Horizontal Machining Centers significantly boost efficiency, precision, and overall productivity in Automotive Parts Manufacturing. These machines streamline production processes, reduce cycle times, and improve part quality for complex automotive parts. The horizontal spindle orientation and advanced capabilities of these machines are key to their efficiency gains. For instance, their design inherently offers superior chip evacuation, which directly enhances CNC Machining Efficiency. What are the benefits of using HMC for automotive components? They include faster production and higher quality. Features like 5-Axis CNC Machining further expand their capabilities, making them indispensable.

Key Takeaways

- Horizontal Machining Centers (HMCs) make car parts faster and better. They cut many sides of a part at once. This saves time and makes parts more accurate.

- HMCs remove metal chips easily. Gravity helps chips fall away. This keeps tools safe and makes parts look good.

- HMCs work well with robots. They have special trays that swap parts quickly. This means machines can run without stopping, making more parts.

- HMCs are very precise. They use smart systems to stay accurate. This is important for new electric car parts like motor housings and battery trays.

Core Advantages of Horizontal Machining Centers in Automotive Production

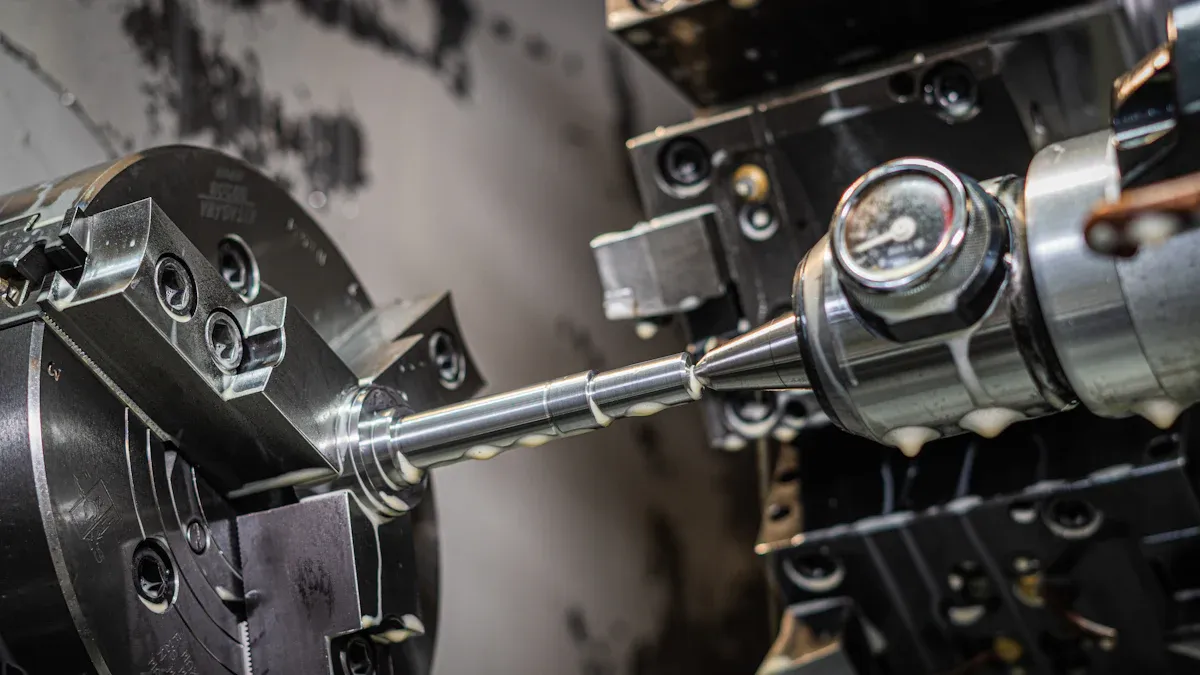

Superior Chip Evacuation and Management

Horizontal Machining Centers (HMCs) offer significant advantages in chip evacuation. Their design inherently promotes efficient chip removal. Gravity assists in moving chips away from the workpiece. This enhances chip evacuation and reduces the risk of re-cutting chips. Re-cutting chips can damage both the tool and the part. The horizontal orientation also contributes to better chip management. This improves cooling and lessens the need for manual cleaning. In contrast, chips tend to accumulate in vertical machining. The horizontal spindle orientation allows chips to fall away from the cutting area naturally. This natural chip removal prevents chips from being re-cut. Preventing re-cutting improves surface finish and extends tool life.

Enhanced Cutting Stability and Tool Life

HMCs provide enhanced cutting stability. This stability directly translates to longer tool life. The horizontal spindle orientation minimizes vibration during machining operations. Stable machining reduces wear on cutting tools. Efficient chip evacuation also contributes to reduced wear on cutting tools. This combination of stability and effective chip removal extends tool life. Automotive manufacturers benefit from fewer tool changes. This reduces downtime and lowers operational costs.

Increased Productivity and Throughput with Horizontal Machining Centers

Horizontal Machining Centers significantly boost productivity and throughput in automotive production. Their design allows for multiple-sided machining in a single setup. This reduces the need for frequent part reorientation. Pallet changers further enhance efficiency. They allow operators to load new workpieces while the machine processes another. This continuous operation minimizes idle time. The robust construction of HMCs supports aggressive cutting parameters. This leads to faster material removal rates. Automotive component manufacturers achieve higher production volumes. They also maintain consistent part quality.

Reduced Non-Cutting Time and Setup Efficiency

Horizontal Machining Centers significantly minimize non-cutting time and enhance setup efficiency, which directly boosts overall production output. A primary contributor to this efficiency is the integration of advanced pallet changer systems. For instance, built-in pallet changers can reduce non-cutting time by up to 30%. These systems allow operators to load new workpieces onto a waiting pallet while the machine actively processes another part. This continuous operation eliminates idle periods between machining cycles. Optional pallet changers further enhance efficiency, particularly for high-speed and high-accuracy machining applications. Additionally, high-efficiency pallet changers support stable, heavy-duty machining, ensuring consistent performance even with demanding automotive components.

Beyond pallet systems, HMCs incorporate several design elements that streamline operations. Optimized acceleration control reduces non-cutting time during short-distance movements, making every motion precise and swift. Rapid traverse speeds also contribute to shorter cycle times; for example, increasing X/Y/Z-axes speeds from 60m/min to 70m/min significantly cuts down on repositioning time.

Setup efficiency also sees substantial improvements with advanced tool management systems. Standard HMCs often feature a 60-tool ring magazine, which provides fast indexing for quick tool changes. Manufacturers can also opt for various tool magazine types, including ring, chain, and rack systems, supporting up to 300 tools. A standard magazine operation panel simplifies all tool setup-related operations, reducing the time and effort required for tool preparation. Furthermore, features like dual-axis motorized nozzles and AI chip removal ensure efficient chip management. This prevents chip accumulation and supports continued unmanned operation, minimizing interruptions and further reducing non-cutting time. These technological advancements collectively ensure that HMCs spend more time cutting and less time waiting, maximizing their productivity in automotive manufacturing.

Key Applications of Horizontal Machining Centers in Automotive Manufacturing

Engine Block and Cylinder Head Production with HMCs

Horizontal Machining Centers significantly enhance the production of engine blocks and cylinder heads. They improve efficiency by reducing part handling. Their horizontal spindle orientation allows multi-sided machining in a single setup. This minimizes repositioning and accelerates processing times. It also allows multiple operations without disruption. Ultimately, this boosts overall productivity. HMCs maintain high precision over long production runs. They handle heavy-duty components. This meets exacting standards and enhances production rates. For engine blocks, typical cycle times range from 20 to 45 seconds per part. Operations producing around 100 pieces per day can use conventional CNCs. However, for volumes reaching thousands per day, specialized machinery is justified. This historically included transfer lines. Now, it often involves ‘modules’ with robotic transfer. A typical cycle time for a block line, potentially involving transfer machinery, is estimated to be between 50 seconds to 1 minute.

Transmission Case and Gear Manufacturing using Horizontal Machining Centers

Automotive manufacturers utilize HMCs for producing transmission components. HMCs are particularly effective for transmission cases in the automotive industry. They also excel at manufacturing gear housings in heavy machinery. The horizontal setup facilitates faster machining of large, heavy parts. These parts often have multiple features. This leads to reduced cycle times and enhanced surface finishes.

Chassis and Suspension Component Machining

HMCs are highly capable machines. They produce complex parts with high efficiency and accuracy. Their ability to perform multi-sided machining without repositioning the workpiece is crucial. They use rotary tables or tombstone fixtures for this. This significantly improves accuracy and consistency. This makes HMCs ideal for manufacturing precision components. These include chassis and suspension systems. CNC machining ensures safety-critical components meet performance and safety standards. Tolerances for these components are very high, often ±0.01 mm. A Horizontal Machining Center offers greater stability and rigidity compared to Vertical Machining Centers. This allows for heavier cuts and larger workpieces. This further contributes to their precision. It also makes them suitable for demanding automotive applications.

Electric Vehicle Powertrain Components and HMC Precision

Electric vehicle (EV) powertrain components demand exceptional precision and consistency. Horizontal Machining Centers (HMCs) play a crucial role in meeting these stringent requirements. They efficiently produce complex parts like motor housings, battery trays, and specialized gear components. The advanced capabilities of HMCs ensure the high quality and reliability essential for EV performance.

HMCs offer specific advantages for EV manufacturing. For example, their design supports specialized operations for unique EV parts.

Our equipment’s dual-spindle design can be used for rotating and milling operations, making it ideal for machining stator housings.

This specialized capability highlights how HMCs adapt to the evolving needs of the automotive industry. They provide the versatility required for innovative EV designs.

HMCs deliver critical benefits for EV powertrain component production. These benefits directly contribute to manufacturing excellence:

- Precision: HMCs achieve tight tolerances and consistency. This reduces human error in complex machining tasks.

- Consistency: They use computer-programmed commands. This produces parts identically every time. It maintains high quality standards across all units.

- Productivity: HMCs significantly increase production speed. They reduce the need for manual labor. This accelerates the manufacturing process.

- Cost-Efficiency: HMCs save time and money. They achieve this through less material waste and improved output. This results from their precision, consistency, and productivity.

The precision of HMCs is vital for EV motor components. These parts require exact dimensions for optimal efficiency and power delivery. HMCs handle the intricate geometries of motor casings and rotor shafts. They ensure every component fits perfectly. This minimizes vibration and maximizes energy conversion.

Battery trays also benefit from HMC precision. These trays must securely house battery cells. They also need to provide structural integrity and thermal management. HMCs machine these large, complex structures with accuracy. This guarantees proper assembly and safety.

Furthermore, HMCs are essential for manufacturing EV gear components. Electric powertrains often use specialized gearboxes. These gearboxes require precise machining for smooth operation and durability. HMCs produce these gears with the necessary accuracy. This contributes to the overall efficiency and quietness of electric vehicles.

Technological Advancements Driving HMC Efficiency

Multi-Axis Machining Capabilities of Horizontal Machining Centers

Multi-axis machining capabilities significantly enhance the versatility and precision of Horizontal Machining Centers. Five-axis machining, in particular, allows the cutting tool to approach the workpiece from more angles without repositioning. This reduces the risk of misalignment and human error, ensuring precise and consistent cuts. Manufacturers can machine complex parts, such as turbines and combustion chambers, as single pieces. This reduces assembly steps, potential failure points, and overall costs.

Five-axis CNC machining moves workpieces across more dimensions without removal. This enables the creation of complex geometries with premium finishes and tighter tolerances. The additional axes (A-axis and B-axis) bring the workpiece closer to the cutting tool. This allows for shorter tools, which are less prone to vibration. The result is improved surface finishes. These extra axes also allow the machine to reach tighter and more complex angles for drilling applications. This leads to parts with finer finishes.

The “Complete-in-One-Setup” capability is a major advantage. Complex parts can be machined from all necessary angles in a single clamping. This eliminates cumulative errors from multiple setups. It also boosts consistency and yield. This is crucial for deep-cavity work or parts with obstructed features. It enables shorter, more rigid tools and avoids collisions. For example, this capability led to an 18% weight reduction and a 40% improvement in dynamic balance for electric vehicle battery enclosures. Modern five-axis machines also feature intelligent compensation systems. These systems use real-time adaptive control and compensation algorithms. They monitor tool wear and thermal drift, automatically adjusting feed rates and spindle speeds. For ceramic turbine blades, this reduces cutting forces by 30-40%. This flexibility supports high-mix, low-volume, and customized production. A leading automotive headlight mold manufacturer compressed mold development cycles by 30% and reduced electrode wear by 60%. They achieved lights-out production with dynamic error compensation, holding intricate cavity dimensions within ±0.005mm.

Automation Integration and Pallet Changers for HMCs

Automation integration, especially through pallet changers, dramatically increases the overall throughput of Horizontal Machining Centers in automotive production. After all machining processes are completed, the pallet holding the finished item automatically moves away. An automated pallet changer then moves another pallet into position. These movements are computer-controlled. The cycle times for pallet changes are typically between 10 and 30 seconds. This continuous operation minimizes idle time.

Sal Swierczek, a sales/applications engineer at Kitamura Machinery USA Inc., highlights the primary reason for purchasing their HMCs: throughput. He states, “Loading more parts on the table and addressing more sides on the workpiece increase output and minimize setups. It also helps that with our horizontal pallet changers, loading/unloading parts takes place as the machine continues to run. Essentially, people are starting to understand owning a horizontal machine can help them stay competitive and manufacture parts more accurately and at a higher rate.” He further explains that standard two-station automatic pallet changers (APCs) and optional pallet pools, which are a form of automation, allow customers to load parts once. They then monitor the machine until all pallets are complete. This frees operators for other tasks like quality control or tending other machines.

Michael Cope, a product technical specialist at Hurco Companies Inc., agrees that HMC use is increasing. Factors like turnaround time, increased productivity, and the ability to quickly adapt to customer demands drive this trend. He notes, “Due to their speed and versatility, HMCs with their common built-in pallet changers lend themselves very well to automation. With the built-in pallet changer, automated loading and unloading can be achieved a little more seamlessly than with a traditional vertical machining center.” Cope also emphasizes that HMCs are a good choice for untended machining operations because they are automation-friendly. This is crucial for Just-In-Time (JIT) manufacturing. For example, YCM’s NH500A 6 PC is designed for industries like automotive that require high volumes of parts. The NH500A features a 30 hp (22-kW) 20,000-rpm spindle and a 500 x 500-mm pallet. It incorporates a high rigidity T-base foundation with rib construction, a one-piece casting spindle headstock, and a dual-wall column design. The direct-drive spindle uses precision ceramic ball bearings. High-precision roller-type guideways are present on all axes. A precision pallet indexing system accommodates a six-pallet APC.

Advanced Control Systems and Integrated Software

Advanced control systems and integrated software are vital for optimizing Horizontal Machining Center performance in automotive applications. Numerical control systems, such as Fanuc 31i Plus and Siemens 840D, provide seamless operation and programming capabilities. These systems offer intuitive interfaces and comprehensive operational features. They empower operators to maximize efficiency and streamline production processes. They also include real-time monitoring, advanced diagnostics, and predictive maintenance capabilities. These features ensure optimal machine performance and uptime. They reduce the risk of unplanned downtime and maximize production output.

CNC automation significantly boosts productivity. It enables continuous machine operation with minimal operator intervention. Automated systems handle repetitive tasks like material loading, unloading, and tool changes. This reduces downtime and accelerates production. Machines can operate 24/7, maximizing output and allowing for faster turnaround times. While initial investment may be high, long-term cost savings are substantial. Automation frees up workers for higher-level tasks. It optimizes material use by reducing waste and scrap. It lowers operating costs through reduced errors and increased machine uptime.

CNC automation enhances part consistency and quality. It eliminates human error and ensures precise, repeatable processes. Once programmed, machines follow exact parameters, producing identical parts with tight tolerances. Real-time monitoring and inspection correct deviations immediately. This leads to higher quality output and fewer defects. Automation also improves safety. It reduces the need for operators to interact directly with potentially dangerous machinery. Robots handle tasks such as material loading, clamping, and tool changes. This minimizes risks of accidents or injuries.

Thermal Compensation and Stability in Horizontal Machining Centers

Maintaining precision in automotive component manufacturing requires exceptional thermal stability. Machines generate significant heat during operation. Environmental temperature fluctuations also affect accuracy. Modern machining centers incorporate advanced technologies to counteract these thermal effects. This ensures consistent part quality, even during extended production runs.

Machine design contributes significantly to overall stability. Robust construction and carefully selected materials help absorb and dissipate heat effectively. This inherent stability forms the foundation for more advanced compensation systems.

Smart Thermal Control and optional Intelligent Kinematic Compensation (IKC) maintain high accuracy during continuous, high-speed operations. Sensors detect thermal drift in real-time. They automatically correct it to maintain tight tolerances. Integrated thermal sensors and compensation algorithms adjust for structural and spindle temperature variations. This reduces inaccuracy caused by thermal growth. It ensures consistent tolerances over extended production cycles. Spindle cooling and a grease lubrication system further enhance thermal stability and reduce maintenance.

Advanced systems like Ai Thermal Shield use spindle speed and machine temperature to prevent changes in cutting edge position. This technology stabilizes continuous machining accuracy. It meticulously controls the machine, considering factors like temperature changes, machine position, and coolant usage. New algorithms enhance compensation accuracy. The system optimizes thermal displacement compensation for specific machining environments. It achieves this by accumulating and learning from subsequent measurement data. These sophisticated systems ensure manufactured parts consistently meet strict automotive specifications. They prevent costly rework and scrap, leading to higher quality components and more efficient production.

Optimizing Performance with Horizontal Machining Centers

Customization for Specific Automotive Applications

Automotive manufacturers often require tailored solutions for their production needs. Manufacturers offer to customize products according to specific needs, providing more valuable solutions. This customization ensures Horizontal Machining Centers meet the exact demands of various automotive components. For instance, equipment packages like ‘Power’ suit medium batch sizes and machining steel or difficult materials. The ‘Speed’ package targets high-volume machining of cast iron, aluminum, and light metals. Different spindle versions, such as ‘Power’ (PC), ‘Speed’ (SC), and ‘Dynamic Cutting’ (DC), cater to varying torque and speed requirements. These versions offer options for HSK-A 63 or HSK-A 100 tool holders. DC units combine high torques and high speeds, for example, a DC 63 i with 16,000 rpm and 180 Nm. A ‘High-Accuracy Package’ improves basic accuracy and surface finishes. It also compensates for temperature fluctuations using ‘AutoCal’ and ‘AutoLin’ software features. An integrable U-axis allows for contour turning operations. This eliminates the need for a separate turning machine in series production, saving time and cost.

Cost-Benefit Analysis and Return on Investment for HMCs

Investing in Horizontal Machining Centers provides significant returns for automotive manufacturers. These machines reduce cycle times and improve part quality. This leads to lower production costs and less scrap material. The enhanced productivity and throughput directly translate into higher output. This allows companies to meet market demands more efficiently. The long tool life and reduced non-cutting time also contribute to operational savings. Manufacturers see a quicker return on their initial investment. The precision and reliability of HMCs minimize rework and warranty claims. This further boosts profitability.

Best Practices for HMC Integration and Implementation

Successful integration of Horizontal Machining Centers into existing automotive production lines requires careful planning. Strategic integration of high-volume automated machining technologies helps achieve optimal quality and cost efficiency. Manufacturers must demand the highest level of accountability from vendors. This includes technology, service, and processes that balance quality and cost. Vendors providing quick turnarounds and meticulous attention to detail during integration projects enable competitive proposals and increased throughput. The ability to acquire and integrate machines quickly, often within six months, is critical. This helps seize market opportunities and avoids missing chances due to long lead times. An integration services strategy that rewards engineers for completing installations correctly and ahead of schedule benefits short lead-time jobs. Ensuring long-term performance, quality, and reliability of the production line is crucial. Even minor errors can cause significant delays or part scrapping.

Maintenance and Longevity Considerations for Horizontal Machining Centers

Proper maintenance ensures the longevity and optimal performance of machining centers. Manufacturers recommend a structured maintenance schedule. Daily checks involve clearing chips and inspecting way covers. Operators also check coolant levels and concentration. They perform visual leak and pressure checks. Basic function and alarm scans are also part of daily routines. Weekly checks extend to hydraulic reservoirs and basic belt tension. Cleanliness of electrical enclosures is verified. Technicians confirm spindle and axis temperatures are within normal ranges.

Monthly tasks include cleaning coolant tanks and strainers. They replace primary coolant filters. Workers also check automatic-lubrication delivery. Quarterly checks verify ball-screw preload and backlash. They inspect encoder signals and drive connections. Technicians perform spindle and table alignment checks. Annual service includes spindle bearing inspection or replacement. It also involves full coolant tank sanitation. A comprehensive control and drive systems review completes the annual service.

Specific component care involves spindle maintenance. This includes maintaining clean tapers and ensuring correct tool clamping. Monitoring vibration and bearing temperature is crucial. Following manufacturer guidance for lubrication is essential. Handling tooling with gloves prevents contamination. Coolant system maintenance requires daily concentration checks. Effective filtration and microbial control are vital. Scheduled tank cleanouts are necessary. Primary filters are changed monthly. Full tank drain-and-sanitize intervals are planned. Ball screw maintenance uses the correct lubricant. It ensures reliable automatic-lube delivery. Regularly checking backlash is important. Technicians measure axial backlash and adjust end-nut preload within safe limits.

Advanced maintenance strategies leverage predictive maintenance. This uses sensor data and analytics. Vibration analysis, temperature monitoring, spindle-load logging, and oil analysis forecast failures. They schedule proactive interventions. Condition-based monitoring deploys wireless vibration monitors and simple gateways. These collect baseline trends and set alert thresholds. This allows for prioritized service actions over reactive fixes. These practices minimize downtime and extend machine life.

Horizontal Machining Centers prove indispensable for modern automotive manufacturing. They deliver significant gains in efficiency and precision. Their advanced features and diverse applications directly enhance productivity and ensure cost-effectiveness. Embracing this Horizontal Machining Center technology is crucial for manufacturers. It allows them to achieve competitive and high-quality automotive component production.

FAQ

What makes Horizontal Machining Centers efficient for automotive parts?

Horizontal Machining Centers (HMCs) offer multi-sided machining in one setup. This reduces part handling. Their robust design supports aggressive cutting parameters. Pallet changers enable continuous operation. These features boost productivity and shorten cycle times for automotive components.

How do HMCs handle chip evacuation effectively?

HMCs’ horizontal spindle orientation uses gravity. Chips fall away from the cutting area naturally. This prevents re-cutting, which damages tools and parts. Efficient chip removal improves surface finish and extends tool life.

What types of automotive components benefit most from HMCs?

HMCs excel at producing engine blocks, cylinder heads, transmission cases, and chassis components. They also precisely machine electric vehicle powertrain parts like motor housings and battery trays. Their stability handles heavy, complex parts.

Can HMCs integrate with automation for higher output?

Yes, HMCs integrate well with automation. Pallet changers are common. They allow operators to load new workpieces while the machine runs. This minimizes idle time. Automation features like robotic loading further enhance continuous, untended operation.

Post time: Dec-26-2025