The 2025 Hannover International Machine Tool Fair (EMO Hannover 2025) is about to open in grand style. As a major event not to be missed for the global manufacturing industry, OTURN cordially invites you to visit Hall 15, Booth B54 to experience our advanced CNC machining centers, CNC lathes, and CNC grinders, and experience the latest turning-edge metalworking technologies and intelligent industrial solutions.

I. Introduction to the 2025 Hannover International Machine Tool Fair

Since its founding in 1951, the Hannover International Machine Tool Fair (EMO) has grown into the world’s largest and most influential event for CNC machine and manufacturing technology, known as the “bellwether of the global machine tool industry.” Held every two years, EMO brings together the world’s most advanced metalworking technologies and intelligent manufacturing achievements, driving the manufacturing industry towards the future of Industry 4.0 and even Industry 5.0. In 2023, the exhibition area will exceed 180,000 square meters, with over 2,200 exhibitors and 130,000 professional visitors. In 2025, we foresee even more exciting technological innovation and cross-border cooperation; hot topics such as green manufacturing, intelligent machine tools, and Industry 5.0 will surely ignite the event.

II. Our Highlights at EMO 2025

OTURN showcased several representative CNC machine tools, encompassing core technologies such as high-precision machining, automated integration, and green energy conservation, to help you achieve more efficient and intelligent production:

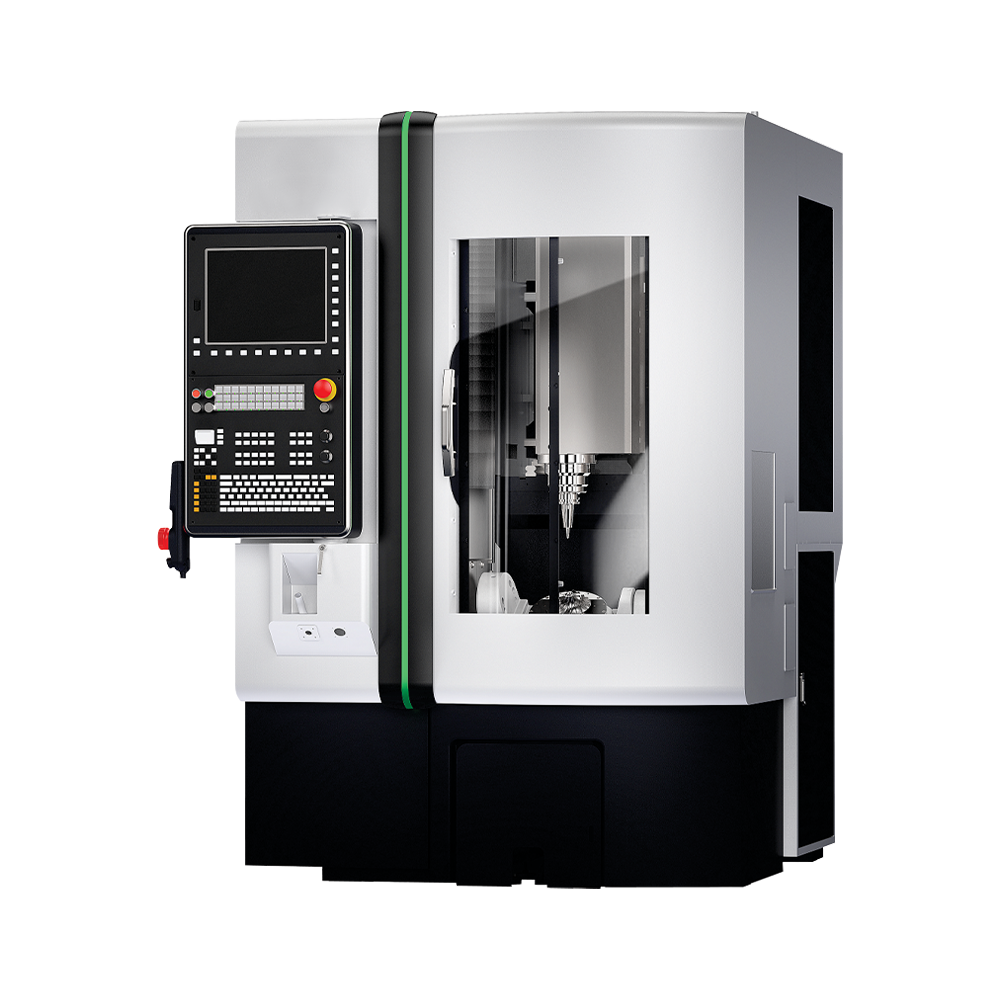

1. High-Performance Five-Axis CNC Machining Center: JK20

· High-rigidity machine design ensures stability and precision during high-speed turning;

· Advanced five-axis CNC system enables high-precision and high-speed machining of complex surfaces;

· Multi-process integration allows for roughing and finishing in a single clamping setup, significantly improving production efficiency and quality;

· Widely applicable for the manufacture of high-precision parts in the automotive, aviation, and medical industries;

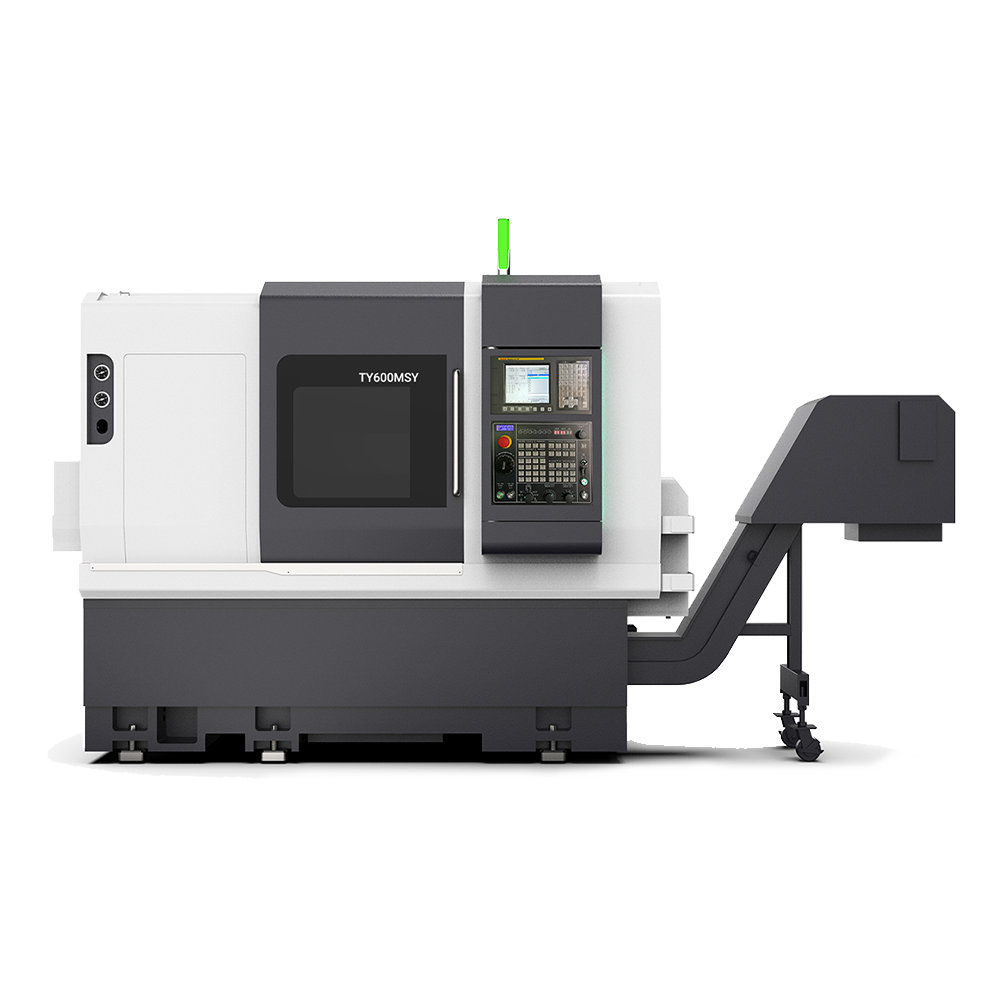

2. CNC Turning and Milling Machine: 600MSY

· Integrating turning and milling, process integration significantly shortens production cycle time;

· High-rigidity spindle and rapid tool change system support high-variety, low-volume production;

· Integrated positive Y-axis structure enables high-quality machining of both flat and complex surfaces;

· Supports synchronized X, Z, Y, S, and main and secondary axes, enabling efficient multi-faceted, multi-process machining of complex parts.

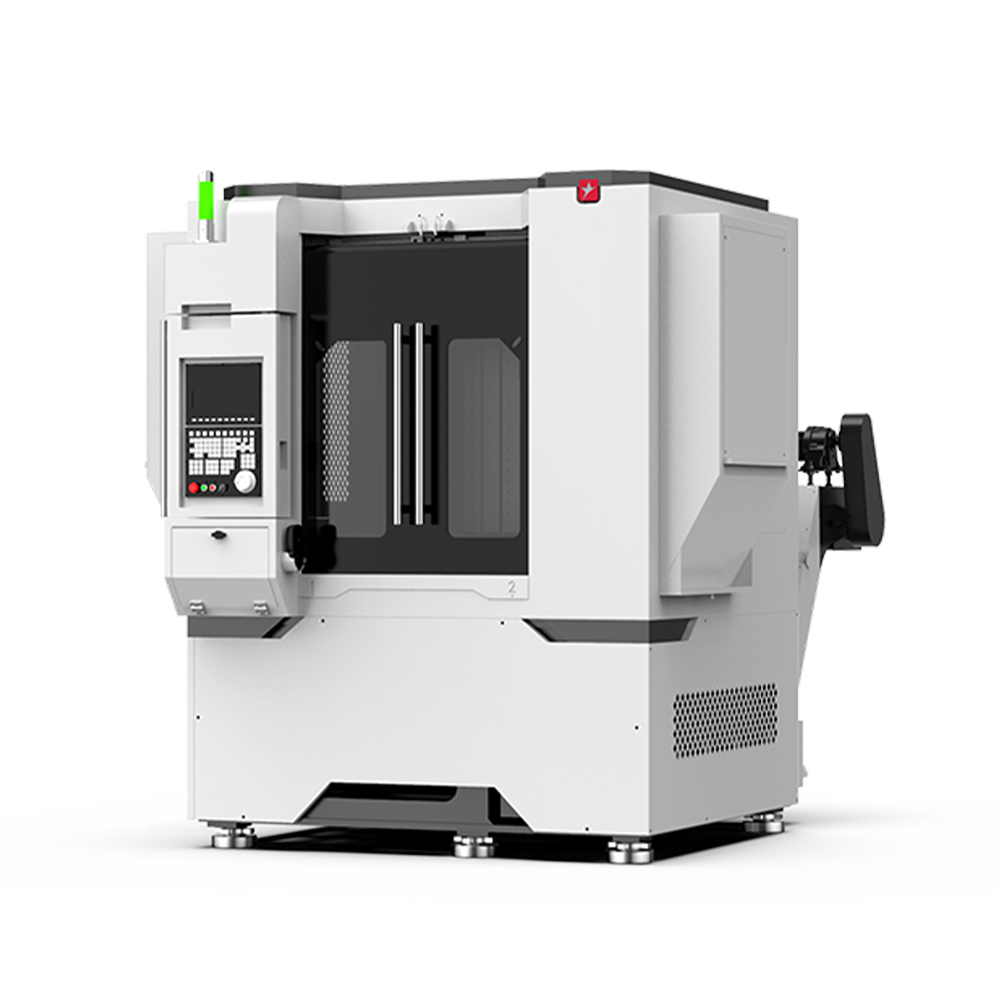

3. CNC Vertical Lathe: LTC80-500-T2

· Turn-milling, completing external cylindrical turning, radial drilling, and slot milling in a single clamping setup, improving machining efficiency.

· Dual-turret design enables efficient mass production.

· Vertical structure provides a compact footprint and smooth chip evacuation, ensuring machining stability.

· Supports bidirectional cutting, effectively offsetting machining distortion and improving part quality.

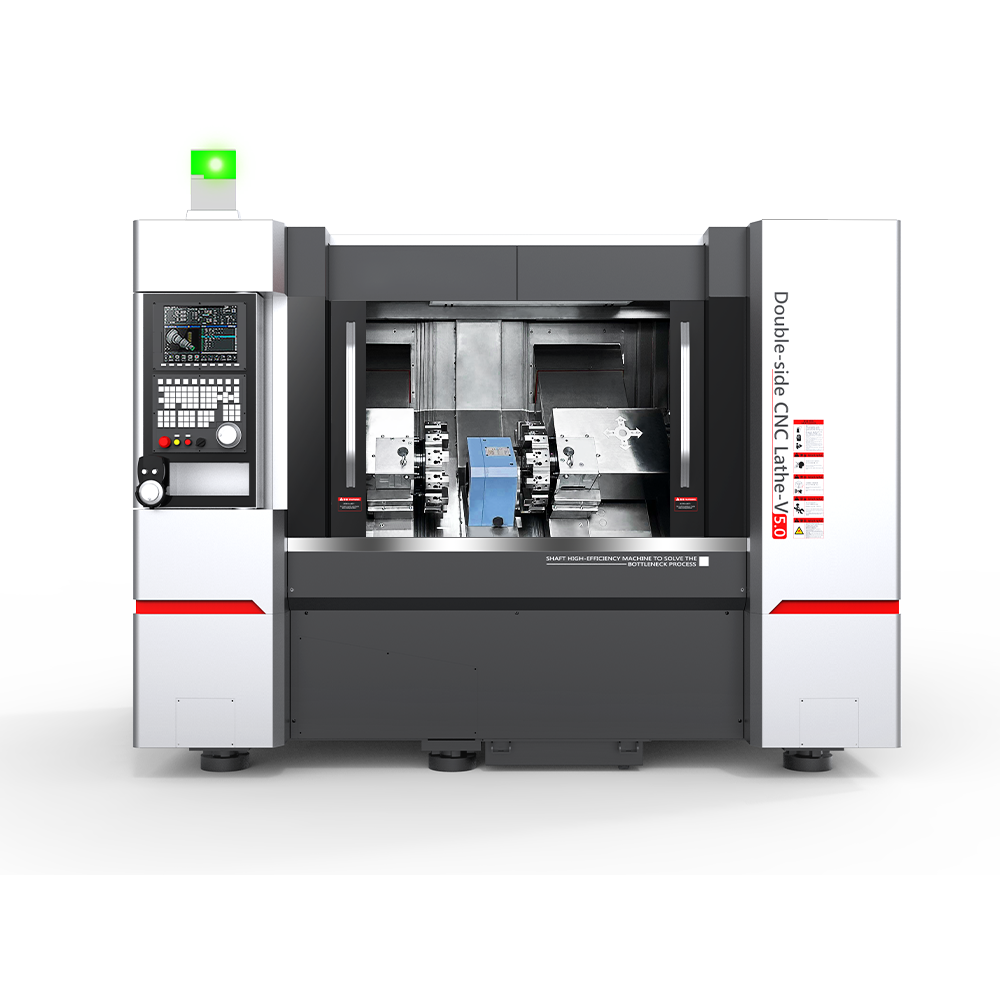

4. Double-Sided CNC Lathe: SC95-120-T

· Equipped with dual control systems and dual-end machining, it enables simultaneous machining of both ends of the workpiece, meeting the demands of complex machining operations.

· The HT300′s integrated cast iron bed and turret provide high rigidity, ensuring tool life and machining stability.

· The inclined Z-axis carriage design effectively controls thermal deformation, making it suitable for high-performance turning with large allowances and high dynamics.

5. CNC OD & ID Grinding Machine: BP22

· Integrating advanced grinding machine manufacturing technology with precision grinding processes, it meets the high-precision requirements of internal and external concentricity for small and medium-sized shafts and discs.

· The multi-station grinding wheel spindle design enables single-clamping grinding of external circles, internal holes, end faces, and chamfers, improving machining efficiency and accuracy.

· The BP22 workpiece spindle (B-axis) offers the option of manual or CNC direct drive, meeting the diverse precision requirements of different grinding processes.

III. On-site Experience and Professional Services

We sincerely invite you to experience these advanced CNC machines firsthand. Here, you’ll enjoy a unique on-site experience:

· Live Machine Demonstrations: On-site engineers will demonstrate the machining process of the three exhibited machines, answer technical questions, and provide a deep understanding of the equipment’s performance.

· Technical Exchanges and Customized Solutions: Based on your machining needs, we provide targeted technical support and customized solution design to help you upgrade your production line.

· Interactive Q&A Sessions: On-site interactive discussions will share the latest industry trends and application cases, helping you seize future development opportunities in the manufacturing industry.

In addition, we support advance reservations for visits, ensuring that dedicated technical consultants provide one-on-one consultation and service, greatly enhancing your exhibition experience.

IV. Equipment Widely Used in Multiple Key Industries

Modern manufacturing technologies and the transformation to intelligent machining are profoundly impacting the development landscape of the metalworking industry. OTURN has been continuously innovating for many years, dedicated to providing leading machine tools and solutions to key industries such as aerospace, automotive, mold manufacturing, medical devices, and semiconductors. Faced with the stringent demands of these industries for ultimate machining quality and efficient production, our equipment, with its superior performance and intelligent features, helps customers meet complex and ever-changing manufacturing challenges and maintain a competitive edge.

At the upcoming EMO 2025, you’ll have the opportunity to witness firsthand how we deeply integrate high-performance CNC machining center, automated grinder, and multi-functional turning and milling machine with digital manufacturing technologies to drive industry transformation and upgrades. Our solutions cover diverse needs, from high-precision part machining to full-process intelligent manufacturing, fully meeting the modern manufacturing industry’s comprehensive pursuit of productivity, environmental protection, and process flexibility.

Through continuous technological innovation, we not only create equipment with stable performance and easy operation, but also build a complete intelligent manufacturing ecosystem that supports the manufacturing industry’s transition to Industry 4.0 and 5.0. We look forward to meeting you face-to-face at EMO Hannover and exploring the boundless future of manufacturing together.

Exhibition Information

※ Exhibition Name: EMO Hannover 2025

※ Date: September 22-27, 2025

※ Venue: Hannover Exhibition Center, Germany

※ Booth Number: Hall 15, Booth B54

Related resources:

EMO Hannover 2025 – Source: EMO

CNC machine product information – Source: OTURN

Post time: Sep-15-2025