You reduce risk and maximize value when you carefully evaluate a CNC Lathe supplier’s technical capability and cost transparency. For example, frequent inspections at each production stage ensure precision, and clear cost analysis helps you avoid unexpected expenses. These steps protect your business and support long-term success.

Key Takeaways

- Choose CNC lathe suppliers with strong technical skills and clear proof of quality to ensure precise, reliable parts and smooth production.

- Look for transparent pricing and certifications like ISO 9001 to avoid hidden costs and guarantee consistent quality.

- Pick suppliers who communicate well, offer fast delivery, and provide excellent after-sales support to keep your projects on track and build lasting partnerships.

CNC Lathe Supplier Evaluation: 7 Critical Factors

Technical Capability

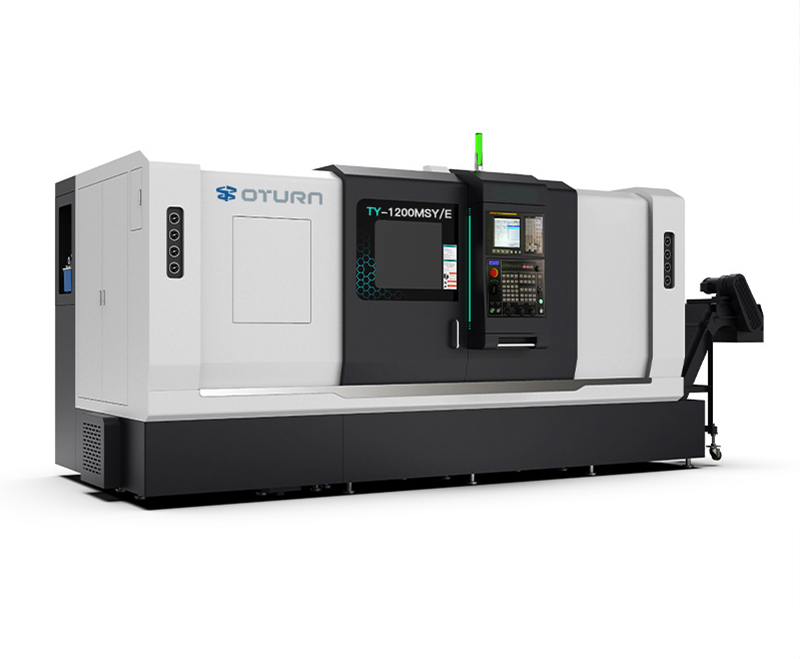

You need a CNC Lathe supplier with advanced technical capability to meet your precision and production requirements. The global CNC lathe machine tools market is expanding rapidly, driven by automation, Industry 4.0, and demand from sectors like automotive and aerospace. This growth highlights the importance of innovation, automation, and precision when you evaluate suppliers. Suppliers who invest in high-speed spindles, robust machine structures, and digital integration can deliver superior accuracy and efficiency. For example, a company that chose a supplier with advanced machining capabilities, even at a higher price, benefited from precise titanium alloy parts, on-time delivery, and responsive technical support. This case shows that technical capability ensures quality, reliability, and smooth production.

Tip: Always request detailed technical documentation and case studies to verify a supplier’s expertise.

Pricing & Cost Transparency

Clear pricing and cost transparency protect your budget and build trust. Direct sales models in the lathe machine market have grown because they remove intermediaries, allowing you to communicate directly with manufacturers. This approach leads to more competitive pricing and easier customization. Transparent pricing helps you avoid hidden costs and supports better planning. When you work with suppliers who provide clear quotes and cost breakdowns, you can make informed decisions and negotiate effectively.

Quality Assurance & Certifications

Quality assurance is essential for consistent results in CNC Lathe projects. Look for suppliers with certifications such as ISO 9001 or AS9100. These certifications prove that the supplier maintains a strong Quality Management System, focusing on customer satisfaction and process consistency. Regular audits, both internal and external, confirm compliance and highlight areas for improvement. Many suppliers use Statistical Process Control (SPC) to monitor production data and catch deviations early. This method ensures stable operations and high-quality output.

Note: Ask for recent audit reports and certification documents to confirm a supplier’s commitment to quality.

Experience & Communication

Supplier experience and effective communication directly impact your project’s success. Suppliers with industry-specific experience understand your standards and can deliver compliant products. A skilled workforce and a proven track record are strong indicators of reliability. Open communication channels, such as dedicated account managers and real-time collaboration tools, improve efficiency and satisfaction. Industry benchmarks show that transparent pricing and instant quotes can boost profit margins, while regular feedback and responsive support increase repeat business.

- Establish clear KPIs for delivery, quality, and responsiveness.

- Schedule regular meetings to discuss progress and challenges.

- Choose suppliers who offer personalized solutions and proactive updates.

Customer Service & After-Sales Support

Strong customer service and after-sales support ensure long-term satisfaction. A supplier with a professional support team can resolve issues quickly and follow up to confirm your satisfaction. Real-time remote monitoring and predictive maintenance services increase machine uptime and productivity. These services help you avoid costly downtime and keep your operations running smoothly.

Good after-sales support goes beyond fixing problems—it builds lasting partnerships.

Turnaround Time & Flexibility

Fast turnaround and flexibility are vital in today’s competitive market. You should assess a supplier’s capacity by reviewing their production levels, ability to handle urgent orders, and inventory management. Reliable delivery performance and disaster preparedness show that a supplier can adapt to your changing needs. Flexible suppliers help you respond to market shifts and keep your projects on schedule.

| Evaluation Area | What to Check For | Why It Matters |

|---|---|---|

| Production Capacity | Facility size, rush order ability | Ensures timely delivery |

| Inventory Management | Stock levels, lead times | Reduces risk of shortages |

| Delivery Reliability | On-time rates, contingency plans | Maintains your workflow |

Supplier Reputation & Reliability

A supplier’s reputation and reliability reflect their ability to deliver on promises. Leading companies in the CNC Lathe market hold significant market share, showing strong reliability and industry trust. You should review a supplier’s compliance history, financial stability, and customer feedback. Supplier scorecards and digital procurement platforms help you track performance and manage risks. Reliable suppliers support your business growth and reduce the risk of disruptions.

Choose suppliers with a proven track record and positive references to ensure consistent results.

How to Assess CNC Lathe Suppliers Effectively

Practical Tips for Evaluation

When you evaluate CNC Lathe suppliers, you should use a structured approach to make the best decision. Industry research highlights several best practices:

- Focus on critical criteria such as quality, cost, delivery, flexibility, and risk.

- Use a multi-criteria decision-making tool like the Analytic Hierarchy Process (AHP) to weigh supplier attributes.

- Prioritize suppliers with industry certifications, such as ISO 9001 or AS9100D, to ensure quality and compliance.

- Assess technical expertise by reviewing advanced machinery capabilities and experience with challenging materials.

- Conduct site visits, request sample parts, and check references to verify claims.

- Review in-process inspection methods and quality control systems, including CMM and SPC.

- Balance cost with quality by requesting detailed quotes and understanding pricing structures.

These steps help you reduce errors, lower scrap rates, and improve throughput in your operations.

Key Questions to Ask CNC Lathe Suppliers

Asking the right questions helps you compare suppliers and uncover strengths or weaknesses. Consider these key performance indicators:

| KPI Category | KPI Description / Question to Ask Supplier |

|---|---|

| Quality | What is your Parts Per Million (PPM) defect rate? |

| Delivery | What percentage of orders do you deliver on or before the agreed ship date? |

| Customer Complaints | How often do you receive and address external customer complaints? |

| Cost of Poor Quality | What is your cost related to external quality issues, scrap, and rework? |

| Safety | What is your record of lost time accidents and reported injuries? |

| Machine Utilization | What percentage of available machine hours are actually used? |

| Labor Utilization | What is your labor capacity utilization rate? |

| Preventative Maintenance | How often is maintenance performed on time? |

| Set-Up Efficiency | How efficient is your machine setup time compared to projections? |

| Customer Satisfaction | How do you measure and track customer satisfaction and service quality? |

Supplier Comparison Checklist

You can simplify your decision process by using a checklist. Review these points for each CNC Lathe supplier:

- Confirm industry certifications and compliance.

- Evaluate technical capabilities and experience with your materials.

- Check delivery performance and flexibility.

- Review customer service and after-sales support.

- Compare cost transparency and pricing details.

- Assess reputation through references and case studies.

Tip: A structured checklist ensures you do not overlook any critical factor during supplier evaluation.

When you evaluate CNC lathe machine suppliers with these seven factors, you set your business up for success. A structured approach helps you reduce risk and build a strong supply chain. Use this framework to choose a partner who supports your goals and delivers reliable results.

FAQ

What certifications should you look for in a CNC lathe supplier?

You should look for ISO 9001 or AS9100 certifications. These prove the supplier follows strict quality management standards and delivers consistent, reliable products.

How do you verify a supplier’s technical capability?

You can request technical documentation, review case studies, and ask for sample parts. Site visits also help you see their equipment and processes firsthand.

Why is after-sales support important for CNC lathe buyers?

- You receive quick issue resolution.

- You gain access to maintenance and training.

- You ensure long-term machine performance and productivity.

Post time: Jun-19-2025