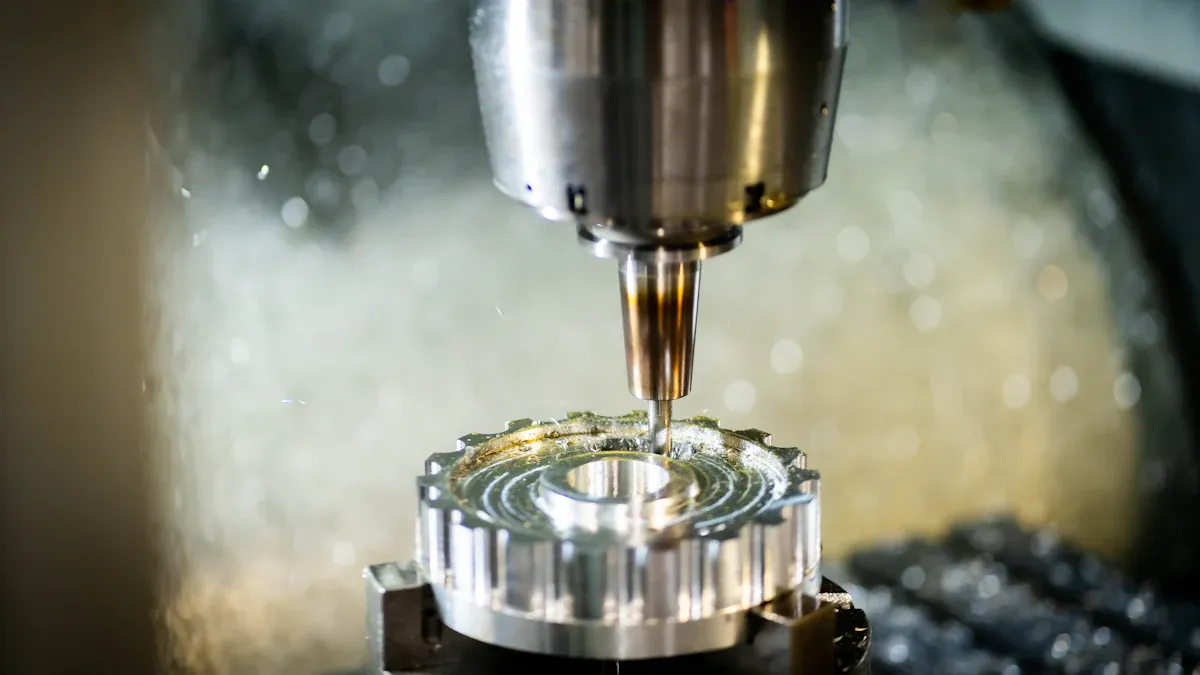

High-precision CNC machining is indispensable for complex new energy vehicle (NEV) components. This technology evolved to meet NEV demands, enabling tight tolerances and intricate geometries. A modern CNC Machining Center, featuring a 5-Axis CNC Machine and CNC Turning Center, delivers precision. An ISO 9001 Certified CNC Machine ensures quality in automotive component machining.

Key Takeaways

- High-precision CNC machining is very important for making new energy vehicle parts. It helps create complex shapes and ensures parts fit together perfectly.

- New energy vehicle parts need special care. They use light materials, need good cooling, and have complex designs. CNC machining helps meet these needs.

- Future CNC machining will use smart technology. AI and robots will make parts even better and faster. This helps make new energy vehicles more efficient.

Unique Demands of New Energy Vehicle Components

New energy vehicle (NEV) components present distinct manufacturing challenges. These components require specialized approaches due to their unique material properties and functional requirements. High-precision CNC machining directly addresses these specific demands.

Lightweighting and Advanced Materials

NEVs prioritize lightweight designs to maximize range and efficiency. Manufacturers extensively use advanced materials for this purpose. Aluminum and advanced alloys significantly reduce vehicle weight. For instance, aluminum alloys 6061 and 6063 are common for lightweight heat dissipation. Aluminum 6061 is a popular choice for battery pack housings due to its lightweight properties and good thermal performance. Carbon Fiber Reinforced Polymer (CFRP) also serves as an advanced lightweight material in NEV construction.

Critical Thermal Management Requirements

Effective thermal management is crucial for NEV performance and safety. Lithium-ion batteries, widely used in commercial electric vehicles, operate optimally between 15°C and 35°C. Maintaining a uniform temperature distribution across all battery cells is essential, ideally with a maximum surface temperature variation of no more than 5°C. This prevents malfunctions and thermal runaways. Both temperature and temperature uniformity significantly influence the performance, lifespan, and safety of energy storage devices. Higher temperatures can increase performance, but extreme heat levels can overload systems. Reliable battery thermal management systems are necessary to dissipate heat and regulate temperature. Liquid-cooled systems are ideal for electric vehicles requiring long-distance travel, larger battery packs, and high thermal loads.

Electrical Conductivity and Insulation Needs

NEV components also demand precise control over electrical conductivity and insulation. Components like busbars and connectors require high electrical conductivity to efficiently transfer power. Conversely, other parts need robust electrical insulation to prevent short circuits and ensure safety. Machining processes must maintain the integrity of these properties.

Complex Geometries and Ultra-Tight Tolerances

NEV components often feature complex geometries and require ultra-tight tolerances. Manufacturers must achieve exceptional precision for optimal performance and reliability. For example, critical components like gear shafts or motor housings often require specific tolerance levels. Aperture accuracy typically demands IT6. Cylindricity, coaxiality, and roundness often require a precision of 0.02mm. For other basic tolerances on shafts and housings, quality class A 7 is utilized.

Evolution of High-Precision CNC Machining Technologies

High-precision CNC machining has undergone significant advancements. These technological developments directly address the complex demands of new energy vehicle (NEV) components. Manufacturers now achieve unprecedented levels of accuracy, efficiency, and reliability in production.

Advanced Multi-Axis Machining Capabilities

The evolution of multi-axis machining capabilities has revolutionized NEV component manufacturing. Traditional 3-axis machines limit part complexity. Modern 5-axis and even 9-axis machines allow simultaneous movement along multiple axes. This capability enables the creation of highly intricate geometries in a single setup. It reduces the need for multiple setups and manual repositioning. This approach significantly improves part accuracy and surface finish. It also shortens production times. For NEV components, which often feature complex curves and internal structures, multi-axis machining is indispensable.

Enhanced Tooling and Cutting Strategies

Advancements in tooling and cutting strategies further boost high-precision CNC machining. Cutting tools now feature new materials, advanced coatings, and optimized geometries. These innovations allow for faster material removal rates and extended tool life. High-speed machining (HSM) and trochoidal milling are examples of advanced cutting strategies. HSM uses high spindle speeds and low radial depths of cut. This method reduces cutting forces and heat, which is crucial for machining lightweight alloys. Trochoidal milling efficiently removes large volumes of material. These strategies improve surface quality and maintain tight tolerances, even with challenging NEV materials.

Integrated Metrology and In-Process Monitoring

Integrated metrology and in-process monitoring systems have become essential for quality control. These systems embed measurement probes and sensors directly into the CNC machining process. They collect real-time data during manufacturing. This real-time feedback ensures parts meet stringent automotive tolerances. It significantly reduces delays and scrap.

Tip: Integrated metrology offers several key benefits:

- It reduces cost, engineering time, and labor.

- Information becomes available immediately at the manufacturing site. This eliminates waiting for data from a separate quality room.

- It enables closed-loop manufacturing. This drastically reduces the time and cost of getting production lines operational.

- It helps ensure the first part produced is good. This prevents costly trial and error upstream and rework downstream.

- It prevents mistakes during ongoing operations, such as incorrect tool placement leading to part damage.

These capabilities allow for immediate adjustments, ensuring consistent quality throughout the production run.

Automation and Digitalization in CNC Machining Center

Automation and digitalization are transforming the modern CNC Machining Center. Robotics and automated material handling systems streamline operations. They reduce human intervention and increase throughput. Digitalization integrates Internet of Things (IoT) devices and sensors. These devices collect concurrent data. Artificial intelligence (AI) and machine learning (ML) algorithms then analyze this data. This analysis identifies bottlenecks and optimizes workflows. It enhances overall efficiency and productivity.

Digital Twins (DTs) significantly enhance CNC machining processes. They create high-fidelity digital counterparts to manufacturing assets. These DTs continuously monitor equipment status. They analyze wear and damage. They predict performance degradation and forecast operational errors. This capability allows for early detection and mitigation of potential failures. It minimizes downtime and extends equipment lifespan. Many CNC machines are compatible with DT integration. They facilitate bidirectional data exchange through adaptable controls, built-in sensors, and standardized communication protocols like MTConnect. Embedded sensors, such as spindle speed encoders and tool position sensors, provide continuous insights into machine conditions. DTs can also replicate the performance of physical systems. They accurately simulate tool paths and milling operations. This setup enables simulation-based optimization and early anomaly detection. A condition-monitoring DT for real-time spindle health tracking, using wireless sensors, has shown accurate identification of tool wear progression. This leads to direct improvements in maintenance scheduling and tool usage efficiency within a CNC Machining Center.

Key Applications of High-Precision CNC Machining in NEV Components

High-precision CNC machining is fundamental to the production of various critical components in new energy vehicles. It ensures the performance, safety, and efficiency of these advanced vehicles. This technology addresses the unique demands of NEV manufacturing across several key areas.

Battery System Components Manufacturing

High-precision CNC machining plays a vital role in manufacturing critical battery system components. These components ensure the safety and efficiency of NEVs. Manufacturers use CNC processes for coolant channel plates, which form the main body of a cooling plate. This method is suitable for prototype development without significant mold investment. High process accuracy is also required for coolant ports. These ports are water inlets and outlets that connect cooling plates with tube line systems, ensuring rigid connections.

CNC machining produces cooling plates, which integrate into assemblies with sealed cooling surfaces. It also manufactures battery housings, including extruded aluminum frames and stamped galvanized steel lower trays. For instance, 5-axis CNC milling machines, operating with spindle speeds of 12,000 to 24,000 RPM, produce battery module mounting surfaces and interfaces to the cooling system. They achieve an accuracy of ±0.005 inches. Manufacturers process aluminum plate stock, typically 10 to 20 millimeters thick, to produce cooling plates. These plates feature channel tolerances of ±0.003 inches. Furthermore, CNC drilling and tapping prepare aluminum frame sections. These sections include mounting holes, electrical feedthrough penetrations, and thermal management fitting holes. They achieve a positional accuracy of ±0.008 inches.

Electric Motor and Drivetrain Components

High-precision CNC machining is essential for manufacturing electric motor and drivetrain components. These components include rotors, stators, and bearings. Precise manufacturing minimizes friction and energy losses. It also reduces cogging, improves torque delivery, and enhances overall motor efficiency. This precision contributes to increased range and an improved driver experience in electric vehicles.

Vertical machining is often preferred for e-motor housings, stators, and rotors. This method achieves the best surface quality and highest geometric accuracy. It utilizes gravity to support workpieces and tools. This prevents negative effects on cutting edges and maintains circular forms, especially with heavy and long tools. Chips fall away from the workpiece, ensuring a clean and damage-free process. Vertical machining offers optimal power flow, no tilting moment from tool weight, and reduced set-up and maintenance times. The efficiency of an EV’s electric motor, a core component, relies on the precise manufacturing of its rotor, stator, and bearings. Pinpoint accuracy in producing these parts directly influences both energy consumption and power delivery.

Power Electronics and Inverter Components

High-precision CNC machining is crucial for power electronics and inverter components in NEVs. These components demand precision, durability, high efficiency, thermal stability, and structural strength. They must perform in demanding environments to support clean technologies. For example, Nanjing Precision Engineering Co Ltd provides high-accuracy CNC machining services for the new energy industry. They produce custom battery enclosures, structural supports, and thermal management components. They also fabricate aluminum piping assemblies for EV battery cooling using automated CNC bending and orbital welding. This ensures efficient thermal management and space-optimized routing.

Manufacturers often use high-pressure die-casting for aluminum enclosures, followed by extensive CNC machining. Casting parameters typically involve temperatures of 640-680 °C and pressures of 40-100 megapascals. This achieves wall thicknesses of 2.5-6 mm, integrated cooling fins, and ±0.3 mm precision. Five-axis CNC machining refines these cast surfaces. It improves sealing and gasket pressure, achieving ±0.005 inches flatness over 250-500 mm. Power connectors’ bolts are fixed with ±0.010 inches accuracy. Enclosure flanges for synchronization have ±0.015 mm perpendicular surfaces. The precision required for these components often necessitates advanced capabilities found in a modern CNC Machining Center.

CNC milling operates at 12,000-18,000 RPM for precise cooling channel control. It enforces a depth of ±0.003 inches for aluminum or cast blanks. Cooling channel surfaces are finished to Ra 1.6-3.2 microns. This minimizes coolant flow resistance. Precision CNC drilling creates sealed control surfaces with ±0.012 inches control for interlocking coolant flow ports. Post-machining heat treatment, typically 170-190 °C for 4-8 hours, ensures dimensional stability of ±0.020 millimeters after assembly.

Integrated motor-inverter housings eliminate high-current cable connections. This reduces parasitic inductance and improves electromagnetic compatibility. These enclosures are optimized for wide-bandgap semiconductors like SiC and GaN. They support enhanced thermal performances with junction temperatures of 150-200°C at 20-100 kHz switching frequencies. This optimization allows passive components to shrink by 30-50%. Flatness tolerances of power module mounting surfaces, within 0.003 inches, ensure optimal thermal management and prevent hot spots. This maintains thermal resistances of 0.1-0.2 Kelvin square centimeters per watt. Flatness tolerances on sealing surfaces, 0.005 inches, ensure uniform gasket compression for IP67 ingress protection. This prevents moisture ingress and high-voltage insulation degradation. Channel cooling geometry with stiffness within ±0.003 inches ensures effective cooling, ranging from 4-10 kW, during continuous high-power operation of 150-250 kW output.

Chassis and Structural Components Precision

High-precision CNC machining plays a critical role in manufacturing lightweight chassis and structural components for new energy vehicles. It offers the flexibility to create custom solutions for automotive applications. These include custom brackets, specialized engine components, or intricate chassis parts, all with exact specifications. This capability allows manufacturers to design unique parts or adjust existing designs. They meet both functional and aesthetic requirements, which is crucial for innovation and differentiation in the automotive industry.

CNC machining is essential because automated casting or stamping alone cannot achieve the required tolerances for many structural components. For example, steering and chassis brackets made from steel or 7075 aluminum typically require a tolerance of ±0.05 mm.

| Component Type | Material | Typical Tolerance |

|---|---|---|

| Steering/Chassis Bracket | Steel / 7075 | ±0.05 mm |

Typical CNC-machined chassis parts include control arm brackets, suspension mounts, and crash-resistant structures. Aluminum 6061/7075 CNC brackets can reduce vehicle weight by 8–12% compared to steel alternatives.

CNC machining enables the creation of hollow internal structures and topology-optimized mechanical parts. It also facilitates the use of lightweight materials like magnesium in structural components. These capabilities can lead to an EV weight reduction gain of up to 10% per platform. New energy vehicles adopt a lightweight design, requiring numerous complex structural parts. These parts are often made from materials like aluminum alloys and carbon fibers. Aluminum alloys, such as the 6061 and 7075 series, are used for electric vehicle bodies, chassis, and motor housings. Carbon fiber composite materials are utilized for lightweight body and roof parts due to their high strength and low weight. CNC machining ensures high-precision, high-quality, and high-efficiency production across every key system of new energy vehicle manufacturing.

Challenges and Solutions in NEV Component Machining

Manufacturing new energy vehicle (NEV) components presents unique challenges. These challenges demand innovative solutions in high-precision CNC machining. Addressing these issues ensures efficient and sustainable production.

Material-Specific Machinability Issues

Advanced materials used in NEVs pose significant machining difficulties. Materials like silicon carbide or titanium alloys exhibit low thermal conductivity. This property causes heat to accumulate in the tool, accelerating wear. Their high strength and hardness require greater cutting forces, increasing machine load. Chemical affinity with tool materials can lead to built-up edges and tool failure. Furthermore, a low elastic modulus makes these materials prone to tool deformation during machining, affecting accuracy. Advanced workpiece materials, including titanium and high-silicon aluminums, also present significant challenges for deburring and finishing processes.

Achieving Ultra-Tight Tolerances and Surface Finishes

NEV components demand ultra-tight tolerances and superior surface finishes. Multi-axis machining, such as 5-axis or 6-axis systems, enables the production of intricate parts with complex curves in a single setup. This minimizes human error and reduces cycle times. Adaptive control systems allow real-time adjustments to cutting parameters, ensuring optimal performance and precision. Optimized milling strategies minimize waste and reduce overall production costs. CNC milled parts achieve superior surface finishes, like N5 quality (Ra 0.8), which reduces friction and enhances component performance. Parts can also achieve dimensional tolerances as tight as ±0.005 inches through CNC milling.

Cost-Effectiveness and Production Scalability

High-precision CNC machining offers solutions for cost-effectiveness and production scalability. Automated operations and optimized workflows minimize downtime, leading to improved productivity and reduced lead times. This technology ensures uniform quality, dimensions, and performance across large-scale production. It also reduces overall manufacturing costs by minimizing material waste and optimizing resource usage. Automated processes lower labor costs and operational inefficiencies, contributing to profitability. Less reliance on skilled labor is another benefit, as pre-programmed CNC machines simplify the production process.

Environmental and Sustainability Considerations

Sustainable machining practices address environmental concerns in NEV component manufacturing. Technologies like cryogenic cooling, dry cutting, and Minimum Quantity Lubrication (MQL) reduce environmental impact. MQL uses a tiny mist of lubricant instead of flooding with coolant. Dry machining eliminates fluids entirely through optimized parameters and coated cutting tools. These practices minimize chemical use, improve air quality, and reduce waste disposal challenges. One automotive manufacturer achieved a 70% reduction in coolant use and a 25% reduction in energy consumption by switching to MQL and recycling metal chips.

Future Trends in High-Precision CNC Machining Center

High-precision CNC machining continues to evolve. Future trends will further enhance efficiency, precision, and sustainability in NEV component manufacturing. These advancements will shape the next generation of production.

Further Integration of AI and Machine Learning

Artificial intelligence (AI) and machine learning (ML) will increasingly integrate into CNC machining. AI analyzes large datasets. It enables real-time decisions in CNC machines. For example, AI adjusts feed rates and tool paths for maximum efficiency. This reduces cycle times and improves accuracy. Predictive maintenance systems use AI to monitor CNC machine performance. They collect data like temperature and vibration. This predicts failures before they occur. It prevents downtime and extends machine lifespan. AI-driven CAM software optimizes tool paths and machining sequences. This reduces material loss and enhances efficiency.

Hybrid Manufacturing Approaches

Hybrid manufacturing combines different production methods. This approach creates complex geometries with superior surface finishes. It allows for internal features impossible with traditional methods. This integration offers greater design freedom and material efficiency. It also reduces production steps. Combining additive and subtractive techniques will become more common.

Advanced Materials and Novel Machining Processes

New energy vehicles continue to adopt advanced materials. These materials often present machining challenges. Novel machining processes address these difficulties. Ultrasonic-assisted machining (UAM) and laser-assisted machining (LAM) are examples. Their hybrid combination (LUAM) also shows promise. These techniques improve the machinability of difficult materials. This includes aerospace alloys like nickel-based superalloys and metal matrix composites.

Towards Lights-Out Manufacturing

The industry moves towards lights-out manufacturing. This involves fully automated production with minimal human intervention. Robotics and advanced automation systems will operate CNC Machining Center facilities continuously. This increases productivity and reduces labor costs. It also ensures consistent quality around the clock.

High-precision CNC machining is fundamental for advancing new energy vehicles. These technological developments directly address the unique demands of NEV components. They highlight the critical role CNC machining plays in shaping the future of sustainable transportation. This precision manufacturing ensures NEVs perform efficiently and reliably.

FAQ

What is high-precision CNC machining?

High-precision CNC machining uses computer-controlled tools. It manufactures complex parts with extreme accuracy. This technology ensures tight tolerances and intricate geometries for various industries.

Why do NEV components require high-precision CNC machining?

NEV components demand high precision due to lightweight materials, critical thermal management, electrical needs, and complex geometries. These factors require exact manufacturing processes.

How do AI and ML impact future CNC machining?

AI and ML integrate into CNC machining. They optimize tool paths, predict maintenance needs, and enhance real-time decision-making. This improves efficiency and accuracy significantly.

Post time: Jan-23-2026