand-alone vertical machine. The B-axis feature on these machines allows for simultaneous machining of multiple parts using a tombstone. This significantly increases productivity because operators can prepare the next tombstone while a cycle runs. It is ideal for jobs needing machining on multiple sides or complex tool paths.

Vertical CNC Turning Machines

Vertical CNC turning machines, often called VTLs, are excellent for specific applications. They are particularly good for heavy workpieces, especially those needing cranes or automation for handling. Gravity helps secure the workpiece on a VTL. This enhances stability and reduces the need for high clamping pressures, which benefits delicate parts. VTLs also save floor space. They occupy less floor space compared to horizontal turning centers, allowing for more machines in the same area. A vertical lathe can take up as little as half the footprint of a horizontal lathe. This is a big advantage for shops with limited space.

Vertical machines are also ideal for nonconforming part shapes. These are parts that need complex fixturing due to their unusual geometry. They also work well for delicate workpieces that need low clamping pressures to avoid damage. The workpiece weight goes straight down into the machine foundation. This prevents off-axis loads on the spindle. VTLs handle complex parts and those with interrupted cuts effectively. They also manage unbalanced workpieces well.

Swiss-Type CNC Turning Machines

Swiss-type CNC turning machines are specialists in precision. They are widely used in industries like medical device manufacturing, aerospace, and electronics. These machines are perfect for producing small, intricate, high-precision parts. This includes medical implants, aerospace components, watch parts, hydraulic fittings, and electrical connectors. They are also common in the automotive industry. Here, they produce parts for suspensions, wheels, brakes, transmissions, engines, exhaust and fuel systems, and electrical systems. They are especially suited for complex components with thin walls, deep cuts, slender designs, and delicate features.

Swiss-type machines achieve very tight tolerances. They can hold tolerances as tight as ±0.0005 inches, depending on the part geometry and material. Some can even achieve ultra-tight tolerances down to ±0.0002 inches or two microns. They handle parts from 1/16 inch to 2 5/8 inches. They can turn micro-parts up to 1-1/4 inch round diameter. They also handle turning diameters as small as 0.125 inches. These machines can run parts with diameters up to 1.259 inches (32mm).

Multi-Axis CNC Turning Centers

Multi-axis CNC turning centers represent the pinnacle of machining technology. They combine turning, milling, and drilling operations into one machine. This capability allows them to create highly complex parts in a single setup. Industries like aerospace, medical, and automotive heavily rely on these machines for intricate components. They produce parts with complex geometries and tight tolerances.

These advanced machines optimize tool orientation. This leads to maximum efficiency and precision. They achieve faster cycles and save significant time by minimizing transitions between tasks. Automation in multi-function CNC machining also reduces risks of human error. This decreases rework and delays often seen with 3-axis machines. Multi-function machines provide superior accuracy and precision. They accommodate intricate designs without manual adjustments or retooling.

Machines with 5-axis setups or more can make deeper precision cuts and shapes. Operators do not need to remove or reposition the workpiece. More axes mean easier creation of complex designs with greater precision. Multi-function CNC machining performs multiple operations without manual tooling changeovers. It uses computer-controlled cutting and positioning to reduce errors. Integrated part probing allows for automated inspection and corrections. These machines produce cleaner, higher-quality finishes. Shorter tools reduce machine vibration effects. Multi-function CNC machining combines operations like drilling, turning, and grinding into one production phase. This eliminates transitional stages. It also enables the creation of complex geometries by orienting tools across different faces and angles.

Five-axis machining achieves tighter tolerances and smoother surfaces. It maintains optimal cutting angles with fewer setups. For low-to-medium volumes of complex parts, 5-axis machining reduces setup time. It also enhances repeatability. These solutions are ideal for parts needing machining on multiple sides with critical tolerances. They also work well when tool access is restricted in standard orientations. Five-axis machining typically achieves a precision range of ±0.01–0.02 mm (±0.0004–0.0008 in). Under optimal conditions, it can reach ±0.005 mm (±0.0002 in) for critical aerospace or medical parts. This is significantly better than general CNC milling’s ±0.05 mm (±0.002 in).

Multi-axis CNC machines offer greater precision. They produce accurately machined and smoother parts. These parts are difficult or impossible with 3-axis machines. They allow complex geometries in a single setup. This eliminates the need for repositioning the workpiece, which compromises accuracy. Multi-axis machining increases production speed. It allows more material removal per rotation. It also improves cycle times through expanded tooling capabilities and simultaneous machining. These machines handle all milling and turning operations for complex geometries in one setup. This leads to faster production, minimized operational costs, and reduced errors. The ability to move workpieces over more dimensions without removal allows for deep cuts and complex shapes. Higher axes lead to better handling of complex designs with high precision. Shorter cutting tools, being closer to the material, result in better surface finishes. This reduces machining vibration and minimizes the need for additional touch-ups. Multi-axis machines maintain precision through various drilling applications. Parts hold their position, and additional axes reach tighter, more complex angles for finer finishes.

However, this advanced capability comes with a higher investment. An entry-level 2-axis CNC lathe might cost less than $5,000. A 3-axis machining center typically ranges from $50,000 to $125,000. In contrast, a 5-axis CNC machine starts at $200,000, with many exceeding $500,000. Larger industrial machining centers with 6 axes or more can cost between $250,000 and $500,000. This higher cost reflects their increased complexity, precision, and versatility.

| Machine Type | Typical Cost Range |

|---|---|

| 3-axis Machining Center | $50,000 – $125,000 |

| 5-axis CNC | $200,000 and up (many over $500,000) |

| 6-axis and Larger Industrial Machining Centers | $250,000 – $500,000 |

Matching Your Material and Part Characteristics to a CNC Turning Machine

Choosing the right CNC turning machine involves carefully considering the materials you process and the specific characteristics of your parts. These factors directly influence the machine’s power, rigidity, and precision capabilities.

Material Type and Hardness Considerations

The type and hardness of your material significantly impact tool selection and machine performance. Harder materials demand more robust machines and specialized tooling. For instance, increased material hardness typically means higher strength. This leads to greater cutting forces and requires more power from the machine spindle. A harder material is also more abrasive, which accelerates wear on the cutting edge. Some materials, like Austenitic Stainless Steel, work harden quickly. This necessitates specialized machining strategies.

Optimal machining parameters depend heavily on machine rigidity, tool geometry, and coolant application. A dramatically increased depth of cut can significantly increase the required spindle power and the risk of vibration. This highlights the importance of machine rigidity.

Here is a guide for recommended tool materials based on workpiece hardness:

| Workpiece Hardness | Recommended Tool Material | Primary Wear Mechanism | Coating Strategy (Example) |

|---|---|---|---|

| Soft (<150 HB) | High-Speed Steel (HSS), Uncoated Carbide | Adhesion, Built-Up Edge (BUE) | None/Smooth Surface |

| Medium (150-300 HB) | Coated Carbide (Cermet) | Diffusion, Crater Wear | TiN, TiAlN |

| Hard (45-65 HRC) | Cermet, Ceramic, Coated Carbide | Abrasive Wear, Thermal Shock | AlTiN, Al2O3 |

| Very Hard (>65 HRC) | Polycrystalline Cubic Boron Nitride (PCBN) | High-Temperature Abrasive Wear | CVD (Chemical Vapor Deposition) |

When you increase workpiece hardness, you must adjust cutting parameters.

| Parameter | Impact of Increased Workpiece Hardness | Strategic Adjustment |

|---|---|---|

| Cutting Speed (Vc) | Increases thermal load on tool tip. | Decrease Vc to manage heat and slow diffusion wear. |

| Feed Rate (f) | Increases cutting force; can prevent work hardening. | Maintain or Slightly Increase f to ensure the tool always cuts beneath the prior cut’s hardened layer. |

| Depth of Cut (ap) | Dramatically increases required spindle power and risk of vibration. | Reduce ap and increase radial engagement (ae) (e.g., in Trochoidal Milling) for better thermal distribution. |

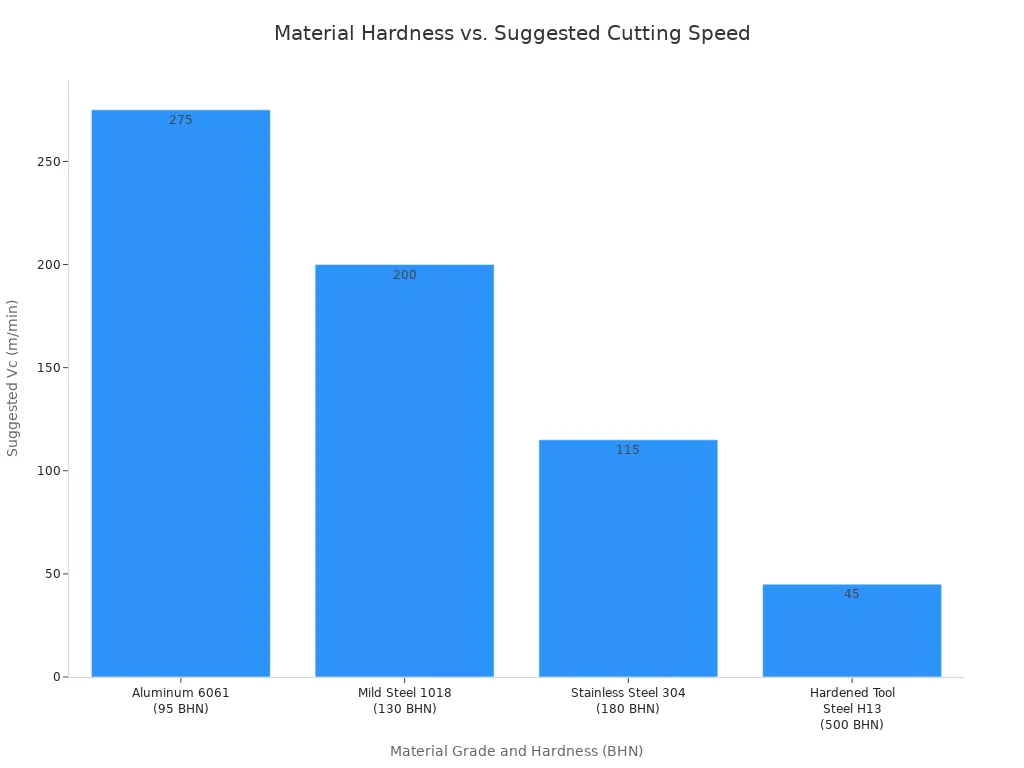

This chart illustrates the relationship between material hardness and suggested cutting speed:

For machining high-strength alloys like Stainless Steel, Inconel 625, Monel 400 & 500, 17-4PH, 13-8, and Nitronic 60, significant torque is necessary, especially at lower speeds. When performing operations like spade drilling or using larger twist drills in these materials, torque becomes crucial. While horsepower is important, sufficient torque, particularly at low RPMs, is essential to effectively cut these challenging alloys.

Consider these spindle specifications for demanding materials:

| Spindle Type | RPM | HP | Torque (ft-lbs) |

|---|---|---|---|

| Standard | 8000 | 17.5 | 60 (at 1500 RPM) |

| High Torque | 8000 | 17.5 | 120 (at 375 RPM) |

Here are some general guidelines for various material grades:

| Material Grade | Hardness (BHN) | Suggested Vc (m/min) (Carbide Tool) | Suggested fz (mm/tooth) (Milling) |

|---|---|---|---|

| Aluminum 6061 | 95 | 200 – 350 | 0.08 – 0.15 |

| Mild Steel 1018 | 130 | 150 – 250 | 0.06 – 0.12 |

| Stainless Steel 304 | 180 | 80 – 150 | 0.05 – 0.10 |

| Hardened Tool Steel H13 | 50 HRC (~500 BHN) | 30 – 60 | 0.01 – 0.04 |

Part Size and Weight Limitations

The physical dimensions and weight of your parts directly dictate the size and capacity of the CNC turning machine you need. The machine’s physical dimensions, including its bed length and swing over bed, determine the maximum part size. For example, the maximum part size that can be machined might be 200 mm in diameter by 500 mm in length. The ‘swing over bed’ specifically dictates the largest diameter a workpiece can have without interfering with the lathe bed. If the swing over bed is 200 mm, the actual part diameter must be slightly less to allow for tool clearance.

Most standard CNC machines handle parts up to 2,000 pounds. However, robust machines designed for heavy-duty applications can manage 10,000 pounds or more. Some shops implement a maximum weight limit for parts, such as 500 kg. This safeguards their equipment from damage to axes or spindles caused by very heavy components.

Here are typical maximum dimensions for various turning machines:

| Machine Type | Max Diameter (mm) | Max Length (mm) |

|---|---|---|

| CNC Turned Components | 5 – 1,000 | Up to 2,000 |

| CNC Lathe | 400 | 1,000 |

| Heavy-Duty CNC Turning Center | 1,000 | 2,000 |

Several factors related to workpiece configuration also influence chuck selection and machine capabilities:

- Workpiece Configuration: The shape and size of the part are primary factors. Round bar stock is simple, but castings or forgings with non-uniform shapes require careful thought.

- Symmetry: Asymmetrical parts (e.g., with a flange or outrigger) can affect speed and balance. This potentially requires counterbalancing or reduced processing speed.

- Part Rigidity: Thin-walled parts may distort with standard clamping. This necessitates chucks like Collet or Diaphragm chucks, or reduced clamping pressure.

- Machine Capabilities: The machine’s swing clearance must accommodate the chuck, part, and tooling. The overall work envelope of the machine can restrict capabilities.

Required Tolerances and Surface Finish

The precision your parts demand directly influences the type and quality of the CNC turning machine you select. For general CNC machining, the standard tolerance limit is approximately ±0.005 inches (0.127 mm). However, many applications require much tighter tolerances.

Different tolerance classes require different machine capabilities:

| Tolerance Class | Range (inches) | Range (mm) |

|---|---|---|

| Standard | ±0.005″ | ±0.13 mm |

| High-Precision | ±0.001″ or better | ±0.025 mm or better |

| Extremely Tight | ±0.0002″ to ±0.0005″ | ±0.00508 mm to ±0.0127 mm |

Achieving a superior surface finish also requires a machine with high rigidity, precise control, and often specialized tooling and cutting strategies. Machines designed for high-precision work typically offer better vibration dampening and finer motion control, which contribute to smoother finishes.

Assessing Part Complexity and Operations for Your CNC Turning Machine

When you choose a CNC turning machine, consider the complexity of the parts you plan to make. The machine’s features directly impact how efficiently it handles intricate designs and multiple operations.

Live Tooling for Complex Parts

Live tooling transforms a standard lathe into a versatile machining center. It allows the machine to perform milling, drilling, tapping, and other operations without moving the part to another machine. This capability is like having a mill built right into your lathe.

Live tooling effectively creates a mill within the lathe, allowing secondary operations such as drilling, tapping, boring, and cutting. Limiting operations to a single, automated workstation guarantees minimal setup and handling time, higher accuracy, and more consistent part quality. With live tooling, we can skip time-consuming part transfers and instead operate on a single machine. Reduced human interaction means less room for human error and better quality control for your parts.

Live tooling offers many benefits. It allows for many operations in a single setup, which streamlines procedures and can shorten cycle times. Production time also significantly reduces due to advanced gears and bearings, leading to faster and more efficient part manufacturing. Datum preservation during machining eliminates errors from material transfer between machines, offering substantial time savings and improving workflow efficiency. More accurate machining is achieved by reducing the number of tool changes, minimizing human error and maintaining high quality. Multipurpose capabilities enable various operations like milling and drilling in a single setup, simplifying production and broadening application range. Intricate machining operations can be performed in a single run, which streamlines setup, lowers manufacturing labor costs, and reduces lead times.

Sub-Spindle for Two-Sided Machining

A sub-spindle is a game-changer for parts needing work on both sides. This feature allows the machine to grab the part from the main spindle, flip it, and machine the other side in the same setup. This eliminates the need for manual re-chucking, which saves time and improves accuracy.

Parts requiring work on both ends, such as shafts, axles, valves, and fittings, benefit greatly from this. Industries like automotive, medical, and aerospace & defense often use sub-spindles. For example, automotive uses them for engine, transmission, and drivetrain components. Medical applications include complex orthopedic implants like bone screws and surgical instruments. Aerospace & Defense benefits from high-strength fasteners, hydraulic fittings, and guidance system components. These industries rely on sub-spindle capabilities for reliable production of high-precision components.

Y-Axis and B-Axis Capabilities

Y-axis and B-axis capabilities further expand a CNC turning machine’s versatility. A Y-axis allows the cutting tool to move perpendicular to the main turning axis, enabling off-center drilling and milling operations. This means you can create features like keyways or flats on a turned part. B-axis functionality provides rotational movement for the tool, allowing it to approach the workpiece at various angles. This is crucial for multi-surface machining and handling complex parts with ease. Both Y-axis and B-axis contribute to ‘DONE IN ONE®’ operations, processing parts in a single setup. This significantly reduces setup times and improves overall efficiency.

Off-Center Drilling and Milling Operations

Off-center drilling and milling operations significantly expand a CNC turning machine’s capabilities. These operations allow the machine to create features that are not perfectly centered on the part’s rotational axis. Think about drilling a hole that is slightly off to the side, or milling a flat surface onto a round component. Traditional lathes could not perform these tasks without moving the part to a separate milling machine.

Modern CNC turning centers, especially those with Y-axis and live tooling, make these operations possible. The Y-axis moves the cutting tool perpendicular to the main turning axis. This movement allows the tool to reach different points across the part’s diameter. Live tooling, as discussed earlier, provides rotating tools like drills and end mills. When these two features combine, the machine can perform complex milling and drilling tasks directly on the turned part.

For example, a machine can drill a series of bolt holes around a flange, or mill a keyway into a shaft. It can also create intricate pockets or slots on the side of a cylindrical part. This capability is incredibly valuable for parts requiring multiple features that are not concentric.

Performing off-center operations on a single machine saves significant time and reduces potential errors. Operators do not need to unclamp the part, transfer it to another machine, and then re-clamp it. Each transfer introduces a chance for misalignment, which affects part accuracy.

This integrated approach ensures higher precision and consistency. It also streamlines the manufacturing process. Companies achieve “done-in-one” machining for many complex components. This means a single machine completes all operations from raw material to finished part. This efficiency boosts productivity and lowers overall production costs. It also reduces lead times for complex parts.

Consider these benefits:

- Reduced Setup Time: No need to move parts between machines.

- Improved Accuracy: Eliminates errors from multiple setups.

- Increased Efficiency: Faster production cycles.

- Greater Part Complexity: Creates features previously impossible on a lathe.

Off-center drilling and milling capabilities are essential for manufacturers producing intricate parts in industries like aerospace, medical, and automotive. They help create components with precise, non-concentric features efficiently.

Integrating Automation with Your CNC Turning Machine for Efficiency

Integrating automation into your manufacturing process significantly boosts productivity and reduces operational costs. Modern CNC turning machines often come with features that allow seamless automation, transforming your production line.

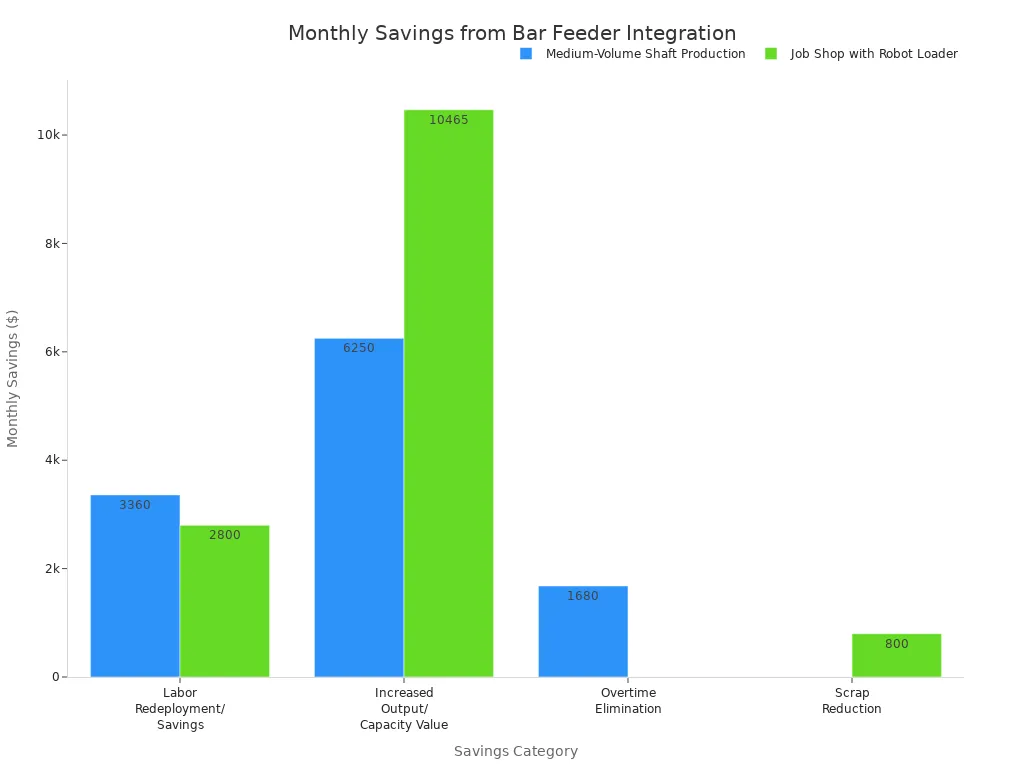

Bar Feeder Integration for Continuous Production

Bar feeders are essential for continuous, unattended production. They automatically supply raw material to the machine, allowing it to run for extended periods without operator intervention. This is ideal for high-volume jobs.

| Savings Category | Scenario 1: Medium-Volume Shaft Production (Monthly Savings) | Scenario 2: Job Shop with Robot Loader (Monthly Savings) |

|---|---|---|

| Labor Redeployment/Savings | $3,360 | $2,800 |

| Increased Output/Capacity Value | $6,250 (from in-house production) | $10,465 (from increased utilization) |

| Overtime Elimination | $1,680 | N/A |

| Scrap Reduction | N/A | $800 |

| Total Monthly Savings | $11,290 | $14,065 |

| ROI Period | 3.1 months | 6.0 months |

Integrating bar feeders typically leads to payback within 12-24 months. These cost savings come primarily from labor savings, increased throughput, and reduced scrap. After recovering the initial investment, productivity gains directly contribute to the bottom line for the equipment’s 8-10 year lifespan.

Different bar feeder models handle various bar diameters and lengths. For example, the Quick Load Servo 80+ handles bars from 1/4” to 3-1/8” in diameter and 11″ to 63″ in length. The GT 342 model accommodates bars from 3 mm to 42 mm in diameter.

Robotic Loading and Unloading Solutions

Robotic loading and unloading solutions further enhance automation by handling parts with precision and consistency. They enable continuous 24/7 operation of machines. Robotiq’s Machine Tending Solution offers a low-risk approach with a reported one-year ROI. This solution helps recover lost runtime and allows one operator to manage multiple cobots.

| Category | Description |

|---|---|

| Productivity | Enables continuous 24/7 operation of CNC machines. |

| Cost and ROI | Features lower upfront costs with a typical ROI achieved within 12 to 24 months. |

| Safety | Eliminates the need for human operators in repetitive and high-risk loading tasks. |

| Ease of Use | Offers simple setup, often with no-code or hand-guided programming, for fast integration. |

| Flexibility | Can be easily reprogrammed to work with different machines or part types. |

| Consistency | Provides reliable and accurate loading and placement. |

Implementing robotic systems requires thorough risk assessments. Manufacturers must identify hazards like moving parts and pinch points. They should implement safety measures such as emergency stops and interlocked barriers. Regular training for operators on safety procedures is also crucial.

Pallet Changers and Part Catchers

Pallet changers and part catchers are vital for achieving lights-out manufacturing. Bar feed systems enable uninterrupted operation by automatically feeding raw materials. Part catchers automatically collect finished parts, eliminating manual handling and reducing downtime.

These systems facilitate unattended operation for extended periods, including overnight. This increases machine utilization and productivity. Automation ensures continuous production, significantly boosting throughput and efficiency. It also lowers labor costs and allows human resources to be reallocated to more strategic tasks. Automated systems enhance precision by minimizing human errors and ensuring consistency in material handling.

Continental Machining Company adopted a Matsuura MX 330 PC10 with a 10-pallet system. This provided the flexibility to run low-volume jobs during the day and higher-volume work during lightly attended night shifts. This demonstrates how pallet changers enable continuous production, including lights-out manufacturing, through flexible scheduling and unattended operation.

Achieving Lights-Out Manufacturing

Lights-out manufacturing represents the ultimate goal for many automated production facilities. It means factories operate without human presence during certain shifts, often overnight or on weekends. Machines run autonomously, handling all tasks from material loading to part unloading. This approach maximizes machine utilization and significantly boosts productivity.

To achieve lights-out manufacturing, businesses integrate several automation technologies. Bar feeders continuously supply raw material to CNC turning machines. Robotic loading and unloading systems precisely handle parts, moving them between machines or into storage. Pallet changers and part catchers further streamline the process. Pallet changers allow machines to switch between different jobs or materials automatically. Part catchers collect finished components, preventing machine stoppages.

This level of automation offers substantial benefits. Companies achieve continuous production, running machines 24/7. This dramatically increases output without adding labor costs. It also reduces human error, leading to more consistent part quality and less scrap. Furthermore, businesses can reallocate human operators to more complex tasks like programming, maintenance, or quality control. This optimizes their workforce.

Lights-out manufacturing transforms a factory into a highly efficient, self-sufficient operation. It allows manufacturers to meet high demand, reduce lead times, and stay competitive in the global market. This strategic move helps secure future growth and profitability.

Key Specifications for Your Optimal CNC Turning Machine Performance

When you select a CNC turning machine, its core specifications really matter. These details determine what kinds of parts you can make and how efficiently you make them. Understanding these key features helps you pick the best machine for your shop.

Spindle Horsepower and RPM Requirements

The spindle’s power and speed are critical for effective machining. Horsepower gives the machine the strength to cut through tough materials. RPM (revolutions per minute) dictates how fast the workpiece spins. Different applications need different levels of power and speed.

| Spindle Power Range (kW) | Typical Applications |

|---|---|

| 0.8-1.5 kW | Small-scale engraving, PCB milling, light woodworking, acrylic cutting. Suitable for hobbyists and small workshops. |

| 2.2-3.5 kW | General woodworking, sign making, plastic fabrication, aluminum engraving. Ideal for small to medium-sized businesses. |

| 4.5-6.0 kW | Heavy-duty woodworking, furniture manufacturing, cabinet making, non-ferrous metal machining. Preferred by professional workshops and industrial users. |

| 7.5-9.0 kW | Industrial-grade applications, large-scale panel processing, complex 3D carving, heavy metal cutting. Designed for high-production environments. |

| 12 kW and above | High-performance industrial machining, aerospace components, automotive parts, mold making. Used in demanding industrial settings for continuous operation and precision. |

Chuck Size and Bar Capacity

The chuck size and bar capacity define the maximum dimensions of the raw material your machine can handle. This directly impacts the size of the parts you can produce. For smaller workpieces, collet chucks offer distinct advantages.

- Collet chucks are particularly advantageous for workpieces under 4 inches in diameter.

- They offer superior tool clearance, 360-degree workpiece contact, and greater gripping force, especially at high RPM.

- Bar capacity for these chucks can extend up to 4 inches (100mm) in diameter.

- They are best suited for parts ranging from 1/16 inch to 4 inches in diameter due to better tool clearance, higher speed capabilities, and superior grip force.

- Collet chucks are primarily designed for smaller parts, typically 3 inches or less, though capacities can reach 6 inches.

- Their lower mass and symmetrical design enable higher operating speeds compared to three-jaw chucks. This leads to more consistent gripping force at high RPMs.

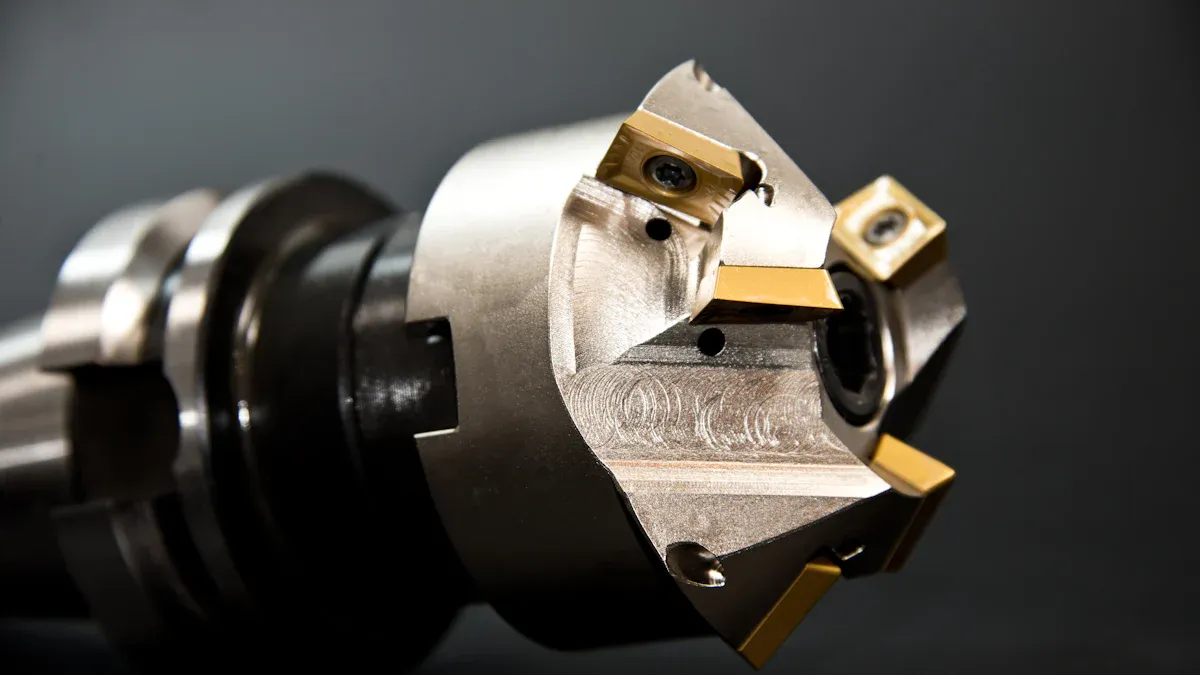

Tooling Capacity and Turret Configuration

The number of tools your machine can hold and how it arranges them affects how many operations it can perform without stopping. A larger tooling capacity means less downtime for tool changes. Turret configuration also plays a big role.

| Turret Type | Tooling Capacity |

|---|---|

| VDI | High (12+ stations) |

| BMT | Limited (6-12 stations) |

VDI (VDI stands for Verein Deutscher Ingenieure, or Association of German Engineers) turrets often provide more stations, giving you greater flexibility. BMT (Base Mounted Tooling) turrets offer robust clamping for heavier cuts. Choosing the right turret helps you maximize efficiency and part complexity.

Effective Chip Management and Coolant Systems

Effective chip management and robust coolant systems are vital for any CNC turning machine. They ensure smooth operations, extend tool life, and maintain part quality. Poor chip evacuation can lead to tool breakage, surface finish issues, and machine downtime. A good system keeps the cutting zone clear and cool.

Manufacturers use several strategies to manage chips effectively. They optimize tool paths to minimize chip accumulation in tight spaces and deep cavities. This enhances productivity and ensures consistent chip evacuation. Choosing the correct tool also helps. Tools with appropriate flute geometry, helix angle, and coating work best. For example, larger flute spaces and higher helix angles are ideal for materials like aluminum that produce longer chips. Chip breakers fragment chips into smaller, manageable pieces. This is especially useful for materials that create long, stringy chips, which reduces blockages.

| Strategy | Material Types | Cutting Conditions/Considerations |

|---|---|---|

| Implement Chipbreakers | Materials producing long, stringy chips (e.g., difficult alloys like titanium and nickel-based materials) | Maintaining correct heat and pressure; various configurations available for specific needs or general applications. |

| Use High-Pressure Coolant | General | Coolant stream close to the cutting zone; appropriate sizing of the high-pressure unit relative to the machine coolant reservoir. |

| Apply Process and Programming Changes | ISO P group steels (chip color indicates heat transfer) | Tool alignment (center height critical); high stability tooling; depth of cut (at least 2/3 of radius, 1-2mm past radius for best results); feed rate (not too low or too high); cutting speed (can be adjusted if other changes fail); programming changes like speed pecking for grooving. |

A good coolant management system directs coolant flow precisely to the cutting area. This flushes chips away and prevents accumulation and overheating. It also maintains coolant quality. Automatic chip extraction systems, like vacuums or conveyors, continuously remove chips. This is crucial for high-volume production. It helps maintain consistent cutting conditions and reduces downtime.

Advanced cooling systems, such as minimum quantity lubrication (MQL) and dry machining, significantly conserve water and reduce coolant use. These systems also decrease the energy required for cooling. This leads to increased overall system efficiency and implied cost savings. Supercritical CO₂ systems offer even more benefits:

- Zero Coolant Waste: Supercritical CO₂ evaporates harmlessly. This eliminates residue and costly disposal.

- Reduced Energy Use: Less energy is needed for operation. Filtration, pumping, and cleanup systems are no longer required.

- Sustainable CO₂ Sourcing: CO₂ is typically reclaimed from industrial processes. This supports a circular economy.

- No Harmful Chemicals: Non-toxic scCO₂ eliminates exposure to hazardous substances. It improves air quality and workplace safety.

- Clean, Residue-Free Operations: It leaves no oily residues. This minimizes maintenance and cleanup.

These advanced systems not only improve machining performance but also offer significant environmental and cost benefits.

Selecting the ideal CNC turning solution for 2025 requires a clear understanding of your unique production goals. A carefully chosen machine becomes a strategic asset, directly contributing to manufacturing success. Businesses make informed decisions to optimize their operations and secure future growth. This comprehensive guide helps manufacturers find the perfect fit for their specific needs.

FAQ

What is the main difference between horizontal and vertical CNC turning machines?

Horizontal machines handle long, heavy parts well, often with easier chip removal. Vertical machines are great for heavy, short parts, using gravity to secure them. They also save floor space.

When should a shop consider a Swiss-type CNC turning machine?

Shops should consider Swiss-type machines for small, intricate, high-precision parts. They excel in industries like medical, aerospace, and electronics, producing complex components with tight tolerances.

What are the benefits of multi-axis CNC turning centers?

Multi-axis centers combine turning, milling, and drilling in one machine. This allows complex parts in a single setup, reducing errors, saving time, and improving accuracy.

How does automation, like bar feeders, help a CNC turning machine?

Bar feeders automatically supply raw material, enabling continuous, unattended production. This increases output, reduces labor costs, and allows machines to run for longer periods without human intervention.

Why are spindle horsepower and RPM important for a CNC turning machine?

Spindle horsepower gives the machine the strength to cut tough materials. RPM dictates how fast the workpiece spins. Both are crucial for efficient machining and depend on the material and part requirements.

Post time: Dec-05-2025