News

-

What is The Difference Between These Two Type Pipe Threading Lathe?

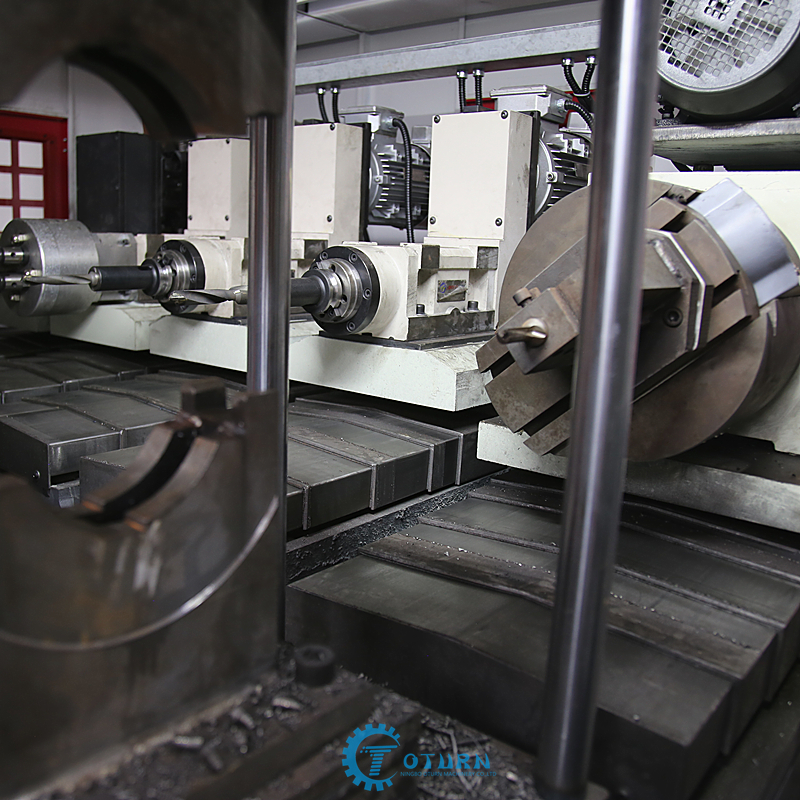

For the Pipe Threading Lathes,lots of customers are accustomed to searching for the machine model when searching.For example,the machine models we usually see are QK1313/QK1319/QK1322/Qk1327/QK1335/QK1343 in the market.For our company’s corresponding model is QK1315/QK1320/QK1323/Qk1328/QK1...Read more -

The feedback from Four-Station Flange Drilling Machine Customer

The epidemic at the end of 2019 has caused many factories to be unable to put into normal production for a long time, such as the flange manufacturing factory in Wenzhou China we mentioned today. For businessmen who frequently visit China, they may know Wenzhou, a city with very developed manufac...Read more -

What are the advantages of the local special valve machine in Brazil with the traditional machine?

Where are the advantages of the valve special machine lathe? First of all, the efficiency of CNC machine tools is relatively high. Anyone who has been in touch with these things should know that when producing a large batch of workpieces, you need to prepare a certain mold first. If you change to...Read more -

How to improve the processing efficiency of CNC drilling and milling machines in Turkey

In recent years, with the continuous emergence of new products and the increasing complexity of parts, CNC drilling machines have been rapidly popularized with their strong advantages, and have become one of the decisive factors for a company to strive for market advantages. At present, improvin...Read more -

6 advantages of 2021 CNC drilling and milling machines in Brazil

The 2021 CNC drilling and milling machine is mainly used for high-efficiency drilling, milling, and tapping processing of flat plates, flanges, discs, rings, and other workpieces. And realize drilling through holes and blind holes on single material parts and composite materials. It is suitable f...Read more -

Matters needing attention when commissioning long-term CNC drilling machines in Mexico

Commissioning of CNC Drilling and Milling Machine: Drilling and milling machine is a kind of high-tech mechatronics equipment. It is very important to start and debug correctly. This determines to a large extent whether the CNC machine tool can exert normal economic benefits and its own service ...Read more -

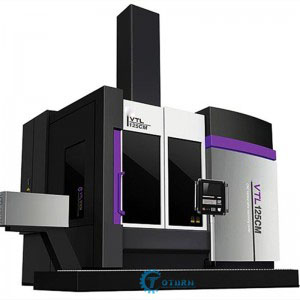

Features and operating procedures of CNC vertical lathes in Russia

Workpieces with relatively large diameters and weights are generally processed by CNC vertical lathes. Features of CNC vertical lathes: (1) Good accuracy and multiple functions. (2) Able to realize stepless speed regulation. (3) Fair structure and good economy. The safety operation regulations o...Read more -

What are the precautions when buying a machining center in Turkey

At present, there are countless brands of machining centers in the market of CNC machine tools, and there are also many models. So when we generally buy machining centers, to avoid detours, what should I pay attention to? The following points are for your reference: 1. Determine the nature of equ...Read more -

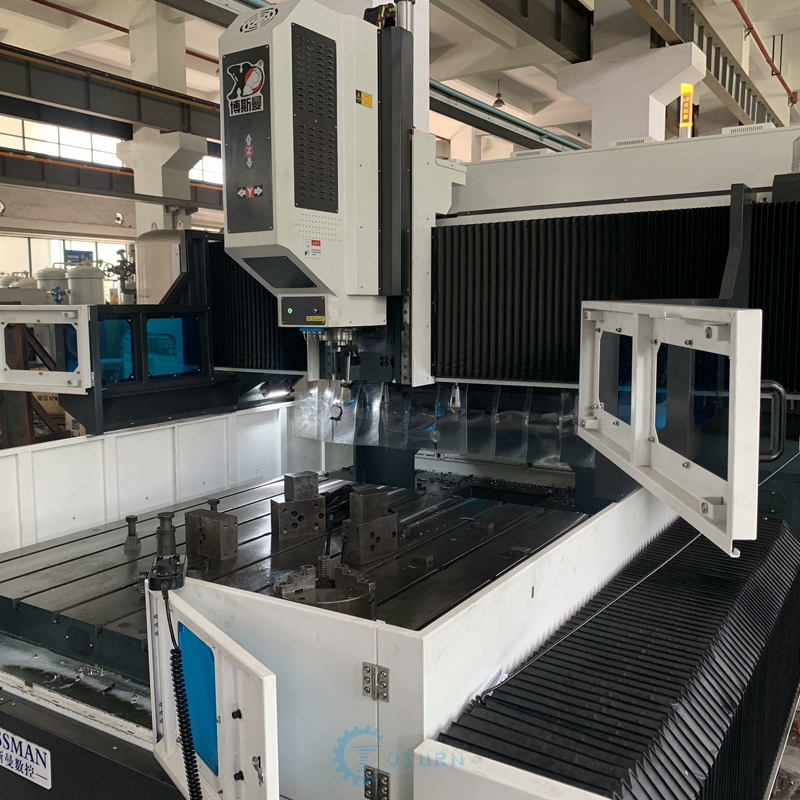

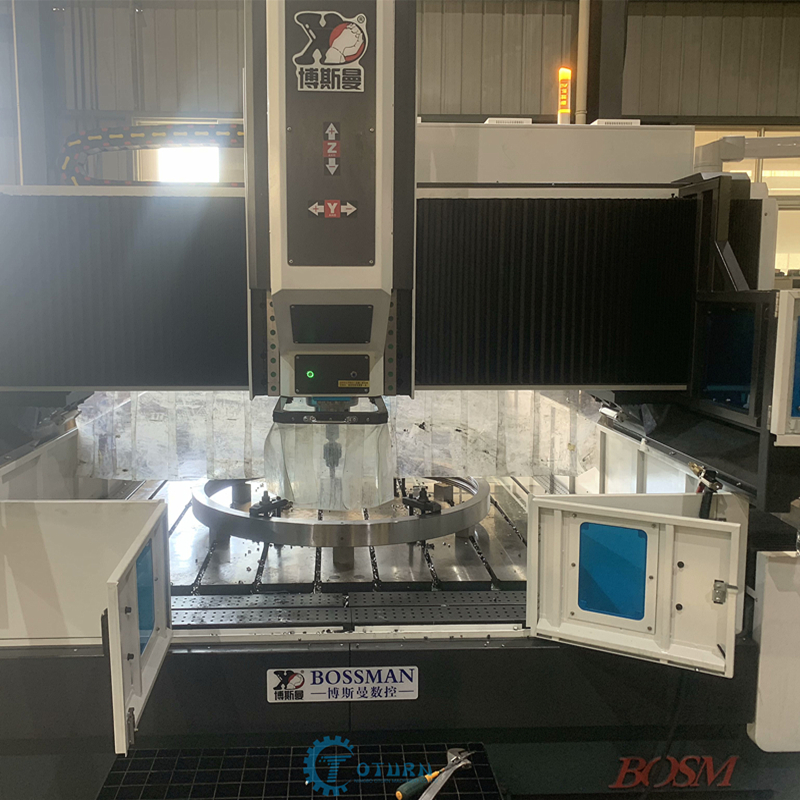

Four-jaw self-centering gantry drilling and milling machine BOSM1616 at the Iranian customer site

The BOSM1600*1600 four-jaw self-centering gantry drilling and milling machine are on the site of Iranian customers. Iranian customers mainly process slewing supports. Since Iranian customers bought this gantry drilling and milling machine, they immediately eliminated the processing technology of ...Read more -

A question asked by a Turkish customer a few days ago: Maintenance of the pneumatic system of CNC drilling machines

1. Remove impurities and moisture in the compressed air, check the oil supply of the lubricator in the system, and keep the system sealed. Pay attention to adjust the working pressure. Clean or replace the pneumatic failure and filter elements. 2. Strictly abide by the operation and daily mainte...Read more -

What are the advantages of the special valve machine over other machines?

Many people know that when processing a workpiece if the structure of a workpiece is more complex, it needs to be combined with many machine. In this process, it is necessary to adjust the machine from time to time. This is relatively troublesome when processing the workpiece, especially For cert...Read more -

What factors can cause problems with CNC drilling and milling machines

No matter how fast and efficient the CNC drilling and milling machine is, it is not absolutely reliable. Because there are problems with other types of machines, we may also inadvertently damage these machines. The following are our common problems. 1. Poor or improper maintenance CNC drilling a...Read more -

The big order is late. The chief programmer takes sick leave

The big order is late. The chief programmer takes sick leave. Your best customer just sent a text message asking for an offer that was due last Tuesday. Who has time to worry about the lubricating oil dripping slowly from the back of the CNC lathe, or wondering if the slight buzzing noise you hea...Read more -

How to choose high-quality CNC pipe threading lathe

CNC pipe threading lathe is a kind of machinery and equipment used in the production and processing of the industry at this stage. With the increase in market demand and the increasing number of machine manufacturers in major cities, the quality problem has become more and more prominent. Then ev...Read more -

2020-2026 Global and China CNC Machine Tool Market Report

As a typical mechatronic product, CNC machine combine mechanical technology with CNC intelligence. The upstream mainly involves castings, sheet weldments, precision parts, functional parts, CNC systems, electrical components and other parts; the downstream is widely involved in machinery, molds, ...Read more