Vertical 5-axis CNC machining center play a vital role in precision manufacturing due to their efficient multi-axis linkage capabilities. However, once a tool magazine tool change failure occurs, it inevitably causes interruptions in the machining process, severely affecting production schedules and product quality. To ensure stable equipment operation, it is crucial to systematically analyze the causes of tool change failures and master scientific solutions.

Tool Installation and Tool Magazine Management Issues Causing Failures

Improper tool installation or poor tool magazine management are common causes of tool change failures. If the tool is not securely installed in the tool holder, it may fall off during tool change, potentially causing severe equipment damage. Tools that are overweight or oversized beyond the tool change mechanism’s capacity can also lead to tool change failures. Therefore, tool installation must strictly follow operating procedures to ensure a tight fit between the tool and holder, using a torque wrench to control clamping force and avoid failures caused by improper tightening. Regular inspection of the tool specifications and weight in the tool magazine is necessary to prevent unauthorized use. Additionally, inadequate cleaning and maintenance of the tool magazine can lead to the accumulation of iron chips, oil, and other debris in the tool holder or tool change mechanism, obstructing normal tool insertion and removal and causing mechanical jams. Regular cleaning is required to maintain internal cleanliness and ensure smooth tool changes.

Electrical Control System Failures Causing Tool Change Abnormalities

The 5-axis CNC machining center tool change process relies on the coordinated operation of sensors, relays, servo motors, and other electrical components. Electrical system failures are also significant causes of tool change abnormalities. When the tool magazine position sensor malfunctions or signal transmission lines have poor contact, the control system cannot accurately obtain tool position information, resulting in tool change errors. At this time, testing tools such as multimeters and oscilloscopes should be used to check sensor output signals, and damaged sensors should be replaced promptly. Electrical wiring connections must be inspected and any loose or broken wires repaired to ensure smooth signal transmission. Moreover, incorrect servo motor driver parameter settings or PLC program logic errors can affect tool change actions. These issues require rechecking driver parameters to ensure motor operation matches the tool change process, and reviewing and correcting PLC programs to eliminate logic errors, thereby ensuring precise and stable electrical control.

Mechanical Transmission Component Abnormalities as Primary Causes of Tool Change Failures

Mechanical transmission component abnormalities are the most common causes of tool magazine tool change failures. Key components such as the tool magazine indexing mechanism, transmission chain, and ball screw nut assembly tend to wear or loosen after long-term use. For example, wear of the positioning pins on the tool magazine indexing plate can cause inaccurate tool positioning, preventing precise tool engagement with the spindle during tool change. To address this, regular inspection of the indexing mechanism’s wear condition is necessary, with timely replacement of severely worn positioning pins, bearings, and other parts, and recalibration of the indexing plate’s positioning accuracy. If the transmission chain becomes slack or broken, the chain tension should be adjusted or the chain replaced promptly. For ball screw nut assemblies with clearance, preload adjustment or replacement of the ball screw can eliminate the gap, ensuring mechanical transmission accuracy and stability, thus fundamentally preventing tool change failures caused by mechanical issues.

Comprehensive Inspection and Precise Repair Are Key to Ensuring Stable Tool Changes

To solve tool magazine tool change failures in 5-axis CNC vertical machining center, a comprehensive inspection approach covering mechanical, electrical, hardware, and software aspects must be followed. By accurately pinpointing the root causes and implementing targeted repair measures, the normal tool change function of the tool magazine can be effectively restored, ensuring the machining center operates efficiently and stably. This approach minimizes equipment downtime, improves machining efficiency, and enhances product quality.

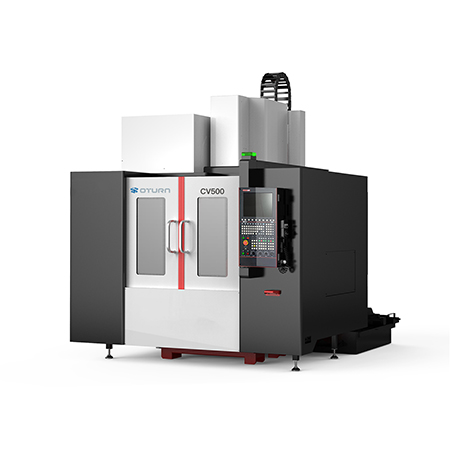

About OTUR

OTURN is committed to providing customers with advanced 5-axis machining centers and supporting solutions. With rich experience and a professional technical team, we not only supply high-quality CNC equipment but also offer comprehensive after-sales service and technical support to help customers achieve stable equipment operation and maximize production efficiency.

Post time: Jun-03-2025