A CNC horizontal machining center is a machining center where the spindle and worktable are parallel, and multi-axis simultaneous and automatic tool changing are controlled by a CNC system. It is commonly used for multi-faceted, high-efficiency, and high-precision milling of complex parts.

Contents:

· Basic Concepts and Working Principles of CNC Horizontal Machining Centers

· Core Differences from Traditional Horizontal Milling Machines and Vertical Machining Centers

· Core Structural Components of CNC Horizontal Machining Centers

· Main Machining Characteristics and Advantages of CNC Horizontal Machining Centers

· Application Areas of CNC Horizontal Machining Centers

· Several Points to Consider When Choosing a CNC Horizontal Machining Center

· Recommended Products

Basic Concepts and Working Principles of CNC Horizontal Machining Centers

A CNC horizontal machining center, simply put, is a high-end machining center where the spindle and worktable are arranged parallel, and multi-axis simultaneous and automatic tool changing are controlled by a CNC system. It is mainly used to solve the needs of multi-faceted, high-efficiency, and high-precision milling of complex parts. In practical operation, the operator clamps the workpiece onto the worktable or pallet in one go. The CNC system automatically selects the cutting tool, adjusts the spindle speed and feed rate according to pre-programmed instructions, causing the tool on the horizontal spindle to move along the coordinate axes, completing multi-process cutting of different surfaces one cut after another. The chips fall naturally under gravity and are collected and removed by the chip removal system, thus achieving stable and highly efficient continuous machining.

Key Difference from Traditional Horizontal Milling Machines and Vertical Machining Centers

| Item | CNC Horizontal Machining Center | Traditional Horizontal Milling Machine | CNC Vertical Machining Center |

| Spindle Direction | The spindle is parallel to the worktable and arranged horizontally, making it suitable for multi-faceted and side cutting. | The main shaft is also arranged horizontally. | The spindle is perpendicular to the worktable, making it suitable for machining planes and cavities. |

| Control and Automation | It features CNC control, multi-axis simultaneous, tool magazine and automatic tool change, and can be connected to pallets, turntables, etc. to achieve high automation. | Most are manual or simple motorized feed, without tool magazines or automatic tool changers, and mainly rely on operators. | It features CNC control, multi-axis simultaneous, and is typically equipped with a tool magazine and automatic tool changer, resulting in a high degree of automation. |

| Multi-Faceted Processing Capability | Complex parts can be machined on multiple sides in a single setup, making it suitable for box-type parts. | Multi-sided processing requires manual flipping multiple times, resulting in low efficiency and poor precision consistency. | A turntable can be added to achieve some multi-sided processing, but overall it is mainly single-sided or two-sided. |

| Chip Removal And Cooling | The chips fall naturally under the influence of gravity, resulting in smooth chip removal and good tool life and surface quality. | The chip removal conditions are acceptable, but they mostly rely on manual labor and simple chip removal devices. | Chips tend to accumulate on the workpiece and worktable, requiring enhanced cooling and chip removal design. |

| Applicable Production Types | Suitable for medium to large batch production lines with high cycle time requirements and a desire for unmanned or minimally staffed operations. | Suitable for traditional workshops, small batches, or rough processing with low requirements. | Suitable for small to medium batch and multi-variety processing, it is a highly versatile CNC equipment. |

| Equipment Investment And Usage Threshold | The equipment price and supporting investment are relatively high, but the unit workpiece cost is low and the automation benefits are high. | The equipment investment is low, but the labor cost is high and the efficiency is limited. | With an investment and usage threshold between the two, it is the “entry-level” CNC machining center choice for many factories. |

In short, if you want high efficiency, multi-faceted processing and automation, you should give priority to CNC horizontal machining centers; if you want low investment and simple processing, you can use traditional horizontal milling machines; if you need versatility and flexibility, CNC vertical machining centers are often a more compromise option.

Core Structural Components of a CNC Horizontal Machining Center:

1. Horizontal Spindle Unit:

High-rigidity spindle, spindle motor, and bearing system, suitable for large depth of cut and high-load cutting.

2. Column and Transverse Moving Slide:

Supports the spindle box to achieve Y/Z direction movement, ensuring rigidity and positioning accuracy.

3. Worktable:

The core carrier for realizing “multi-faceted high-efficiency + automated continuous machining” directly determines the machine tool’s applicability and production cycle time.

4. X/Y/Z Axis and Drive System:

Achieves high-precision linear motion through ball screws and linear guides, driven by servo motors and with encoder feedback.

5. ATC:

Disc-type or chain-type tool magazine, supporting multiple tools, automatically completing tool changes, improving cycle time, and automation level.

6. CNC System and Electrical Control:

Responsible for interpolation calculations, axis control, spindle control, tool management, fault diagnosis, and communication with automated lines and robots.

7. Cooling, Lubrication and Chip Removal System:

High-pressure cooling, centralized lubrication, and chain/spiral chip conveyors ensure a continuous and stable processing environment.

Key Machining Features and Advantages of CNC Horizontal Machining Centers:

1. High-Efficiency Multi-Face Machining:

Multiple facets of workpieces, such as housings and shells, can be machined in a single setup, significantly reducing the number of setups and auxiliary time.

2. High Rigidity and High Precision:

The machine tool has a high structural rigidity, suitable for heavy cutting and high-precision machining of holes, planes, and datum surfaces.

3. Excellent Chip Removal and Tool Life:

Chips fall naturally, avoiding repeated chipping and accumulation, improving tool life and surface quality, especially suitable for heavy cutting scenarios involving steel and cast iron.

4. Automated Production:

Enables continuous machining for extended periods, reducing reliance on manual labor.

Application Areas of CNC Horizontal Machining Centers:

1. Automotive Industry:

Multi-faceted housing parts, such as engine blocks, cylinder heads, gearbox housings, differential housings, and steering knuckles, used to ensure assembly datum and batch stability.

2. Aerospace:

Landing gear components, fuselage structural parts, high-strength alloy brackets, and seat hole parts, requiring multi-faceted, high-precision, and repeatable machining capabilities.

3. Construction Machinery and Hydraulic Industry:

Hydraulic valve bodies, pump bodies, motor housings, and other multi-hole, multi-oil-circuit parts are improved in efficiency through multi-faceted machining and drilling/boring capabilities.

4. Molds and General Machinery:

Medium and large mold frames, jig base plates, and precision machinery housings are produced using a combination of high rigidity and efficient roughing and finishing processes.

Several points to consider when choosing a CNC horizontal machining center

When purchasing a CNC horizontal milling machine, the key is to comprehensively consider whether the stroke and pallet specifications, spindle power, tool magazine capacity, control system, and chip removal and cooling capabilities match your production rhythm and upgrade plans, based on the workpiece size and shape, machining cycle time, and automation requirements.

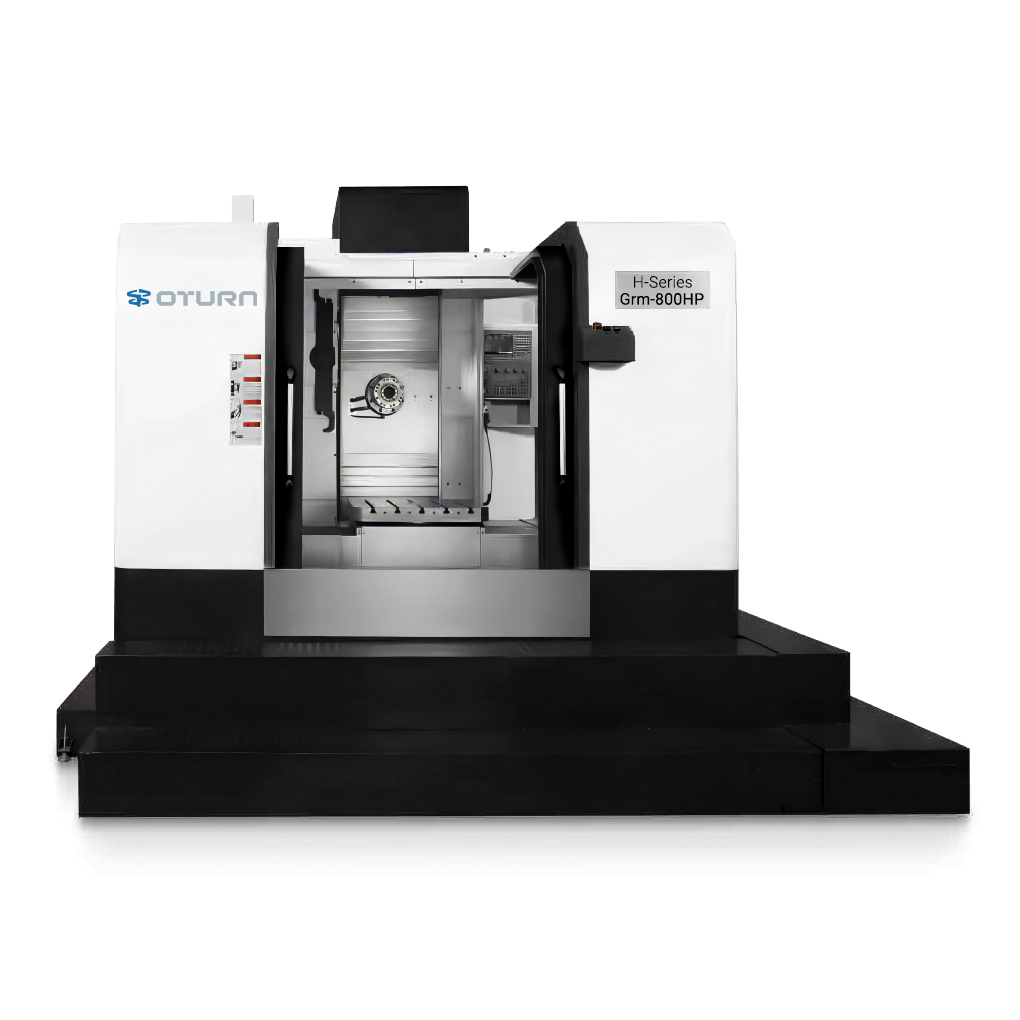

OTURN offers high-rigidity CNC horizontal machining centers. Our machine tools adopt a horizontal spindle + moving column structure, ensuring high-precision motion and heavy-duty cutting rigidity in the Y/Z directions; equipped with a high-efficiency rotary table and ATC, it enables multi-face machining in a single setup and automated continuous production, making it particularly suitable for high-volume applications of complex box-type parts such as automotive cylinder blocks and aerospace structural components.

Product Recommendation

The OTURN HT series CNC horizontal moving column machining center adopts a Meehanite casting + high-precision curved surface coupling indexing table (0.001° x 360), perfectly adapting to multi-face heavy-duty cutting of medium and large box-type parts. It supports dual-pallet APC and BT50 high-torque spindles, achieving efficient automated batch production.

The OTURN HP series CNC horizontal moving column machining center is designed for mold making and heavy cutting. It features a Meehanite casting + curved surface coupling indexing table (1°x360) to support precision machining of large-size housings on multiple sides. Equipped with a BT50 high-torque spindle and a 30-tool ATC, it perfectly matches the mass production needs of the automotive/aerospace industry.

Post time: Dec-23-2025