A successful CNC Turning Center investment requires identifying essential factors. Strategic planning guides this acquisition. The global CNC machining and turning centers market projects significant growth, with a 6.6% Compound Annual Growth Rate from 2024 to 2030. Its high-speed segment anticipates a 5.8% CAGR between 2025 and 2035. This expansion underscores the need for informed decisions. A Multi-Function CNC Lathe Manufacturer provides various options. Understanding Turning Center Precision is paramount. Buyers often ask, “What is the difference between a CNC Turning Center and a CNC Lathe?” and “How to choose between Vertical and Horizontal Turning Centers?“. Ten critical considerations guide an informed purchase.

Key Takeaways

- Understand your production needs and part requirements. This helps you choose the right machine size and power.

- Look at machine specifications like spindle power and tooling options. These features affect how well the machine works.

- Check the control system and software. They make the machine easy to use and connect with other systems.

- Consider the machine’s accuracy and how it handles heat and vibrations. This ensures high-quality parts.

- Think about the total cost, not just the price. This includes running costs, maintenance, and future value.

Production Needs and Part Requirements for Your CNC Turning Center

Selecting a CNC Turning Center begins with a clear understanding of production needs and part requirements. These factors directly influence the machine’s necessary specifications and capabilities.

Part Size and Weight Capabilities

The physical dimensions and weight of the parts a shop intends to produce are fundamental considerations. A machine’s capacity must accommodate the largest and heaviest components. For instance, CNC turning operations handle a wide range of part sizes.

| Part Size Category | Dimensions (mm) | Dimensions (in) |

|---|---|---|

| Minimum | 2×2 | 0.079×0.079 |

| Maximum | 200×500 | 7.9×19.7 |

Machine specifications like the distance between centers determine the maximum part length, often around 500 mm (19.7 in). The swing over bed dictates the maximum part diameter, typically around 200 mm (7.9 in). Buyers must ensure the chosen CNC Turning Center can physically hold and machine their target parts.

Material Types to Process

The types of materials a shop processes significantly impact machine and tooling selection. Different materials possess varying hardness levels, which demand specific machine power and cutting tools.

| Material Hardness Category | Rockwell Hardness (HRC) | Typical CNC Lathe Types |

|---|---|---|

| Hard-to-Machine Alloys | 45–70 HRC | High-Torque CNC Lathes |

| Medium-Hard Industrial Materials | 25–45 HRC | Horizontal CNC Lathes |

| Soft & Easily Machinable Metals | <25 HRC | Any CNC Lathe (including Entry-level, Benchtop, High-speed Spindle Machines) |

Standard CNC tooling generally reaches a practical limit at HRC 40. Machining materials above HRC 50 often requires specialized setups, which can double both machining time and cost. For example, carbon/alloy steels like 4140 are standardly machined up to HRC 35. They become challenging above HRC 40. Stainless steels like 304 are efficient up to HRC 30, becoming difficult beyond HRC 35. Tool steels such as A2 are machinable through HRC 45, but specialized setups are necessary above HRC 50. Aluminum alloys generally present no hardness limitations for CNC machining.

Production Volume and Throughput

Production volume and required throughput dictate the machine’s speed, efficiency, and potential for automation. High-volume production demands faster cycle times and reliable operation. Shops producing large quantities of parts benefit from features like automatic bar feeders and robotic integration. These additions minimize manual intervention and maximize continuous operation. Conversely, lower volume or prototype work may not require such extensive automation. The machine’s ability to maintain consistent output over long periods is crucial for meeting production targets.

Machine Specifications and Capabilities of a CNC Turning Center

Machine specifications and capabilities directly influence a shop’s ability to produce parts efficiently and accurately. Buyers must carefully evaluate these technical aspects.

Spindle Configuration and Power

The spindle is the heart of any turning operation. Its configuration and power determine the machine’s cutting ability. Spindle speed, measured in revolutions per minute (RPM), dictates how fast the workpiece rotates. High RPMs are crucial for smaller diameters and softer materials. Spindle torque, the rotational force, is essential for machining larger diameters and harder materials. A powerful spindle ensures efficient material removal and reduces cycle times. Shops must match spindle specifications to their typical part sizes and material types.

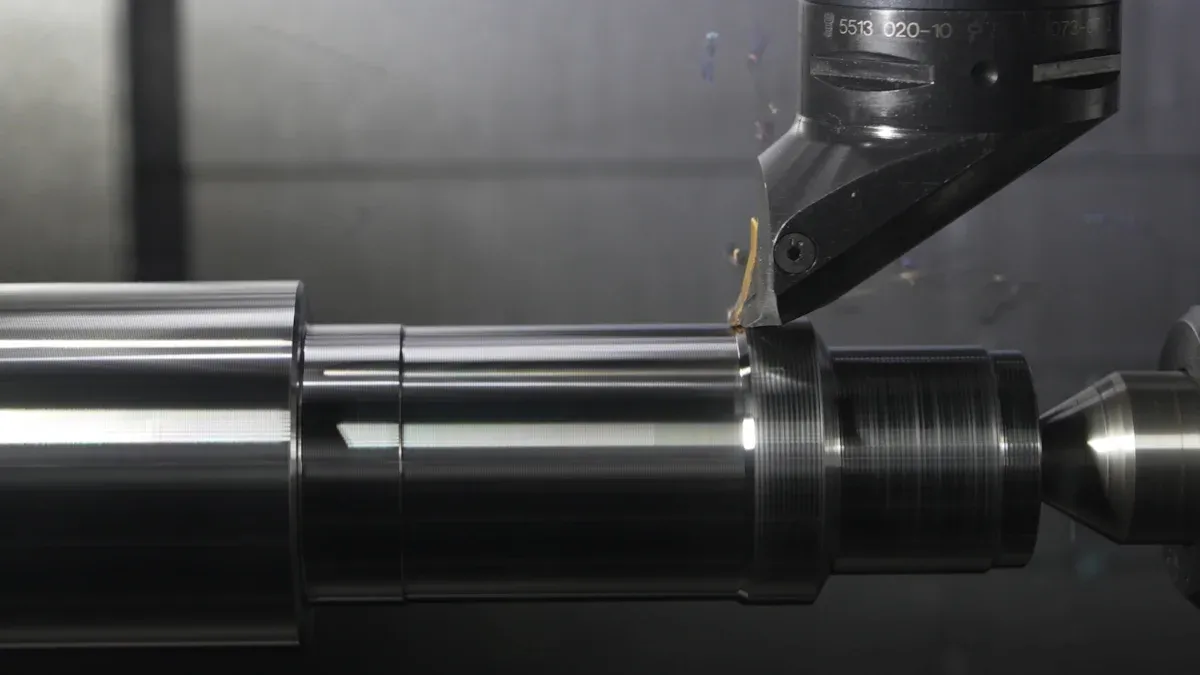

Turret and Tooling Options

The turret holds the cutting tools and presents them to the workpiece. Its design significantly impacts machining versatility and efficiency. Turrets come in various configurations, such as VDI (Association of German Engineers) or BMT (Base Mounted Tooling), each offering different rigidity and tool-holding capabilities. The number of tool stations on the turret determines how many different tools the machine can access without manual intervention. More tool stations allow for complex operations in a single setup, minimizing downtime for tool changes.

Axis Configuration and Live Tooling

Axis configuration defines the machine’s movement capabilities. A basic 2-axis lathe performs turning operations along the X and Z axes. More advanced machines, like a multi-axis CNC Turning Center, offer additional axes, such as a Y-axis for off-center drilling or milling. Live tooling is a significant enhancement for a CNC Turning Center. It allows the machine to perform milling, drilling, and tapping operations without transferring the part to another machine. Live tooling offers greater design flexibility for precision-machined parts. It enables more complex machining processes in a single run, streamlining setup and reducing labor. This capability enhances accuracy and repeatability by minimizing unnecessary setup procedures. Shops achieve faster fabrication due to advanced gears and bearings. Live tooling preserves the datum, which often gets lost when moving material between machines, saving time. It also allows for numerous milling processes directly on the lathe, such as edge rounding or adding axial/radial features. This eliminates the need to transfer parts to a CNC mill.

Control System and Software for Your CNC Turning Center

The control system and software form the brain of any modern machine tool. They dictate how operators interact with the equipment and how the machine executes complex operations. Selecting the right control system ensures efficient programming, reliable operation, and seamless integration into a manufacturing environment.

CNC Control Brand and Features

The choice of a CNC control brand significantly impacts machine performance and user experience. Different manufacturers offer distinct advantages tailored to various production needs.

| Brand | Key Turning Center Products | Key Features for Turning Centers |

|---|---|---|

| Haas Automation | Haas ST Series CNC lathes | User-friendly interfaces, high torque, rigid construction, durability, reliability, affordable pricing. |

| DMG Mori | NLX Series universal turning centers | High rigidity, stability, precision, integrated automation solutions, digitalization, Industry 4.0 readiness. |

| Mazak | INTEGREX Series multi-tasking machines | Combines turning, milling, drilling, tapping; ideal for complex parts; iSMART Factory concept (IoT integration), extensive service and support. |

| Okuma | LB Series CNC lathes | Power, precision, versatility, Thermo-Friendly Concept (thermal stability), open-architecture OSP-P control system (customization, software integration). |

| Doosan/DN Solutions | CNC Lathes | Precision turning operations, multi-axis capabilities, high spindle speeds, advanced control systems. |

Each brand provides unique features. Haas Automation focuses on user-friendliness and affordability. DMG Mori emphasizes rigidity and Industry 4.0 readiness. Mazak offers multi-tasking capabilities for complex parts. Okuma provides thermal stability and open-architecture controls. Doosan/DN Solutions delivers precision and multi-axis functionality.

Programming and User Interface

An intuitive programming interface simplifies machine setup and operation. Operators need a system that allows for efficient G-code programming or conversational programming, depending on their skill level and the complexity of the parts. A well-designed user interface reduces training time and minimizes errors. It also enhances productivity by making program creation and modification straightforward.

Integration with Existing Systems

Seamless integration with existing manufacturing execution systems (MES) or enterprise resource planning (ERP) systems is crucial for modern shops. This connectivity allows for real-time data exchange, improving production monitoring and overall efficiency. Successful integration requires careful planning.

- Thoroughly map out processes before digitizing to avoid automating inefficiencies.

- Start small with a pilot project to limit risk and learn from experience.

- For companies with modern machinery, begin with machine connectivity and OEE (Overall Equipment Effectiveness) monitoring to gain real-time insights for optimization.

- Recognize that MES implementation changes how people work and requires careful guidance.

- Involve the team from the start, explaining the necessity and benefits.

- Invest in training to ensure everyone understands the new systems.

- Appoint ‘digital champions’ to provide extra support and training to colleagues.

These practices ensure a smooth transition and maximize the benefits of a connected manufacturing environment.

Accuracy and Precision of the CNC Turning Center

Achieving high-quality parts consistently depends heavily on a machine’s accuracy and precision. These attributes directly impact part conformity and overall manufacturing efficiency.

Repeatability and Positional Accuracy

Repeatability refers to a machine’s ability to return to a programmed position consistently. Positional accuracy describes how closely the machine can reach a target position. Both are critical for producing identical parts within tight tolerances. A machine with high repeatability ensures each part matches the last, minimizing scrap and rework. High positional accuracy means the machine places tools exactly where programmed, which is essential for complex geometries and critical dimensions. Manufacturers often provide these specifications, and buyers must ensure they meet their production requirements.

Thermal Stability Considerations

Temperature fluctuations significantly affect machine accuracy. As machine components heat up during operation, they expand, causing dimensional shifts. This thermal expansion can lead to inaccuracies in machined parts. Effective strategies mitigate these effects. Shops maintain controlled temperature settings in machining areas, often insulating the space and using sophisticated HVAC systems. Advanced cooling systems and optimized turning parameters minimize heat generation during machining. Some systems employ advanced algorithms to predict and correct thermal errors in real-time using temperature sensors and compensation models. For example, an aerospace firm achieved ±0.01 mm precision on Inconel disks using cryogenic cooling, while a crankshaft maker maintained parts within 0.05 mm tolerances with standard cooling.

Vibration Dampening Mechanisms

Vibrations during machining degrade surface finish, reduce tool life, and compromise part accuracy. Effective vibration dampening mechanisms are therefore crucial. Utilizing tool holders with face and taper contact significantly enhances rigidity and reduces chatter. High-precision and high-clamping force work-holding eliminates part vibration. Adjusting machining speeds and feeds to stable zones on the lobe diagram can also eliminate chatter. This involves carefully managing chip load while increasing or decreasing speed. Using thicker tool shanks or reducing tool extension from the secured end increases stiffness, reduces deflection, and shifts vibration frequency to more stable zones. Anti-vibration damping tool handles, designed with advanced materials, absorb and dissipate vibrations, preventing transfer from the tool to the workpiece.

Footprint and Shop Space for the CNC Turning Center

The physical space available in a manufacturing facility significantly influences machine selection. Shops must carefully consider the footprint of a machine and its surrounding requirements. This planning ensures efficient operation and a safe working environment.

Machine Dimensions and Layout

The actual dimensions of the machine itself are a primary concern. Manufacturers provide detailed specifications regarding length, width, and height. Shops must ensure the chosen machine fits within the designated area. Furthermore, the layout must accommodate peripheral equipment, such as chip conveyors, coolant tanks, and electrical cabinets. An optimal layout facilitates workflow and prevents bottlenecks.

Accessibility for Maintenance

Adequate space around the machine is crucial for routine maintenance and repairs. Technicians require clear access to all sides of the machine for inspections, part replacements, and troubleshooting. Cramped spaces can prolong maintenance times and increase safety risks. Planning for maintenance access from the outset streamlines future service operations.

Material Handling Space Requirements

Efficient material handling around the machine directly impacts productivity and safety. Shops need sufficient clearance for loading raw materials and unloading finished parts. A minimum of 36 inches (3 feet) often serves as a baseline for clear pathways. For larger or longer parts, shops recommend 7 to 8 feet of spacing. This accommodates tools, toolboxes, pallets, and carts, preventing accidental contact with controls. One user specifically allocated 10 feet between a lathe and a mill to maximize space and facilitate the use of a jib crane for loading parts. Consideration for operator movement, especially for larger individuals, suggests a minimum of 6 feet. Allowing space for equipment like die carts to swap heavy fixtures might require 7 to 8 feet. Shops must also account for the removal of coolant tanks. They must ensure the chuck of the lathe is not in line with where an operator might stand at an adjacent machine for safety.

Budget and Total Cost of Ownership for a CNC Turning Center

A comprehensive budget analysis extends beyond the initial purchase price. It includes all costs associated with owning and operating the machine over its lifespan. This total cost of ownership (TCO) provides a more accurate financial picture.

Initial Purchase Price

The initial purchase price represents the upfront investment for a machine. This cost varies significantly based on the machine’s class, features, and capabilities. Buyers must align their budget with their production needs.

| CNC Lathe Machine Class | Initial Purchase Price Range |

|---|---|

| Benchtop CNC Lathe | $5,000 – $20,000 |

| Mid-Range Production Lathe | $30,000 – $100,000 |

| Multi-Spindle or Swiss-Type CNC Lathe | $100,000 – $300,000+ |

These figures illustrate the wide spectrum of available options. A shop’s specific requirements dictate the appropriate investment level.

Operating Costs and Efficiency

Operating costs encompass ongoing expenses beyond the initial purchase. These include energy consumption, tooling, maintenance, and labor. An efficient machine minimizes these recurring costs. Modern machines often feature energy-saving components, reducing electricity bills. High-quality tooling lasts longer, decreasing replacement frequency. Regular maintenance prevents costly breakdowns and extends machine life. Efficient operation also reduces labor hours per part, further lowering overall expenses.

Resale Value and Depreciation

Machines depreciate over time, meaning their value decreases. However, some machines retain value better than others. Factors affecting resale value include the manufacturer’s reputation, the machine’s maintenance history, and its technological relevance. Investing in a well-regarded brand with a strong service network often leads to better resale value. Proper maintenance also preserves the machine’s condition, making it more attractive to future buyers. Buyers should consider the long-term value and potential depreciation when making their investment decision.

Service and Support for Your CNC Turning Center

Effective service and support are paramount for maximizing machine uptime and ensuring long-term productivity. Buyers must evaluate a manufacturer’s commitment to customer satisfaction and the availability of local assistance.

Manufacturer Reputation and Reliability

A manufacturer’s reputation for reliability directly impacts a machine’s long-term performance and a shop’s operational continuity. Companies with a strong track record often provide superior products and support. For instance, DMG MORI boasts a 95% customer retention rate, indicating high satisfaction. Haas Automation earns trust from over 10,000 US workshops due to its reliability and ease of use. Hermle also achieves greater than 95% customer satisfaction. These metrics highlight manufacturers who consistently deliver dependable machinery and excellent post-purchase care.

Local Service Availability

Local service availability is crucial for minimizing costly production delays. Quick response times from technicians ensure machines return to operation swiftly.

| Priority Level | Response Time (Typical) |

|---|---|

| Priority 1 (Critical) | 2-4 hours |

| Priority 2 (High) | 4-8 hours |

| Priority 3 (Medium) | Next business day |

| Priority 4 (Low) | 2-5 business days |

Manufacturing facilities with production line dependencies often require 24/7 coverage with guaranteed 2-hour response times. Methods Machine emphasizes fast response times for service, offering 24/7 live technical support through a U.S.-based agent call center. Seasoned technicians are stationed at regional offices across North America. However, service quality can vary. One user reported a 9-day wait for a belt replacement from a repair company. Another user mentioned almost always getting next-day service for their Haas, Mazak, and Mori machines, even when located several hours away.

Warranty and Technical Support

Understanding the warranty and available technical support protects an investment. Standard warranty periods for new machines typically range from one to three years, varying by manufacturer and model. These warranties generally cover defects in materials and workmanship, often including parts and labor, performance guarantees, and access to technical support. Extended warranty options are frequently available for purchase. It is crucial to understand the specific terms, including what the warranty covers and what it excludes. Key support offerings include:

- Access to qualified technical support and prompt service.

- Inclusion of software updates and support to keep the machine current and efficient.

- Availability of on-site service and repairs to minimize downtime.

Automation and Future Expansion with a CNC Turning Center

Considering automation and future expansion capabilities is vital when purchasing a machine. These features ensure a shop’s investment remains relevant and productive for years. They allow businesses to adapt to changing production demands and technological advancements.

Robotic Integration Potential

Robotic integration significantly boosts productivity and efficiency. Robots achieve ±0.05 mm repeatability, enabling 24/7 production and increasing machine utilization by 30%. Six-axis robots with specialized grippers handle up to 80 kg loads. They operate 2-2.5 times faster than manual methods. This reduces loading and unloading time by up to 60%. Advanced CNC welding robots provide ±0.1 mm accuracy. They reduce defect rates by 40-50% and increase production speed by 30-35%. Robots with vision systems perform precise assembly with ±0.02 mm repeatability. They reduce setup time by up to 70% through flexible fixtures. Robotic automation for material loading, tool changes, and part unloading can boost equipment utilization from 52% to over 82%. This represents a 30% improvement. Integration with CNC machines can decrease average cycle time per part by 25%. This leads to significant productivity gains. Consistent, error-free part handling and automated verification reduce scrap rates by approximately 8%. Robots also handle repetitive, physically demanding, and hazardous tasks. This frees human workers for more complex roles and improves workplace safety.

Bar Feeder Compatibility

Bar feeder compatibility is another key aspect of automation. A bar feeder automatically supplies raw material to the machine. This enables continuous, unattended operation for extended periods. Shops can run production overnight or during off-hours. This maximizes machine utilization and throughput. Bar feeders reduce labor costs by eliminating the need for manual material loading. They also ensure consistent part quality by maintaining a steady material flow.

Modular Design for Upgrades

Modular design principles allow for future upgrades. This makes these specialized machines future-proof. Modular designs enable the reconfiguration of machinery based on specific project needs. They provide the flexibility to integrate key functionalities as required. These designs facilitate easier upgrades of certain components. This happens without necessitating the replacement of the entire machine. It ensures the machinery remains relevant as technology advances.

Energy Efficiency and Environmental Impact of a CNC Turning Center

Considering energy efficiency and environmental impact has become crucial for modern manufacturing. These factors influence both operational costs and a shop’s commitment to sustainability. Businesses seek machines that perform efficiently while minimizing their ecological footprint.

Power Consumption and Costs

A machine’s power consumption directly affects operating costs and environmental impact. Modern CNC machines often feature energy-saving components and intelligent power management systems. These systems optimize energy use during operation and idle times. Selecting a machine with high energy efficiency reduces electricity bills and lowers carbon emissions. Shops should evaluate the power requirements of different models and consider their long-term energy consumption.

Coolant Management Systems

Effective coolant management is a financially savvy strategy. It provides significant cost savings and environmental benefits. Proper coolant disposal reduces soil and water pollution. It prevents harmful materials from contaminating ecosystems. This practice also decreases harmful emissions through sustainable waste management techniques. Recycling coolants conserves natural resources, reducing demand for raw materials.

Proper coolant management also offers economic advantages. It lowers waste management costs through efficient disposal and recycling systems. Recycling can even generate revenue from recovered materials. Furthermore, it enhances brand reputation for companies practicing sustainable disposal. Shops meet environmental regulations, ensuring adherence to waste environmental laws. This avoids legal penalties and fines associated with non-compliance. Operationally, it improves workplace safety and health by reducing risks for employees. It also encourages innovation and technological adoption.

Proper coolant management is crucial for minimizing environmental impact and costs. It prolongs coolant sump life, reducing the need for frequent replacement. This boosts workplace productivity by keeping machines running smoothly. It improves the quality of machined parts, ensuring better surface finishes. It also keeps target concentration stable, leading to more reliable machining performance. This promotes a safer and healthier work environment. It safeguards expensive machining equipment and extends tool life. Fusion Coolant Systems’ CO₂-based Pure-Cut® CNC cooling system offers a cleaner alternative. This system uses supercritical CO₂ (scCO₂) as a cooling medium. It minimizes environmental impact, eliminates harmful coolant waste, and enhances safety through:

- Zero Coolant Waste: scCO₂ evaporates harmlessly after use.

- Reduced Energy Use: Pure-Cut® requires less energy.

- Sustainable CO₂ Sourcing: The CO₂ used is typically reclaimed.

Waste Reduction Strategies

Implementing effective waste reduction strategies minimizes material consumption and disposal costs. Shops can adopt several proven methods.

- Use Nesting Software: This automates part placement to minimize unused space. It reduces sheet metal scrap, cut time, tool wear, and disposal costs.

- Switch to Near-Net-Shape Machining: This starts with a blank that closely resembles the final part. It reduces the amount of material to be removed, shortens cycle times, and extends tool life.

- Choose Smarter Toolpaths: Strategies like adaptive clearing optimize material removal. They reduce redundant moves and prevent cutting air, minimizing scrap and wear.

- Dial In Feeds and Speeds: Proper adjustment prevents poor surface finishes, material deformation, and excessive chip generation. This reduces rework and disposal volumes.

- Simulate Before You Cut: Running virtual test cuts helps identify and correct potential errors. This prevents material loss and rework.

Operator Training and Safety Features of the CNC Turning Center

Ease of Operation and Learning Curve

The learning curve for CNC machining can initially be steep. However, it becomes more intuitive with practice. Several factors influence this complexity. These include technical knowledge in mechanical and electrical systems, CAD/CAM proficiency, programming skills like G-code, and practical experience. Modern control systems aim to simplify this process. For example, the HEIDENHAIN TNC7 features an intuitive and user-friendly interface. Operators can customize the home screen with their specific favorites, which reduces the learning curve. Built-in process videos guide users through simple tasks, helping new operators get up to speed faster. Similarly, the Brother controller is very similar to Haas, making it easy to adapt for those with Haas experience. Documentation for Brother Speedio is excellent and well-written. The Speedio control is extremely easy to use. Users can get up and running quickly. Modern controls are generally easy to learn for basic operations like setting up tools, work offsets, and running programs, typically within a few hours.

Training Programs Offered

Comprehensive training programs are essential for new operators. Training should cover fundamental CNC concepts, G-code programming, and simulations. It also includes CAD/CAM software, tool selection, blueprint reading, essential math, and material science. Hands-on experience is crucial for practical skill development. This includes supervised machine operation, simulator use, and real-world project work. Operators need training in troubleshooting and problem-solving. This involves predictive maintenance, identifying and resolving machine issues, adjusting offsets, understanding alarm codes, and knowing when to escalate problems. Safety protocols are also vital. Comprehensive training must include OSHA compliance, machine safety, emergency stop procedures, and ergonomics to prevent injuries. Modern training also incorporates Industry 4.0 concepts, simulation-based or virtual reality (VR) training, and modules on green manufacturing.

Safety Interlocks and Guards

Machine guards are safety barriers or devices that enclose hazardous parts of equipment. They prevent contact with moving parts. OSHA publishes specific machine guarding standards. Three main types of machine guards exist: fixed guards, interlocking guards, and adjustable guards. Interlocking guards, or safety interlocks, are movable barriers combined with a safety mechanism. This mechanism stops the machine when opened. Other safety precautions include light curtains, safety contact mats, and CNC machine safety glass. Emergency Stop Switches (E-stops) are large red buttons that quickly shut down the machine. Lockout/Tagout (LOTO) procedures physically de-energize equipment. Pre-operational inspection is crucial for operators. Before starting, operators should check for loose or missing guards, damaged cables, loose fixtures, and the functionality of all safety features. ANSI 11.19 (2010) provides performance criteria for safeguarding. This standard applies to all machines and equipment. It simplifies guarding standards.

A comprehensive evaluation is crucial for any CNC Turning Center purchase. Shops must prioritize long-term value and return on investment over initial cost. This strategic approach ensures an optimal investment. Carefully consider all factors discussed. This diligence leads to a successful, productive acquisition for your shop, enhancing its capabilities for years to come.

FAQ

What is the difference between a CNC Turning Center and a CNC Lathe?

A CNC lathe primarily performs turning operations. A CNC turning center offers more advanced capabilities. It often includes live tooling, multiple axes, and automation features. These additions allow for milling, drilling, and tapping in a single setup.

What are the main benefits of live tooling on a CNC Turning Center?

Live tooling significantly enhances a turning center’s versatility. It allows the machine to perform milling, drilling, and tapping operations. This eliminates the need to transfer parts to another machine. Shops achieve greater design flexibility and reduce setup times.

Why is thermal stability important for a CNC Turning Center?

Thermal stability is crucial for maintaining accuracy. Machine components expand as they heat during operation. This expansion causes dimensional shifts. Effective cooling systems and compensation models mitigate these effects. They ensure consistent part quality.

What does Total Cost of Ownership (TCO) mean for a CNC Turning Center?

TCO includes all costs associated with a machine over its lifespan. This goes beyond the initial purchase price. It covers operating costs like energy, tooling, and maintenance. TCO also considers labor, depreciation, and potential resale value.

Post time: Dec-12-2025