Discovering elite Chinese Cnc Machining Center suppliers is paramount for business success. The global CNC machining center market, including China, is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.7% from 2024 to 2033. This significant growth emphasizes the need for a reliable CNC Machining Center Supplier China. This guide helps businesses identify and evaluate top-tier Chinese CNC Machining Center manufacturers. For instance, OTURN MACHINERY specializes in high-quality, high-efficiency industry-specific machines. Determining Which CNC Machining Center Is Best for Your Application? requires careful consideration. This resource assists in finding the Best CNC Machining Center Supplier for Export.

Key Takeaways

- Chinese CNC machining center suppliers offer good prices and high quality. They also use new technology and can customize machines for different needs.

- Top Chinese suppliers have important quality certificates like ISO 9001. They also use advanced technology and have modern factories to make precise parts.

- To find a good supplier, research online and talk to manufacturers. Ask for samples and visit their factories to check their work.

- Good after-sales support is very important. It includes warranties, repairs, and help to keep your machines working well for a long time.

- Avoid common problems like ignoring quality checks or poor communication. Also, be careful of very low prices, as they can mean lower quality.

Why Choose Chinese CNC Machining Center Suppliers?

Cost-Effectiveness and Quality in CNC Machining Centers

Chinese CNC machining center suppliers offer a compelling combination of cost-effectiveness and robust quality. The average hourly rate for CNC machining in China typically ranges from $20 to $50 per hour. This contrasts significantly with Western markets, where rates can reach $50 to $100 per hour. Labor costs in China are also considerably lower, averaging $4-$8 per hour compared to $20-$40 in Western countries. Material costs, such as Aluminum 6061, also show a similar trend, costing $2-$3 per kg in China versus $4-$6 per kg elsewhere. Despite these lower costs, leading Chinese manufacturers maintain high quality standards. They adhere to international certifications like ISO 9001, ensuring strict compliance with regulatory requirements. Quality control involves comprehensive pre-production inspections of raw materials, in-production monitoring of each part, and post-production inspections using advanced tools such as Coordinate Measuring Machines (CMMs). Machine operators also perform article inspections during or immediately after machining to identify tolerance issues.

Innovation in CNC Machining Center Technology

Chinese manufacturers actively drive innovation in CNC machining center technology. Companies like Shenyang Machine Tool Group (SMTG) have introduced intelligent CNC systems, such as the i5 series, which integrate intelligent operation, programming, maintenance, and management. This system achieves high accuracy, for example, ±0.005mm for parts under 50mm diameter. Manufacturers also focus on smart manufacturing and IoT integration, equipping CNC machines with sensors for real-time data collection and predictive maintenance. This emphasis on advanced technology enhances precision, productivity, and user experience. Furthermore, many suppliers support digital transformation in manufacturing, promoting sustainable and cost-effective solutions through energy-efficient machines and advanced automation.

Diverse CNC Machining Center Options and Customization

Chinese suppliers provide diverse CNC machining center options and extensive customization capabilities. They support a wide range of materials, including various metals like Aluminum 6061, Stainless Steel SUS304, and plastics such as ABS and Nylon-PA6. Manufacturers offer comprehensive machining processes, including CNC milling, turning, sheet metal fabrication, and 3D printing. This flexibility allows for single-piece orders, ideal for prototyping and small-batch runs. Customization extends to surface finishes, with options like anodizing for improved corrosion resistance, bead blasting for a matte texture, and polishing for a smooth, glossy finish. Suppliers can also handle complex designs with tight tolerances, combining techniques like wire cut and EDM for high-precision parts.

Key Criteria for Elite Chinese CNC Machining Center Suppliers

Businesses seeking a top-tier Chinese CNC Machining Center supplier must evaluate several critical factors. These criteria ensure they partner with manufacturers delivering quality, innovation, and reliable support.

Quality Certifications for CNC Machining Centers

Elite Chinese CNC Machining Center suppliers consistently demonstrate their commitment to quality through various international certifications. These certifications validate their adherence to rigorous standards and best practices. For example, ISO 9001 Quality Management represents a widely accepted standard for quality management systems. It focuses on customer satisfaction, robust quality management, and continuous improvement. Suppliers serving specialized industries often hold additional certifications. The AS9100 Aerospace Standard builds upon ISO 9001 with specific requirements for aerospace manufacturing, emphasizing risk management, product safety, traceability, and configuration management. Similarly, ISO 13485 Medical Devices specifically targets businesses involved in medical devices, focusing on risk management, documentation, traceability, and regulatory compliance to ensure safety and effectiveness.

Furthermore, ITAR Compliance (International Traffic in Arms Regulations) governs the import and export of defense-related goods and services, crucial for companies in defense and aerospace. It focuses on strict control over the export of defense technologies and secure processes. Environmentally conscious suppliers often achieve ISO 14001 Environmental Management, an international standard for environmental management systems. This framework helps minimize environmental impact, comply with legal requirements, and improve environmental performance. Finally, ISO 45001 Occupational Health and Safety provides a standard for occupational health and safety management systems, offering a framework to identify, control, and minimize workplace risks. These certifications collectively assure buyers of a supplier’s dedication to high standards across various operational aspects.

Technological Prowess in CNC Machining Center Manufacturing

A supplier’s technological prowess directly impacts the quality and capability of their CNC machining centers. Elite manufacturers invest heavily in advanced technologies to enhance precision and efficiency. They utilize multi-axis machining centers, optimized for specific tasks, enabling the crafting of intricate parts with unparalleled accuracy. Automation integration significantly enhances efficiency, reduces errors, and paves the way for lights-out manufacturing. CAD/CAM Integration fuses Computer-Aided Design and Computer-Aided Manufacturing technology, enhancing precision and speed. This allows for the creation of complex geometries. Materials innovation expands the range of materials compatible with CNC machining, including exotic alloys, composites, and advanced plastics.

Leading global manufacturers exemplify this technological leadership. Makino, for instance, offers 5-axis machining centers like the T1 and MAG4 models. These tackle intricate aerospace and industrial components with unmatched precision. Their T1 model features a 155-degree tilting A-axis for comprehensive five-sided machining. Makino also employs its Machining Complex (MMC2) with MOS-A5 software, supporting up to 15 machines with automated pallet handling and achieving over 90% spindle utilization. DN Solutions (formerly Doosan Machine Tools) provides DNM 5AX and DVF series 5-axis CNC machining centers. These enable complex operations with high accuracy, reducing setup times and boosting productivity. They incorporate high-speed spindles and sophisticated control systems for optimal performance. FANUC Corporation’s Series 30i and 31i-A5 CNCs control up to 40 axes simultaneously for efficient production of high-precision parts. Mazak Corporation’s VARIAXIS series showcases simultaneous 5-axis capabilities, reducing setup times by 50% and enhancing accuracy to within ±0.0002 inches. Their hybrid multi-tasking machines combine additive manufacturing with 5-axis milling, addressing complex part geometries and boosting productivity by up to 30%. DMG MORI uses fast spindles and smart controls in advanced machines to create detailed parts, supported by their user-friendly CELOS system. Okuma Corporation’s GENOS M560V-5AX and MU-V Series deliver precision within ±0.001 mm, featuring their proprietary OSP CNC control system with closed-loop positioning and thermal compensation. These examples highlight the advanced capabilities a top Chinese supplier should emulate or possess.

Advanced CNC Machining Center Production Facilities

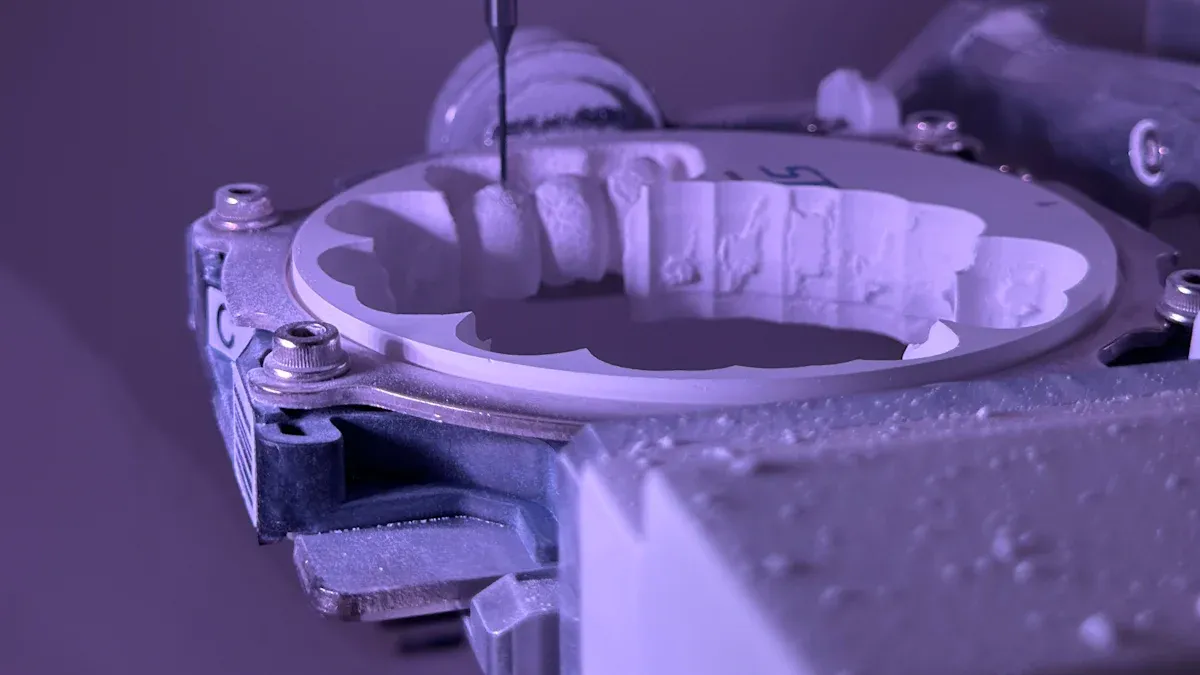

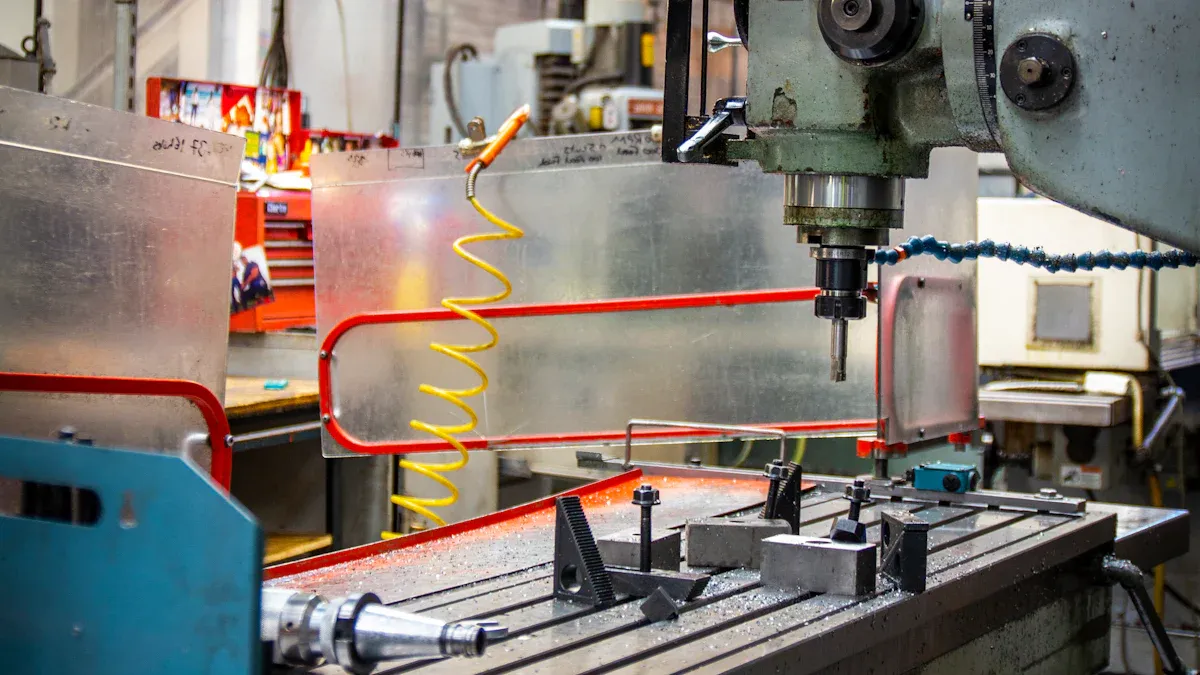

The sophistication of a supplier’s production facilities directly reflects their manufacturing capabilities. Advanced facilities utilize cutting-edge processes and equipment to ensure high-quality output. CNC machining is a computerized manufacturing process. It uses pre-programmed software to precisely control various types of production equipment. The process begins with computer-aided design (CAD) software to create the design. This design then translates into a format understandable by the CNC machine’s computer. Machinists program the CNC machine based on this design to produce intricate metal and plastic components.

Engineers program CNC operations using data from digital part designs created with CAD software. Computer-aided manufacturing (CAM) software then translates this data. CNC Mills offer machining at various depths along the x-axis, in addition to horizontal and vertical movement along the x and y axes. CNC Lathes provide both x and y axis movement for cutting on a changeable circular index. Both mill and lathe movements are programmed using G-code specifications.

Advanced facilities also incorporate waterjet cutting, a form of computer numerically controlled equipment. It uses a high-powered stream of water, often mixed with garnet, to cut through tough materials like 6-inch stainless steel. This method primarily creates two-dimensional gaskets or cuts thermal materials and RF absorbers. It allows for very precise lines, smooth edges, and corners. It can handle a large volume of parts simultaneously due to its multiple cutting heads and the use of layering and nesting techniques. These facilities feature advanced CNC machines equipped with automation features to streamline manufacturing, reduce production time, and lower costs. They also boast multi-axis capabilities, including 3-axis, 4-axis, and 5-axis machining, for precise and intricate cuts, curves, and contours in both metals and plastics.

Comprehensive CNC Machining Center Product Ranges

Elite Chinese suppliers offer a broad spectrum of machines and services. They provide diverse options to meet various industrial needs. Their product lines include professional high-precision machining centers, user-friendly CNC machine tools, and high-speed machining centers. Customers can find high-precision 5-axis vertical machining centers, horizontal machining centers, and gantry machining centers. They also offer composite profile machining centers, CNC lathes, 5-axis machining centers, and CNC cutting machines.

These manufacturers support a wide array of machining processes. They perform CNC milling, CNC turning, and CNC cutting. They also specialize in CNC prototyping, CNC routing, and CNC bending. Their capabilities extend to EDM machining, 4-axis CNC machining, and 5-axis CNC machining. Leading Chinese suppliers are equipped with modern multi-axis CNC machines, CNC milling systems, turning centers, and advanced cutting tools. This enables them to handle complex geometries and tight tolerances effectively. A comprehensive Cnc Machining Center product range ensures businesses find the exact solution for their specific production requirements.

Customer Feedback on CNC Machining Center Suppliers

Positive customer feedback consistently highlights several strengths of Chinese CNC machining center suppliers. These strengths contribute to their growing global reputation.

- Cost-Effectiveness and Competitive Pricing: Chinese suppliers offer unbeatable cost-efficiency. This results from economies of scale, complete manufacturing ecosystems, and fierce local competition. This leads to significantly lower CNC machining quotes, even with high-end equipment. Their advanced facilities and competitive pricing help businesses meet market demands and lower labor costs. This increases competitiveness and ensures favorable commercial margins.

- Mature Technical & Manufacturing Capabilities: Leading Chinese CNC suppliers have advanced beyond basic manufacturing. They now serve demanding global industries. They gain experience with difficult materials and complex geometries. They also provide one-stop solutions, from Design for Manufacturability (DFM) to post-processing and quality inspection.

- Strong Supply Chain Resilience & Speed: Manufacturing clusters in China ensure quick sourcing of tools and materials. This enables fast response times and flexible production schedules. This setup is ideal for rapid prototyping and adapting to market changes.

- Increasingly High Quality Standards & Certifications: To compete globally, Chinese machine shops adhere to international quality standards. These include ISO 9001, AS9100, ISO 13485, and IATF 16949. They also invest in advanced quality control equipment. Many Chinese CNC machining companies adhere to international quality management systems like ISO 9001. This ensures rigorous standards, precision, and reliability. They use state-of-the-art CNC machine tools and robust quality management systems. This meets tight tolerances and global market requirements.

- Trustworthy Communication & Project Management: Export-oriented providers employ English-speaking project managers and engineers. These professionals often have relevant certifications and backgrounds. This ensures clear communication and understanding of Western expectations. They maintain transparent processes, including RFQ, DFM feedback, and production updates.

After-Sales Support for CNC Machining Centers

Comprehensive after-sales support is crucial for long-term operational success. Elite Chinese suppliers offer robust support packages. These packages typically include maintenance services, technical assistance, training, and warranty coverage.

A robust warranty is a critical component. It offers peace of mind by protecting against defects and unexpected breakdowns. This leads to significant cost savings by reducing repair or parts replacement expenses. It also signifies the manufacturer’s confidence in product quality and reliability. Standard warranties typically last 12 months from delivery. They cover manufacturing defects and faulty materials under normal commercial use. Covered components often include CNC control systems, servo motors, electronic control boards, hydraulic/pneumatic systems, linear guides, and VFDs. Suppliers may also offer optional 24-month and 36-month extended warranty plans. These extended plans often provide benefits like priority technical response, discounted spare parts pricing, and scheduled remote maintenance checks with firmware assistance.

Beyond warranties, suppliers provide essential repair and maintenance services. These services cover CNC electronic parts, such as servo motors, circuit boards, power supplies, and spindle drives. They also include ball screw assembly repair and maintenance, CNC spindle rebuilds, CNC way cover repair, and chip conveyor repair. This comprehensive support ensures machines remain operational and efficient throughout their lifespan.

Top Regions for CNC Machining Center Manufacturing in China

China’s vast manufacturing landscape features several key regions specializing in CNC machining center production. These areas offer unique advantages, from comprehensive industrial chains to advanced technological capabilities.

Guangdong Province for CNC Machining Centers

Guangdong Province stands out as a primary hub for CNC machining within China’s economically developed eastern coastal regions. Cities like Dongguan, Shenzhen, and Zhongshan boast a strong industrial base for manufacturing. Guangdong’s bustling factories offer significant advantages for CNC machining, enabling the production of components at a much lower cost compared to local manufacturing processes in other regions. The precision of CNC machines in the province allows manufacturers to offer products of high complexity at competitive rates. This presents an ideal opportunity for price reduction and increased efficiency. Guangdong benefits from strong government support, with policies encouraging advanced manufacturing and automation. The presence of industrial clusters helps to lower costs and boost efficiency. Foreign investment and joint ventures further enhance this by introducing advanced technology into local plants. As part of China’s manufacturing hub, Guangdong offers a comprehensive industrial chain. This includes raw materials, tools, fixtures, and precision measurement equipment. This provides exceptional supply chain flexibility and responsiveness. Manufacturers quickly adapt to design changes and accelerate production cycles. Leading manufacturers in the region invest in advanced CNC centers from top brands like Mazak, DMG Mori, and GF. They utilize high-speed, high-precision machines with CMM and laser scanners. This ensures faster, smoother machining processes and maintains high precision. Nearly all factories implement ISO 9001 quality management systems and employ trained engineers to meet international standards. This guarantees controllable and traceable machining steps and consistent product accuracy.

Jiangsu Province’s Industrial CNC Machining Center Base

Jiangsu Province also plays a crucial role in China’s advanced manufacturing sector. It has a robust industrial base, particularly in heavy machinery and automation. Manufacturers in Jiangsu focus on developing and producing high-quality industrial equipment. This includes various types of CNC machinery. The province’s strong infrastructure and skilled workforce support its position as a significant contributor to the national manufacturing output. Many companies here specialize in providing comprehensive solutions for diverse industrial applications.

Zhejiang Province for Precision CNC Machining Centers

Zhejiang Province is another key region known for its precision manufacturing capabilities. Manufacturers here specialize in a wide array of CNC services. For example, PCBWay, located in Hangzhou, provides general CNC machining services. T-Artisan, headquartered in Ningbo, offers CNC laser cutting, CNC turning, CNC milling, and CNC precision machining. They recently purchased a 4-axis milling machine for high-speed and complex manufacturing solutions. Ningbo Haitian Precision Machinery Co., Ltd., also in Ningbo, specializes in the development, production, and sales of CNC vertical machining centers, CNC horizontal machining centers, and CNC gantry machining centers. These examples highlight Zhejiang’s focus on advanced and specialized CNC solutions.

Vetting Potential Chinese CNC Machining Center Suppliers

Businesses must carefully vet potential Chinese CNC Machining Center suppliers. This process ensures they select a partner capable of meeting specific production needs and quality standards. A thorough vetting strategy involves several key steps, from initial research to detailed evaluations.

Initial Research for CNC Machining Center Suppliers

Effective initial research forms the foundation for identifying suitable suppliers. Buyers should begin by exploring various online platforms specializing in manufacturing services. These platforms streamline the sourcing process and provide access to a wide network of manufacturers. For instance, PartsBadger offers online CNC machining services with instant pricing through an Instant Quote tool. They also provide a Rapid Quote system for higher volumes. Prototek delivers CNC machining and digital manufacturing services. Customers can upload CAD files for instant or engineer-assisted quotes and Design for Manufacturability (DFM) feedback via the Prototek IQ platform.

Other notable platforms include Xometry, an AI-driven online marketplace. It connects buyers with a vetted network of manufacturers. Xometry handles quoting, engineering evaluation, quality assurance, and project management centrally. Fictiv operates as a digital manufacturing platform. It connects buyers with a managed global network of partners. Fictiv oversees quoting, manufacturability analysis, quality inspections, and logistics. Norck provides on-demand CNC machining and other services. It relies on a distributed supplier network and engineering expertise for prototypes and high-volume production. Quickparts offers engineering and manufacturing services, including CNC machining. It provides instant pricing and lead times through its QuickQuote® platform. Finally, eMachineShop allows users to design parts, upload CAD files, and receive real-time cost estimates. It offers automated feedback on potential issues before placing orders. These platforms offer efficient starting points for comprehensive supplier searches.

Direct Communication with CNC Machining Center Manufacturers

After initial research, direct communication with potential manufacturers becomes essential. This step allows buyers to clarify capabilities, discuss specific requirements, and assess responsiveness. Buyers should prepare a list of targeted questions to ensure a productive dialogue. For example, they should inquire about the manufacturer’s experience in specialized fields, such as medical device machining.

Key questions to ask include:

- What experience do you have in medical device machining?

- What technologies and equipment do you use for precision CNC milling?

- How do you ensure quality control throughout the manufacturing process?

- Can you accommodate customization and quick turnarounds?

- How transparent and responsive is your communication?

Additionally, buyers should ask about the machines themselves. They can inquire:

- How long will this particular machine last?

- Is assembly included, or will I have to put the machine together myself?

- Where is the machine built?

- What options are available for this machine for future upgrades, if any?

- What sets your technology apart from the competition?

- Can I demo the machine before purchasing it?

These questions help buyers gauge a manufacturer’s expertise, technological sophistication, and commitment to customer service.

Requesting CNC Machining Center Samples and Demos

Requesting samples and demos provides tangible evidence of a supplier’s capabilities. This step allows buyers to evaluate the quality and precision of the manufacturer’s work firsthand. When assessing samples and demos, buyers should focus on specific technical parameters and past performance indicators.

Consider the following parameters for evaluation:

| Parameter | Standard | Evaluation Method |

|---|---|---|

| Tolerance Range | ±0.01 mm to ±0.001 mm | Review inspection reports, CMM data |

| Repeatability | ±0.005 mm or better | Analyze production run data |

| Surface Roughness (Ra) | 0.4–0.8 µm for precision parts | Inspect sample parts, surface profilometer |

| Positional Accuracy | ±0.002 mm | Check machine specifications |

| Process Capability (Cpk) | ≥1.33 | Request SPC control charts |

Key metrics for assessing machining precision include:

- Tolerance Range: High-precision applications typically require ±0.01 mm to ±0.001 mm. Manufacturers must demonstrate consistent achievement with calibrated equipment.

- Repeatability: The machine’s ability to produce identical parts across multiple runs is crucial. Critical components often require ±0.005 mm or better.

- Positional Accuracy: This refers to the machine’s ability to move to exact programmed coordinates. High-end machines achieve accuracy within ±0.002 mm.

- Surface Roughness (Ra): Measured in micrometers (µm), 0.8 µm indicates a smooth finish for functional surfaces. High-precision applications demand 0.4 µm or lower. Buyers can validate this by reviewing sample parts with measurement reports.

To evaluate a provider’s past performance, buyers should request:

- Sample Parts: Physical samples or detailed inspection reports of parts similar to their project requirements.

- Customer References: Contact previous clients to verify delivery times, quality consistency, and responsiveness.

- Defect Rates: Providers should share data on defect rates. Ideally, these rates should be below 1% for high-precision industries.

This comprehensive evaluation ensures the chosen supplier meets all technical and quality expectations.

Factory Audits for CNC Machining Center Production

Factory audits provide a critical step in evaluating potential Chinese suppliers. These audits offer direct insight into a manufacturer’s operational capabilities, quality control processes, and overall production environment. A thorough audit helps ensure the supplier meets specific production needs and quality standards.

Auditors begin by assessing basic supplier information. This includes company details, location, ownership, and workforce size. They also verify relevant certifications, such as ISO 9001 and ISO 14001, which demonstrate a commitment to quality and environmental management. Auditors evaluate the supplier’s production capacity and capabilities, ensuring they can scale to meet demand. They also review the supplier’s reputation and history, checking past performance records, references, and compliance history.

A key part of the audit involves evaluating the Quality Management System (QMS). Auditors examine the supplier’s quality policies and objectives. They review documentation of employee training and skill levels, especially for roles critical to quality. Document control procedures are assessed to ensure proper management and updating of manufacturing SOPs and quality manuals. Process control procedures are also scrutinized to monitor production consistency, quality checkpoints, and corrective actions for deviations.

Critical checkpoints during a factory audit for CNC machining center production include several key areas. Auditors ensure production reliability and repeatability by checking process documentation and strict adherence to standard operating procedures (SOPs). They verify regular equipment maintenance records to ensure optimal machinery operation and prevent downtime. Quality checks are implemented at critical production stages to prevent defects and ensure product consistency.

Auditors also monitor key safety parameters. They regularly check fire safety equipment, proper use of personal protective equipment (PPE), and clear emergency exits. Adherence to machinery safety guidelines and ventilation in hazardous areas also receives scrutiny.

Furthermore, auditors evaluate geometric design elements. They assess how geometric features align with manufacturing capabilities, identifying complex curves and intricate details. They examine whether specified tolerances serve functional requirements or unnecessarily increase manufacturing complexity. Process integration considerations are also assessed, looking at how different manufacturing steps interact and considering the sequence and compatibility of operations. Material and surface requirements are reviewed for compatibility with manufacturing processes.

For Design for Manufacturability (DFM), auditors identify opportunities to standardize radius values and ensure all internal corners have radius specifications. They assess complex curved surfaces. They also evaluate whether angled features serve critical functions or can be modified for efficiency. Deep pockets and narrow channels are assessed for specialized CNC machining requirements.

A visual inspection or walkaround of the facility provides valuable insights. Auditors assess the general environment, cleanliness, and presence of damage, rust, or missing parts. They verify the operability of touchscreens, brightness, button wear, and overall interface function on control panels. Maintenance logs are reviewed for maintenance, calibrations, and repairs, noting any recurring issues. The cabin or enclosure is checked for cleanliness, lighting, secure windows, smooth-operating access doors, and functional safety lock-outs. The lubrication system is inspected for quality, smell, and condition of the lubricant tank and delivery lines. Auditors listen to the spindle for smooth operation and transitions, inspecting for noise from bearings, belts, or pulleys. They examine the tool changer for broken, missing, or damaged pockets and test its ability to change tools. Finally, they perform a thorough check of the axis travels, listening, measuring, and qualifying accuracy, and inspecting linear guides for lubrication signs.

Negotiating CNC Machining Center Contracts

Negotiating a comprehensive contract with a Chinese supplier is essential for a successful partnership. A well-structured contract protects both parties and clarifies expectations regarding quality, delivery, and payment.

The contract should mandate the seller to maintain a Quality system compliant with international standards like ISO 9001 or AS9100. This ensures personnel competency. It prohibits Material Review Board (MRB) authority and requires the seller to notify the buyer of nonconforming processes, products, or services for disposition. The seller must also notify and obtain written approval from the buyer for any proposed changes in design, fabrication methods, or processes.

Raw materials must be accompanied by certifications, chemical, and/or physical test results. For raw materials used in purchased articles, test results or detailed analysis of acceptance tests must be available to the buyer upon request. The contract stipulates that products must have a minimum of 75% remaining shelf-life upon receipt for age-controlled and limited-life products. For traceability, the seller must apply unique identification to products or materials and record this data, traceable to seller records. The seller must maintain legible inspection and test records for a minimum of seven years, traceable to the product.

The contract requires the seller to inspect and/or test all characteristics defined by the purchase order and applicable specifications. All measuring tools and equipment used for acceptance and compliance must be calibrated according to NIST requirements, with proof kept on file. The contract defines performance criteria for on-time delivery (90.0%) and quality (98.0%), requiring an action plan for missed targets. It also requires the flow-down of all applicable quality requirements to all suppliers and sub-tier suppliers for contracts with DPAS ratings.

Payment terms detail how and when the OEM will pay the manufacturer. This includes invoice timing, credit terms, and handling of disputes. It should cover taxes, raw materials, late payment costs, and offsets. Material ordering and planning are also crucial. Manufacturers use demand forecasting, such as rolling 12-month forecasts, to determine raw material needs. Specific arrangements for long lead-time or minimum order quantity components should appear in an appendix.

The contract addresses managing excess stock. This covers situations where manufacturers must purchase more material than strictly necessary, for example, due to minimum order quantities or end-of-life components. It outlines how costs for financing and storing excess stock are handled, often requiring customer responsibility. Technical requirements ensure clarity and transparency of product technical specifications. These include the Bill of Material (BOM), Approved Vendors List, PCB specifications, mechanical drawings, product markings, test specifications, traceability, packaging, and shipping instructions. Mechanisms for managing engineering changes should also be defined.

Quality assurance, inspection, and test clauses clarify what quality actions are taken by default. If more in-depth inspection or testing is required beyond standard workmanship checks, the agreement must explicitly stipulate this, along with any associated costs. Finally, the product warranty defines the responsibilities of both the OEM, who holds design authority and specifies parts, and the EMS provider, who orders parts, performs assembly, and potentially tests with customer-provided equipment and instructions.

Common Pitfalls When Sourcing CNC Machining Centers from China

Businesses often encounter challenges when sourcing CNC machining centers from China. Avoiding common pitfalls ensures a successful partnership and high-quality outcomes.

Neglecting Quality Control for CNC Machining Centers

Neglecting quality control can severely impact production. Inadequate servicing of CNC machines leads to precision loss, resulting in deviations from specifications, defective parts, and wasted materials. This becomes critical in industries demanding tight tolerances. Skipping First Article Inspection (FAI) risks batch failures. Measurement tool errors, such as those from uncalibrated calipers or micrometers, produce unreliable results. These issues lead to high rejection rates, inconsistent part performance, and potential recalls. Neglecting CNC machine upkeep causes misalignments or wear, affecting product accuracy. This results in defective parts, increased scrap, and rework. Inconsistent product quality damages a business’s reputation, leading to costly returns, warranty claims, dissatisfied customers, and negatively impacting long-term profitability.

Poor Communication with CNC Machining Center Suppliers

Poor communication with Chinese suppliers creates significant risks. Effective communication prevents design misinterpretations. It ensures clear discussions on tolerances, materials, and specifications. It also reduces production delays through timely updates, avoiding bottlenecks and unexpected lead time issues. Proactive communication improves cost efficiency by identifying savings opportunities and preventing unnecessary rework. To improve communication, use bilingual drawings to prevent technical term misinterpretation. Schedule weekly calls to manage time differences and avoid lead time extensions. Provide clear specifications, Engineering Change Notices (ECNs), and tolerance notes for all projects. Sign Non-Disclosure Agreements (NDAs) to define CAD/CAM data ownership. Utilize secure transfer channels like SFTP or VPN to reduce IP leakage risks. Limit file access to authorized engineers, especially for industries requiring ITAR/EAR compliance.

Overlooking After-Sales Service for CNC Machining Centers

Overlooking after-sales service for CNC machining centers can undermine initial cost savings. A survey by the Association for Manufacturing Technology reveals approximately 60% of companies fail to allocate sufficient budgets for post-sales support. This leads to an average productivity loss of 10% due to machine downtimes and inefficiencies. Customers experiencing breakdowns or malfunctions are left without quick resolution, leading to frustration. This reduces customer loyalty. Frequent equipment failures due to inadequate maintenance can tarnish a company’s reputation for reliability. Lack of ongoing support, including software updates, can lead to increased vulnerabilities and lower profitability. Customers are forced to source replacement parts from third parties at higher costs when readily available parts are not provided. Maintenance issues can affect a machine’s productivity well before complete failure. For instance, a ballscrew might gradually decline in performance, reducing part quality and causing productivity drag before anyone realizes the problem’s extent.

Failing to Verify CNC Machining Center Certifications

Businesses often overlook the critical step of verifying supplier certifications. This oversight carries significant risks. Clients and partners may lose trust in the business. Manufacturers can fail to meet stringent industry standards. This compromises quality and safety in manufacturing processes. Production errors increase. Operational efficiency reduces. Businesses may also find themselves unable to access specialized markets, such as aerospace or medical device production. This puts them at a disadvantage in global competition. Always confirm a supplier’s certifications to ensure compliance and maintain high standards.

The Risk of Unusually Low-Priced CNC Machining Centers

An unusually low price for a Cnc Machining Center often signals potential problems. Such deals can lead to higher defect rates. Low-cost suppliers may compromise on materials, tooling, or quality control. This results in more defective parts. Businesses face increased scrap and rework costs. Poorly manufactured components often require expensive fixes or complete replacements. Supply chain disruptions can occur. Unreliable vendors cause production delays. Some suppliers use inferior materials to cut costs. This substitution can lead to premature part failure, safety risks, and performance issues. A lack of rigorous quality control is common. The absence of certified processes, like ISO 9001 and AS9100, leads to inconsistent tolerances and customer dissatisfaction. Inadequate customer support and communication also plague cheaper shops. This causes misunderstandings, delayed responses, and unresolved issues.

Leading Chinese CNC Machining Center Manufacturers

China hosts several prominent manufacturers of CNC machining centers. These companies offer advanced technology and reliable solutions for various industries.

SMTCL CNC Machining Centers

SMTCL, established in 1935, stands as a global leader in the machine tool industry. The company is recognized for its innovation, quality, and customer-centric approach. SMTCL offers a comprehensive range of products. These include CNC lathes, milling machines, and grinding machines. Their machines ensure precision and efficiency in manufacturing processes across diverse industries. SMTCL is one of China’s largest and oldest CNC machine tool builders. They provide horizontal and vertical machining centers, along with CNC turning machines. SMTCL is known for its cost-effective design and Fanuc-compatible controls. Their machines find use in general manufacturing, railways, and heavy industry. SMTCL holds the broadest market share in China. Government growth initiatives support this market strength.

DMTG CNC Machining Centers

DMTG offers a robust lineup of CNC machining centers. These machines incorporate advanced technological features. They use hollow cooling technology on X, Y, and Z screws. This controls heat and ensures high processing accuracy with temperature compensation. DMTG machines feature an electric spindle structure. This supports high speeds and dual-speed transmission for both low-speed cutting and high-speed machining. High-rigidity linear guides complement this for rapid axis movement. A linkage tool changing mechanism provides quick and reliable automatic tool changes, enhancing productivity. The main structure uses resin sand casting and an integrally cast bed. This provides outstanding rigidity for all movement components. DMTG optimizes the frame structure and overall machine layout through finite element analysis during design. This strengthens stability and mechanical performance. DMTG’s product lines include conventional lathes, flat and slant bed CNC lathes, CNC turning centers, vertical machining centers, horizontal machining centers, gantry machining centers, and automatic lines.

QCMTT CNC Machining Centers

BOOHI CNC Machining Centers

BOOHI stands as a notable manufacturer in China’s CNC machine tool industry. The company focuses on producing reliable and efficient machining solutions for various industrial applications. BOOHI offers a range of CNC machines designed for precision and durability. Their product line often includes vertical and horizontal machining centers, catering to diverse manufacturing needs. BOOHI aims to provide cost-effective equipment without compromising on performance. Manufacturers seeking dependable machinery for general machining tasks often consider BOOHI’s offerings.

3ERP Precision CNC Machining Services

3ERP provides comprehensive precision CNC machining services. The company specializes in delivering high-quality components for demanding industries. 3ERP offers a variety of specialized machining capabilities. These services ensure clients receive parts with exact specifications and superior finishes.

- CNC Milling: This process uses a rotating cylindrical cutting tool to machine materials. 3ERP leverages CNC milling to create parts requiring precise contours, slots, and channels.

- CNC Turning: CNC turning creates cylindrical parts by removing unwanted material. 3ERP excels in producing components that need precise circular shapes and internal threads.

- CNC Drilling: This process creates exact holes and cavities in materials. 3ERP’s advanced CNC drilling services support high-volume production with impeccable precision.

- 5-Axis CNC Machining: This advanced technique allows for complex geometries and intricate designs.

- Precision Machining: 3ERP focuses on achieving tight tolerances and high accuracy across all its services.

Blue Elephant CNC Machining Centers

Blue Elephant is a well-known Chinese manufacturer specializing in CNC machinery. The company primarily focuses on producing CNC routers and related equipment. Blue Elephant machines serve industries such as woodworking, advertising, and mold making. They offer a variety of models, from entry-level machines to advanced multi-axis systems. Blue Elephant emphasizes user-friendly interfaces and robust construction in its designs. The company aims to provide versatile and affordable CNC solutions to a global customer base. Their machines are often recognized for their adaptability to different materials and project scales.

TAICNC Machine Tools

TAICNC Machine Tools specializes in the research, development, and manufacturing of high-quality machine tools. The company offers a diverse product portfolio. This includes vertical machining centers, horizontal machining centers, and gantry machining centers. TAICNC focuses on providing precision and reliability to its customers. Their machines serve various industries, including automotive, aerospace, and general manufacturing. TAICNC integrates advanced control systems into its equipment. This ensures high accuracy and efficient operation. The company emphasizes continuous innovation. It aims to meet the evolving demands of modern production environments. TAICNC also provides comprehensive technical support. This assists customers with installation, training, and maintenance.

WMTCNC China Offerings

WMTCNC is a prominent Chinese manufacturer of machine tools. The company provides a wide range of products. These include conventional lathes, milling machines, and drilling machines. WMTCNC also offers advanced CNC solutions. Their product line features vertical machining centers, horizontal machining centers, and CNC lathes. WMTCNC focuses on delivering cost-effective and reliable machinery. This supports small to medium-sized enterprises. The company maintains strict quality control standards. This ensures the durability and performance of its equipment. WMTCNC has a strong presence in both domestic and international markets. It continues to expand its global reach.

Yijin Hardware CNC Machining Services

Yijin Hardware provides specialized CNC machining services. The company focuses on producing high-precision components. Yijin Hardware offers a variety of machining capabilities. These include CNC milling, CNC turning, and surface finishing. The company works with a wide range of materials. These materials include aluminum, stainless steel, and various plastics. Yijin Hardware caters to industries requiring tight tolerances and complex geometries. These industries include electronics, medical devices, and robotics. The company emphasizes quality assurance throughout its production process. This ensures every part meets exact customer specifications. Yijin Hardware also offers rapid prototyping services. This helps clients accelerate their product development cycles.

OTURN MACHINERY Special Purpose Machines

OTURN MACHINERY operates as a reliable manufacturer of special purpose machines. The company serves as an overseas marketing and sales center for its group factories. OTURN MACHINERY focuses on the research and development (R&D) of high-quality, high-efficiency industry-specific machines for customers. They also design complete production line solutions for clients, guiding them from initial concept to full implementation. The company aims to provide the most efficient processing methods available. This approach helps customers save equipment investment costs and recover input costs sooner.

OTURN MACHINERY’s machines and production lines cater to various industries. These include industrial valves, pipe fittings, flanges, construction machinery parts, energy, shipping, and molds. The company possesses a professional team dedicated to designing valve manufacturing production lines. This expertise covers building casting assembly lines, processing various industrial valves, valve testing, and welding. OTURN MACHINERY has extensive market experience and successful case studies in these areas. They ensure their solutions meet the precise demands of specialized manufacturing.

Finding a reliable Chinese supplier is achievable with diligent effort. Businesses apply these comprehensive criteria to identify and partner with top-tier manufacturers. They secure the best Cnc Machining Center for their operations through informed decisions. This strategic approach ensures long-term success, competitive advantage, and high-quality outcomes in the global market.

FAQ

What advantages do Chinese CNC Machining Center suppliers offer?

Chinese suppliers provide cost-effectiveness and high quality. They also drive innovation in CNC technology. Businesses benefit from diverse options and extensive customization capabilities. This combination helps companies achieve competitive pricing and advanced manufacturing solutions.

Which certifications are crucial for elite Chinese CNC Machining Center suppliers?

Elite suppliers hold certifications like ISO 9001 for quality management. Specialized industries require AS9100 for aerospace or ISO 13485 for medical devices. These certifications demonstrate a commitment to rigorous standards and best practices.

How do businesses effectively vet potential Chinese CNC Machining Center suppliers?

Businesses should conduct initial research on online platforms. They must engage in direct communication with manufacturers. Requesting samples and demos provides tangible evidence of capabilities. Factory audits offer critical insights into production facilities and quality control processes.

Why is after-sales support important for CNC Machining Centers?

Robust after-sales support ensures long-term operational success. It includes comprehensive warranty coverage, maintenance services, and technical assistance. This support minimizes downtime, reduces repair costs, and maintains machine efficiency throughout its lifespan.

Post time: Dec-15-2025