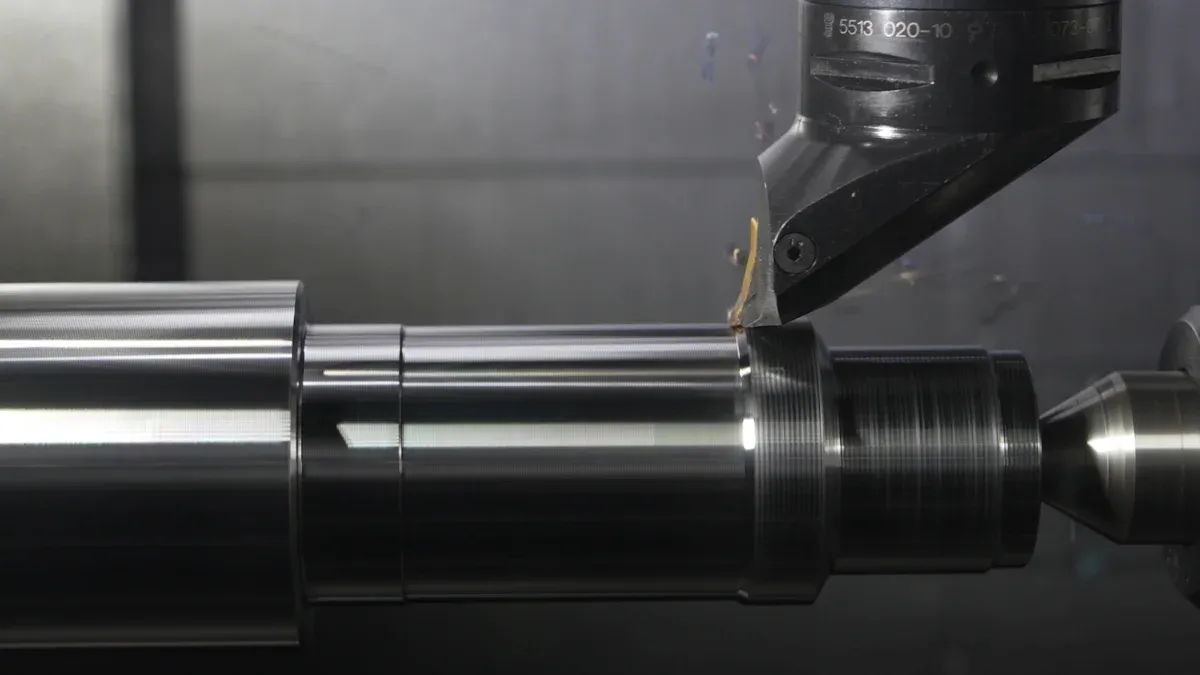

For simple cylindrical parts, a CNC Turning Machine offers a cost-effective solution. Automated CNC Turning processes make high-volume production efficient. What are the advantages of CNC turning compared to conventional lathes? It delivers speed and consistent quality. Manufacturers often seek a CNC Turning Machine for Sale to achieve Precision CNC Turning for their projects. This helps produce High Precision Turning Parts efficiently. However, for complex, non-symmetrical parts, CNC milling typically provides better cost efficiency. The choice often depends on the part’s geometry and production needs.

Key Takeaways

- CNC turning is best for simple, round parts. It makes many parts quickly and costs less for high-volume jobs.

- CNC milling is better for complex parts. It can make many shapes that turning cannot. It costs more but is worth it for detailed designs.

- Machine cost, tools, and setup time affect total cost. Milling machines and their tools often cost more than turning machines.

- The material you use changes the cost. Harder materials wear out tools faster. This makes the job more expensive.

- New technology like robots and better software helps lower costs. They make machines work faster and reduce mistakes.

Cost Factors for CNC Turning Machine Operations

Machine Acquisition and Depreciation

A significant cost factor for CNC turning operations comes from the initial investment in the machine itself. In 2025, a standard CNC Turning Machine suitable for various turning tasks costs around $65,000. This figure represents a mid-range model, capable of handling more complex turning jobs. Machines depreciate over time, and businesses account for this wear and tear. For general machine tools like lathes, the Australian Tax Office suggests a 10-year effective life with a 10% prime cost depreciation rate. This depreciation adds to the hourly cost of operating the machine. Businesses factor this cost into the price of each part produced, ensuring they recover the initial investment over the machine’s lifespan.

Tooling and Consumable Expenses

Tooling and consumables also contribute significantly to the overall cost. CNC turning uses various cutting tools, including inserts, tool holders, drills, and reamers. Each tool has a limited lifespan and requires periodic replacement. The type of material being machined directly impacts tool wear; harder materials dull tools faster. Beyond cutting tools, consumables like cutting fluids, coolants, and machine lubricants are essential for efficient operation and machine longevity. These items need regular replenishment, adding to the ongoing operational expenses.

Setup and Programming Efficiency

Setting up and programming a new part on a CNC Turning Machine directly impacts production costs. This non-productive time can vary widely. For a simple part, programming might take only 15 minutes. However, complex parts, especially those requiring custom tool-paths, can demand over 45 hours for programming and setup. Some professionals budget jobs, estimating around 15 minutes for programming a simple part. Other users report programming, setting up, and running an average of one unique part every workday. This means some days involve several parts, while others take multiple days for a single part. Iterative processes, like “change this, machine this, start over,” also extend these times. Efficient programming and quick setup minimize idle machine time, directly reducing the cost per part.

Operational Labor and Maintenance

Operating a CNC turning machine requires skilled individuals, and their wages significantly contribute to overall costs. You might wonder, what does it cost to have someone run these machines? The hourly labor cost for a CNC turning machine operator varies based on their experience.

| Operator Type | Hourly Wage (U.S. Average) |

|---|---|

| Entry-Level Machinist | $18–$25/hr |

| Experienced Setup Tech | $25–$40/hr |

For instance, a CNC Operator’s labor cost often sits around $35 per hour. This figure includes not just their direct wage but also benefits and overhead. Beyond daily operations, maintenance also plays a crucial role. Regular preventative maintenance keeps machines running smoothly and prevents costly breakdowns. This includes routine checks, lubrication, and part replacements. Unexpected repairs, however, can quickly add up, requiring specialized technicians and expensive parts. Therefore, investing in skilled operators and a robust maintenance schedule helps control these operational expenses.

Material Utilization for Cylindrical Parts

CNC turning excels at efficiently using materials, especially for cylindrical parts. This process typically starts with round bar stock. The machine then removes material to create the desired shape. Because the starting material already closely matches the final part’s form, turning often generates less waste compared to other machining methods. This efficient material usage directly translates into cost savings. For example, when you produce a simple shaft, the amount of material you cut away is minimal. This reduces scrap and lowers the overall material cost per part. The design of the part also influences material utilization; simpler cylindrical designs lead to even greater efficiency.

Cost Factors for CNC Milling Operations

Machine Acquisition and Complexity (3-axis vs. 5-axis)

The initial cost of a CNC milling machine significantly impacts overall expenses. In 2025, a standard 3-axis Vertical Machining Center (VMC) for general job-shop work typically costs between $80,000 and $150,000. This price often includes essential features like probing, an automatic tool changer (ATC), coolant systems, and service. Businesses commonly buy these machines for making various metal parts. Five-axis machines, which offer greater flexibility for complex geometries, come with a much higher price tag due to their advanced capabilities and intricate mechanics. The choice between a 3-axis and a 5-axis machine depends heavily on the complexity of the parts a company plans to produce.

Tooling Variety and Cost

CNC milling requires a wide array of tools, and their costs add up quickly. A practical starter tool library, including carbide end mills, drills, face mills, and spot/center drills, usually costs $1,500 to $6,000. This range depends on the materials and coatings needed. Beyond the cutting tools themselves, tool holders, collets, pull studs, and spare sleeves can add another $1,500 to $5,000 for small to mid-size setups. For faster tool changes and consistent lengths, off-machine tool presetters, carts, and storage solutions might contribute $800 to $5,000. Many experts suggest budgeting about 10% to 25% of the machine’s purchase price for tooling and fixturing.

Setup and Programming Complexity

Milling operations often involve more complex setups and programming compared to turning. This complexity directly affects the time and cost involved. A milling machine can create intricate shapes, pockets, and features, which demand detailed programming. Programmers must define tool paths for multiple axes, consider collision avoidance, and optimize cutting strategies. This process takes more time, especially for unique or highly complex parts. Longer setup times mean less machine uptime for actual production, increasing the cost per part. The skill level of the programmer also plays a big role; experienced programmers can reduce this non-productive time.

Operational Labor and Maintenance

Operating a CNC milling machine also requires skilled personnel. These operators manage complex setups and intricate machining processes. Their expertise directly impacts the quality and efficiency of production. You might wonder about the cost of these skilled individuals. An experienced CNC milling operator or programmer often commands a higher hourly wage than a basic turning operator. This reflects the increased complexity of milling tasks. For instance, a skilled milling machinist might earn between $28 and $45 per hour, depending on their experience and the region. This figure includes not just their direct pay but also benefits and other overheads.

Maintenance is another critical cost factor. Regular preventative maintenance keeps milling machines running smoothly. This includes routine inspections, lubrication, and replacing worn components. Neglecting maintenance can lead to costly breakdowns. When a complex milling machine fails, it often requires specialized technicians and expensive replacement parts. These unexpected repairs can significantly increase operational costs and disrupt production schedules. Therefore, investing in skilled operators and a robust maintenance program helps control these expenses effectively.

Material Utilization for Complex Geometries

CNC milling truly shines when creating complex, non-symmetrical parts. However, this versatility often comes with a trade-off in material utilization. Unlike turning, which often starts with a cylindrical blank, milling frequently begins with a rectangular block or plate. The machine then removes a substantial amount of material to achieve the desired intricate shape. This process can generate more scrap material compared to turning simple parts.

Consider a complex aerospace component. Manufacturers might start with a large block of expensive aluminum or titanium. The milling process carves out the intricate features, leaving behind a significant volume of chips and waste. This higher material waste directly contributes to the overall cost of the part. Engineers and designers try to optimize material usage through various strategies. They might use near-net-shape blanks or employ advanced nesting software to minimize waste. Still, the inherent nature of creating complex geometries via subtractive manufacturing means material utilization often remains a key cost consideration for milling operations.

Direct Cost Comparison: CNC Turning vs. CNC Milling

Initial Machine Investment

The initial investment for a CNC machine significantly impacts overall project costs. When comparing CNC turning and milling, you will find a noticeable difference in their price tags. A basic CNC Lathe, often called a CNC Turning Machine, typically costs between $30,000 and $80,000. An entry-level CNC Mill, however, usually falls into a higher range, from $45,000 to $100,000.

Let’s look at the average costs. A basic CNC Lathe averages around $55,000. An entry-level CNC Mill averages about $72,500. This means CNC milling machines are, on average, $17,500 more expensive in terms of initial investment. This higher cost for milling machines reflects their greater versatility and ability to create complex geometries.

Tooling Costs and Lifespan

Tooling costs represent another key difference between CNC turning and milling. CNC turning generally requires fewer tools for cylindrical parts. This often leads to lower overall tooling expenses. Turning primarily uses single-point cutting tools, like turning tools and boring bars. These tools remove material as the workpiece rotates.

CNC milling, on the other hand, can have higher tooling costs. This is especially true for complex geometries. Milling requires a variety of end mills, drills, and other specialized tools. These are multi-point cutting tools that rotate to remove material from a stationary or moving workpiece. The tooling setup for milling is more complex. It needs a larger inventory of tools to create intricate shapes and features. Tool wear in turning is usually predictable. Milling tool wear can vary more, depending on the cutting path. This might mean more frequent tool changes or monitoring.

Setup and Programming Time Impact

Setup and programming time directly affect the cost per unit for both CNC turning and milling. Setup costs include all expenses before machining begins. This involves creating a 3D model using CAD software. It also includes design optimization and CAM preparations. These are fundamental components of the overall cost in CNC machining processes.

In CNC milling, setup time is a big part of the total machining time. This includes installing fixtures, debugging programs, and presetting tools. These are fixed costs. You calculate the per-unit fixed cost by dividing total fixed costs by the production quantity. For example, a larger production batch spreads these fixed costs over more units. This significantly reduces the per-unit cost.

| Production Quantity | Per-Unit Fixed Cost |

|---|---|

| 100 pieces | $20/piece |

| 10 pieces | $200/piece |

Smaller batches result in higher per-unit costs. The same fixed setup cost gets spread across fewer items. This highlights how production volume plays a crucial role in cost efficiency.

Labor Skill and Hourly Rates

The expertise of the people running the machines significantly influences production costs. CNC turning and milling both require skilled operators, but the specific demands can differ. Generally, a CNC turning operator needs to understand machine setup, tool offsets, and basic programming. They ensure the machine runs efficiently and produces parts to specification.

CNC milling, especially for complex, multi-axis operations, often demands a higher level of skill. A milling machinist or programmer must navigate intricate geometries, manage a wider array of tools, and troubleshoot more complex issues. This increased complexity often translates into higher hourly rates for milling specialists. For example, a highly experienced CNC milling programmer might command a higher wage than a turning operator focused on simpler cylindrical parts. These higher labor costs directly contribute to the overall expense of producing parts, particularly for milling operations that require more specialized human intervention.

Production Volume and Cycle Times

Production volume and cycle times are critical factors in determining the final cost per part. When a company produces a large quantity of identical parts, the fixed costs, like setup and programming, spread across more units. This significantly reduces the cost of each individual part. Conversely, small batches mean each part absorbs a larger share of those initial costs, making them more expensive.

Cycle time, the total time it takes to produce one part, also plays a huge role. Faster cycle times mean a machine can produce more parts in a given period, which lowers the per-part cost. For simple cylindrical parts, CNC turning often boasts very efficient cycle times. For instance, consider turning a 100 mm long shaft. With a feed rate of 0.2 mm per revolution and the spindle spinning at 800 RPM, the actual cutting time is about 37.5 seconds.

Calculating the full cycle time involves several steps:

- Total Length Calculation: This includes the job length, any tool overtravel (multiplied by the number of passes), and the tool’s approach length. For example, if a job is 200 mm long, with 5 mm overtravel for three passes, and a 10 mm approach, the total length becomes 225 mm.

- RPM Calculation: You determine Revolutions Per Minute (RPM) by using the formula: (1000 x Cutting Speed) / (3.14 x Average Diameter). If the cutting speed is 100 meters per minute and the average diameter is 50 mm, the RPM is approximately 637.

- Feed per Revolution: This value comes from multiplying the feed per tooth by the number of teeth involved. For instance, if the feed per tooth is 0.1 mm and there are 30 teeth, the feed per revolution is 3 mm.

- Cycle Time Calculation: Finally, you find the cycle time by dividing the Total Length by the product of RPM and Feed per Revolution. Using the previous examples, the Cycle Time equals 225 mm / (637 RPM x 3 mm/revolution), which is about 0.118 minutes.

CNC milling, especially for complex parts, might have longer cycle times due to the intricate tool paths and multiple operations required. However, its ability to create complex geometries in a single setup can still make it more cost-effective than trying to achieve the same complexity with multiple turning operations or other manufacturing methods. The optimal choice always balances production volume, part complexity, and the efficiency of each machining process.

When Each Process Becomes More Cost-Effective

Cost-Effectiveness for Simple Cylindrical Parts

For simple cylindrical parts, CNC turning often becomes the most cost-effective choice. This process excels at making components like shafts, pins, and bushings. CNC turning is a faster process. It produces large quantities of these cylindrical components at high speeds. The material continuously rotates while the tool removes material in a single, smooth operation. This leads to tighter tolerances and better roundness. For example, consider an industrial shaft made from stainless steel.

| Scenario | Machining | Material | Volume | Approx. Cost/Part |

|---|---|---|---|---|

| Industrial Shaft | Lathe | Stainless steel | 2000 | $5.20 |

This example shows how turning keeps costs low for high-volume, simple parts.

Cost-Effectiveness for Complex Geometries

CNC milling truly shines when you need complex, non-symmetrical parts. It offers greater versatility. Milling machines can create intricate shapes, pockets, and features that turning cannot. If a part has many angles, curves, or internal features, milling is usually the better and more cost-effective option. While milling might have higher initial setup costs, its ability to produce complex geometries in one setup often saves money compared to trying to achieve the same results with multiple operations or different machines.

Impact of Production Volume on Cost

Production volume significantly influences which process is more cost-effective. For high-volume production, CNC turning often wins. It quickly makes many identical cylindrical parts. The fixed costs, like setup and programming, spread across a large number of units. This makes each part very inexpensive.

| Feature | CNC Milling | CNC Turning |

|---|---|---|

| Quantity of Parts | Low to medium volume production | High volume production |

CNC milling is more suitable for low to medium volume production. It handles unique or custom parts well. For smaller batches, the higher setup costs of milling are more acceptable because the part’s complexity justifies the investment. When you make many parts, turning’s speed and efficiency drive down the per-unit cost.

Key Cost Drivers in CNC Machining

Part Geometry and Design Complexity

The shape of a part significantly drives its machining cost. Complex part geometries make machining harder. They prolong the manufacturing cycle and increase expenses. Machining intricate features can slow down the process. Sometimes, parts even get discarded if machining difficulties arise. Intricate tooling or multiple operations can also reduce machining efficiency. This might lead to part rejection. Designs with features like holes, cutouts, fine details, and tight tolerances need slower machining speeds. This ensures accuracy but increases machining time. Such designs often require frequent tool changes or specialized tools. They also need more sophisticated setups or custom fixtures. Programming for complex designs is more involved and takes more time. This demands higher skill from programmers. Components needing multi-axis machining involve longer setup and toolpath programming times. This leads to higher labor and machine usage costs. Simplifying a design can directly reduce its cost.

Required Surface Finish and Tolerances

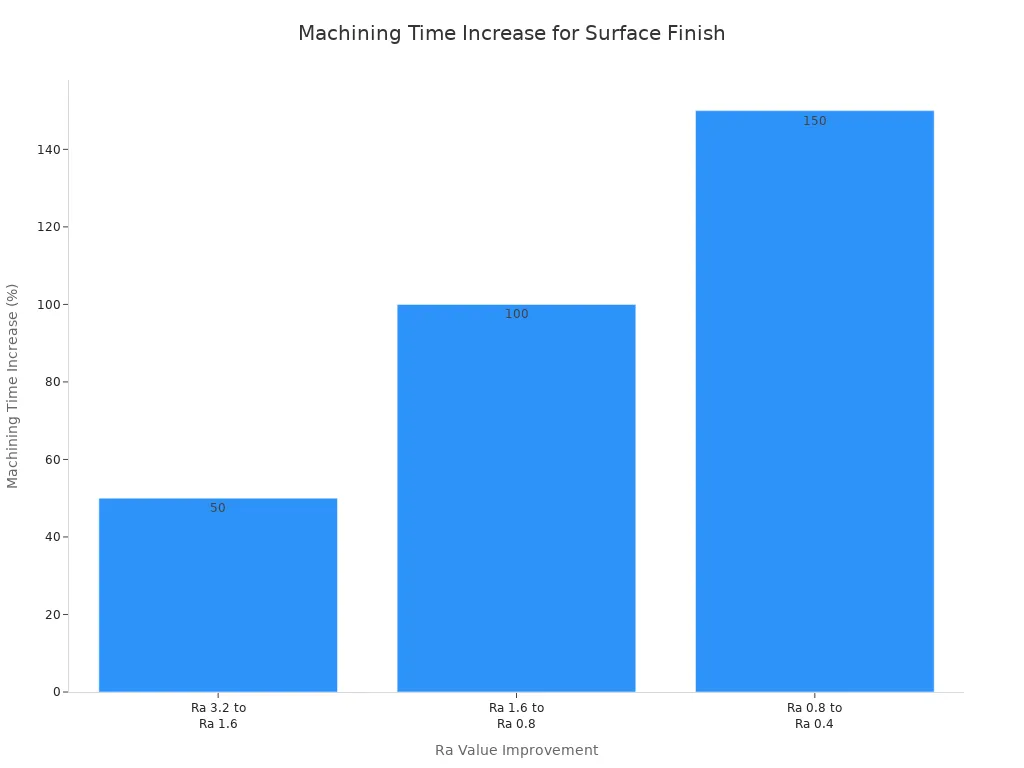

The desired surface finish and how tight the tolerances are also greatly affect costs. Achieving a smoother surface or very precise dimensions takes more time and effort. You might think a slightly better finish costs a little more, but it often increases exponentially. For example, improving a surface from Ra 3.2 to Ra 1.6 can increase machining time by 50%. Going from Ra 1.6 to Ra 0.8 doubles the machining time. And improving from Ra 0.8 to Ra 0.4 increases it by 150%.

This means additional costs come from specialized tooling, more tool changes, and extra quality inspections. Each time you halve the Ra value, the total machining cost roughly doubles. This includes setup, tool changes, and inspection. If a part needs extensive light finishing cuts, surface grinding, polishing, and lapping, its production cost can double or even triple.

Material Type and Cost

The type of material you choose has a big impact on the overall cost. Some materials, like titanium or certain exotic alloys, are simply more expensive to buy. Beyond the raw material price, the material’s properties also affect machining costs. Harder materials wear out cutting tools much faster. This means you need to replace tools more often, increasing tooling expenses. Some materials are also harder to machine, requiring slower cutting speeds and longer cycle times. This increases machine usage costs and labor time. Material availability and supply chain stability can also cause price fluctuations. These factors all add to the final cost of your machined part.

Production Lead Times

Production lead times directly influence the overall cost of CNC machining. This refers to the total time from placing an order to receiving the finished parts. Shorter lead times often mean lower costs because they reduce inventory holding expenses and allow for quicker market response. Conversely, longer lead times can tie up capital and delay projects.

Several factors affect lead times. Part complexity plays a major role. Simple cylindrical parts, ideal for CNC turning, usually have shorter lead times. The machines can produce them quickly and efficiently. Complex parts, which often require CNC milling, demand more intricate programming and setup. This extends the time before production even begins.

Material availability also impacts lead times. If a specific material is not readily in stock, manufacturers must wait for its delivery. This adds days or even weeks to the production schedule. Post-processing steps, such as heat treatment, surface finishing, or assembly, also extend the lead time. Each additional step requires extra time and coordination.

Consider a scenario where a company needs a custom part urgently. They might pay a premium for expedited services. This includes faster shipping for materials or prioritizing their job in the production queue. Such rush orders increase the cost per part. Efficient scheduling and streamlined processes help minimize lead times. This keeps costs down and ensures timely delivery. Manufacturers constantly look for ways to optimize their workflows. They aim to reduce the time it takes to get products to customers.

Ultimately, managing production lead times effectively is crucial for cost control. It helps businesses stay competitive and meet customer demands efficiently.

Factors Influencing Costs in 2025

Advancements in Automation and Robotics

Automation and robotics are rapidly changing the landscape of CNC machining. By 2025, these advancements will significantly influence manufacturing costs. Manufacturers must strategically integrate automation to address rising unit labor costs. If these costs go unchecked, they can erode competitive advantages and long-term viability. Automation offers immediate returns, especially for repetitive and physically demanding tasks. It reduces labor expenses, improves safety, and increases throughput.

Consider Gilco Manufacturing. They implemented automated machine tending robotics and successfully halved their production time. This directly led to significant cost savings. This example shows how advancements in CNC robotics can substantially reduce labor-related expenses and improve efficiency for job shops by 2025. Machine tending automation will be essential in CNC machining to reduce labor costs and boost productivity. Traditional manual methods are often inefficient and prone to error, especially with ongoing labor shortages in manufacturing. CNC machine tending robots address this by handling repetitive tasks. This frees skilled workers for higher-value responsibilities. It also minimizes downtime and allows for greater flexibility and scalability in production, ultimately improving profitability.

Robotics-as-a-Service (RaaS) further democratizes automation. It allows companies to shift from capital expenditure to operational expenditure. Businesses can scale operations flexibly and avoid the financial burdens of depreciation. This makes advanced automation accessible to a wider range of manufacturers. It directly impacts labor-related expenses.

Software and Simulation Tools Evolution

Software and simulation tools continue to evolve at a rapid pace. These advancements will play a crucial role in managing CNC machining costs by 2025. Modern CAD/CAM software offers more sophisticated features. It allows engineers to design complex parts with greater precision and optimize tool paths more efficiently. This reduces programming time and minimizes errors before any material is cut.

Simulation tools are also becoming more powerful. They can accurately predict how a part will behave during machining. This helps identify potential issues like tool deflection or material stress. Engineers can make adjustments in a virtual environment. This saves valuable time and expensive materials that might otherwise be wasted on physical prototypes. Digital twin technology, for example, creates a virtual replica of a machine or process. It allows for real-time monitoring and predictive maintenance. This helps prevent unexpected breakdowns and extends machine lifespan. Ultimately, better software and simulation lead to fewer mistakes, faster development cycles, and more efficient production, all contributing to lower overall costs.

Material Cost Fluctuations and Supply Chains

Global supply chain disruptions have created significant challenges for the CNC machining industry. These disruptions lead to price volatility and availability issues for essential materials. Raw material shortages can occur due to global demand surges or problems at source locations. This causes price spikes and scarcity, impacting production schedules and costs.

Tariffs also contribute to unpredictable costs. For instance, US Section 301 tariffs on Chinese goods can drastically increase the cost of raw materials or finished parts. China’s reciprocal tariffs further add to this cost volatility. The EU trade landscape will also see changes by 2025-2026. This includes shifts in tariff quotas and suspensions for industrial products. The EU’s Carbon Border Adjustment Mechanism (CBAM, starting in January 2026) will increase import costs for carbon-intensive goods. This indirectly affects CNC material costs. Discussions are also ongoing about potential retaliatory duties on US steel and aluminum tariffs.

The scarcity of essential components, such as semiconductors and specialized metals, has resulted in extended lead times and increased prices for CNC machinery itself. This poses challenges for manufacturers. They struggle to maintain production schedules, manage costs, and ensure timely product delivery. For metals like aluminum, steel, and titanium, manufacturers face higher raw material costs and longer lead times. This impacts profit margins and delays production. It also increases demand for alternative materials like composites and hybrid alloys. For semiconductors, crucial for CNC controllers, manufacturers experience extended machine delivery timelines and higher CNC machine costs. This slows down expansion projects and increases capital investment requirements. It also limits the availability of advanced features, delaying technological adoption.

Energy Consumption and Efficiency

Energy consumption plays a significant role in the operating costs of CNC machines. Both turning and milling machines require substantial electrical power to run their motors, spindles, and control systems. As energy prices fluctuate and generally trend upwards, manufacturers must pay close attention to the efficiency of their equipment. Older machines often consume more energy than newer, more advanced models. This is because modern CNC machines incorporate energy-saving technologies, such as more efficient motors and intelligent power management systems.

The type of machining operation also affects energy use. High-speed machining, common in both turning and milling for faster material removal, can demand more power. However, optimizing cutting parameters can sometimes reduce overall energy consumption by shortening cycle times. For example, a machine running at peak efficiency for a shorter period might use less total energy than a less efficient machine running for a longer time. Manufacturers also consider the energy required for auxiliary systems like coolant pumps, chip conveyors, and climate control within the workshop. These elements add to the overall energy footprint. Investing in energy-efficient machines and implementing smart energy management practices can lead to substantial cost savings over the lifespan of the equipment.

Labor Skill Availability and Wages

The availability of skilled labor and the wages paid to these professionals significantly impact CNC machining costs. Finding experienced CNC operators, programmers, and maintenance technicians remains a challenge for many manufacturers. This scarcity drives up wages, directly increasing the cost of production. The Bureau of Labor Statistics (BLS) projects “solid growth” for the CNC operator occupation in the coming years. However, the BLS also estimates a more modest 2% increase in overall machinist employment over a 10-year period, from 298,000 to 303,000 between 2023 and 2033. This limited growth in the broader machinist category is largely due to technological advancements in automation and robotics. These technologies allow fewer workers to produce more output.

The demand for specialized skills, particularly for complex 5-axis milling operations or advanced programming, often commands higher hourly rates. Companies must invest in training programs to upskill their existing workforce or offer competitive wages to attract new talent. This investment in human capital becomes a critical cost factor. Furthermore, current policies, such as reshoring manufacturing efforts, are not fully factored into these BLS projections. Reshoring could potentially influence the actual job outlook by increasing domestic manufacturing demand and, consequently, the need for skilled labor. This could further intensify competition for talent and push wages higher. Therefore, managing labor costs involves a delicate balance of competitive compensation, continuous training, and strategic adoption of automation to optimize workforce efficiency.

In summary, CNC turning remains the most cost-effective option for simple, cylindrical components. It benefits from lower overheads. For intricate, non-symmetrical parts, CNC milling justifies its higher investment through unmatched versatility. The optimal choice always depends on your part’s design, the scale of production, and required precision. Looking ahead to 2025, technological advancements and market forces will continue to shape these cost dynamics.

FAQ

What makes CNC turning more cost-effective for simple parts?

CNC turning is generally more cost-effective for simple cylindrical parts. It quickly produces large quantities. This process benefits from lower setup times and efficient material use.

When does CNC milling become the better choice for cost?

CNC milling becomes more cost-effective for complex, non-symmetrical parts. It creates intricate shapes and features that turning cannot. Its versatility justifies the higher initial investment for these designs.

How does production volume impact the cost of CNC machining?

High production volumes reduce the per-part cost for both processes. Fixed costs, like setup, spread across more units. CNC turning excels in high-volume simple parts. Milling suits low-to-medium volume complex parts.

What are the biggest factors driving CNC machining costs?

Part geometry, required surface finish, material type, and production lead times are key cost drivers. Complex designs, tight tolerances, expensive materials, and urgent deadlines all increase expenses.

Post time: Dec-04-2025