Our CNC Turning Center excels in complex part manufacturing, achieving extreme precision through simultaneous 5-Axis Machining. These advanced machines drastically cut down on setups and significantly improve both surface finish and geometric accuracy. This capability is essential for Precision Machining, directly tackling intricate geometries and tight tolerances that prove challenging for traditional 3-axis or 4-axis machines. The market for these sophisticated CNC Turning Centers is experiencing strong growth, with experts forecasting the 5-axis CNC machine market to grow at a Compound Annual Growth Rate (CAGR) of approximately 5.5% from 2025 to 2035. Manufacturers are increasingly adopting Customized CNC Turning Machining Solutions, frequently incorporating a High Efficiency CNC Lathe with ATC, to meet stringent production demands.

Key Takeaways

- A 5-axis CNC machine can move its tools in more ways than a 3-axis machine. This helps it make very complex parts in one go.

- These machines are very good for making parts for airplanes, medical devices, cars, and energy equipment. These parts need to be super exact.

- Using a 5-axis CNC machine saves time and money. It does this by doing many steps at once and making fewer mistakes.

- 5-axis CNC machines can work with many different materials. This includes metals, plastics, and special strong materials.

The 5-Axis Advantage in CNC Turning Centers

Enhanced Movement Beyond 3-Axis

A 3-axis machine moves its cutting tool along three linear paths: X, Y, and Z. The machine keeps the workpiece fixed during operation. In contrast, a 5-axis machine introduces two additional rotational axes, typically designated A and B or B and C. These extra axes allow the tool or the workpiece to tilt and rotate, significantly expanding machining possibilities. This table highlights the fundamental kinematic differences:

| Attribute | 3-Axis | 5-Axis |

|---|---|---|

| Linear Motion | X, Y, Z | X, Y, Z |

| Rotational Motion | None | A/B or B/C (two additional axes) |

| Tool/Workpiece Movement | Tool moves, workpiece stationary | Tool or workpiece can tilt and rotate |

| Machining Capabilities | Flatness, parallelism, positional accuracy, square pockets, planar faces | Angled ports, undercuts, compound tapers, complex contours, accessing more faces in one setup |

These additional axes overcome many geometry restrictions inherent in 3-axis machining. A 5-axis machine can reach areas of the workpiece and make complex cuts that a 3-axis machine cannot. For example, 3+2-axis machining tilts the cutting tool or workpiece into position. This allows machining multiple sides of a part without manual repositioning. This reduces the need for manual intervention, cutting down cycle time and lowering production costs. It also allows the use of shorter, more rigid cutting tools, improving tool stability and resulting in better dimensional accuracy and surface finish.

Simultaneous 5-axis machining moves the cutting tools dynamically through all five axes. This allows continuous movement and rotation during cuts. This proves especially valuable for parts with curved surfaces, undercuts, or complex contours. The ability to approach the workpiece from more angles without repositioning reduces the risk of misalignment and human error. This leads to precise and consistent cuts. Manufacturers can machine complex parts like turbines and combustion chambers as single pieces, reducing assembly steps and potential failure points. Operators can work on multiple faces of a part in a single setup, decreasing setup time and human intervention. This leads to faster production. This unparalleled versatility allows for the production of intricate geometries, undercuts, and compound angles challenging or impossible with 3-axis machining.

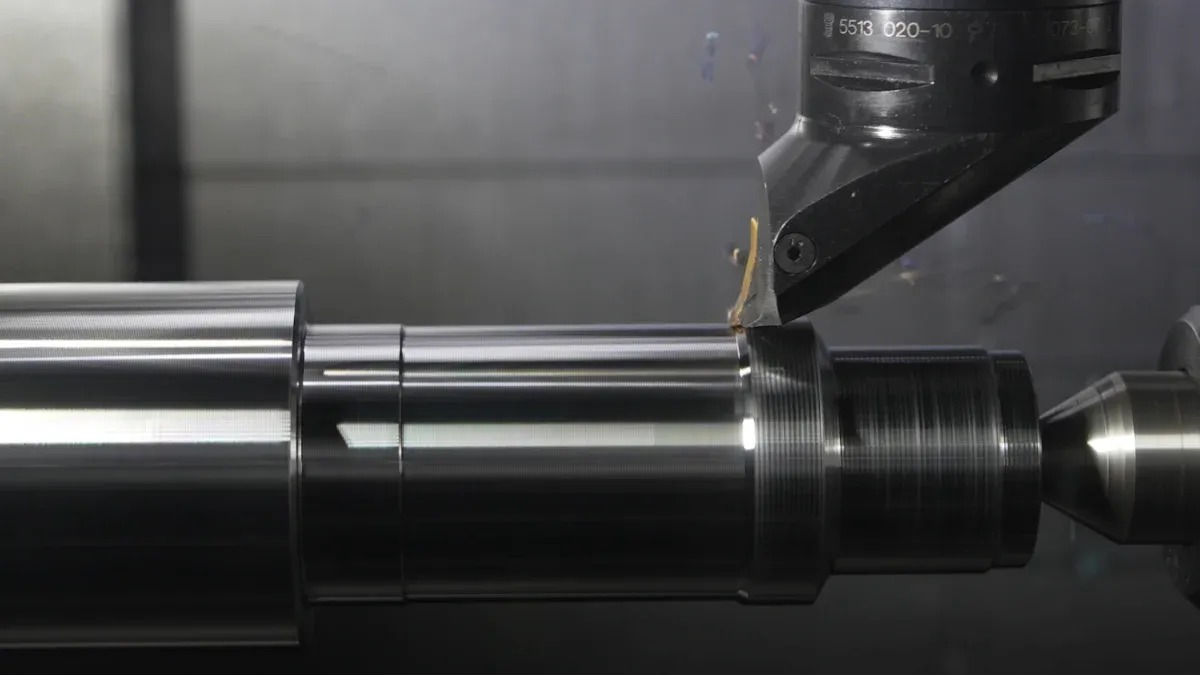

Integrated Turning and Milling Capabilities

A 5-axis CNC Turning Center often combines turning and milling operations into a single machine. These mill-turn machines merge the high productivity of CNC lathes with the geometric accuracy of CNC milling. This integration offers several technical advantages. Mill-turn machines allow simultaneous milling and turning operations, such as creating a groove with a milling tool while a turning tool shapes a cylinder. This leads to faster completion of complex parts, increasing efficiency and saving time. They also offer enhanced flexibility, performing multiple operations concurrently and creating more intricate parts in fewer steps. By performing more operations simultaneously, mill-turn machines achieve higher accuracy and precision in manufactured parts. The use of multiple tools and axes further improves part accuracy. This combination provides a wider range of capabilities, facilitating the creation of more complex parts, especially those with intricate shapes or features. Compared to dedicated 5-axis milling machines, a broader range of personnel can often operate mill-turn machines, reducing training costs and boosting productivity.

This integrated approach suits various complex parts. These include aerospace components like turbine blades and intake guide vanes, which demand high precision. Medical implant and device parts, with their intricate surfaces and small components, also benefit greatly. The automotive industry uses them for engine blocks and cylinder heads, requiring high-precision machining of complex surfaces. High-end molds, including injection and die-casting molds, also require this level of precision. Furthermore, box-shaped parts with multiple holes and cavities, common in machinery, automotive, and aerospace industries, are ideal candidates. Complex curved surfaces, prevalent in aerospace, automotive, marine, and defense products such as impellers and propellers, also benefit. Special-shaped parts, often requiring multi-station mixed processing, and disc, sleeve, and plate parts with key grooves or radial holes, are also well-suited for these advanced machines.

Breakthrough Applications for 5-Axis CNC Turning Centers

Five-axis CNC turning centers revolutionize manufacturing across several high-stakes industries. These machines deliver the precision and complexity necessary for critical components. They enable advancements previously unattainable with less sophisticated machinery.

Aerospace Component Manufacturing

The aerospace industry demands the highest levels of precision and reliability. Components must withstand extreme conditions and perform flawlessly. Five-axis CNC turning centers are indispensable for producing these critical parts. They machine complex geometries like turbine blades, impellers, and structural components with exceptional accuracy. Aerospace precision machining consistently achieves tolerances of ±0.0001 inches or better. For cylindrical components, precision CNC turning achieves roundness within 0.0001 inches. Concentricity for these cylindrical parts is also maintained within 0.0002 inches. These tight tolerances ensure optimal performance and safety in aircraft and spacecraft. The ability to machine intricate features in a single setup reduces errors and improves overall part integrity.

Medical Implant and Device Production

The medical industry relies heavily on advanced manufacturing for patient safety and efficacy. Five-axis CNC turning centers are becoming the standard for creating next-generation medical devices. They move a part or cutting tool along five axes simultaneously. This enables the creation of highly complex shapes in a single setup. This process reduces the need to move parts between machines, improving accuracy and efficiency. For instance, a complex orthopedic implant with curved surfaces and deep pockets can be created with exceptional precision.

The medical industry heavily relies on 5-axis capabilities for producing:

- Customized implants

- Surgical instruments

- Dental devices

These components often feature highly contoured surfaces. They require precise manufacturing to ensure patient safety. High-quality medical implants produced by CNC machining include:

- Facial reconstruction implants

- Heart valves

- Knee and hip joint implants

- Stents

- Ventricular assist devices (VADs)

Micromachined components for medical device applications require an even higher degree of precision. These include:

- Catheters

- Parts for pacemakers

- Small implant screws

- Stents

- Systems for drug delivery

Medical implants and prosthetics significantly benefit from precision machining. Implants like hip replacements, spinal fusions, and dental implants require a perfect fit. This prevents pain, rejection, or the need for revision surgeries. Custom implants, crafted from MRI or CT scan data, improve patient comfort and long-term success. Prosthetics, with their complex joints and moving parts, demand extreme accuracy for smooth, natural movements. This leads to lighter, stronger, and more functional artificial limbs.

Automotive Industry Precision Parts

The automotive industry constantly seeks to improve vehicle performance, fuel efficiency, and safety. Five-axis CNC machining is essential for automotive components. This is particularly true in high-mix, small-lot production scenarios requiring rapid acceleration and deceleration rates. These machines produce critical parts like automotive steering knuckles and lightweight automotive components.

Five-axis CNC turning centers contribute significantly to lightweighting and performance improvements.

- Engine Components: Five-axis machining facilitates the creation of intricate geometries. This includes optimized combustion chambers and complex cooling channels. This allows for greater power density in smaller engine spaces, thereby enhancing performance.

- Suspension Parts: This technology enables the precise manufacturing of components such as control arms and knuckles. It ensures high strength and lightweight designs, which contribute to improved vehicle performance.

The increased precision of 5-axis machines maintains optimal tool-to-part orientation. This leads to tighter tolerances and improved geometric accuracy. Their ability to approach workpieces from multiple angles allows for the production of intricate shapes and undercuts. Continuous 5-axis interpolation results in smoother toolpaths and consistent chip loads. This leads to superior surface finishes. Multi-surface machining can be completed in a single setup. This reduces errors from repositioning and ensures precise machining. A 5-axis CNC Turning Center can process geometrically complex parts, including undercuts and curved surfaces. This is crucial for high-precision automotive applications.

Intricate Mold and Die Making

Mold and die making demands extreme precision and flawless surface finishes. These components form the backbone of many manufacturing processes, from plastic injection molding to metal stamping. Five-axis CNC turning centers provide the capabilities necessary to produce these intricate tools. They handle complex contours and geometries, adding two rotational axes for advanced movement and optimized tool paths. This leads to higher accuracy in the final product.

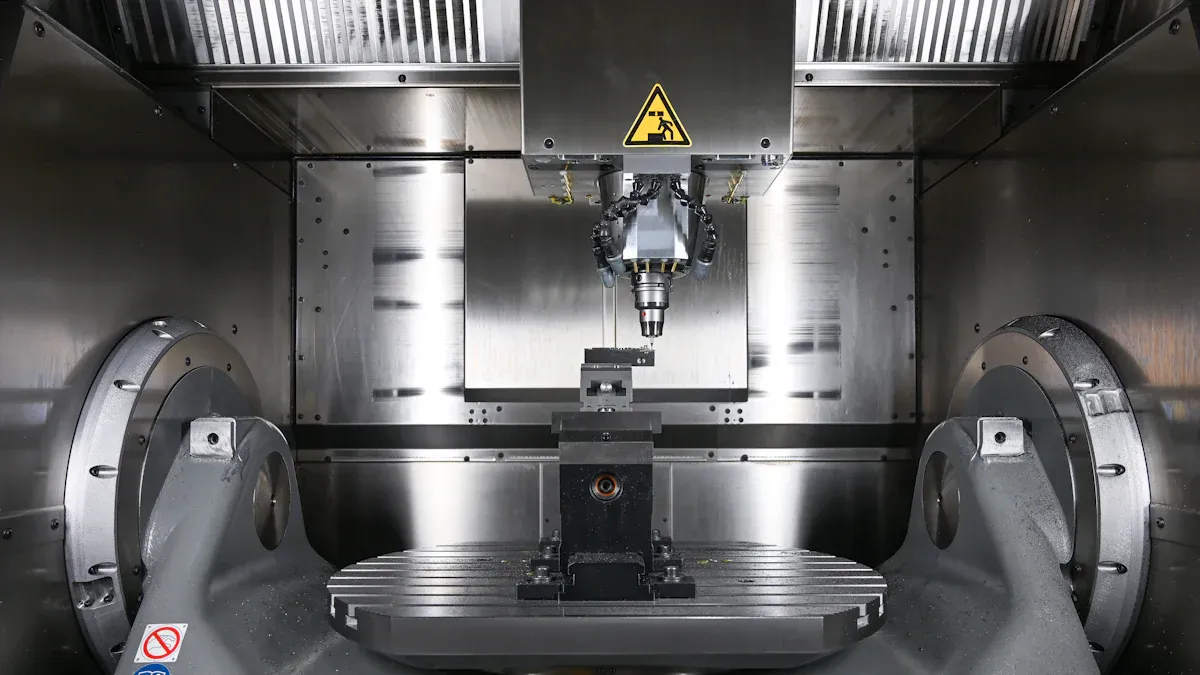

The design of these machines contributes significantly to their precision. Robust and stable construction features like optimized thermal management systems and water-cooled direct drives ensure consistent performance. Vibration-damping machine beds and flexible, highly dynamic spindles further contribute to achieving the best surface finishes and highest accuracy. Sturdy portal cast bases and hand-scraped key components ensure enduring precision, even over long machining times. This is critical for consistent high surface quality in mold and die production.

Five-axis machining also optimizes tool usage. It allows for more productive use of traditional cutters, such as ball nose end mills, by tilting the tool. This increases the effective cutting diameter, boosting metal removal rates by 40-50%, and generates better surface finishes. The technology also enables the use of barrel-shaped tools with contoured profiles for wider cutting contact. This provides equivalent or better surface finish with larger stepovers, reducing passes and minimizing blending issues. The ability to tilt the toolholder away from adjacent pocket walls allows for the use of shorter tools without collision risks. This leads to more productive machining processes and improved surface finish, especially in deep cavities where 3-axis machining would require longer, less stable tools.

Machine construction also plays a vital role. Features like constant spindle support (X and Z on the column) and full table support (Y axis under the table) provide greater structural rigidity. This permits heavier machining with less vibration, which directly impacts surface finish. High positioning accuracy (±0.000060”) achieved through core-cooled, fine-pitch ballscrews with 0.05 micron scale feedback enables precise execution of surface blends, matches, and complex geometry cuts. Spindles offering up to 30,000 rpm and thermal control ensure exacting cutting conditions over long periods, producing tight-tolerance, high-finish workpieces. Proprietary Super Geometric Intelligence (SGI.5) software mitigates factors like dwells, axis over-shoot/under-shoot, and vibration to generate higher quality surfaces. It maintains high feed rates even during abrupt directional changes, ensuring the actual toolpath is sustained at the programmed feed rate. This is crucial for smooth finishes in complex 3D contouring. Ultimately, these capabilities result in smoother, more accurate machined surfaces and less need for secondary processes like EDM and benching.

Energy Sector Component Machining

The energy sector, encompassing renewable and traditional sources, relies on robust and precisely manufactured components. These parts often operate under extreme conditions, demanding exceptional material properties and manufacturing accuracy. Five-axis machining provides the necessary precision for these critical applications.

Manufacturers utilize a variety of materials for energy sector components. These include:

- Metals: Aluminum, Stainless Steel, Titanium, Inconel & Superalloys, Copper, Brass, Nickel Alloys, Tungsten

- Plastics: Acrylic (PMMA), Nylon, Polycarbonate

- Composites: CFRP, GFRP

- Advanced Materials: Ceramics, Graphite

Each material serves specific functions within the energy industry. Aluminum is used for components benefiting from lightness and corrosion resistance, such as wind turbine parts and solar panel frames. Stainless steel finds employment for its robustness and corrosion resistance in nuclear reactors and oil and gas exploration equipment. Titanium is ideal for high-stress components in turbine blades and offshore drilling rigs due to its exceptional strength and resistance to corrosion and extreme temperatures. Copper is essential in electrical components like generators, motors, and wiring within renewable energy systems due to its excellent conductivity. Brass is used in applications requiring low friction and excellent corrosion resistance, such as valve parts and connectors. Plastics and composites are chosen for versatility and insulation properties in insulative housings and non-conductive parts. Nickel alloys are used in turbine components and exhaust systems for high-temperature resistance and durability. Tungsten is crucial in wear-resistant parts found in drilling and mining operations due to its hardness and high-temperature resistance.

Five-axis machining excels at processing these diverse materials into complex shapes. It creates components for wind turbines, oil and gas exploration equipment, nuclear reactors, and solar energy systems. The ability to machine hard-to-cut materials with high precision and complex geometries ensures optimal performance and longevity for energy infrastructure.

Key Benefits of 5-Axis CNC Turning Centers

Unparalleled Precision and Surface Finish

Five-axis CNC turning centers deliver exceptional precision and superior surface finishes. These machines achieve remarkable accuracy. For example, a Kern five-axis Evo machining center achieved positional accuracies of ±0.5 micron. This machine was sufficient to achieve ±2 microns on the workpiece. High-precision CNC machining produces complex metal components with tolerances measured in microns. Modern CNC machining achieves tolerances within ±0.001 inches, and even tighter in some applications. The speed and quality from 5-axis numerical control machines are clearly superior to any manual production methods.

Five-axis CNC machines excel at maintaining consistent surface finishes throughout the entire production process. They dynamically adjust tool angles and orientations during cutting operations. This ensures smooth transitions between different surfaces or contours. This results in exceptional surface quality. It eliminates the need for labor-intensive post-processing steps. Better tool life in 5-axis machining results from optimal cutting angles. These angles reduce tool wear and breakage. By maintaining proper cutting geometry, tools last longer and perform more consistently. This contributes to higher quality finishes and minimizes production interruptions.

Reduced Setup Times and Increased Efficiency

Five-axis CNC turning centers significantly reduce setup times and boost overall efficiency. They consolidate multiple operations into a single setup. This table illustrates the difference:

| Manufacturing Approach | Required Setups | Setup Time (hours) |

|---|---|---|

| 3-Axis Machining | 5-7 | 4-6 |

| 5-Axis Machining | 1-2 | 1-2 |

This shows a significant reduction in both the number of setups and the total setup time. For a typical medium-complexity part, 5-axis machining reduces direct labor setup costs by approximately 75%. Setup labor decreases from 2-3 hours with traditional methods to 30-45 minutes. Setup time reductions of up to 80% have been observed for complex geometries when switching from 3-axis to 5-axis processes. This improved efficiency comes from several factors:

- Improved Accuracy: It eliminates accuracy loss from tolerance stacking and variations in part loading. Parts are ‘done in one’.

- Longer Tool Life: Shorter cutting tools provide greater rigidity, leading to longer tool life.

- Increased Throughput: Higher speeds and feed rates are achieved due to improved tool rigidity and optimal part orientation.

- Reduced Work-in-Progress (WIP): Less part handling and shorter lead times contribute to reduced WIP.

Enhanced Part Complexity and Design Freedom

Five-axis CNC turning centers enable the creation of highly complex part geometries. They allow simultaneous 5-axis movement (X, Y, Z linear axes and A/C or B/C rotary axes) in perfect synchronization. This capability allows the tool to reach deep between twisted blades and into deep pockets. It maintains a consistent chip load and prevents collisions. Examples include blisks (blade integrated disks) found in jet engines. These require the tool to reach deep between twisted blades while maintaining consistent chip load. Structural spars and ribs with thin walls also benefit. The machine’s dampening characteristics prevent chatter and allow for aggressive machining strategies.

This technology significantly expands design freedom. It liberates engineers from traditional tooling constraints. This enables the creation of designs previously deemed impossible. It offers precision and repeatability at production scale. This fosters innovation by providing the freedom to create complex parts with confidence. For engineers, design freedom is crucial. Every angle, curve, and dimension is critical. While 3-axis machining is effective for simpler projects, 5-axis indexed milling unlocks new possibilities. It allows for the creation of intricate geometries and contours with ease. This pushes the boundaries of product innovation.

Cost Savings Through Optimized Production

Five-axis CNC machining significantly reduces overall project costs. It achieves this through optimized production processes. These machines reduce total project costs on complex parts by 20-40%. Single-setup accuracy is a major contributor to these savings. This eliminates positioning errors that occur when parts are repositioned multiple times. This is especially crucial for complex components and expensive materials like titanium. The result is notably lower scrap rates and a substantial decrease in material waste.

Single setups in 5-axis CNC machining reduce scrap rates to below 2%. Furthermore, AI-error correction innovations can further decrease scrap rates to less than 1%. Real-time AI adjustments to toolpaths mid-operation reduce defects by 35%. This addresses traditional risks where manual calibration errors caused 8–12% scrap rates. SmartCut AI, for instance, predicts tool wear for 0.3% scrap rates in ceramics. This table highlights the difference:

| Metric | Traditional CNC | Five-Axis + OPMT Tech |

|---|---|---|

| Scrap Rate | 6–8% | <1% |

Five-axis CNC turning centers reduce material waste and scrap rates by avoiding repeated setups and calibrations. This significantly lowers cumulative errors caused by multiple adjustments. It leads to higher machining accuracy and part consistency. This is particularly important for industries requiring high precision. It substantially decreases scrap rates resulting from secondary positioning. Optimizing nesting and toolpaths in 5-axis machining also minimizes raw material waste.

Versatility Across Materials

Five-axis CNC machines demonstrate remarkable versatility across a wide range of materials. They effectively process everything from common metals to advanced composites. This capability allows manufacturers to select the best material for specific applications. They do not face limitations from machining constraints. For example, these machines precisely cut tough alloys like Inconel and titanium. They also handle softer materials such as aluminum and brass with ease. This broad material compatibility makes them invaluable for diverse industries. A single CNC Turning Center can adapt to various production needs. This reduces the need for specialized equipment. This versatility ensures manufacturers can meet stringent material requirements for critical components. It also supports innovation in product design.

5-axis CNC turning centers represent a revolution in precision machining. They enable industries to achieve previously unattainable levels of accuracy and complexity. Their critical role in driving innovation across high-tech sectors is undeniable. These machines are essential for addressing future manufacturing challenges. They integrate advanced technologies like AI, automation, and IoT, leading to reduced production times and minimized waste. The market for these advanced machines, including the CNC Turning Center, continues to grow, underscoring their vital role in future manufacturing.

FAQ

What is the main difference between 3-axis and 5-axis CNC turning centers?

A 3-axis machine moves along X, Y, and Z linear paths. A 5-axis machine adds two rotational axes. This allows the tool or workpiece to tilt and rotate. It enables complex cuts and multi-sided machining in a single setup.

Which industries benefit most from 5-axis CNC turning centers?

Aerospace, medical, automotive, mold and die making, and the energy sector significantly benefit. These industries require extreme precision, complex geometries, and high reliability for critical components.

How do 5-axis machines improve surface finish?

Five-axis machines dynamically adjust tool angles. This ensures smooth transitions and consistent chip loads. It results in superior surface quality. They also use shorter, more rigid tools, which reduces vibration and improves finish.

Can 5-axis CNC turning centers save costs?

Yes, they reduce costs by minimizing setup times and consolidating operations into a single setup. This lowers direct labor, decreases scrap rates, and optimizes material usage. It leads to significant overall project savings.

What materials can 5-axis CNC turning centers process?

They process a wide range of materials. These include metals like aluminum, titanium, and stainless steel. They also handle plastics, composites, and advanced materials such as ceramics. This versatility supports diverse manufacturing needs.

Post time: Dec-12-2025