In mass production scenarios, dual-spindle CNC turning centers stand out for their efficiency. These machines can complete most parts in half the time compared to single-spindle lathes. By performing two operations simultaneously, they enhance machining flexibility, which is crucial for high-volume manufacturing.

Key Takeaways

- Dual-spindle CNC turning centers significantly reduce cycle times by performing multiple operations simultaneously, making them ideal for mass production.

- Single-spindle CNC turning centers are simpler and more cost-effective, but they are less efficient for high-volume production due to longer cycle times.

- Investing in dual-spindle machines can lead to lower costs per part and increased productivity, providing a competitive edge in manufacturing.

Overview of CNC Turning Center

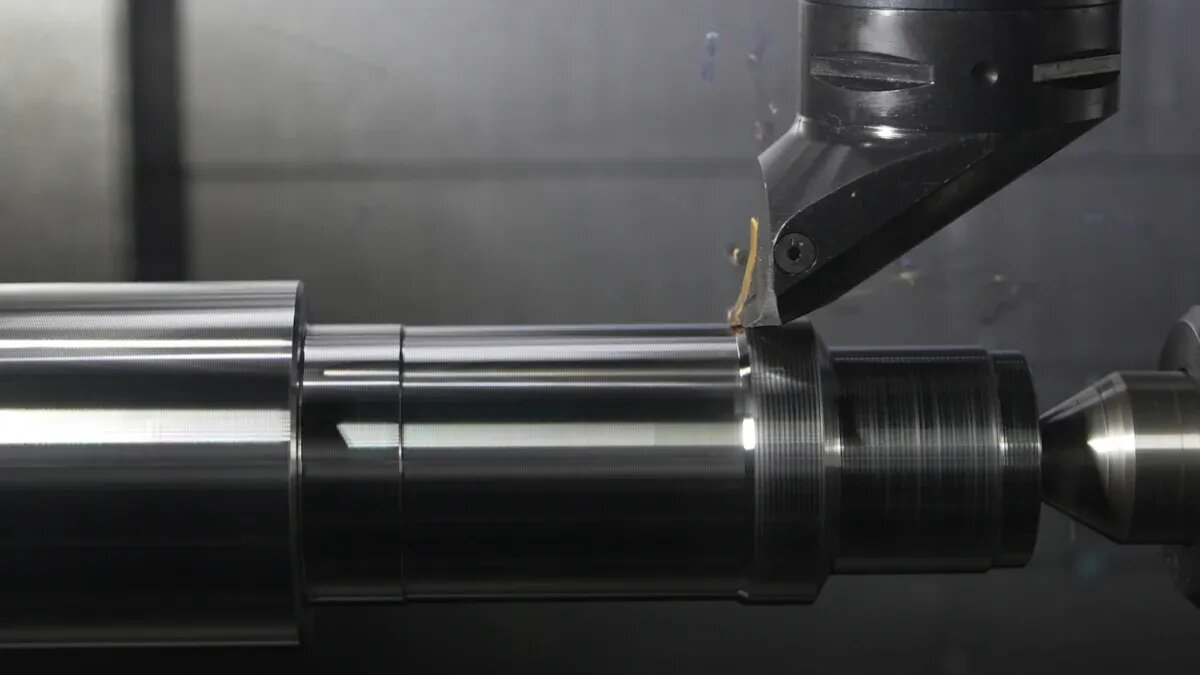

A CNC turning center is a sophisticated machine designed for precision machining. It automates the turning process, allowing you to create complex shapes with high accuracy. These machines consist of several key components that work together to achieve optimal performance.

| Component | Description |

|---|---|

| Headstock | Houses the main spindle and speed-gear mechanisms, often driven by an electric motor. |

| Bed | Serves as the base, connecting the headstock to the carriage and tailstock. |

| Feedscrews | Drive the carriage along the Z-axis, enabling movement for X-axis operations. |

| Carriage | Holds the turning tool, moving it longitudinally or perpendicularly for various operations. |

| Tailstock | Positioned opposite the headstock, it supports tooling and travels longitudinally. |

CNC turning centers excel in various operations, including facing, threading, and drilling. Their design enhances precision, ensuring symmetry in round parts, which is crucial for durability. You will find that these machines produce parts quickly, significantly improving production rates while maintaining quality. Additionally, they can work with a wide range of materials, making them versatile for industries like electronics.

Single-Spindle CNC Turning Center

Single-spindle CNC turning centers are essential machines in many manufacturing environments. They excel in producing a variety of parts, especially when you prioritize simplicity and cost-effectiveness. These machines operate with one spindle, which means they perform one operation at a time. This design leads to several key characteristics.

Advantages of Single-Spindle CNC Turning Centers

- Simplicity in Design: The straightforward design makes these machines easier to operate and maintain.

- Lower Initial Cost: You can acquire single-spindle models at a lower price compared to dual-spindle options.

- Easier Maintenance: With fewer components, maintenance tasks become less complex and more manageable.

Disadvantages of Single-Spindle CNC Turning Centers

- Longer Cycle Times: Since they can only perform one operation at a time, cycle times tend to be longer.

- Limited Efficiency: You may find that these machines are less efficient for high-volume production due to their sequential operation.

Here’s a quick comparison of the advantages and disadvantages:

| Type of Lathe | Advantages | Disadvantages |

|---|---|---|

| Single Spindle | - Simplicity in design and operation | - Longer cycle times |

| - Lower initial cost | - Limited to sequential operations, reducing efficiency | |

| - Easier maintenance and lower maintenance costs |

Production Capacities

Single-spindle CNC turning centers can handle various production capacities. Here’s a table showcasing some typical models and their specifications:

| Model | Chuck Size | Max. Turning Diameter | Max. Turning Length | Max RPM | Number of Turret Stations | Machinery Size |

|---|---|---|---|---|---|---|

| 106 | 6″ | φ380 | 380mm | 5500 | 12T | 2200*2000*1800 (m) |

| 600 | 10″/8″ | φ670 | 600mm | - | 12T | 3100*2110*2100 (m) |

| 750 | 8″ | φ460 | 720mm | 4300 | 12T | 2900*2100*1900 (m) |

Common Applications

You will find that single-spindle CNC turning centers are ideal for producing various parts, including:

- Shafts & Axles: Core components in machines, such as motor shafts and car drive shafts.

- Pins & Dowels: Used for alignment and connections, including alignment pins and clevis pins.

- Bushings & Bearings: Elements that reduce friction, like bronze bushings and custom bearing housings.

- Fasteners & Connectors: Custom fasteners and fittings, including special bolts and hydraulic fittings.

- Spacers & Standoffs: Parts that create space between components, such as standoffs in electronics.

- Complex Contoured Parts: Intricate shapes for applications like medical implants and turbine parts.

Maintenance Requirements

To ensure optimal performance, regular maintenance is crucial. Here’s a breakdown of maintenance tasks based on frequency:

| Frequency | Maintenance Tasks |

|---|---|

| Daily | Regular checks for operational integrity and minor adjustments. |

| Monthly | Inspect and potentially replace filters, evaluate coolant quality, check motor performance, clean chuck. |

| Quarterly | Check axis drive backlash, perform extensive cleaning, inspect safety devices. |

| Semi-Annual | Clean radiator, perform alignment checks, re-torque connections. |

| Annual | Evaluate spindle play, drain and replace hydraulic oil, verify machine leveling, inspect bearings. |

Dual-Spindle CNC Turning Center

Dual-spindle CNC turning centers represent a significant advancement in machining technology, particularly for mass production scenarios. These machines excel in efficiency and versatility, making them a preferred choice for manufacturers aiming to optimize their production processes.

Key Features of Dual-Spindle CNC Turning Centers

You will find that dual-spindle CNC turning centers come equipped with several features that enhance their operational efficiency:

- Simultaneous Operations: These CNC machines allow you to perform multiple tasks at once, significantly reducing cycle times.

- Integration of Smart Technologies: Many models incorporate IoT and AI for real-time monitoring and predictive maintenance, which enhances operational efficiency.

- Enhanced Processing Consistency: You can expect reliable and uniform results, crucial for high-end manufacturing sectors like automotive and aerospace.

- Multitasking Capabilities: Dual-spindle machines enable you to complete complex machining tasks faster and with greater precision compared to single-spindle machines.

- Versatility: They can handle both horizontal and vertical machining tasks, catering to a wide range of industrial applications.

Cycle Time Reduction

One of the standout advantages of dual-spindle CNC turning centers is their ability to reduce cycle times significantly. Here’s how they achieve this:

- They enable simultaneous operations on different workpieces, leading to substantial time savings.

- The indexing sequence allows for multiple machining positions, where various turning tools can work on different parts at the same time.

- The presence of a synchronous spindle facilitates back-end operations without the need for re-fixturing, further minimizing cycle times.

Cost Implications

Investing in dual-spindle CNC turning centers can lead to substantial financial benefits. The following table outlines the cost implications associated with these machines:

| Evidence Description | Cost Implication |

|---|---|

| Reduced cycle times | Lower cost-per-part |

| Lower labor costs | Enhanced productivity |

| Improved part quality | Increased profitability |

| Elimination of work-in-process inventory | Reduced waste |

By transitioning from a multi-machine process to a single dual-spindle setup, you can reduce cycle times by up to ten times. This directly translates to lower costs per part and maximized return on investment.

Handling Complex Part Geometries

Dual-spindle CNC turning centers also excel in handling complex part geometries in high-volume production. They enable machining of intricate parts with features on both sides of the workpiece simultaneously. This capability allows for secondary machining operations on the previously machined side of a part without manual intervention, enhancing efficiency.

If your production requires both turning and milling in a single setup, consider a multi-axis turn/mill machine with live tooling. Twin-spindle machines allow operations on both sides of the part, streamlining the entire process.

Comparative Analysis of CNC Turning Centers

When comparing single-spindle and dual-spindle CNC turning centers, several key performance factors emerge. Understanding these differences can help you make informed decisions for your production needs.

| Feature | Single-Spindle CNC Turning Center | Dual-Spindle CNC Turning Center |

|---|---|---|

| Operations Performed | One operation at a time | Multiple operations simultaneously |

| Clamping and Repositioning | More time required | Reduced time, enhancing productivity |

| Processing Speed | Slower due to sequential tasks | Faster due to concurrent tasks |

| Flexibility for Complex Tasks | Limited | High flexibility with quick tool switching |

| Integration with Automation | Limited | High integration for unmanned operation |

Investing in a dual-spindle CNC machine can lead to significant long-term savings. These machines reduce cycle times and increase production rates. As a result, you can minimize labor costs and energy consumption due to simultaneous machining operations. In fact, dual-spindle machining can lower energy costs by approximately 40%.

Labor requirements also differ between the two types of machines.

| Machine Type | Labor Requirements | Efficiency Impact |

|---|---|---|

| Single-Spindle | Higher manual handling and setup time | Increased labor costs |

| Dual-Spindle | Simultaneous operations, reduced cycle time | Alleviates labor shortages, improves efficiency |

Single-spindle lathes often require multiple setups for different operations, making them more labor-intensive. The cost difference between single and dual-spindle lathes is diminishing, especially when considering labor costs. The trend is moving towards minimizing handling and maximizing efficiency with setups that allow for complete machining in one go.

Real-World Applications of CNC Turning Centers

CNC turning centers play a crucial role in various industries, enhancing production efficiency and precision. Here are some key sectors where you will find these machines making a significant impact:

- Automotive: You can use CNC turning centers to manufacture essential components like cylinder blocks, fluid system parts, and exhaust systems. These machines ensure high precision, which is vital for vehicle performance and safety.

- Electronics: In the electronics industry, CNC turning centers produce electric components such as heat sinks, sockets, and semiconductors. The ability to create intricate designs with tight tolerances makes these machines indispensable.

- Construction: CNC turning centers create various components that require precision and high-volume production. From fittings to structural elements, these CNC machines help meet the demands of modern construction projects.

For dual-spindle CNC turning centers, the benefits extend even further. They allow for simultaneous operations, which leads to increased productivity. Here are some advantages you can expect:

- Cost Efficiency: Dual-spindle machines reduce the cost per part by minimizing idle time and manpower.

- Increased Productivity: You can produce more parts in less time due to simultaneous operations.

- Space Optimization: These machines occupy less floor space compared to two separate machines, making them ideal for facilities with limited space.

Dual-spindle CNC turning centers significantly enhance your mass production capabilities. They offer higher productivity by machining two parts simultaneously, which reduces idle time. You can expect lower labor costs and increased efficiency due to continuous operation. As you consider your options, remember that these machines provide a competitive edge in high-volume manufacturing.

FAQ

What is the main advantage of dual-spindle CNC turning centers?

Dual-spindle CNC turning centers allow simultaneous operations, significantly reducing cycle times and increasing production efficiency.

Are single-spindle CNC turning centers suitable for mass production?

Single-spindle CNC turning centers are less efficient for mass production due to longer cycle times and sequential operations.

How do I choose between single and dual-spindle CNC turning centers?

Consider your production volume, complexity of parts, and budget. Dual-spindle centers excel in high-volume scenarios, while single-spindle centers suit simpler tasks.

Post time: Oct-09-2025