5-axis simultaneous CNC machining offers unparalleled precision, efficiency, and complexity in manufacturing. This advanced technology excels at producing intricate geometries, tight tolerances, and high material removal rates. The global 5-axis CNC machining centers market projects significant expansion, growing by $792.5 million from 2024 through 2028.

The global 5-Axis CNC Machining Service market shows substantial growth. This technology provides excellent CNC Machining Efficiency, enabling Complex Surface Machining. How does 5-axis machining improve surface finish? It achieves superior results with continuous tool contact. Can a horizontal 5-axis machine handle heavy workpieces? Yes, a Horizontal Machining Center often handles such tasks. Industries like aerospace, medical, automotive, mold and die, energy, defense, and tool and fixture manufacturing benefit most from 5-Axis CNC Machining.

Key Takeaways

- 5-axis CNC machining offers high precision. It creates complex parts efficiently. This technology helps many industries.

- Aerospace and medical industries use 5-axis CNC. It makes critical parts with great accuracy. This improves safety and performance.

- Automotive and mold industries benefit from 5-axis CNC. It speeds up production. It also makes better surface finishes.

- The energy and defense sectors rely on 5-axis CNC. It builds strong, reliable components. These parts work well in tough conditions.

- Tool and fixture makers use 5-axis CNC. It allows custom designs. It also improves part quality and reduces setup time.

Aerospace Industry: Precision and Complex Geometries with 5-Axis CNC Machining

Why 5-Axis CNC Machining is Crucial for Aerospace

The aerospace industry demands extreme precision and reliability. Manufacturers require tolerances measured in thousandths of an inch or microns. They need consistent and repeatable production of components for safety and reliability. Aerospace designs often feature complex geometries, including airfoil profiles, mounting features, and pocketed designs. These parts require accurate milling. Furthermore, components need tight surface and dimensional control, with roughness average (Ra) often less than 1.6 μm. 5-Axis CNC Machining provides the necessary capabilities to meet these stringent requirements.

Specific Aerospace Applications of 5-Axis CNC Machining

5-axis CNC machining manufactures many critical aerospace components. It produces vanes on aerospace blisks, which are integral to engine performance. The technology also creates parts for NASA’s Orion bulkhead and intricate fuselage sections. Landing gear components, known for their complex shapes and high strength requirements, also benefit from this advanced machining. This method excels at producing uniquely-shaped parts with complex geometries, essential for modern aircraft and spacecraft.

Key Benefits of 5-Axis CNC Machining in Aerospace

5-axis CNC machining offers significant advantages in aerospace manufacturing. It reduces the number of setups required for complex parts. What once took four operations on a 3-axis machine can now be completed in one. This leads to faster cycle times, less handling, simpler fixturing, and improved accuracy. The technology minimizes part repositioning between operations, which reduces cumulative tolerance stack-up. This improves overall part accuracy by minimizing setup transitions, which are opportunities for misalignment. Furthermore, 5-axis machining achieves a superior surface finish by maintaining optimal cutting angles. This reduces tool marks and produces smoother surfaces, often eliminating or reducing secondary finishing. Improved surface finish contributes to better durability and more predictable behavior under stress, critical for high-performance components and aerodynamic efficiency.

Medical Industry: Intricate Implants and Instruments via 5-Axis CNC Machining

Why 5-Axis CNC Machining is Crucial for Medical Devices

The medical industry requires extreme precision and reliability. Components often interact directly with the human body. Therefore, manufacturers must produce parts with tight tolerances and excellent surface finishes. Biocompatibility is also a critical factor. Medical devices frequently feature complex, organic shapes. These designs demand advanced machining capabilities. 5-Axis CNC Machining provides the necessary accuracy and flexibility to meet these stringent requirements. It ensures the safety and effectiveness of medical products.

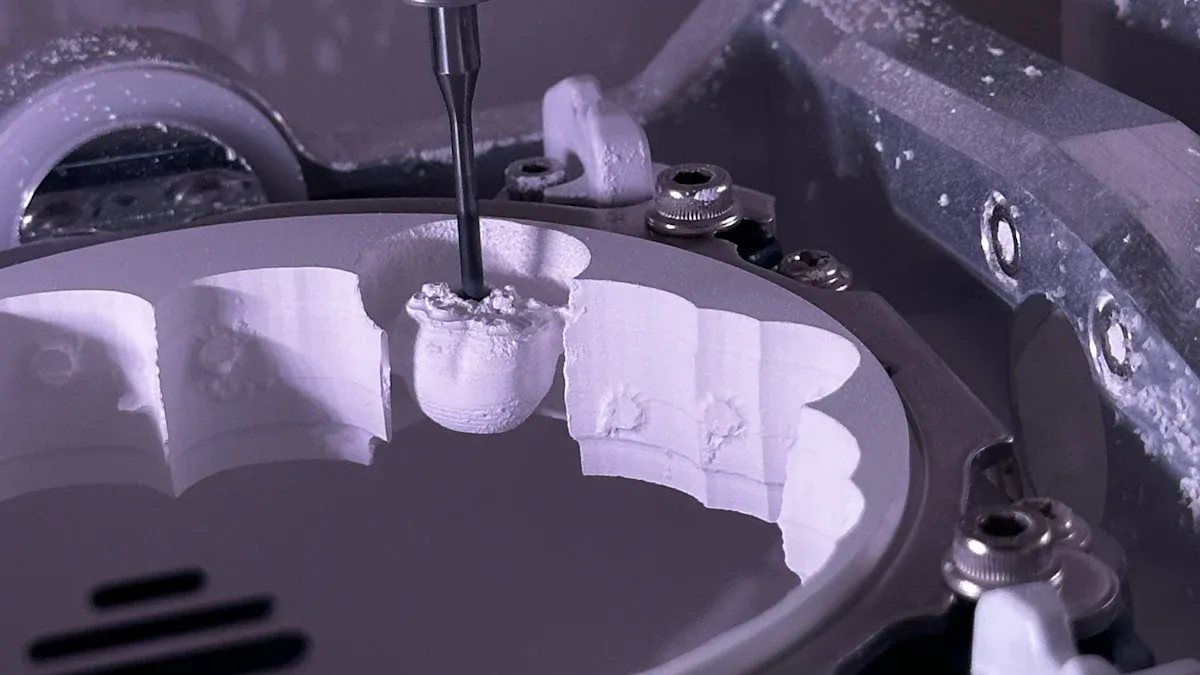

Specific Medical Applications of 5-Axis CNC Machining

5-axis CNC machining produces a wide range of critical medical components. It manufactures various implants. These include orthopedic screws, plates, and prostheses. Dental implants also benefit from this technology. Manufacturers create cardiovascular implants and joint replacements. They also produce spine screws and rods. Pacemakers, drug delivery devices, and coronary stents are other examples. The technology also creates intricate surgical instruments. These include surgical scissors, scalpels, forceps, clamps, and retractors. Dental instruments like probes, scalers, mirrors, and drills are also made. Furthermore, 5-axis machining produces components for robotic-assisted surgery, such as end-effectors, couplings, and mounts.

Key Benefits of 5-Axis CNC Machining in Medical Manufacturing

5-axis CNC machining offers significant advantages for medical device production. It achieves superior surface finishes. This reduces the need for secondary polishing. It also minimizes material waste. This is crucial for expensive, specialized medical-grade materials. The technology allows for the creation of highly complex geometries in a single setup. This reduces production time and costs. It also improves part accuracy by eliminating multiple setups. This ensures consistent quality for critical medical applications. The precision of 5-axis machining directly contributes to patient safety and product reliability.

Automotive Industry: Performance and Prototyping with 5-Axis CNC Machining

Why 5-Axis CNC Machining is Crucial for Automotive Components

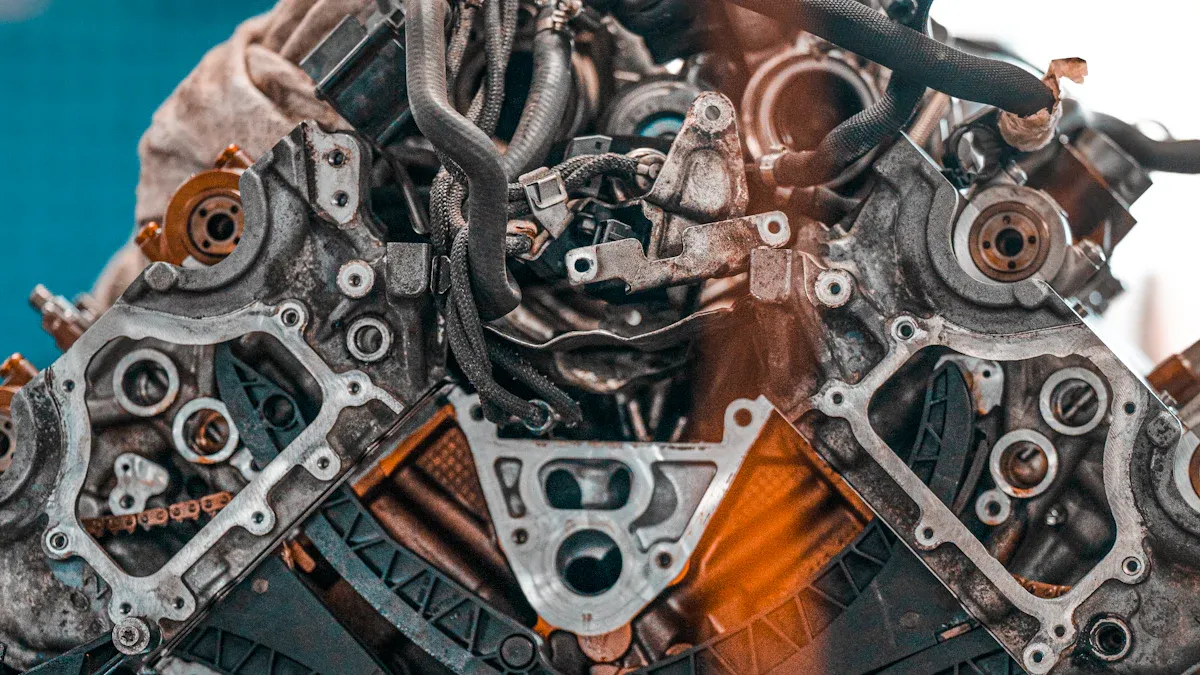

The automotive industry constantly pushes for higher performance, greater efficiency, and innovative designs. This demand requires manufacturing processes capable of producing complex components with extreme precision. Automotive parts often feature intricate shapes and require tight tolerances for optimal function. Engine components and transmission parts widely utilize advanced machining to achieve these precise fits and enhance overall performance. Components like engine blocks, cylinder heads, drive axles, and rims frequently require complex geometries. 5-axis machining effectively addresses parts with hard-to-reach features, such as angled holes and sculpted surfaces. This technology also allows for consolidating multiple simpler components into a single, integrated part. This approach reduces assembly time, eliminates potential failure points, and results in lighter, stronger, and more reliable final products.

Specific Automotive Applications of 5-Axis CNC Machining

5-axis CNC machining plays a vital role in developing and producing critical automotive parts. It is indispensable for creating high-performance automotive components. Manufacturers use it extensively for prototyping new designs, allowing for rapid iteration and testing. This includes the production of high-performance engine components, where precision directly impacts power and fuel efficiency. The technology also supports the creation of specialized parts for racing vehicles and luxury cars, where unique designs and superior quality are paramount.

Key Benefits of 5-Axis CNC Machining in Automotive

5-Axis CNC Machining offers significant advantages for automotive manufacturing. It dramatically reduces the number of setups required for multi-angled parts. A part needing eight setups on traditional machines might finish in one or two setups on a 5-axis machine. This leads to quicker lead times and substantial labor cost savings. Eliminating six setups, each taking two hours, saves 12 labor hours per part. This translates to significant direct labor savings. Cycle time improvements typically range from 25-50% faster machining for complex parts. This results from optimal cutting angles, shorter cutting tools, and reduced air cutting time. Faster cycle times increase machine capacity and reduce the cost per part. Quality improvements also reduce scrap rates and rework costs. Manufacturers often report a 50-75% reduction in scrap rates for complex parts when using 5-axis machining.

Mold and Die Industry: Superior Surface Finish and Accuracy with 5-Axis CNC Machining

Why 5-Axis CNC Machining is Crucial for Mold and Die Production

The mold and die industry demands exceptional precision and surface quality. Manufacturers create tools that shape countless products, from automotive parts to consumer goods. These tools require intricate geometries and smooth finishes to ensure the final product’s integrity and aesthetic appeal. Achieving an Ra 0.4μm finish is often necessary, which reduces the need for polishing and provides an as-machined quality. This advanced machining also reduces scallop marks, especially on curved surfaces, by maintaining constant tool perpendicularity. It eliminates extensive polishing requirements due to improved surface quality, often avoiding secondary operations entirely. This leads to significant time and cost savings.

Specific Mold and Die Applications of 5-Axis CNC Machining

5-Axis CNC Machining produces a wide array of complex molds and dies. It creates compression molds used in automotive and heavy truck body applications for Sheet Molded Composites (SMC). The technology also manufactures diecast dies for automotive components like aluminum transmission cases and suspension parts. Forging dies, essential for durable automotive components such as connecting rods and crankshafts, also benefit from this process. Furthermore, it produces pellet dies for livestock feed, pet foods, and biofuels. Prototype/low volume stamping dies for body development and crash testing vehicles also utilize this technology. Manufacturers also use it for roto molds, die-casting molds, stamping and forging dies, ship molds, automotive molds, and aluminum prototypes.

Key Benefits of 5-Axis CNC Machining in Mold and Die

5-axis CNC machining offers significant advantages for mold and die production. It minimizes post-polishing needs, directly contributing to faster production cycles. The technology also enhances tool life and surface finish.

| Metric | Improvement |

|---|---|

| Tool life (with circle segment end mills) | Doubled |

| Surface finish (with circle segment end mills) | 50% improvement |

| Post-polishing needs | Minimized |

This precision also ensures high repeatability, achieving ±0.0002″ across complex geometries. This consistency is vital for producing high-quality molds that yield consistent final products.

Energy Sector: Durability and Efficiency through 5-Axis CNC Machining

Why 5-Axis CNC Machining is Crucial for Energy Components

The energy industry demands components that withstand extreme operating conditions. These parts often function in harsh environments. They play a critical role in safety and security. This necessitates precise manufacturing and finishing to exact specifications. The oil, gas, and energy sectors place extreme demands on mechanical components. Manufacturers need strong, durable, and perfectly machined materials for these parts. Examples include high-temperature bolting, flanges, and pressure fittings. The process also shapes heat-resistant alloys. It creates complex threading and grooving for secure connections in critical systems.

Specific Energy Applications of 5-Axis CNC Machining

This technology manufactures critical components for various energy applications. It produces turbine blades, essential for power generation. It also creates blisks, which are integral to engine efficiency. Furthermore, it machines impellers for fluid dynamics and other specialized parts for drilling equipment. These components require high precision due to their operational demands.

Key Benefits of 5-Axis CNC Machining in the Energy Sector

5-Axis CNC Machining offers significant advantages for the energy sector. It enhances the performance and durability of critical components. This leads to more reliable and efficient energy systems.

| Industry | Typical Applications | Key Benefits |

|---|---|---|

| Energy | Impellers, turbine components | Enhanced performance, durability |

This precision machining reduces wear and tear on parts. It also extends the lifespan of expensive equipment. This minimizes downtime and maintenance costs. The ability to machine complex geometries in a single setup also improves production efficiency.

Defense Industry: High-Performance Components with 5-Axis CNC Machining

Why 5-Axis CNC Machining is Crucial for Defense Applications

The defense industry requires components with unwavering reliability and peak performance. These parts often operate in harsh, unpredictable environments. Manufacturers must achieve micron-level tolerances for critical components. This ensures the safety and effectiveness of military equipment. Defense applications frequently involve complex geometries. These designs demand advanced manufacturing capabilities. 5-Axis CNC Machining provides the necessary precision and flexibility. It meets stringent regulatory standards like AS9100, ISO 9001, and NADCAP. This integration with advanced inspection systems ensures compliance.

Specific Defense Applications of 5-Axis CNC Machining

This technology produces a wide array of critical defense components. It creates missile guidance system housings and fin assemblies. These parts ensure optimum aerodynamic performance. Manufacturers also produce high-strength, wear-resistant drivetrain gears for military ground vehicles. Lightweight, durable machined aluminum parts are made for advanced fighter jets. Custom-machined heat sinks provide efficient cooling for sensitive radar and communication systems. The process also creates rugged weapon system components, from gun barrels to trigger mechanisms. These parts ensure performance in battlefield conditions. Other applications include naval engines, structural systems, and vessel components. It also makes rotor hubs and other helicopter parts.

Key Benefits of 5-Axis CNC Machining in Defense

This machining offers significant advantages for defense manufacturing. It machines complex shapes in a single setup. This shortens cycle times due to fewer part repositionings. The process achieves better surface finishes with optimal tool angles. This reduces the need for secondary finishing. It also improves tool life and cutting performance. This technology reduces material waste by up to 25%. It cuts production times by as much as 40%. For example, a project involving lightweight structural brackets for a next-generation aircraft reduced bracket weight by 30%. This maintained required strength and durability. It enhanced aircraft performance, reduced fuel consumption, and lowered emissions. These benefits contribute to faster deployment and enhanced operational capabilities.

Tool and Fixture Manufacturing: Customization and Accuracy with 5-Axis CNC Machining

Why 5-Axis CNC Machining is Crucial for Tool and Fixture Production

Tool and fixture manufacturing demands extreme customization and precision. Manufacturers create specialized components to hold parts during machining or to guide cutting tools. These custom jaws securely hold parts. Specialized cutting tools reduce cycle times. Tool wear and chip evacuation require careful consideration when selecting tools. Softjaws are a common custom fixture in machining. They are custom-machined vise jaw profiles. These profiles match the specific contour of the part. Manufacturers frequently use softjaws in a double vise setup. A part is initially machined in one vise. Then, it transfers to softjaws for the second operation. This allows completion of the part in two stages.

Specific Tool and Fixture Applications of 5-Axis CNC Machining

This technology produces many complex tools and fixtures. It creates components for turbine blades and engine parts. Manufacturers also make orthopedic implants and electronic casings. Precision shafts and many other specialized components benefit from this process. The ability to machine intricate shapes in a single setup makes it ideal for these diverse applications.

Key Benefits of 5-Axis CNC Machining in Tool and Fixture Manufacturing

This machining offers significant advantages for tool and fixture production. It reduces lead times and work-in-process (WIP). It cuts down on the number of operations, often from multiple to just one. This minimizes part handling, damage risk, and exposure to revision changes. The process requires less setup time and fewer fixtures. This saves costs associated with fixture design, manufacturing, setup, storage, and tracking. It improves overall part quality. Completing parts in a single setup eliminates accuracy loss from tolerance stacking. It also removes variations in operator loading and incorrect part loading. This leads to better overall part quality. The technology allows optimal part orientation. This enables the use of shorter, more rigid cutting tools. It results in longer tool life and improved surface finishes. This increases throughput due to higher speeds and feed rates. Maintaining perpendicularity between the workpiece and cutter further enhances tool life and productivity.

5-axis simultaneous CNC machining is an indispensable technology. Industries demand precision, complexity, and efficiency. This technology produces highly intricate parts. It offers superior surface finishes and reduced setup times. These features provide significant competitive advantages. This technology drives innovation. It enhances manufacturing capabilities across diverse sectors. These sectors include aerospace, medical, and energy.

FAQ

What is 5-axis simultaneous CNC machining?

5-axis simultaneous CNC machining moves a cutting tool along five different axes at the same time. This allows for complex part geometries. It also enables intricate cuts in a single setup. This technology offers high precision and efficiency.

How does 5-axis machining improve surface finish?

5-axis machining maintains optimal cutting angles. This reduces tool marks. It produces smoother surfaces. This often eliminates or reduces secondary finishing operations. Superior surface finish contributes to better durability.

Which industries benefit most from 5-axis CNC machining?

Many industries benefit significantly. These include aerospace, medical, automotive, and mold and die. The energy, defense, and tool and fixture manufacturing sectors also gain advantages. These industries require high precision and complex parts.

Does 5-axis machining reduce production time?

Yes, it significantly reduces production time. It minimizes the number of setups required for complex parts. This leads to faster cycle times. It also reduces part handling and simplifies fixturing. This increases overall efficiency.

Post time: Dec-29-2025