Achieving top-tier accuracy in a CNC Machining Center hinges on consistent cnc machining center maintenance. Proactive routines directly prevent costly breakdowns and significantly extend the machine’s operational lifespan. Understanding how to maintain a CNC Machining Center is crucial for peak performance.

Predictive maintenance for CNC machines can decrease downtime by as much as 50%. This is achieved by utilizing sensors and data analytics to identify potential issues before they lead to failures, enabling maintenance to be scheduled during pre-planned downtime periods.

This article explores actionable strategies for cnc machining center precision maintenance, showing how to improve CNC Machining Center accuracy and even how to check geometric accuracy of a CNC machine. These routines are essential for long-term reliability and precision.

Key Takeaways

- Regular maintenance keeps your CNC machine accurate. It prevents breakdowns and makes the machine last longer.

- Daily checks like cleaning the spindle and checking coolant levels stop small problems from becoming big ones.

- Weekly and monthly tasks, such as inspecting way covers and lubricating parts, help your machine run smoothly over time.

- Deeper checks done every few months or once a year find hidden issues. These include checking ball screws and machine leveling.

- New methods like predictive maintenance and good environmental control help machines stay very accurate. Skilled operators are also very important.

Daily Checks for Immediate CNC Machining Center Precision

Maintaining a Cnc Machining Center at its peak requires daily attention. These quick checks prevent small issues from becoming big problems, ensuring your machine stays accurate.

Spindle and Tool Holder Cleaning

Cleanliness directly impacts precision. Operators should clean the spindle taper and tool holders every day. This removes chips, dust, and coolant residue that can affect tool seating and runout. For effective cleaning, consider these options:

- Nu-Tool Cleaning Protectant & Rust/Debris Remover: Use the protectant each time you change a CNC bit. The rust/debris remover is for rust or heavy debris. Weekly cleaning is a minimum to extend tool life.

- Alcohol: Use alcohol after brushing to ensure no chemical residues remain.

- Mild cleaning solution or specialized tool holder cleaner: These are good for weekly cleanings to remove residue. Avoid harsh chemicals; they can damage the tool holder material.

Coolant Level and Concentration Monitoring

Coolant is vital for cooling and lubrication. Daily checks of coolant levels prevent overheating and tool wear. Also, monitor the coolant concentration. A refractometer helps measure this. Different materials need different coolant concentrations. For example, aluminum often uses mineral oil or soluble oil with 96% water, while alloy steels might use 90% mineral oil with 10% lard oil.

Tip: If coolant concentration is too low, you might see microbial growth, faster tool wear, and corrosion. Too much concentration can cause foaming, toxicity, and poor lubrication.

Machine Bed and Workholding Inspection

Inspect the machine bed and workholding fixtures daily. Look for any signs of wear or damage. Check the machine bed and table for scratches, dents, or gouges. Ensure the surface is clean and free from debris. Also, inspect the ways and guide rails for wear or contamination. They should feel smooth and move without resistance.

Workholding fixtures also need attention. Constant use wears them down. Even small slippage can lead to inaccurate parts. Look for cracks, defects, or any visible surface damage like scoring or pitting. Promptly replacing worn parts keeps your machining consistent and accurate.

Lubrication System Verification

A well-oiled machine runs smoothly, and this holds true for any advanced manufacturing equipment. The lubrication system is the lifeblood of your machinery, preventing friction and wear. Operators must verify its proper function daily to ensure the machine’s longevity and maintain precision.

They should start by checking fluid levels. This includes the central lubrication reservoir, the hydraulic tank, and the coolant tank. Always top these off with the manufacturer-recommended fluids. This simple step prevents critical components from running dry.

Next, visually inspect the lubrication lines. Look for any kinks, leaks, or damage. Such issues can obstruct oil flow, leaving parts unlubricated. A damaged line means a dry component, which quickly leads to wear and tear.

Finally, confirm oil delivery to the critical points. During pump cycles, observe the linear guide blocks and ball screw nuts. You should see fresh oil reaching these areas. If any spots appear dry, address them immediately. Dry spots indicate a blockage or a faulty delivery mechanism, which can severely impact accuracy and lead to costly repairs. A properly functioning lubrication system reduces friction, minimizes heat, and extends the life of moving parts. This directly translates to consistent, high-quality output from your machine.

Weekly and Monthly Routines for Sustained CNC Machining Center Accuracy

Beyond daily checks, regular weekly and monthly maintenance routines keep your machine running smoothly and accurately. These tasks prevent wear and tear, ensuring consistent performance over time.

Way Cover and Wiper Inspection

Way covers protect the delicate linear guides from chips, coolant, and debris. Operators should inspect them weekly. Look for tears, cracks, or signs of damage. Damaged covers allow contaminants to reach the guides, causing premature wear and accuracy issues. Also, check the wipers on the way covers. Worn wipers cannot effectively clean the guides, leaving them exposed. Replace any damaged covers or wipers promptly to maintain protection.

Axis Lubrication and Greasing

Proper lubrication is crucial for the smooth movement and accuracy of machine axes. Weekly or monthly, depending on machine usage, technicians should check and replenish lubricants. For recirculating guideways, EP Lithium Grease is an excellent choice. It offers superior water washout resistance, which is very helpful in environments with moisture or coolant spray. Four-axis machines benefit from Synthetic Slide Oil, which provides extended drain intervals. This reduces maintenance frequency and fluid consumption.

Many machines also use air-oil mist lubricants. This system efficiently delivers a precise mixture of air and oil to machine parts. It reduces overall oil consumption while ensuring adequate lubrication. Remember, a variety of lubricants are essential for different parts, including hydraulic oils, spindle oils, greases, and cutting coolants. Each plays a vital role in machine health.

Coolant System Filtration and Sump Cleaning

The coolant system needs regular attention to maintain its effectiveness and prevent issues. Monthly, or as needed, operators should clean the coolant sump and check the filtration system. A dirty sump can harbor bacteria, leading to foul odors and skin irritation. It also reduces coolant effectiveness. Clean filters ensure the coolant remains free of chips and debris, protecting tools and workpieces. Some experts suggest changing CNC coolant every 4 to 6 months. However, with proper maintenance, coolant can last for at least a year or even two before needing a full change. Regular cleaning and filtration extend coolant life and maintain machining quality.

Air Pressure and Filtration Checks

Proper air pressure and clean air are vital for a Cnc Machining Center. They power many critical components, including tool changers and pneumatic clamps. Operators should check air pressure and filtration systems weekly. A machine needs a minimum air pressure of 110 PSI to operate. A dedicated compressor should also provide at least 10 CFM for optimal performance.

Clean air is just as important. Air must be chilled and filtered to remove moisture and tiny particles. A dew point of 37.4 degrees Fahrenheit (3 degrees Celsius) ensures effective air drying. Filtration systems should remove particles smaller than one micron. This prevents damage to sensitive pneumatic components.

Sometimes, a CNC router’s low cut-off pressure sits too close to the line pressure. This can cause the machine to stop during a tool change if the regulator needle briefly drops below 100 PSI. To fix this, some shops install a booster regulator. This small, cost-effective device boosts pressure without extra power. It ensures the system operates reliably, even with borderline plant pressure. Another solution involves building an air amplifier. This setup boosts pressure to 150 PSI, then regulates it down to 120 PSI for the machine. This helps when the plant supply is only 100 PSI but the machine experiences pressure drops during tool changes or rapid Z-axis movements.

Tool Changer Mechanism Inspection

The tool changer is a complex part of the machine. It needs regular inspection to ensure smooth and accurate tool changes. Operators should inspect the tool changer mechanism weekly. They look for wear on key components like gripper pads, magazine indexing, and sensors. Worn gripper pads can cause tools to drop or not seat correctly. This leads to inaccurate machining or even damage.

Weekly checks should include verifying the ATC (Automatic Tool Changer) magazine indexing and the condition of the gripper. Every quarter, technicians should perform a full tool-change cycle. This verifies the ATC’s overall reliability. If the machine misses a tool change, it often points to issues with the gripper pads, sensors, or magazine indexing. Replacing worn pads quickly prevents further problems and maintains machining accuracy.

Quarterly and Annual Deep Dives for CNC Machining Center Reliability

Beyond daily and weekly checks, a Cnc Machining Center needs deeper inspections. These quarterly and annual routines catch hidden issues. They ensure long-term reliability and maintain peak accuracy.

Ball Screw and Linear Guide Inspection

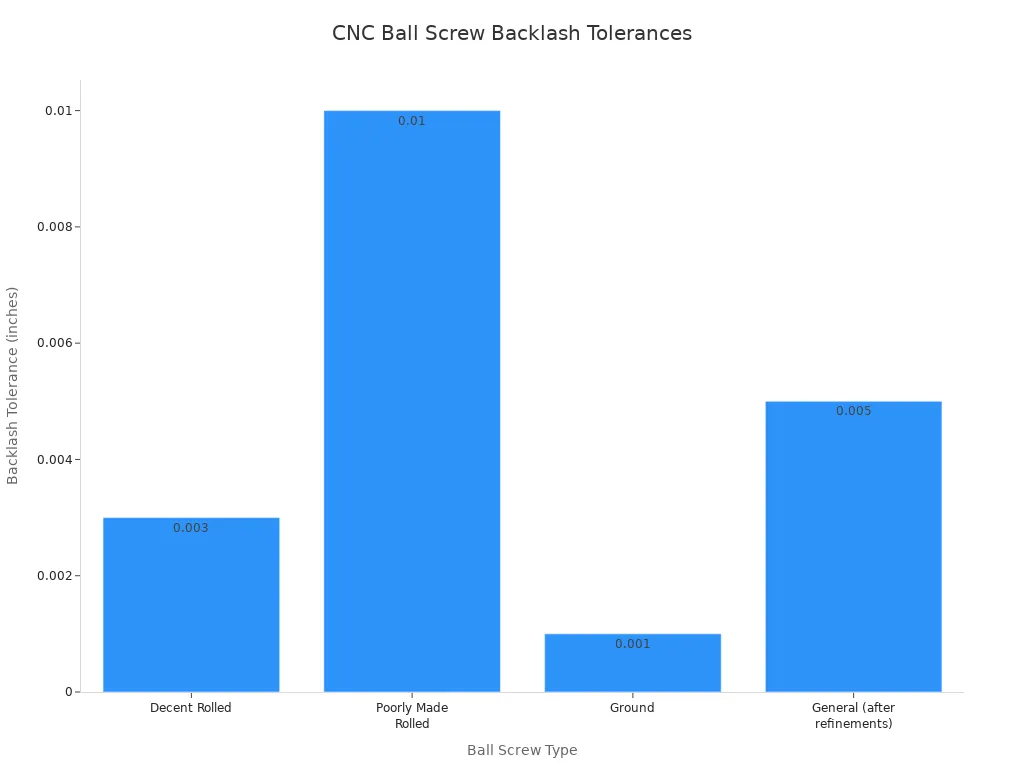

Ball screws and linear guides are critical for precise movement. Technicians should inspect them quarterly for wear, damage, and proper lubrication. Backlash in ball screws can significantly reduce accuracy. They measure backlash to ensure it stays within acceptable limits.

| Ball Screw Type | Backlash Tolerance (inches) |

|---|---|

| Decent Rolled | 0.003 |

| Poorly Made Rolled | 0.010 |

| Ground | 0.001 or less |

| General (after refinements) | Under 0.005 |

Many ball screws come preloaded. Control systems use backlash parameters, usually from 0.001 to 0.005 inches, to electronically compensate for backlash when the screw reverses direction. However, backlash can vary along the screw’s travel. It often feels tighter at the ends because of less wear. If the backlash compensation value goes over 0.004 inches, it often signals a need to check or replace bearings or re-tension the ball nut.

Machine Leveling and Alignment Verification

Proper leveling and alignment are fundamental for machine accuracy. Annually, or after any significant machine movement, technicians must verify these settings. They use precision tools to ensure the machine’s base is perfectly level and all axes are perpendicular.

Here are key steps for verification:

- Level the base: Use a three-plane laser or machinist’s level. Place it on bridge and base rails at multiple fixed points. This ensures alignment and creates a level plane along linear rails.

- Square the bridge (X-to-Y): Adjust the fixed X-axis in relation to Y. This creates a perpendicular axis.

- Square the backbone front-to-back (Z-to-Y): Shim the entire backbone carriage between the bridge rails. Use a laser or granite blocks to align to the Y plane. This makes the Z-axis perpendicular to Y.

- Square the backbone side-to-side (Z-to-X): Repeat the previous step. Indicate off the side. Shift the backbone by leaving one bolt tight as a pivot point. Use an adjustment wedge with an indicator until Z-to-X is square.

Electrical Cabinet and Component Cleaning

Dust and debris inside electrical cabinets can cause overheating and electrical issues. Annually, technicians should clean these cabinets thoroughly.

- Turn off all power.

- Take pictures of the setup.

- Use dry compressed air to blow out loose dust.

- Replace filters and clean fans.

- A good vacuum cleaner with a long bristle brush attachment also works well. Some advise against compressed air as it can move debris into harmful areas.

- Routinely clean cabinets using regulated compressed air (e.g., 60 psi) with a desiccant filter. Early cleaning prevents fan failures and extends equipment life.

Dust buildup insulates components. This shortens their lifespan and can cause electrical problems. Blowing off control boards with compressed air (around 30 psi) often resolves many issues by removing conductive dust.

Hydraulic and Pneumatic System Checks

Hydraulic and pneumatic systems are the muscles of a Cnc Machining Center. They power many functions, from clamping workpieces to operating tool changers. Regular checks ensure these systems deliver consistent force and movement. Technicians should perform these checks quarterly. They look for common indicators of issues. For example, the system might not generate enough pressure. This shows when actuators or cylinders fail to operate correctly. Weak or inconsistent airflow, or tools operating at reduced power, also point to pressure problems.

Operators also watch for actuators moving abnormally slow. This can happen due to excessive air choke. An incorrectly adjusted flow control valve, a plugged air silencer, or an air leak can cause this. A squeezed tube, a plugged filter, or a damaged cylinder or seal also contribute. Low pressure can also slow actuators. This might come from a damaged or incorrectly adjusted pressure regulator valve. Other causes include a plugged filter, system leaks, or a dirty or failed directional valve. Sometimes, a continuous air leak at the regulator’s small vent hole indicates a leaky main bonnet or diaphragm. Beyond slow movement, the system might not operate at all. It could run too quickly or unpredictably. The oil might foam or overheat. Control valves can bind, drop loads, or leak. Cylinders might leak, knock, or lower incorrectly. Addressing these signs quickly prevents bigger problems and maintains machine reliability.

Spindle Taper Runout Measurement

The spindle is the heart of any machining operation. Its accuracy directly affects part quality. Measuring spindle taper runout is a crucial annual task. This check ensures the spindle holds tools precisely. A runout of .0001″-.0002″ in the taper is generally acceptable. Most new machine installations typically show a taper runout between .00005″ and .0001″. Surprisingly, some spindles with a runout of .0004″ have operated without issues for extended periods.

However, even small improvements in runout can significantly impact performance. For instance, improving Total Indicated Runout (TIR) from 0.0006″ to 0.00008″ resulted in a threefold increase in tool life for solid carbide drills. This shows the direct link between spindle precision and operational efficiency. A survey indicated that the average tool user considered 0.0005″ TIR to be acceptable. Regular measurement helps identify wear or damage early. This allows for timely repairs or adjustments. Maintaining optimal spindle taper runout ensures consistent part accuracy and extends tool life.

Advanced Strategies for Optimal CNC Machining Center Accuracy in 2025

As we look to 2025, new strategies will further boost the accuracy of your Cnc Machining Center. These methods go beyond traditional maintenance. They use technology and skilled people to keep machines running perfectly.

Predictive Maintenance Integration

Predictive maintenance is a game-changer. It helps you fix problems before they happen. This approach uses smart tools to watch your machines. For example, IoT sensors collect real-time data on temperature, vibration, and energy use. Artificial intelligence algorithms then process this data. They find unusual patterns and predict possible failures. Remote monitoring systems let you check machine status from anywhere. This helps you make smart decisions. Digital twins also create virtual models of your machines. They simulate behavior and foresee issues before they affect physical equipment. Other tools like vibration monitoring, thermography, and ultrasonics also help detect problems early.

Environmental Control Optimization

The environment around your machine greatly affects its accuracy. Optimal temperature and humidity levels are crucial. The best temperature range for a CNC machining center is between 15°C and 25°C. This prevents materials from expanding or shrinking, which can cause errors. Humidity also matters. Keep it between 40% and 60% relative humidity (RH). This range stops corrosion, keeps materials stable, and reduces electrical problems. Studies show that an optimal humidity level around 53.6582% RH can lead to the best production value. A well-controlled environment improves precision, extends machine life, and lowers scrap rates.

Operator Training and Skill Enhancement

Even with advanced technology, skilled operators remain vital. They need strong digital control skills. This includes knowing CNC programming and software interfaces. Operators should be good with controllers like FANUC and Siemens. They also need to master CAD/CAM platforms for designing and simulating operations. Practical experience is also key. Operators must install tools correctly, verify offsets, and ensure low runout. They also need to calculate speeds and feed rates. Disciplined inspection is another critical skill. Operators use tools like micrometers and CMMs for precise measurements. They also understand Geometric Dimensioning and Tolerancing (GD&T). Training programs focus on CNC troubleshooting, handling machine malfunctions, and proper tool use.

Data-Driven Maintenance Scheduling

Data-driven maintenance scheduling transforms how facilities manage their equipment. This approach uses smart tools to predict potential problems before they cause breakdowns. It moves away from fixed schedules. Instead, it relies on actual machine conditions.

Teams collect real-time machine data. This data is fundamental for predictive maintenance. It allows for proactive intervention. They monitor tool wear patterns, spindle load anomalies, and axis irregularities. These details help identify impending failures. They also optimize tool replacement times. Operators track alarm trends and irregular cycle times. This indicates stress on machinery. They also watch for overheating issues and usage spikes. These signals potential component failures. Comprehensive alarm and downtime tracking helps uncover recurring issues. It links them to maintenance needs. Historical trend analysis detects subtle performance shifts over time. This prevents unexpected breakdowns.

Implementing data-driven maintenance scheduling involves several best practices. Facilities use historical data and trends to make informed decisions. This optimizes future schedules. It also anticipates peak maintenance periods. They prioritize work based on criticality and risk. This allocates resources to high-impact tasks first. They ensure accurate resource allocation and availability. This accounts for technician availability, necessary spare parts, and specialized tools. Many facilities start with high-value or critical machines. This demonstrates quick successes. They also involve maintenance and operations teams early. This fosters collaboration. It ensures the system meets daily needs. Regular reviews and updates of predictive models continuously improve detection accuracy.

A comprehensive maintenance schedule plays an indispensable role in maintaining a Cnc Machining Center’s accuracy. Neglecting these routines directly impacts product quality, leading to defective outputs and increased waste. This also damages brand reputation. Consistent precision and reliability give businesses a competitive edge. Without proper upkeep, expensive machinery experiences a reduced lifespan, leading to higher replacement costs over time. Implementing these routines ensures a future-proof operation, avoiding escalated repair costs and significant revenue loss from extended downtime.

FAQ

How often should one perform maintenance on a CNC machine?

Maintenance routines vary. Daily checks ensure immediate precision. Weekly and monthly tasks sustain accuracy. Quarterly and annual deep dives guarantee long-term reliability. Following a comprehensive schedule keeps your machine performing its best.

What happens if you neglect CNC machine maintenance?

Neglecting maintenance leads to several problems. Accuracy decreases, causing defective parts and increased waste. The machine’s lifespan shortens, increasing replacement costs. You also face higher repair expenses and significant revenue loss from unexpected downtime.

Can environmental factors affect CNC accuracy?

Yes, environmental factors significantly impact accuracy. Optimal temperature (15°C to 25°C) prevents material expansion or shrinkage. Humidity (40% to 60% RH) reduces corrosion and electrical issues. Controlling the environment improves precision and extends machine life.

What is predictive maintenance for CNC machines?

Predictive maintenance uses smart tools and data. Sensors collect real-time data on machine conditions. AI algorithms analyze this data to predict potential failures before they occur. This allows you to schedule maintenance proactively, reducing downtime and costs.

Post time: Dec-09-2025