I. What is the CNC Machining Center

The CNC Machining Center is a highly automated machine tool controlled by computer numerical control, which can complete multiple processing operations with just one time clamping. It concentrates functions such as milling, boring, drilling, and turning on one device, giving it a variety of process means.

The main components of a CNC Machining Center include the spindle, ball screw, guide rails, tool magazine, and CNC control system.

The spindle is the core component of a CNC Machining Center, responsible for transmitting speed and torque to the turning tool to perform the turning operation. Spindles can be either electric spindles or mechanical spindles, and mechanical spindles can be further categorized as belt-type driven or direct drive spindles. The ability of the spindle to maintain stability at high speeds ensures high-precision turning and a consistent surface finish.

The ball screw has less friction because of the rolling contact. The ball screw is sensitive and operates accurately, allowing for precise control of minute movements. It features high precision, high efficiency, long lifespan, high rigidity, and low noise.

The guide rail is a device that bears, fixes, and guides moving equipment and reduces friction. It not only needs to be able to withstand high pressure, but also must have excellent flexibility.

Automatic tool changing enables automated tool handling and replacement, accommodating complex, multi-step continuous machining.

The CNC control system is the brain of the lathe, which realizes high-precision machining of complex parts through programmed instructions.

II. What Types of CNC Machining Centers are There?

Based on their structure, they can be categorized as CNC vertical Machining Center, CNC Horizontal Machining Center, and CNC Gantry Machining Center.

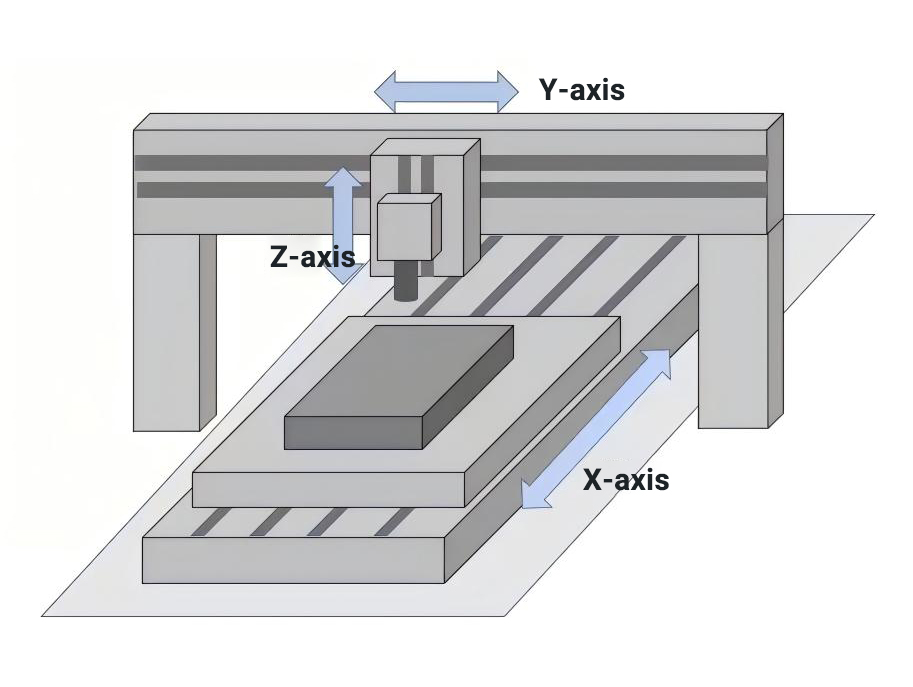

CNC Vertical Machining Center: The spindle is perpendicular to the worktable. The worktable, which holds the workpiece, generally moves horizontally (X and Y axes), while the tool moves vertically (Z axis) for machining. Its compact structure and minimal installation footprint make it suitable for machining plates, discs, and complex parts such as molds and small housings. Its advantage is that it can achieve high-precision machining even on heavy and long workpieces. Sometimes, turning fluid is needed to wash away the chips and dust produced during the turning process in order to complete the turning.

CNC Horizontal Machining Center: The spindle is mounted horizontally. In addition to the three X, Y, and Z axes, a horizontal machining center can also control the four rotational axes of the worktable. This structure allows for easier loading and unloading of workpieces and provides ample space for chip removal. It is suitable for box-type parts, car cylinder blocks, and aircraft engine blades.

CNC Gantry Machining Center: A CNC gantry machining center secures the worktable and allows the machine head to move in the X, Y, and Z directions, enabling machining of large and heavy workpieces. Its characteristic feature is that the spindle support acts like a gantry, spanning above the worktable. Compared to other types, it is large in size and therefore is mostly used for processing large objects.

Based on the number of axes, they can be categorized as 3-axis, 4-axis, or 5-axis CNC Machining Centers.

3-axis CNC Machining Center: The most traditional type, consisting of three linear axes (X, Y, and Z). Suitable for routine operations, it performs well in processing flat surfaces and simple three-dimensional parts, but is limited in handling complex curved surfaces.

4-axis CNC Machining Center: In addition to the three-axis model, a rotary axis (either A or B) is added. The fourth axis is an electric dividing head that can rotate 360 degrees, installed on the mobile platform. This allows for automated indexing for bevel drilling, bevel milling, and other tasks. The accuracy will not be lost due to the second clamping process, thus enabling the processing of complex geometric shapes.

5-axis CNC Machining Center: In addition to the existing three-axis model, two rotary axes (A and B or C) are added. Tools and workpieces that can be rotated and tilted enable more complex three-dimensional processing. This allows for continuous machining of multiple surfaces and complex curved surfaces without re-clamping the workpiece. However, controlling multiple axes simultaneously requires more advanced programming skills.

III. What are the Characteristics of A CNC Machining Center?

High-Precision Machining. CNC Machines Center automatically controls the position of tools and workpieces, resulting in smaller deviations in finished parts compared to manual operations. Compared to the Numerical Control Machine Tool, this also reduces mistakes caused by multiple manual installations.

Reduced Costs And Improved Efficiency. Changing tools often requires physical and time costs, while CNC machining centers can automatically change tools. The automatic tool changer allows the spindle to be changed in a single setup, enabling multiple machining functions.

Enhanced Safety. The tools and cutters used in the machine tools are very heavy and sharp, requiring careful handling. Therefore, tools and cutters are automatically changed, significantly reducing operator effort. This reduces manual handling accidents and protects the safety of the operator.

IV. Conclusion

CNC Machining Center is considered the most precise form of manufacturing, as it allows for precise control of material tolerances, surface finish, and part quality. It also offers greater speed and efficiency, as well as lower production costs, than traditional machining methods. With a wide range of applications, CNC Machining Center has become an essential tool across many industries, and its use is rapidly growing. It is also becoming increasingly popular due to its ability to produce complex parts quickly and accurately.

OTURN has 16 years of experience in overseas markets. We offer CNC machine tools produced by top Chinese machine tool manufacturers, along with one-stop operation services.

Post time: Sep-26-2025