The ideal CNC Turning Machine for small batch production in 2025 perfectly suits your specific operational demands. It masterfully balances part complexity, material needs, budget, and automation goals. Achieving High Precision Turning becomes a reality with the right choice. Consider How to optimize CNC turning cycle time; this boosts your efficiency. Always ensure your Cnc turning machine CE certification requirements are met for safety and compliance. Smart B2B CNC machine sourcing empowers you to find this perfect solution.

Key Takeaways

- Choose a CNC turning machine that fits your specific needs, considering part complexity, materials, budget, and automation goals.

- Understand the different machine types like lathes, turn-mills, and Swiss-type machines to match them with your part’s size and complexity.

- Look for features like powerful spindles, live tooling, and automation options to make your production more efficient.

- Consider the machine’s size, control system, and the support offered by the vendor to ensure smooth operations.

- Evaluate the total cost, including maintenance and energy, to make sure your investment is profitable in the long run.

Understanding Small Batch Production Needs for a CNC Turning Machine

Success in small batch production begins with a clear understanding of its unique demands. Businesses thrive when they match their equipment to these specific needs. This foundational knowledge guides the selection of the perfect CNC Turning Machine.

Defining Small Batch Volume and Variety

Small batch production offers incredible flexibility and opportunity. It caters to projects that do not require mass production volumes. Typically, low-volume production ranges from 1 to 10,000 units annually. This broad range allows for significant adaptability. Many manufacturers define low-volume CNC machining as 1 to 100 pieces. Other manufacturers extend this low-volume range up to 1,000 pieces. Orders can be as small as prototypes or a few dozen parts. The exact quantity often depends on the part’s complexity. This flexibility means a business can handle anything from a single prototype to several thousand production parts. The variety of projects within this volume range is vast, demanding a versatile approach.

Key Characteristics of Small Batch Parts

Small batch parts often present unique characteristics that challenge conventional manufacturing. These parts are typically axisymmetric. They frequently include basic shapes such as shafts and fasteners. Examples of components produced through this method are camshafts, crankshafts, custom vessels, and various hand tools like hammers, punches, gauges, and screwdrivers. The materials used for these parts are incredibly diverse. Aluminum is valued for its light weight and ease of machining, often appearing in aerospace. Stainless Steel offers corrosion resistance, ideal for medical devices. Brass provides aesthetic qualities and good machinability. Titanium boasts a high strength-to-weight ratio, suitable for aerospace and medical applications. Copper excels in electrical and thermal conductivity. Tool Steel provides hardness for tooling. Carbon Steel balances durability and machinability. Nickel Alloys resist high temperatures and corrosion. Tungsten handles extreme heat. A capable CNC Turning Machine must skillfully process this wide array of materials and part complexities.

Essential Factors for Choosing a CNC Turning Machine

Selecting the right CNC Turning Machine is a pivotal decision for any small batch production facility. This choice directly impacts efficiency, part quality, and overall profitability. Manufacturers must carefully consider several key factors to ensure their investment truly empowers their operations.

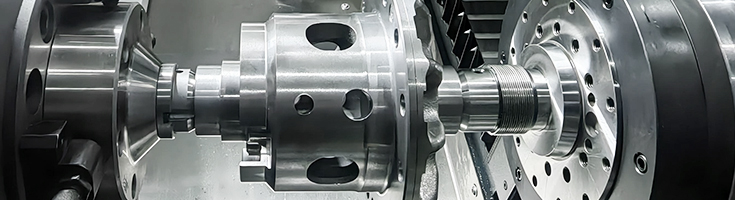

Machine Type: Lathe, Turn-Mill, or Swiss-Type

The foundation of successful turning lies in choosing the correct machine type. Each offers unique advantages for specific part geometries and production goals. Understanding these differences helps manufacturers make an informed decision.

- CNC Lathes are the workhorses of turning. They excel at producing cylindrical parts with precision. These machines are versatile for a wide range of sizes and materials.

- Turn-Mill Machines combine turning and milling capabilities into one platform. This integration allows for complex parts with features like holes, slots, and angled surfaces to be completed in a single setup. This reduces handling and improves accuracy.

- Swiss-Type Lathes specialize in small, intricate parts with extremely tight tolerances. Their unique design supports the workpiece close to the cutting tool, minimizing deflection. This makes them ideal for long, slender components.

Each machine type brings distinct features and applications to the table. For instance, Swiss-type machines are renowned for their sliding headstock design. The workpiece remains stationary while tooling moves, which minimizes vibration and deflection, especially for small-diameter parts. A guide bushing system further supports the workpiece near the cutting tool. This reduces vibration, improves surface finish, and extends tool life, proving especially useful for slender parts. Modern Swiss lathes often feature multi-axis capabilities and live tooling integration. This extends their abilities to include milling and drilling without compromising precision. They also offer high-speed processing and automatic bar feeders for continuous operation. These machines are ideal for industries demanding high precision, such as watchmaking, medical device manufacturing, and electronics. They produce intricate and complex parts with exceptional accuracy and tight tolerances.

Here is a comparison to help clarify the distinctions:

| Feature / Application | CNC Lathe | CNC Swiss Lathe |

|---|---|---|

| Distinguishing Features | Limited multi-axis capabilities; standard tooling systems (time-consuming changes); single-spindle configuration; basic coolant systems; sequential tool motion. | Multi-axis capabilities (up to 13 axes); modular tooling systems (rapid changes); sub-spindle technology; high-pressure coolant systems; synchronized tool motion. |

| Part Size & Geometry | Greater flexibility, suitable for small to large diameter workpieces; better for shorter, larger-diameter, round/cylindrical parts; limitations for long, slender components due to deflection. | Excels at small, precise parts (typically under 32mm diameter); ideal for long, slender components with length-to-diameter ratios exceeding 3:1. |

| Precision & Surface Finish | Can achieve good precision, but may struggle with very tight tolerances on long, slender parts due to deflection. | Superior precision and surface finish on small parts due to guide bushing support, reducing deflection and enabling tighter tolerances. |

| Production Volume | Suitable for both small and medium production runs; may require more frequent setups and operator attention for complex parts. | Optimized for high-volume production of small parts; automated features (bar feeding, part collection) allow for extended, uninterrupted runs with minimal operator intervention. |

| Complexity of Parts | Can produce complex parts but often requires multiple setups or secondary operations. | Excels at complex parts with multiple features in a single setup; performs simultaneous operations on multiple sides. |

| Material Utilization | Often lower material utilization, especially for small parts, due to minimum gripping length. | Excels in material utilization, especially for long, slender parts; machines very close to the collet, minimizing waste. |

| Flexibility & Adaptability | More versatile, handles a broader range of part geometries and sizes; easier setup changes. | Highly efficient within its niche (long, slender parts); limited adaptability to a wide range of part types/sizes; significant changes may require extensive tooling/setup modifications. |

| Initial Investment & Operating Costs | Generally lower initial investment; operating costs can be lower upfront, but overall cost per part might increase for high-volume. | Higher initial investment; often leads to lower per-part costs in high-volume due to efficiency, reduced scrap, and minimal labor. |

| Programming & Operation Complexity | Typically easier to program and operate; larger pool of experienced operators. | Generally more complex due to unique design, multiple axes, and specialized tooling; requires in-depth knowledge. |

| Secondary Operations | May require multiple setups or additional secondary operations (milling, grinding). | Often eliminates the need for secondary operations, completing parts in a single setup. |

| Automation Potential | N/A | Inherently designed for automation with built-in bar feeding and part collection for lights-out manufacturing. |

Spindle Configuration and Power for CNC Turning

The spindle is the heart of any turning operation. Its configuration and power directly influence machining capabilities. Manufacturers must match spindle specifications to their material and part requirements.

- Spindle Power: Higher horsepower allows for deeper cuts and faster material removal, especially with tough materials like stainless steel or titanium. For softer materials or lighter cuts, a less powerful spindle may suffice.

- Spindle Speed: High RPMs are crucial for achieving fine surface finishes and efficient machining of smaller diameters. Lower RPMs provide the torque needed for larger parts and harder materials.

- Main Spindle vs. Sub-Spindle: A machine with a sub-spindle can perform operations on both ends of a part without manual re-chucking. This significantly reduces cycle times and improves accuracy by eliminating repositioning errors. For small batch production, this capability can be a game-changer, allowing for complete part production in a single setup.

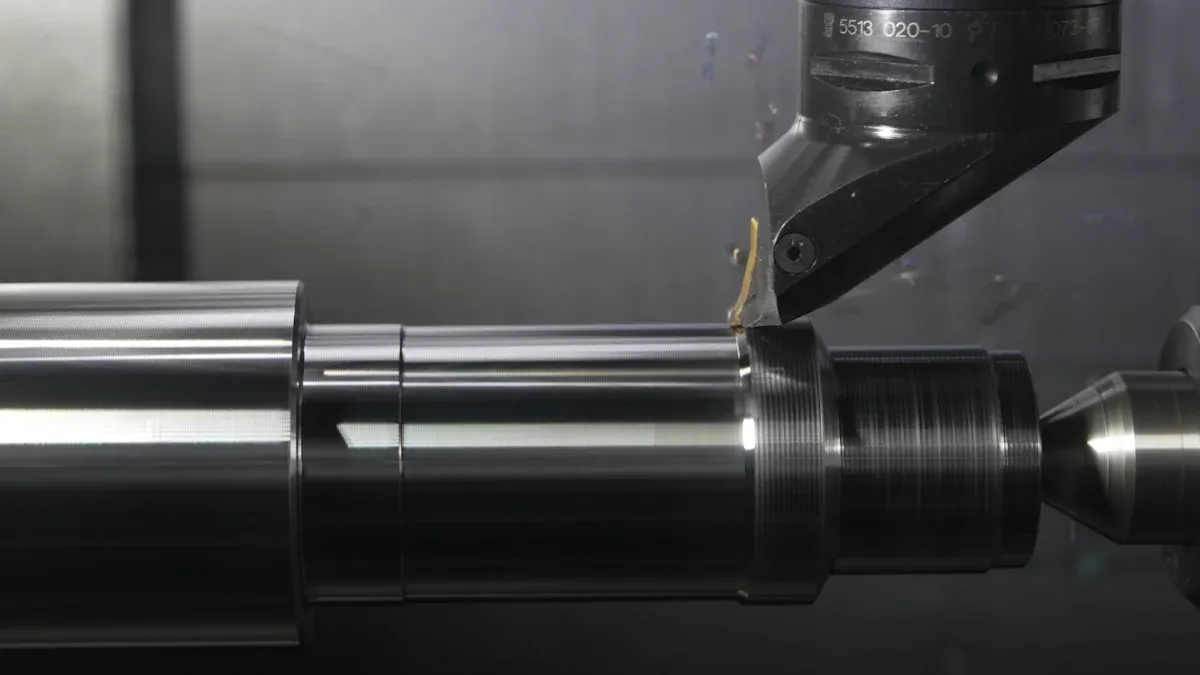

Tooling Capacity and Live Tooling Options

The ability to hold a variety of tools and perform multiple operations without manual intervention dramatically boosts productivity. Tooling capacity and live tooling are critical considerations.

- Tooling Capacity: A larger tool magazine means more tools are readily available. This reduces the need for frequent tool changes by the operator. It also allows for greater flexibility in machining complex parts that require many different tools.

- Live Tooling: This feature transforms a standard lathe into a multi-tasking powerhouse. Live tools are rotating tools that can perform milling, drilling, tapping, and other operations directly on the lathe. This eliminates the need to transfer parts to a separate milling machine.

Live tooling offers numerous benefits for small batch production efficiency:

- Single-Setup Machining: Live tools enable secondary operations like milling, drilling, or tapping within the same setup as turning. This significantly reduces non-productive setup time and minimizes errors from repositioning.

- Lower Tool Changeover: Multiple machining operations can occur sequentially or in parallel with a single machine tool magazine. This reduces tool changeover time and simplifies tool management, leading to shorter cycle times.

- Integrated Operations for Complex Geometries: Live tools allow machinists to perform a series of operations (e.g., drilled holes, slots, threaded areas) in one uninterrupted process, speeding up workflows.

- Higher Productivity per Machine: Simultaneous milling and turning capabilities allow a single CNC machine to produce more parts per hour without requiring extra equipment or floor space.

- Greater Accuracy and Consistency: Minimizing setups and part handling reduces variation in part quality. This leads to tighter tolerances, better surface finish, and improved repeatability.

- Reduced Cycle Times: Continuous machining operations, where secondary operations occur simultaneously with turning, reduce total cycle times. This leads to faster order delivery and improved machine utilization.

For example, a parts manufacturer producing auto components with both turned and milled features traditionally had to machine parts on a lathe and then transfer them to a milling center. This effectively doubled setup time and increased error potential. By incorporating live tools, this producer finished turning and milling in one setup. This resulted in a 30% reduction in cycle time, increased throughput, and consistent quality. This investment quickly yielded returns through saved labor, lower scrap rates, and quicker delivery.

Machine Footprint and Shop Space Considerations

Every workshop has its limits, and the physical size of a CNC turning machine directly impacts a shop’s layout and capacity. Smart manufacturers carefully evaluate the machine’s footprint. A compact design can free up valuable floor space. This allows for better workflow, additional equipment, or improved operator movement. For small batch production, maximizing space efficiency often becomes a priority. Some machines offer a smaller footprint without sacrificing power or capability. This makes them ideal for shops with limited square footage. Consider how the machine’s dimensions fit into your current layout. Think about future expansion plans. An efficient use of space can lead to a more organized and productive environment.

Automation Features for Small Batch CNC Turning

Automation might seem like a feature only for mass production, but it offers significant advantages for small batch operations too. Even small improvements in automation can dramatically boost efficiency and reduce labor costs.

- Bar Feeders: These systems automatically feed raw material into the machine. They allow for continuous, unattended operation. This means a machine can run through an entire batch of parts without an operator constantly loading new material. This capability enables “lights-out” manufacturing during off-hours.

- Part Catchers and Conveyors: Once a part finishes machining, a part catcher safely collects it. A conveyor then moves it away from the work area. This prevents damage to finished parts. It also prepares the machine for the next cycle without manual intervention.

- Robotic Loading/Unloading: For more complex parts or higher volumes within small batch production, robotic arms can load raw material and unload finished components. This further reduces manual labor. It also ensures consistent part handling.

- Automatic Tool Changers: A machine with an automatic tool changer can select and replace tools as needed. This eliminates the need for an operator to manually swap tools. It saves time and reduces the risk of human error.

These automation features transform a standard CNC Turning Machine into a highly efficient production unit. They reduce cycle times, improve consistency, and free up operators for other critical tasks. Embracing automation empowers small batch producers to compete effectively.

Control System and Programming Ease

The control system acts as the brain of the CNC turning machine. Its user-friendliness and programming capabilities directly influence operator efficiency and overall productivity. A powerful yet intuitive control system can make a significant difference.

- User-Friendly Interface: Modern control systems feature graphical interfaces. These interfaces simplify complex operations. Operators can navigate menus and input data with ease. This reduces the learning curve for new users.

- Programming Options: Many machines offer both G-code programming and conversational programming. G-code provides precise control for experienced programmers. Conversational programming uses a question-and-answer format. This allows operators to create programs directly at the machine. It does not require extensive G-code knowledge. This flexibility benefits small batch production. It often involves frequent program changes for different parts.

- Simulation Software: Integrated simulation software allows operators to test programs virtually. They can identify potential collisions or errors before actual machining begins. This prevents costly mistakes and material waste. It also optimizes tool paths for maximum efficiency.

- Connectivity: Advanced control systems offer connectivity options. These include integration with CAD/CAM software and DNC (Direct Numerical Control) systems. This seamless data transfer streamlines the entire manufacturing process. It ensures that the latest designs and programs are always in use.

A well-chosen control system empowers operators. It reduces setup times. It also enhances the overall efficiency of small batch CNC turning operations.

Budget and Return on Investment for a CNC Turning Machine

Investing in a new CNC Turning Machine represents a significant financial commitment. However, it also offers immense potential for growth and profitability. Smart manufacturers carefully evaluate the budget and project the return on investment (ROI). This ensures the machine becomes a powerful asset, not just an expense.

The initial purchase price is only one part of the equation. Consider the total cost of ownership. This includes installation, tooling, software, and ongoing maintenance. A lower upfront cost might seem appealing. However, a machine with higher efficiency and lower operating costs often delivers a better long-term return.

Calculating the payback period helps assess the financial viability of your investment. You can determine this by dividing the total investment by the annual net benefit. For example, if a CNC machine and related costs total $250,000 and are estimated to generate $100,000 in net benefits annually, the payback period would be 2.5 years. After this period, the machine continues to generate pure profit. For a highly profitable CNC machine investment, aiming for a payback period of under three years is advisable. This ensures a quick return and sustained profitability.

Think about the potential for increased production capacity. Consider the improved part quality and reduced labor costs. These factors all contribute to the annual net benefit. A well-chosen machine can unlock new opportunities. It allows you to take on more complex jobs and expand your customer base. This strategic investment empowers your business to thrive.

Service, Support, and Training for Your CNC Turning Machine

The journey with your new CNC Turning Machine extends far beyond the purchase date. Excellent service, reliable support, and comprehensive training are crucial for maximizing your investment. They ensure smooth operations and sustained productivity.

Choose a vendor with a strong reputation for customer service. A responsive support team can quickly address any technical issues. This minimizes downtime and keeps your production running. In small batch manufacturing, every minute of uptime counts. Look for vendors who offer readily available spare parts. This prevents long delays if a component needs replacement.

Comprehensive training programs are equally vital. They empower your operators to fully utilize the machine’s capabilities. Well-trained staff can program efficiently, troubleshoot minor issues, and maintain the machine properly. This reduces errors and extends the machine’s lifespan. Many vendors offer various training options. These include on-site instruction, online courses, or dedicated training centers. Investing in your team’s knowledge pays dividends in efficiency and confidence.

A strong partnership with your machine vendor provides peace of mind. It ensures you have the resources and expertise to overcome any challenge. This support system allows you to focus on what you do best: producing high-quality parts. It helps you achieve your manufacturing goals with confidence.

Axis Configuration: 3-Axis vs. 5-Axis CNC Turning Machine

Choosing the right axis configuration for your CNC turning machine unlocks incredible potential for your small batch production. This decision shapes your capabilities, influencing the complexity of parts you can create and the efficiency of your operations. Understanding the differences between 3-axis and 5-axis machines empowers you to make a choice that propels your business forward.

Benefits of 3-Axis CNC Turning for Simpler Parts

A 3-axis CNC turning machine offers a fantastic starting point for many small batch operations. It excels at producing parts with simpler geometries, primarily cylindrical shapes. These machines move along three linear axes (X, Y, and Z), providing straightforward and reliable turning capabilities. They are often more budget-friendly, making them an accessible option for businesses beginning their CNC journey. For parts like shafts, bushings, or simple fasteners, a 3-axis machine delivers precision and efficiency without unnecessary complexity. It allows you to master fundamental turning operations and build a strong foundation for your production needs.

Advantages of 5-Axis CNC Turning for Complex Geometries

Embracing a 5-axis CNC turning machine opens up a world of possibilities for intricate and challenging parts. This advanced configuration adds two rotational axes, allowing the cutting tool or workpiece to tilt and rotate. This capability dramatically expands the machine’s versatility. It offers high production efficiency, reducing setup time by machining multiple surfaces in a single setup. This is ideal for small lot sizes and rapid prototyping.

A 5-axis machine truly shines in its ability to process complex geometries. It handles intricate 3D shapes and free-form surfaces, supporting highly customized and detailed structures. You can machine all sides of a part without repositioning, which is crucial for small batches. This configuration supports complex shapes, enabling the creation of curved, angled, or organic features. It also facilitates simpler assemblies, allowing you to design parts as a single, complex piece instead of multiple components. The two rotational axes allow the tool or part to tilt and rotate, reaching multiple sides in a single setup. This benefits parts with awkward angles or deep pockets. A 5-axis CNC machine is perfect for prototyping complicated designs or producing parts with extensive detail. Its ability to move workpieces across more dimensions without removal allows it to tackle complicated angles, creating complex geometries with premium finishes and tighter tolerances.

Specific CNC Turning Machine Types for Small Businesses

Small businesses often seek specialized equipment to meet their unique production demands. The right CNC turning machine can transform their capabilities. It allows them to produce high-quality parts efficiently. Exploring specific machine types helps businesses make informed decisions.

Vertical Turning Lathes

Vertical Turning Lathes (VTLs) offer a powerful solution for specific manufacturing needs. These machines orient the workpiece vertically. This design is ideal for machining large, heavy, and short parts. Gravity assists in holding the workpiece securely on the chuck. This simplifies clamping and reduces deformation. VTLs are perfect for components like large gears, flywheels, or turbine disks. They provide stability and precision for these challenging items.

CNC Turning Centers

CNC Turning Centers are versatile workhorses for small batch production. They combine turning with other machining operations. This integration allows for multiple processes in a single setup. This significantly reduces potential errors. It also decreases cycle times. For example, a robotics client saw a 25% reduction in machining time for Ø30 mm shafts. This was achieved by using turn-mill functionality. CNC Turning Centers excel at shaping rotating workpieces. They are ideally suited for producing cylindrical components such as shafts. Their ability to complete parts in one go boosts efficiency and accuracy.

Compact CNC Lathes

Compact CNC Lathes offer significant advantages for businesses with limited space or budget. These machines are more affordable initially. They also have lower operational costs. This is due to reduced power consumption. They also require less specialized tooling. Their space-saving design is a major benefit. Benchtop metal lathes fit easily on workbenches or small stands. This design is perfect for workshops with limited room. Businesses can maximize floor space. They can increase production capacity within the same footprint. This optimizes workflow and enhances scalability. These machines are also energy-efficient. They lead to lower power consumption. They reduce cooling and ventilation costs. This offers overall sustainability advantages.

Multi-Tasking Lathes

Multi-tasking lathes represent a pinnacle of modern machining technology. They empower small businesses to achieve remarkable efficiency and precision. These innovative machines combine multiple machining functions into one integrated unit. This capability transforms the production process. It allows manufacturers to complete complex parts in a single setup. This significantly improves efficiency and dramatically reduces setup times. Businesses can then produce more parts faster.

These versatile machines handle diverse materials with ease. They process everything from robust steel to lightweight aluminum. This broad material compatibility makes them invaluable for small batch production. Manufacturers often work with a variety of materials for different projects. Multi-tasking lathes streamline operations in mechanical engineering. They ensure consistent quality across various components. This integration of functions means fewer machine transfers. It also reduces the potential for errors.

The power of a multi-tasking lathe lies in its ability to perform turning, milling, drilling, and even grinding operations. All these tasks happen on a single platform. This capability enhances precision in tasks that demand tight tolerances. It also allows for the creation of highly complex geometries. Businesses can produce intricate parts that once required multiple machines and setups. This consolidation saves valuable floor space. It also reduces labor costs. Investing in a multi-tasking lathe unlocks new possibilities for small batch manufacturers. It allows them to take on more challenging projects. It also helps them deliver superior quality products to their customers. This strategic choice propels businesses toward greater success and innovation.

Optimizing Small Batch CNC Turning Processes

Achieving success in small batch production requires more than just a powerful machine. It demands smart strategies to optimize every step of the process. Businesses can unlock greater efficiency and profitability by focusing on material choices, tooling approaches, and long-term cost management.

Material Compatibility and Tolerances

Selecting the right material and setting appropriate tolerances are crucial for efficient small batch CNC turning. Different materials behave uniquely during machining. Understanding these characteristics helps you choose the best cutting parameters. For instance, aluminum machines easily, while titanium requires more robust tools and slower speeds. Always match the material to the part’s functional requirements. Similarly, apply tight tolerances only when absolutely necessary. Overly tight tolerances increase machining time, tool wear, and inspection costs. They also lead to higher scrap rates. Looser tolerances, where acceptable, save significant time and money.

Cost-Effectiveness Without Custom Tooling

Smart design choices dramatically reduce costs in small batch production. You can minimize tooling expenses by simplifying part designs. Avoid complex geometries and intricate features. Instead, use straight edges, flat surfaces, and symmetrical designs. Design parts that require minimal repositioning. This reduces the need for specialized cutting tools or custom jigs and fixtures. Selecting materials with good machinability, like aluminum or brass, also helps. These materials allow faster processing and less tool wear. This directly lowers production costs. Always optimize your design for manufacturing (DFM). Use dimensions and radii that align with standard cutting tools. This reduces setup times and tooling costs.

Long-Term Cost Considerations for a CNC Turning Machine

The initial purchase price of a machine is only one part of the financial picture. Long-term costs significantly impact your overall profitability. Regular maintenance is essential. This includes lubrication, calibration, and software updates. Neglecting these tasks can lead to expensive repairs, such as a spindle replacement. Such repairs can cost tens of thousands of dollars. Downtime during repairs also means lost production, which quickly adds up.

Energy consumption is another vital factor. A typical machine can consume substantial power per hour. This leads to thousands of dollars in electricity bills annually, especially with multiple shifts. Inefficient designs, both in the machine and the parts it produces, can increase energy usage. Always consider these ongoing expenses. They ensure your investment remains profitable for years to come.

Top CNC Turning Machine Recommendations for Small Batch Production in 2025

Choosing the right equipment can transform a small batch production facility. The market offers a diverse range of machines, each designed to empower businesses with specific capabilities. Discovering the perfect fit for your operations can unlock new levels of efficiency and precision.

Entry-Level and Budget-Friendly CNC Turning Machines

Starting a new venture or expanding an existing small shop requires smart investments. Entry-level machines provide a powerful foundation without overwhelming the budget. They offer reliability and precision, allowing businesses to produce quality parts consistently.

The Haas ST-10 stands out as a top entry-level CNC lathe. It offers exceptional value for startups and small batch production. This machine provides robust performance for its price point. Its cost typically ranges between $65,000 and $80,000. This makes it an accessible option for businesses seeking to establish their turning capabilities. Investing in such a machine allows shops to confidently take on a variety of projects. It builds a strong reputation for quality and efficiency.

Mid-Range and Versatile CNC Turning Solutions

Many job shops thrive on versatility. They need machines capable of handling a wide array of projects. Mid-range solutions offer a balance of power, precision, and adaptability. They empower businesses to meet diverse client demands.

Machines like the Haas VF-2/VF-3 and ST-20 provide outstanding coverage for job shops. These versatile solutions efficiently handle 85–90% of typical job shop work. This capability allows shops to confidently bid on a wide range of opportunities. This versatility proves particularly beneficial when clients have diverse needs. Part volumes vary, new parts are frequently quoted, or floor space is limited. These machines maximize the utility of each piece of equipment.

These versatile machines offer impressive performance metrics:

- Speed and efficiency: They achieve high material removal rates for cylindrical parts through continuous cutting.

- Superior surface finish: Consistent tool-to-work contact results in excellent finishes. This often eliminates the need for secondary operations.

- Cost-effectiveness: They deliver lower per-part costs at medium to high volumes. They also feature shorter setup and cycle times.

- Material utilization: These machines minimize waste by effectively using round bar stock.

- Excellent concentricity: Features machined in a single setup maintain perfect concentricity. This proves crucial for rotating assemblies.

Recent innovations in automation further enhance these machines:

- IoT and AI integration: Real-time machine monitoring, predictive maintenance, and on-the-fly adjustments reduce downtime and ensure consistent output.

- Hybrid mill-turn centers: These combine turning and milling in one setup for complex parts. This eliminates multiple processes.

- Smart tooling and wear detection: Built-in sensors and AI track tool wear. This allows for timely tool swaps to maintain quality and extend tool life.

- Automation upgrades: Faster bar feeders and robotic arms enable continuous, minimally supervised operation.

These advancements transform mid-range machines into highly productive assets. They allow businesses to achieve greater output with less manual intervention.

High-Precision and Complex Part Specialists

For businesses tackling the most intricate and demanding projects, specialized machines offer unparalleled precision. These solutions cater to industries requiring extremely tight tolerances and complex geometries. They empower manufacturers to create parts previously considered impossible.

Swiss-type lathes, for instance, excel at producing small, intricate components with exceptional accuracy. Their unique design minimizes deflection, ensuring superior surface finishes and dimensional stability. Multi-axis turn-mill centers also fall into this category. They integrate advanced milling and drilling capabilities directly into the turning process. This allows for complete part production in a single setup. Such machines are indispensable for aerospace, medical device manufacturing, and defense industries. These sectors demand flawless execution and the ability to work with exotic materials. Investing in these high-precision specialists opens doors to lucrative, high-value contracts. It positions a business at the forefront of manufacturing innovation.

Making Your Final Decision: A Checklist for Your CNC Turning Machine

Choosing the perfect machine for your workshop is a pivotal moment. It shapes your future success and production capabilities. You can make a confident and informed decision with a clear, comprehensive checklist. This tool guides you through every essential consideration. It ensures your investment truly empowers your small batch production. Embrace this structured approach to unlock your full potential.

Here is a powerful checklist to guide your selection process:

- Type of Machine: Consider horizontal or vertical lathes. Think about single or multi-turret machines for productivity. Decide between two-axis or multi-axis for part complexity.

- Workpiece Size and Weight: Ensure the machine handles your parts. Check its maximum turning diameter, length, chuck size, and weight capacity.

- Spindle Specifications: Evaluate spindle speed for efficient machining. Look at spindle power for handling materials. Check spindle bore size for material pass-through.

- Tooling Capacity: Assess the number of tool stations. This minimizes downtime. Ensure the turret holds all necessary tool types and sizes.

- Control System: Seek a user-friendly interface. Check compatibility with your existing software. Look for advanced programming features like CAD/CAM integration.

- Accuracy and Precision: Verify repeatability for consistent tight tolerances. Check resolution for the desired surface finish and detail.

- Construction and Durability: Prioritize heavy-duty build quality for longevity. Ensure effective vibration dampening for accuracy.

- Support and Maintenance: Consider manufacturer support and training. Check spare parts availability. Look for ease of maintenance to lower total ownership costs.

- Cost and Budget: Account for the initial purchase price. Also, consider ongoing operating costs. These include power, maintenance, and tooling.

- Additional Features: Evaluate automation options, like robotic loaders. Look for efficient coolant systems and essential safety features.

This checklist empowers you to select a machine that perfectly aligns with your vision. It helps you build a foundation for remarkable achievements.

The best CNC turning machine for small batch production in 2025 is ultimately the one that aligns perfectly with a business’s specific operational demands, part characteristics, and budget. Businesses empower themselves by making this strategic choice. They optimize their production, elevate efficiency, and unlock new possibilities. This thoughtful investment ensures lasting success and drives significant growth.

FAQ

What defines small batch production for CNC turning?

Small batch production typically involves 1 to 1,000 units. It focuses on flexibility and variety. This approach allows businesses to create prototypes or specialized components efficiently. It empowers manufacturers to meet diverse client needs.

How do multi-tasking lathes benefit small businesses?

Multi-tasking lathes combine turning, milling, and drilling in one machine. This integration completes complex parts in a single setup. Businesses reduce setup times and improve efficiency. They achieve higher precision and expand their capabilities.

Why is a sub-spindle important for small batch CNC turning?

A sub-spindle allows machining on both ends of a part without re-chucking. This capability significantly reduces cycle times. It also improves accuracy by eliminating repositioning errors. Manufacturers achieve complete part production in one setup.

What role does automation play in small batch production?

Automation features like bar feeders and part catchers enable continuous operation. They reduce manual labor and improve consistency. Businesses achieve “lights-out” manufacturing. This boosts productivity and frees operators for other tasks.

Post time: Dec-03-2025