Top-tier Chinese CNC machine suppliers combine advanced technology with stringent quality control. An Industrial CNC machine supplier China offers competitive pricing and exceptional customer support for reliable CNC machines. Businesses often seek an OEM CNC machine China for dependable manufacturing solutions. Identifying trustworthy partners, such as OTURN machinery, is essential for long-term operational success. Understanding how to identify trustworthy CNC suppliers in China is crucial for acquiring a quality CNC milling machine China. This ensures machine reliability.

Key Takeaways

- Chinese CNC machine suppliers offer good prices. They have advanced technology and new ideas. This makes them a good choice for many businesses.

- Reliable Chinese suppliers have a good history. They use strong quality checks and have important certifications. They also offer good help after you buy the machine.

- Top Chinese suppliers like OTURN MACHINERY and PARTMFG offer special machines. They also provide fast services and high precision for many industries.

- When you choose a supplier, check their quality papers and what other customers say. Visit their factory if you can. Also, ask about their warranty and how they will help you after you buy the machine.

Why Choose Chinese CNC Machine Suppliers?

Businesses worldwide increasingly turn to Chinese CNC machine suppliers. These suppliers offer a compelling combination of advantages. They provide cost-effective solutions, advanced manufacturing capabilities, and rapid innovation. This makes them attractive partners for various industries.

Cost-Effectiveness for CNC Machines

Chinese CNC machine suppliers offer significant cost savings. Companies can often save 30-50% compared to Western counterparts. This cost advantage applies across different levels of part complexity.

This cost-effectiveness does not compromise quality. Suppliers maintain competitive standards.

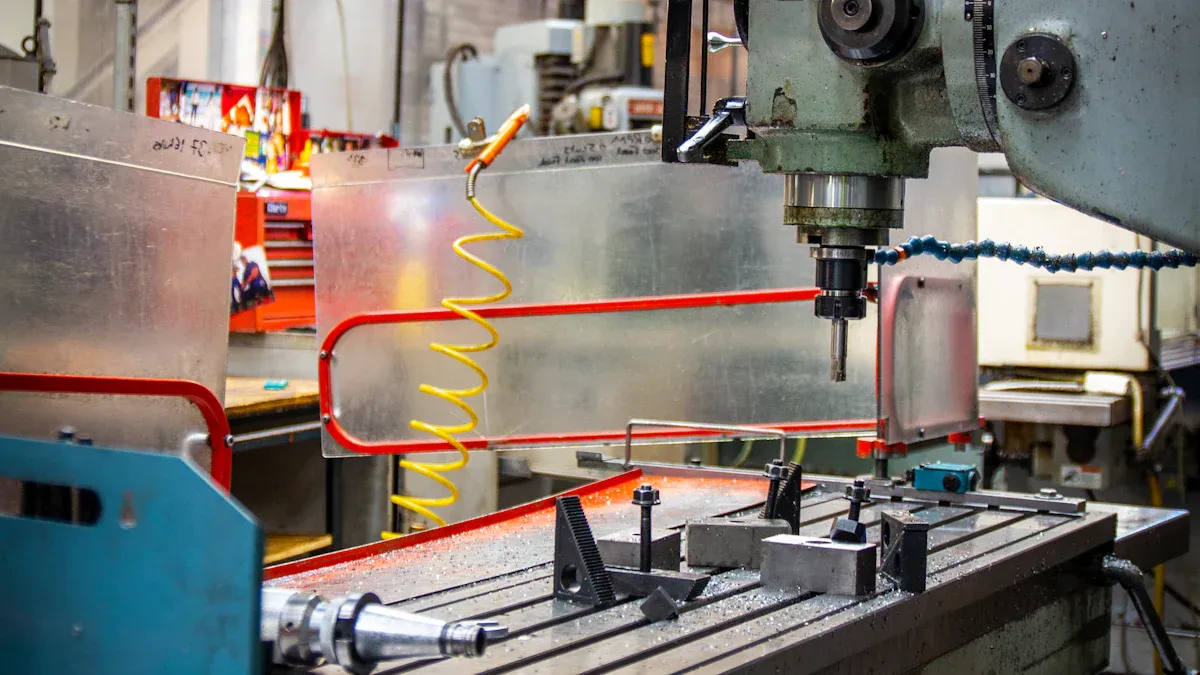

Advanced Manufacturing Capabilities for CNC Machines

Chinese manufacturers utilize state-of-the-art technologies. They integrate Industry 4.0 principles into their production. This merges physical and digital manufacturing landscapes.

- Accelerated Automation and Robotics Integration: Advanced robotics boost automation and operational efficiency. Robots perform repetitive tasks with precision.

- Smart Manufacturing and Industrial IoT Adoption: Widespread adoption of IIoT technologies is common. This includes Digital Twins for remote audits and AI for optimizing production. Blockchain ensures full lifecycle traceability.

- Expansion into High-End and Complex Applications: Manufacturers develop sophisticated machinery. This includes advanced turn-milling composite machine tools. These serve sectors like aerospace and defense.

These capabilities allow for the production of complex geometries and tight tolerances.

Rapid Innovation and Technology Adoption in CNC Machines

Chinese suppliers quickly adopt new technologies. They invest heavily in research and development. This leads to continuous improvements in their offerings.

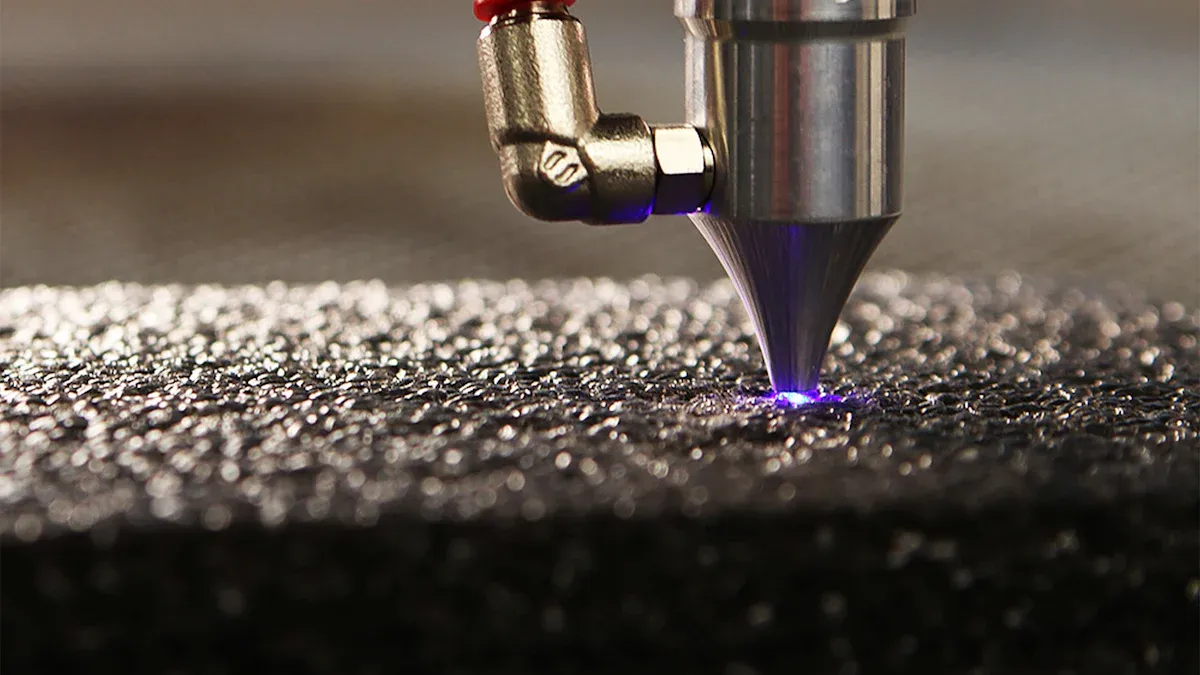

- Multi-axis CNC machines: These machines handle intricate designs with high precision.

- Automated control systems: These systems enhance efficiency and reduce human error.

- Hybrid processes: Manufacturers combine machining with additive manufacturing. This creates unique production solutions.

Companies like LEADCNC specialize in intelligent production lines. Silver CNC offers innovative zero-point positioning systems. Conprofe Technology Group focuses on rotary ultrasonic machining. These examples highlight the rapid pace of technological advancement.

Extensive Product Range and Customization Options for CNC Machines

Chinese CNC machine suppliers offer an extensive product range. They provide solutions for diverse industrial needs. Companies find CNC routers, CNC milling machines, and CNC lathe machines readily available. Laser cutters, engravers, and welders also form part of their offerings. Additionally, suppliers provide CNC plasma cutters, digital cutting machines, and automatic edgebanders. These machines cater to various applications and budgets. For example, CNC routers range from $2,580 to $150,000. CNC milling machines cost between $3,000 and $120,000. Laser cutters can range from $2,600 to $1,000,000.

Chinese CNC machining companies adapt quickly to customer requirements. They provide tailor-made solutions for prototypes or large batches. This demonstrates their flexibility for businesses of all sizes. Most Chinese CNC companies offer customization options. Users tailor their machines to specific needs and applications. Suppliers provide custom CNC machining tailored to client needs. They create customized plastic blocks for specific materials. They also offer comprehensive 3, 4, and 5-axis CNC services.

Global Supply Chain Efficiency for CNC Machines

Chinese CNC machining providers significantly enhance global supply chain efficiency. They offer high precision, often within ±0.005 mm. This meets international quality standards. Such precision is crucial for industries like aerospace, automotive, and medical devices. It ensures high-quality components. China offers extensive CNC machining services. These include milling, turning, drilling, grinding, 5-axis machining, and precision micromachining for intricate parts.

Many Chinese CNC manufacturers utilize state-of-the-art machines. These machines feature multi-axis machining, laser cutting, and automated systems. They integrate AI, IoT, and automation for improved efficiency and precision. Chinese CNC service providers handle large-scale production volumes. They suit both mass production and custom orders. Their services are highly cost-competitive due to lower labor costs and economies of scale. This offers lower pricing for high-quality services. Providers excel in customized machining and rapid prototyping. They cater to various industry-specific requirements. Chinese CNC manufacturers have significant experience with international clients. They ensure smooth delivery and fulfillment through familiarity with export regulations and international shipping. This reliable support helps businesses accelerate time-to-market.

Key Characteristics of Reliable Chinese CNC Machine Suppliers

Reliable Chinese CNC machine suppliers offer more than just competitive prices. They demonstrate specific characteristics that ensure long-term success for their clients. These traits build trust and guarantee machine performance.

Proven Track Record and Industry Experience

Experienced suppliers have a history of delivering quality products. They understand the complexities of manufacturing and client needs. A long track record shows stability and expertise in the industry. Such suppliers often handle diverse projects and solve various technical challenges. Their experience translates into better machine design and more efficient production processes.

Robust Quality Control and Certifications

Top Chinese suppliers implement strict quality control measures. They ensure every product meets high standards. ISO 9001 certification is a fundamental guarantee within the CNC machining parts industry. It shows a manufacturer provides parts meeting customer and regulatory requirements. Manufacturers without ISO 9001 are generally not ideal partners.

Reliable suppliers often hold several key certifications:

- ISO 9001 (Quality Management System): Ensures consistent quality and customer satisfaction.

- ISO 14001 (Environmental Management System): Demonstrates commitment to environmental responsibility.

- ISO 45001 (Occupational Health and Safety Management): Guarantees safe working conditions.

- ISO/TS 16949 (Automotive Quality Management): Specific for the automotive industry.

- AS9100C: Crucial for aerospace manufacturing.

- ISO 13485: Essential for the medical field.

Many companies proudly display their adherence to these standards:

| Company | Certifications |

|---|---|

| Hikam Metal Tech | ISO 9001, ISO 13485 |

| Wayken Rapid | ISO 9001 |

| 3ERP | ISO 9001, AS9100 |

Comprehensive After-Sales Support and Service

A reliable supplier provides excellent support long after the sale. This support helps users solve production problems. It also lowers the entry barrier for new users. Customers can expect perfect after-sales service and technical support from a professional team.

Typical after-sales services include:

- 24 hours online technical consultation

- Paid custom factory installation testing and training service

- 24 months warranty for the whole machine, with free spare parts for issues under normal use

- Spare parts available at cost price after 24 months

- Technical support and service for the machine’s entire lifetime

Reliable Chinese suppliers prioritize client operational continuity. They offer attention and advice. They ensure operations resume within 24 to 48 hours after a fault report. They repair the problem first. Then, they evaluate if it falls under warranty or requires an extra cost.

Transparent Communication and Business Practices

Reliable Chinese suppliers prioritize clear and honest communication. They provide detailed quotations and specifications. This transparency helps avoid misunderstandings and builds trust. Ethical business practices ensure fair dealings and long-term partnerships. Suppliers respond promptly to inquiries and offer clear explanations. They maintain open lines of communication throughout the entire process, from initial contact to after-sales support. This commitment to transparency fosters strong relationships with international clients.

Strong Research and Development Investment

Leading Chinese suppliers invest heavily in research and development. This commitment ensures they offer cutting-edge technology and innovative solutions. Their R&D efforts focus on several key areas:

- Advanced Technologies: They increasingly adopt AI and Machine Learning for predictive maintenance and process optimization. They also deploy 5G and IoT for connected manufacturing ecosystems.

- Machine Capabilities: Suppliers continue to expand multi-axis and hybrid systems for complex geometries. They also develop modular and flexible platforms for diverse applications.

- Component Localization: There is a growing emphasis on localized R&D for core components and software, including high-end controllers.

- Sustainability: They develop energy-efficient and environmentally friendly solutions, focusing on green manufacturing and designs.

- Process Optimization: Integration of digital twins and simulation technologies helps optimize manufacturing processes.

- New Applications: They expand into new application areas like medical and additive manufacturing, and adopt advanced materials processing capabilities.

These investments allow suppliers to offer advanced and reliable machinery. They also ensure continuous improvement and adaptation to evolving industry needs.

Top Chinese CNC Machine Suppliers for Precision and Performance

Businesses seeking high-quality and reliable CNC solutions often look to leading Chinese manufacturers. These suppliers combine advanced technology with robust production capabilities. They deliver precision and performance across various industrial applications.

OTURN MACHINERY: Specialization in Industrial-Specific CNC Machines

OTURN MACHINERY stands out as a reliable manufacturer of special purpose machines. The company focuses on the research and development of high-quality, high-efficiency industrial-specific machines. They also design complete production line solutions for customers. OTURN MACHINERY serves diverse sectors. Their machines and production lines cater to various industrial valve, pipe fitting, flange, construction machinery parts, energy, shipping, and mold industries.

OTURN MACHINERY’s specialization extends to critical applications. They manufacture components for aerospace, including turbine blades, jet engine parts, and spacecraft components. In the automotive sector, they craft complex parts such as transmission housings and engine components. They also produce large-scale components and structures for construction and ships. For molds and dies, OTURN MACHINERY achieves intricate details and tight tolerances. They also support the energy sector, manufacturing components for oil and gas, wind power, and other related industries. Their expertise also covers general machining, handling a wide range of turning applications from prototypes to large-scale production.

PARTMFG: Technological Advantages and Rapid Turnaround CNC Machining

PARTMFG offers significant technological advantages in CNC machining services. They simplify complex geometries with multi-axis setups. This approach handles intricate forms with fewer operations. They achieve ±0.005mm tolerance for aerospace turbine blades. This also leads to 30% faster mold production for automotive parts. PARTMFG’s CNC mills consistently hold tolerances of ±0.002mm. They easily achieve ±0.001mm for medical implants. Optical components see 50% less post-processing due to this extreme precision.

The company prioritizes speed and efficiency. Multi-tool spindles and high-speed machining reduce cycle times. Automation cuts setup times by up to 40%. Advanced cutting strategies enable 60% faster material removal. PARTMFG demonstrates material versatility. They work with materials from aluminum to titanium, plastics, and composites. They offer three times faster cutting speeds with modern aluminum tooling. Optimized cooling paths extend titanium tool life by 50%. This leads to cost optimization, especially for high-volume runs. Batches of 10,000 or more parts lead to up to 35% cost savings. Adaptive toolpaths result in 25% less material waste. PARTMFG also offers enhanced precision with better control over tool paths. This leads to higher accuracy and reduced errors. They machine highly complex parts with intricate shapes and angles. Their processes ensure consistent quality across high-volume production. Machined parts adhere to high quality standards, including ISO 2768, ISO 9001, and AS9100.

PARTMFG also provides rapid turnaround times for CNC machining projects. They deliver prototypes in one to two weeks. Production runs typically take three weeks. They also offer emergency and rush services for urgent needs. For quality prototyping parts, customers can expect delivery in three to nine days. Rapid injection molding projects take two to five weeks. More complex parts or those with special features may require longer. Shipping via air freight from China to Europe or North America takes only a few days.

Blue Elephant and Omni CNC: Reputable CNC Machine Manufacturers

Blue Elephant CNC and Omni CNC are well-known manufacturers in the Chinese CNC industry. Both companies offer a wide array of CNC solutions.

Blue Elephant CNC’s primary product lines include:

- Woodworking engraving machines

- Stone engraving machines

- Metal engraving machines

- Laser cutting machines

- Plasma cutting machines

- Customized furniture production lines

- CNC cutting series

Omni CNC also offers a comprehensive range of products. They are a leading manufacturer of 3-axis, 4-axis, and 5-axis CNC routers. Their main products encompass:

- Router CNC

- CNC Wood Router

- CNC Plasma Cutting Machine

- CNC Laser Machine

- Engraving Machine

- Woodworking CNC Router

- Wood CNC Router

- Laser Engraving Machine

- Digital cutting machines

- Water jet cutting machines

These companies provide reliable and versatile equipment for various industries.

XYZ-TECH: Diverse Product Range in CNC Machinery

XYZ-TECH offers a comprehensive and diverse product range in CNC machinery. This supplier caters to various industrial needs, providing solutions for different manufacturing processes. Their offerings typically include a wide array of CNC routers, which serve woodworking, advertising, and mold-making industries. They also supply precision CNC milling machines, essential for metalworking and complex part fabrication. Furthermore, XYZ-TECH provides CNC lathe machines, crucial for turning operations and cylindrical component production.

The company often extends its product line to include specialized equipment. This may involve laser cutting and engraving machines for intricate designs on various materials. They also offer plasma cutting machines for heavy-duty metal fabrication. XYZ-TECH focuses on delivering versatile and reliable equipment. Their diverse portfolio allows customers to find suitable machinery for both general manufacturing and highly specialized applications. This broad selection makes XYZ-TECH a significant player in the Chinese CNC machinery market.

Shenyang Machine Tool and Zhejiang Headman: Technological Leadership in CNC Machines

Shenyang Machine Tool (SMTCL) and Zhejiang Headman represent technological leadership within the Chinese CNC industry. SMTCL, as one of the world’s largest machine tool manufacturers, consistently pushes the boundaries of innovation. They specialize in developing advanced CNC machine tools, including sophisticated multi-axis machining centers and high-precision grinding machines. Their focus lies in providing solutions for high-end manufacturing sectors such as aerospace, automotive, and heavy equipment. SMTCL invests heavily in research and development, integrating smart manufacturing technologies and automation into their products. This commitment ensures their machines deliver exceptional accuracy, efficiency, and reliability.

Zhejiang Headman also demonstrates strong technological prowess, particularly in specialized CNC equipment. They often focus on specific niches, developing highly efficient and precise machines tailored to particular industrial demands. Their leadership stems from continuous innovation in machine design, control systems, and material processing capabilities. Both companies contribute significantly to China’s reputation for producing technologically advanced and high-performance CNC solutions. They set benchmarks for quality and innovation in the global machine tool market.

3ERP: Trusted ISO-Certified CNC Machining Manufacturer

3ERP has established itself as a trusted ISO-certified CNC machining manufacturer. The company provides high-quality manufacturing services, specializing in rapid prototyping and low-volume production. They offer a wide range of CNC machining capabilities, including milling, turning, and drilling, for various materials such as plastics and metals. 3ERP’s commitment to quality is evident through its certifications. 3ERP is an ISO 9001:2015-certified provider for its CNC machining manufacturing processes. This certification indicates adherence to industry standards for quality management, assuring clients of consistent quality and reliable processes.

Clients trust 3ERP for its precision, efficiency, and ability to handle complex projects. They utilize advanced CNC equipment and employ skilled technicians to ensure every component meets stringent specifications. Their services support industries requiring high accuracy and quick turnaround times, such as medical devices, aerospace, and consumer electronics. 3ERP’s dedication to quality management and customer satisfaction reinforces its position as a reliable partner in the CNC machining sector.

TAICNC: Affordable and Reliable Metalworking CNC Machines

TAICNC provides reliable and precise metalworking machines. The company offers affordable solutions with optimum performance. Their machines meet the demands of various industrial applications. TAICNC focuses on delivering value without compromising quality.

TAICNC offers a diverse range of machines designed to enhance productivity and precision. Their mainstream product series include:

- Vertical machining center series

- Horizontal machining center series

- Double column machining center series

- CNC tapping center series

- CNC turning center series

These machines cater to different manufacturing needs, from intricate part production to heavy-duty machining. Customers consistently praise TAICNC’s commitment to quality. For example, Latek Ltd. has used TAICNC’s Vertical Machining Center products for over six years. They consider these machines the gold standard for heavy machinery.

We at Latek Ltd. have been using CNC Vertical Machining Center products for over 6 years. We note that their machines are considered the gold standard for heavy machinery. TAICNC Machines specializes in metalworking machinery and cutting tools. The company offers affordable CNC machines with optimum performance and reliability. We will continue to work with them.

TAICNC emphasizes cost-effective solutions. They provide high-performance machines at competitive prices. The company adheres to global quality standards. They hold ISO 9001 and CE Marking certifications. These certifications ensure reliability and safety for all their products. TAICNC’s offerings include Vertical Machining Centers (VMCs), CNC Lathes, 5-Axis Machines, and CNC Milling Machines. They also provide customizable solutions to meet specific client requirements.

Evaluating CNC Machine Suppliers: What to Look For

Businesses must carefully evaluate CNC machine suppliers. This ensures they choose reliable partners. Several key factors guide this assessment.

Quality Certifications and Standards Compliance

Suppliers must demonstrate adherence to strict quality standards. ISO 9001 is an international standard for quality management systems. It ensures consistent, high-quality output. AS9100 builds on ISO 9001 for the aerospace sector. It emphasizes risk management and product integrity. ISO 13485 outlines strict controls for medical device manufacturing. NADCAP accredits special processes critical to aerospace and defense.

Beyond system certifications, individual competencies matter. NIMS CNC Operators Certification validates essential skills. These include blueprint reading and machine setup. Programming certifications, like Mastercam, confirm expertise in toolpath creation. Machine-specific certifications offer specialized training. Smart Automation Certification Alliance (SACA) certification attests to advanced skills in robotics. ITAR compliance is essential for defense-related projects. It ensures secure handling of sensitive designs.

Customer Reviews and Testimonials

Customer reviews offer valuable insights into a supplier’s performance. Roderick MasonVI praised Wattsan’s machines as reliable and versatile. He highlighted their user-friendly interface. Truman Reinger GB purchased a Wattsan 1290 laser machine. He commended the professional service and fast delivery.

Platforms like Trustpilot help buyers find reliable feedback. Trustpilot allows anyone to write a review. It champions verified reviews when companies invite customers. The platform actively combats fake reviews. It ensures the latest reviews are shown. Trustpilot encourages constructive feedback. It also advocates against bias.

Factory Audits and Site Visits

Conducting a factory audit or site visit is crucial. This allows direct assessment of a supplier’s operations. Evaluate foundational business risk. This includes financial stability and QMS certifications. Assess technical and engineering capability. Look at equipment, maintenance practices, and precision inspection tools. Verify the “living” quality system. Ensure process controls and traceability are actively used. Assess digital maturity. Check their use of ERP/MES systems. Finally, evaluate organizational resilience and partnership potential. Look at their talent pipeline and communication practices.

Warranty and Service Level Agreements for CNC Machines

Reliable suppliers offer clear warranty terms and service level agreements. These agreements protect buyers and ensure machine uptime. A typical warranty period often lasts 13 months after the Bill of Lading date. During this time, suppliers provide free replacement parts for quality issues. This excludes problems caused by human error or improper operation. Most CNC machines come with a warranty period ranging from one to three years. Some manufacturers also offer extended warranty options for longer coverage. Warranty terms can vary significantly. Some cover only parts, while others include labor or offer comprehensive coverage. For outsourced CNC machining, typical warranty periods range from 6 to 12 months. These cover machining defects or premature failures.

Suppliers also provide quick technical support. Specialists are often available seven days a week, 24 hours a day. They deliver solutions through platforms like WhatsApp or WeChat, using video and written instructions. Overseas commissioning and installation services are available, usually for a fee. Buyers can contact the salesperson for cost details. Service Level Agreements (SLAs) define expected performance. A minimum of 95% On-Time Delivery (OTD) is an industry standard. Reliable partners often exceed 97%. Capability indices (Cp/Cpk) should be ≥1.33 for standard parts and ≥1.67 for safety-critical components. Contracts should limit defect levels to less than 500 Parts Per Million (PPM) for general industry. For high-reliability sectors, this limit is less than 100 PPM.

Spare Parts Availability and Technical Support

The availability of spare parts and quick technical support are crucial for machine longevity. Buyers must confirm that critical spare parts are stocked locally. Alternatively, suppliers should ship them quickly. Response times for technical support vary by manufacturer. Reliable suppliers provide structured remote support and clear troubleshooting workflows. They also ensure regional spare-part availability. Buyers should verify response time commitments. They also need to check spare part lists and lead times for critical components. This verification should happen as a technical requirement before purchase. Some suppliers offer established Service Level Agreements (SLAs) for different support tiers. These tiers might include response times of 24, 48, or 72 hours. This ensures timely assistance and minimizes downtime.

Navigating the CNC Machine Purchase Process

Purchasing a CNC machine requires careful planning and execution. Buyers must navigate several critical steps. This ensures a successful acquisition and long-term operational efficiency.

Requesting Detailed Quotations and Specifications

Requesting detailed quotations is a crucial first step. A comprehensive quote provides transparency and prevents future misunderstandings. It should include a detailed job analysis. This analysis understands material type, dimensions, tolerances, and surface finish requirements. It also assesses part complexity, machining time, and tooling needs. Accurate calculation of raw material costs, including waste, is essential.

The quotation must also cover resource allocation. This includes machine availability, specific tooling/fixture needs, and estimated labor costs. Labor costs factor in skill level, setup, operation, and inspection time. Tooling and consumables, such as cutting fluids and wear and tear, also contribute to the cost. Furthermore, the quote should detail scheduling and planning. This involves realistic lead times, a detailed production plan, and buffer time for unexpected challenges. Specific details like machine setup fees, tooling costs, design complexity, required tolerances, and surface finishes significantly impact the overall price.

Understanding Payment Terms and Shipping Logistics

Understanding payment terms and shipping logistics is vital for a smooth transaction. Most Chinese suppliers require an upfront deposit, typically 30-50% of the total cost. Buyers then pay the remaining balance upon completion or before shipment. Common payment methods include bank transfers (T/T) or Letters of Credit (L/C) for larger orders.

Shipping logistics also demand attention. Buyers must clarify Incoterms, such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight). These terms define responsibilities for costs and risks during transit. FOB means the buyer assumes costs and risks once the machine loads onto the ship. CIF means the seller covers costs and insurance until the machine reaches the destination port. Buyers should also discuss estimated delivery times and customs clearance procedures.

Importance of Pre-Shipment Inspections for CNC Machines

Pre-shipment inspections are a critical quality control measure. They ensure the machine meets all agreed-upon specifications before leaving the factory. An independent third-party inspector can conduct this inspection. They verify machine functionality, accuracy, and adherence to quality standards. This includes checking components, electrical systems, and safety features.

The inspection also confirms proper packaging for international transport. It identifies any potential defects or discrepancies early. Addressing issues before shipment saves significant time and cost. It prevents receiving a faulty or damaged machine. This proactive approach safeguards the investment and ensures the machine arrives ready for operation.

Installation and Training Support for CNC Machines

After purchasing a machine, proper installation and comprehensive training are crucial. Reputable suppliers offer on-site installation services. Their technicians set up the equipment, calibrate it, and perform initial tests. This ensures the machine operates correctly from the start. They also verify all safety features function as intended.

Suppliers provide thorough training programs for operators and maintenance staff. These programs cover machine operation, programming, and routine maintenance. They teach users how to troubleshoot common issues. Effective training minimizes downtime and maximizes machine efficiency. It also helps operators use the equipment safely and effectively. This support ensures buyers quickly integrate new machinery into their production lines.

Building Long-Term Supplier Relationships

Establishing long-term relationships with suppliers offers significant advantages. These partnerships go beyond single transactions. They create a foundation for mutual growth and stability.

| Benefit | Description |

|---|---|

| Cost Savings | Long-term agreements often include favorable pricing structures, bulk discounts, and opportunities for value engineering, leading to significant cost reductions over time. |

| Improved Quality | Consistent collaboration allows for better understanding of quality requirements, implementation of continuous improvement processes, and reduced defects. |

| Enhanced Efficiency | Streamlined communication, established processes, and a deeper understanding of each other’s operations lead to faster turnaround times and increased productivity. |

| Risk Mitigation | A stable partnership reduces supply chain disruptions, ensures consistent material availability, and provides a reliable source for critical components. |

| Innovation and Growth | Collaborative efforts can lead to joint research and development, new product introductions, and shared market opportunities, fostering mutual growth. |

| Strategic Alignment | Long-term partners are more likely to align on strategic goals, invest in compatible technologies, and work together to achieve long-term business objectives. |

| Predictability | Long-term agreements provide stability and predictability in pricing, delivery schedules, and product availability, which is crucial for planning and budgeting. |

| Reduced Administrative Burden | Established relationships and processes minimize the need for frequent contract negotiations and supplier vetting, freeing up resources. |

| Access to Expertise | Partners can leverage each other’s specialized knowledge, technical skills, and industry insights to solve complex challenges and drive innovation. |

| Stronger Relationships | Over time, these partnerships build trust, foster open communication, and create a foundation for mutual support and problem-solving. |

The Importance of Long-Term Partnerships in Aerospace Contract Manufacturing with the right supplier help ensure continuity and stability. Having a supplier that is familiar with their customers technical requirements, a supplier that has technical knowledge and is aligned with manufacturing and quality standards, are more likely to deliver consistent quality that meets required deliveries. Strong partnerships produce familiarity that can go beyond just product knowledge. It can develop into an understanding of their customers business, better anticipating needs and adjust their capabilities accordingly. It creates a more resilient supply chain.

These relationships foster better communication and alignment on quality standards. They also drive continuous improvement initiatives. Suppliers often invest more in training, infrastructure, and certification for long-term partners. This commitment ensures continuity and stability in the supply chain. It also helps suppliers understand customer business needs, allowing them to anticipate requirements and adjust capabilities. This creates a more resilient supply chain for all parties involved.

Selecting the right Chinese CNC machine supplier is a strategic investment for long-term success. Businesses must prioritize a balance of quality, cost-effectiveness, and reliable support for their CNC machines. Thorough due diligence ensures a successful partnership and dependable machinery. This careful approach leads to optimal operational efficiency and sustained growth in manufacturing endeavors.

FAQ

How can businesses ensure quality from Chinese CNC machine suppliers?

Businesses ensure quality by checking certifications like ISO 9001. They conduct factory audits and site visits. Reviewing customer testimonials and verifying robust quality control processes also helps. Pre-shipment inspections are crucial for final verification.

What are the typical payment terms for Chinese CNC machines?

Most Chinese suppliers require an upfront deposit, usually 30-50% of the total cost. Buyers pay the remaining balance upon completion or before shipment. Common payment methods include bank transfers (T/T) or Letters of Credit (L/C) for larger orders.

How important is after-sales support from Chinese CNC machine suppliers?

After-sales support is very important. It ensures machine uptime and helps solve production problems. Reliable suppliers offer 24/7 technical consultation, warranty services, and spare parts availability. This support minimizes downtime and maximizes operational efficiency.

Can Chinese CNC machine suppliers offer customization?

Yes, many Chinese CNC machine suppliers offer extensive customization options. They tailor machines to specific client needs and applications. This includes custom designs for prototypes or large batches. Suppliers provide solutions for various materials and complex geometries.

Post time: Jan-12-2026