Businesses embarking on the selection of a CNC Turning Center must first meticulously define their production requirements. This involves understanding the characteristics of the parts they will machine, including size, geometry, and material types. The market for these machines shows significant growth, highlighting the demand for advanced manufacturing.

| Market Segment | Growth Rate (CAGR) | Period |

|---|---|---|

| CNC machining centers and turning centers market | 6.6% | 2024 to 2030 |

| CNC Vertical Lathe and CNC Vertical Turning Center market | 9.7% | 2025 to 2032 |

Achieving high Lathe Machine Precision is crucial for many applications. Evaluating an Automated CNC Lathe‘s capabilities becomes essential for optimizing throughput. Companies also consider the CNC turning center price performance ratio to ensure a sound investment. Many look to Industrial CNC lathe suppliers in China for competitive solutions.

Key Takeaways

- Understand your production needs. Think about part size, material, and how many parts you need to make. This helps you pick the right machine.

- Look at the machine’s features. Check the number of axes, spindle type, and tool capacity. These features affect what the machine can do.

- Consider adding automation. Bar feeders and robots make production faster. They help the machine run longer without stopping.

- Evaluate the control system and software. Good software makes the machine easy to use. It also helps with design and data management.

- Think about the total cost. Look beyond the price tag. Consider maintenance, training, and future growth. This ensures a smart investment.

Define Your Production Needs for a CNC Turning Center

Selecting the right CNC turning center begins with a clear understanding of specific production demands. This foundational step ensures the chosen machine aligns perfectly with operational goals.

Part Size and Geometry

The physical characteristics of the parts a business plans to machine directly influence the required machine specifications. Consider the maximum diameter and length of the workpieces. Complex geometries may also necessitate additional axes or specialized tooling. For instance, the largest CNC turning centers, such as the SL 603, can handle parts with diameters up to 930 mm and lengths up to 4000 mm. This capability allows for machining very large components.

| Part/Feature | CNC Turning |

|---|---|

| Maximum size | The largest CNC turning centers, such as the SL 603, can handle parts with diameters up to 930 mm and lengths up to 4000 mm. |

Material Types to Machine

The materials a company processes significantly impact the choice of a CNC turning center. Different materials possess unique properties that affect machinability, tool wear, and the required cutting parameters. For example, aluminum is generally easier to machine than stainless steel, which demands more robust machines and specialized tools.

- Machinability: Directly impacts ease of cutting; e.g., aluminum is easier to machine than stainless steel.

- Tool Wear: Harder materials like titanium and certain steels increase tool wear, requiring more frequent changes.

- Cutting Speed and Feed Rate: Different materials necessitate varied speeds; softer materials allow higher speeds, while harder ones require slower rates.

- Thermal Conductivity: Low thermal conductivity materials (e.g., some plastics) can retain heat, leading to melting or warping, and may require adjusted cooling.

The selection of materials is crucial for CNC machining projects. It dictates not only the final part’s properties and performance but also profoundly impacts the machining process itself. Key factors influenced by material choice include tool wear, cutting speeds, surface finish, and ultimately, the cost and efficiency of production. Materials with good machinability allow for faster cutting, fewer tool changes, and better surface finishes, reducing machining time and labor costs. Conversely, materials with poor machinability require slower speeds, specialized tooling, and more frequent tool changes, increasing costs and machine wear.

Production Volume Requirements

Production volume dictates the level of automation and speed a CNC turning center needs. High-volume production benefits from machines with fast cycle times, automated loading/unloading systems, and robust construction to ensure continuous operation. Lower volumes might prioritize versatility and ease of setup over sheer speed. Businesses must assess their current and projected production needs to make an informed decision.

Required Precision and Surface Finish

The desired precision and surface finish of machined parts significantly influence the selection of a CNC turning center. Different applications demand varying levels of accuracy. For instance, medical-grade components often require exceptionally tight tolerances. Modern CNC turning services achieve micron-level precision when machining these critical parts from specialized alloys.

Manufacturers must consider the specific tolerances their parts require. Protolabs, for example, maintains a standard prototype and production machining tolerance of +/- 0.005 inches (0.13mm). For more demanding applications, their standard precision or production machining tolerance tightens to +/- 0.002 inches (0.051 mm). They can hold even finer tolerances, such as +/- 0.0005 inches (0.0127mm), on reamed holes. Furthermore, they achieve +/- 0.002 inches (0.051mm) on feature locations, provided the machine processes those features on the same side of the part. Generally, modern CNC turning centers achieve dimensional accuracy typically within ±0.0001 inches to ±0.005 inches for tight tolerance CNC machining.

Achieving these precise specifications requires a machine with superior rigidity, advanced control systems, and high-quality tooling. A robust machine frame minimizes vibration, which directly impacts surface finish and dimensional accuracy. The control system must offer fine interpolation capabilities to execute complex tool paths smoothly. High-quality cutting tools, appropriate for the material, also play a crucial role in meeting stringent surface finish requirements. Businesses must match the machine’s inherent capabilities with their part’s precision demands.

Evaluate CNC Turning Center Configuration and Features

Businesses must carefully assess the configuration and features of a CNC turning center to match their specific manufacturing needs. These elements directly impact the machine’s capabilities, efficiency, and the types of parts it can produce.

Number of Axes

The number of axes a CNC turning center possesses significantly determines its versatility and complexity. A machine with more axes can perform more intricate operations. For instance, a 5-axis machining strategy offers several advantages over 3-axis machines. It reduces lead times, requires less setup, and decreases fixturing needs. Five-axis machines also enhance quality and surface finishes while extending tool life. A 3-axis machine might require multiple operations for a complex workpiece, increasing work in process and handling. In contrast, 5-axis machines enable “done in one” processing, significantly cutting down work in process and lead time. They achieve smoother surfaces and more precise parts by allowing the cutting tool to move along five axes. This capability also allows simultaneous machining from multiple angles without repositioning the workpiece, improving surface finishes and reducing cycle times for complex parts.

Spindle Configuration Options

Spindle configuration plays a crucial role in a CNC turning center’s productivity. A common and highly beneficial option is the sub-spindle. This configuration allows for numerous counter-operations, avoiding additional handling and ensuring high-precision bar turning. It significantly reduces machining time, often making it four to five times shorter for the same part compared to a single-spindle lathe. A sub-spindle eliminates the need to transfer parts between machines for further operations, enabling manufacturers to take on higher volume orders and commit to shorter lead times. It also improves energy efficiency by performing multiple machining operations simultaneously on a single machine, reducing overall processing time and cost per part. This setup offers versatility in operations, making complex designs possible and boosting shop floor productivity.

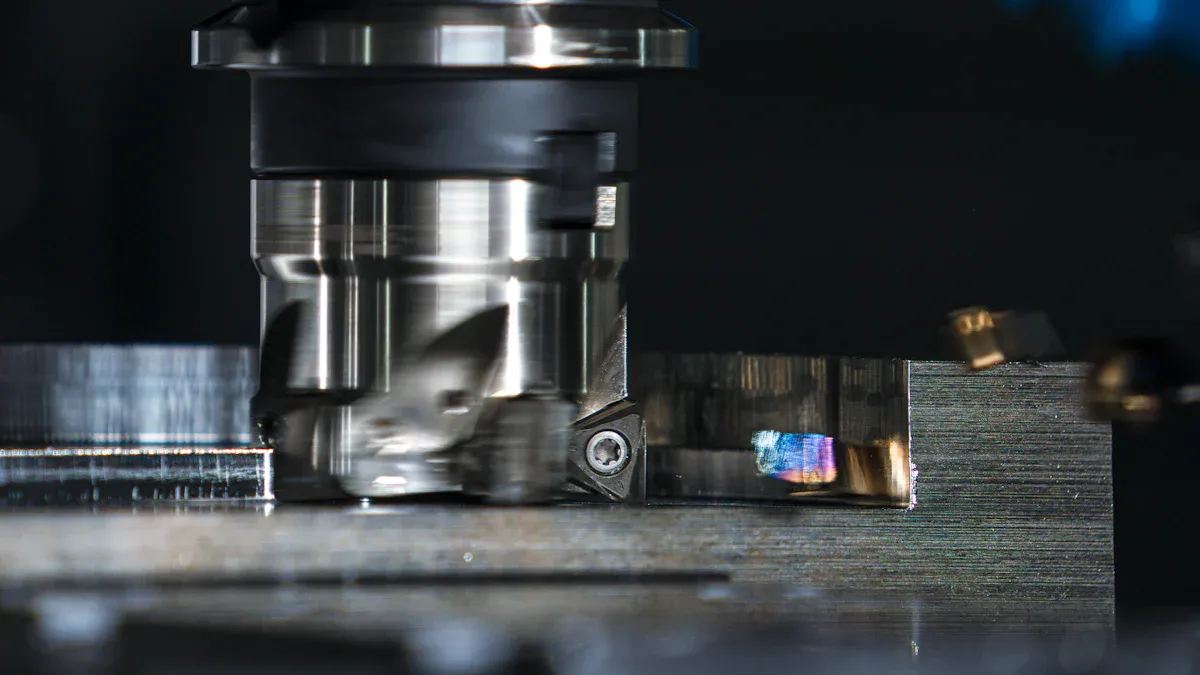

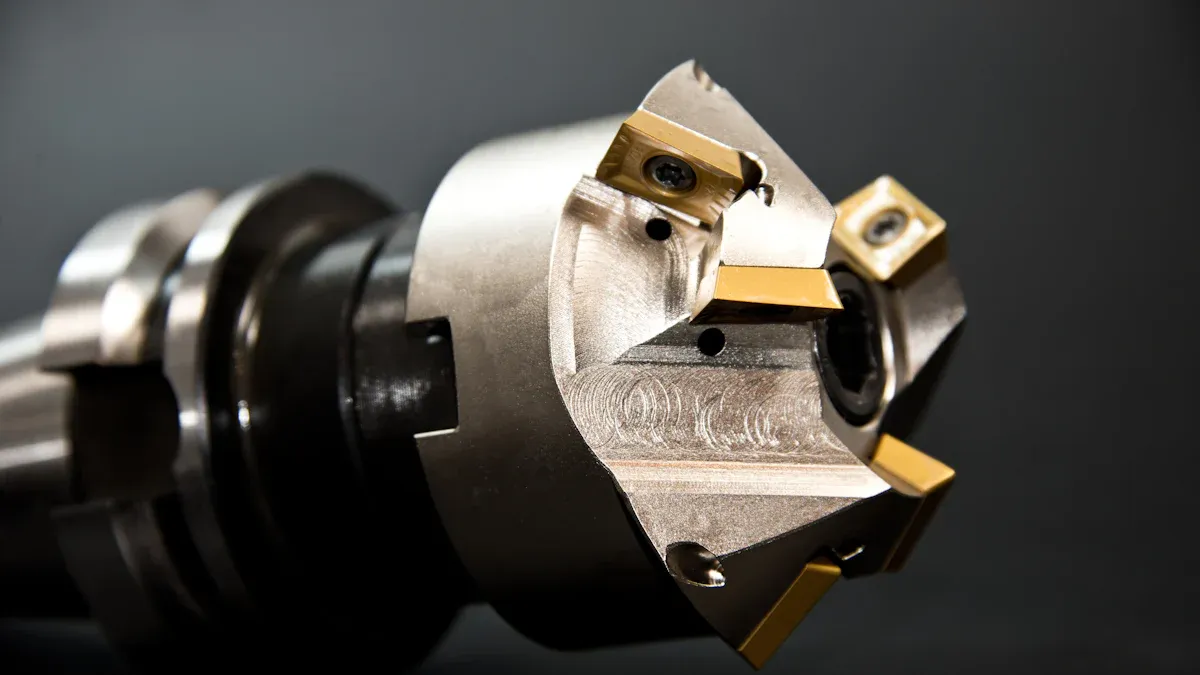

Turret Type and Tooling Capacity

The turret type and its tooling capacity directly affect the range of operations a CNC turning center can perform without manual intervention. Different turret designs offer varying levels of tool stations.

| Turret Type | Tooling Capacity |

|---|---|

| VDI | High, up to 12 or more tool stations; ranges from 12 to 80 tool stations |

| BMT | Limited, typically 6 to 12 tool stations |

A higher tooling capacity allows for greater operational flexibility and reduces the need for frequent tool changes, which enhances efficiency during complex machining tasks.

Chuck Size and Workholding Solutions

The chuck size on a CNC turning center directly determines the maximum diameter of the workpiece it can securely hold. Selecting the correct chuck size is crucial for accommodating the parts a business plans to machine. Common chuck sizes range significantly to meet diverse manufacturing needs.

| Chuck Size |

|---|

| 6″ |

| 8″ |

| 10″ |

| 12″ |

| 15″ |

| 18″ |

| 24″ |

For vertical CNC turning centers, chucks can range from 12 inches up to 59.06 inches (Φ1500mm). Multi-tasking machines often use chucks between 6 inches and 12 inches, while horizontal multi-tasking machines might feature chucks from 10 inches to 50 inches. Vertical multi-tasking machines can even accommodate very large workpieces with chucks from Φ610 to Φ2500. Beyond the chuck, various workholding solutions exist, such as collets for smaller parts or specialized fixtures for irregularly shaped components. Businesses must choose workholding that provides secure clamping, minimizes vibration, and allows for efficient part loading and unloading.

Machine Power and Torque

Machine power and torque are critical specifications that dictate a CNC turning center’s ability to cut various materials efficiently. Higher horsepower and torque allow the machine to remove material faster, especially from tough alloys like stainless steel or titanium. The spindle motor’s power rating directly influences the cutting forces it can generate without stalling. High torque at lower RPMs is particularly beneficial for heavy roughing cuts, while higher horsepower at elevated RPMs supports fine finishing operations. Businesses must match the machine’s power and torque capabilities to the materials they frequently process and the desired material removal rates.

Machine Rigidity and Construction

The overall rigidity and construction of a CNC turning center significantly impact its precision, surface finish, and tool life. A robust machine frame, often made from cast iron, absorbs vibrations generated during cutting. This stability prevents chatter marks on the workpiece and maintains tight tolerances. The design of the machine’s guideways, such as linear roller guides or box ways, also contributes to its stiffness and accuracy. Box ways typically offer greater damping and rigidity for heavy cuts, while linear guides provide faster traverse rates. A well-constructed machine ensures consistent performance over time, reducing wear on components and extending the lifespan of cutting tools.

Consider Automation and Ancillary Equipment for Your CNC Turning Center

Integrating automation and ancillary equipment significantly enhances the efficiency and productivity of a CNC Turning Center. These additions streamline operations, reduce labor costs, and improve overall output.

Bar Feeders for Continuous Production

Bar feeders are essential for achieving continuous production. They eliminate non-cutting time, allowing machines to run without interruption. This continuous operation significantly increases spindle uptime. For example, a machine running at 55% uptime produces 440 parts per eight-hour shift with a three-minute cycle per part. However, with 85% uptime achieved through automation, the same machine produces 680 parts, a gain of 240 parts per shift. This translates to an additional $1,200 in daily profit from a single machine, assuming a $5 profit margin per part. Bar feeders constantly push bar stock through the headstock, eliminating the need to open the chuck for each individual blank. After a part is completed and cut off, the bar automatically advances for the next cycle. This ensures the spindle never stops rotating except for scheduled tool changes. Modern bar feeders include sensors that facilitate automatic switching to the next bar in the magazine in under 10 seconds, maintaining a nearly constant production flow.

| Metric | Manual Operation | With Automation |

|---|---|---|

| Spindle Uptime | 50-60% | 85%+ |

| Throughput Increase | Baseline | 30-50% higher |

| Operator Supervision | Constant | Periodic checks only |

| Night/Weekend Production | Requires overtime | Runs unattended |

| ROI Timeline | N/A | 12-24 months |

| Best Applications | Low-volume custom work | Batches of 500-1,000+ parts |

Part Catchers and Conveyors

Part catchers and conveyors play a vital role in automating part removal and handling. They protect sensitive parts from damage and improve ergonomics by replacing manual collection boxes.

| Part Catcher Type | Components | Application |

|---|---|---|

| Uni-Mate® | Mini-Mover Lite Series conveyor, Mini-Mover Rotary Table Accumulator (RTA) | Portable and adaptable solution for unattended parts unloading, protecting sensitive parts, improving ergonomics by replacing collection boxes. |

| Mini-Mover Conveyor products (Lite Series or LP Series) | Lite Series or LP Series conveyors | Integrate into machines for parts catching, protecting precision machined parts. |

| Rotary Table Accumulator (RTA) | Rotary Table Accumulator | Improves ergonomics by replacing old collection boxes, used for unmanned accumulation strategies with faster cycle times. |

These systems ensure a smooth flow of finished parts, preventing bottlenecks and allowing for unattended operation.

Robotics Integration for Efficiency

Robotics integration offers significant cost benefits and efficiency gains. Robots provide long-term savings in labor costs and deliver higher productivity with consistent output due to 24/7 operation without fatigue. They improve product quality by reducing human error, waste, and rework. Robotics also increase machine utilization as CNC machines can run continuously. Companies often see an ROI within six months to a year, despite the initial installation cost.

- 24/7 lights-out production converts idle hours into output.

- Lower labor costs mean one operator can oversee multiple machines.

- Improved part quality results from consistent positioning, reducing damage or variation.

- Faster changeovers occur with pre-programmed setups and dual grippers.

- A safer work environment reduces injury risk by automating dangerous tasks.

Tool Presetting and Measurement Systems

Tool presetting and measurement systems are vital for modern machining operations. They allow shops to measure and set cutting tools outside the machine. This process significantly reduces machine downtime. Operators can prepare the next tool while the machine actively produces parts. This improves overall operational efficiency and throughput. A study demonstrated the superiority of laser tool setting systems for improving machining accuracy. Researchers achieved this by comparing automatic non-contact tool setting using a laser tool setter against conventional manual and touch-type auto tool setting methods. The research involved defining correct tool-setting methods for various tool shapes and sizes. They then machined pocket features with each setting tool. An inspection probe system measured these features to verify machining accuracy. The cutting results from a CNC machining center fitted with a laser tool setting system confirmed its benefits. These systems ensure tools are accurate before they enter the machine. This leads to better part quality, less scrap, and faster setup times, ultimately contributing to a more profitable operation.

Chip Management Systems

Effective chip management is crucial for any machining operation. Chips are metal shavings produced during the cutting process. If chips build up, they can damage cutting tools or workpieces. They can also interfere with the machining process itself, leading to poor surface finishes or even machine stoppages. Chip conveyors are common solutions for this issue. They automatically remove chips from the machine’s work area. Different types of conveyors exist, such as hinge belt or magnetic systems, each suited for various chip types and volumes. Proper chip removal extends tool life by preventing chip recutting and heat buildup. It also maintains a cleaner work environment, which improves safety for operators. Some advanced systems include chip crushers or centrifuges. These process chips for easier recycling or disposal, adding an environmental benefit. Good chip management keeps machines running smoothly and reduces manual cleaning time. This directly contributes to higher productivity and machine uptime, ensuring continuous production.

Assess Control System and Software for Your CNC Turning Center

Businesses must carefully evaluate the control system and software for a CNC turning center. These components form the machine’s brain, dictating its capabilities and ease of use.

CNC Control Brand and Features

The CNC control system significantly impacts machine performance and operator experience. Leading brands like Fanuc and Siemens offer distinct features. Fanuc systems are known for their stability and robust self-diagnostic features. They also provide multi-axis control. Siemens controls, conversely, offer high intelligence and flexibility, especially for complex machining tasks. They support digital production and remote monitoring.

| Brand | Key Features |

|---|---|

| Fanuc | Stability, reliability, multi-axis control, robust self-diagnostic features |

| Siemens | High intelligence, flexibility (especially in complex machining), digital production support, remote monitoring |

Fanuc systems typically use isolated power supplies, making them adaptable to various grid requirements. Their PLC programs are noted for better stability. Siemens systems require 380V mains. Siemens CNC systems are considered easier to use, even for those without extensive programming knowledge. This is due to features like shopmill and graphic programming. Fanuc panels, with their numerous functions, require more effort to master.

Software Compatibility with CAD/CAM

Seamless integration with CAD/CAM software is crucial for efficient programming and operation. EZ-Turn Cad/Cam Software is specifically designed for CNC Turn Machines. It offers capabilities from 2-axis to C and Y-axis machining. It also has an extensive post library, ensuring compatibility with various CNC turning equipment. MasterCAM is another widely recognized CAM package. It is popular for its multi-axis milling and turning capabilities. It also offers a broad selection of preset CNC machine configurations. Fusion 360, developed by Autodesk, is an integrated CAD/CAM solution. It covers the entire product development cycle, from design to advanced CAM. Its seamless CAD/CAM integration is a key feature.

Network Connectivity and Data Management

Network connectivity provides significant benefits for data management. It offers real-time visibility from the shop floor. This enables faster issue resolution and better resource allocation. It also supports more agile production planning. Network connectivity acts as a universal translator. It bridges the gap between equipment and software regardless of brand or age. This includes legacy systems. It enforces a consistent data structure, eliminating inconsistencies. This reduces engineering effort for integration. As an open-source protocol, it lowers the cost of ownership. It reduces dependency on proprietary interfaces. This cuts software licensing and system development costs. Centralized access to real-time machine data enhances cross-functional collaboration. This benefits operations, engineering, and quality teams. It also supports scalable and sustainable integration. Shops can start small and scale over time as they introduce new machines or systems.

Factor in Budget, Support, and Future Growth of Your CNC Turning Center

Businesses must consider several factors beyond the machine’s technical specifications. These include financial aspects, manufacturer reliability, and the skills of their workforce. A comprehensive evaluation ensures a sustainable and profitable investment.

Initial Investment vs. Total Cost of Ownership

Businesses often focus on the upfront cost of a new machine. However, they must consider the total cost of ownership (TCO). TCO includes the initial purchase price, installation, tooling, energy consumption, maintenance, and operator training. A lower initial price might lead to higher long-term expenses due to frequent breakdowns or expensive spare parts. Conversely, a higher initial investment in a quality CNC Turning Center can result in lower operating costs and greater reliability over its lifespan. Evaluating TCO provides a more accurate financial picture.

Manufacturer Reputation and Support

The manufacturer’s reputation and support services are crucial. A reputable manufacturer, like OTURN MACHINERY, offers reliable machines and excellent after-sales support. This includes technical assistance, readily available spare parts, and comprehensive warranty coverage. Strong manufacturer support minimizes machine downtime. It ensures quick resolution of any issues. This factor directly impacts productivity and profitability. Businesses should research a manufacturer’s track record for service and customer satisfaction.

Training and Operator Skill Requirements

Operating a sophisticated machine requires skilled personnel. Businesses must assess their current workforce’s capabilities. They should plan for necessary training. Essential training programs for operators include:

- CNC mill, lathe, and grinder set-up and operation

- Tool identification, set-up, use, and maintenance

- Machining processes and statistical process control

- Quality and cycle time optimization

- CNC program operation and fixture set-up

- CNC troubleshooting and maintenance for operators

- Precision measurement and gauging, along with print reading

- Geometric dimensioning and tolerancing

- Interfacing with a CNC and making tooling decisions

- Responding to machine malfunctions

- Basic technical drawing, CNC operations, and machine codes

- Industrial safety and quality concepts

- Hand and power tools, and basic machining

- CNC technology and programming, including foundational knowledge of basic word address programming, CAD/CAM, and machining and turning centers.

Proper training ensures efficient machine operation. It reduces errors and maximizes the machine’s potential.

Scalability and Future Needs

Businesses should consider their future growth plans when selecting a machine. A machine with room for expansion or upgrades can adapt to evolving production demands. This foresight prevents the need for premature replacement. It also protects the initial investment.

Scalability and Future Needs

Businesses must consider their future growth plans when selecting a machine. This foresight prevents the need for premature replacement. It also protects the initial investment. A machine with room for expansion or upgrades can adapt to evolving production demands. This adaptability ensures the investment remains relevant and productive over time. It allows businesses to adapt to evolving production demands and technological advancements.

Evaluating a machine’s capabilities for robotic integration is a crucial consideration for future expansion. This involves assessing how easily the machine can integrate with automated systems. Robotic integration ensures the investment remains relevant and productive over time. It allows businesses to adapt to evolving production demands and technological advancements. For example, a machine capable of robotic loading and unloading can transition from manned to lights-out operation. This significantly increases production capacity without requiring additional labor.

Consider the machine’s modularity. Can businesses add features like a sub-spindle or live tooling later? Some manufacturers offer upgrade paths for their machines. This allows companies to start with a basic configuration and enhance it as their needs grow. This approach manages initial costs while providing flexibility for the future.

The control system’s ability to handle more complex programming is also important. As production demands evolve, parts may become more intricate. A control system that supports advanced features and software updates will serve a business longer. It avoids the need for a complete machine overhaul. Planning for scalability means choosing equipment that grows with the business. It supports long-term operational goals and maximizes return on investment.

Businesses confidently choose a CNC turning center that optimizes manufacturing processes. This strategic decision enhances productivity and achieves a strong return on investment. High-quality machines reduce labor costs and offer faster production times. They also provide unmatched precision and consistency, minimizing waste. Modern machines improve uptime through predictive maintenance. Aligning the selection with operational goals ensures long-term success.

FAQ

What is a CNC turning center?

A CNC turning center is a machine tool. It uses computer numerical control to precisely shape workpieces. It rotates the material against a cutting tool. This creates cylindrical parts. Manufacturers use them for high-precision production.

Why is spindle configuration important?

Spindle configuration affects machine versatility and efficiency. A sub-spindle allows simultaneous operations. This reduces machining time significantly. It eliminates extra part handling. This boosts productivity for complex parts.

How does automation benefit production?

Automation increases efficiency and reduces labor costs. It enables continuous, unattended operation. This boosts output and improves product quality. Robots and bar feeders are common automation tools. They maximize machine utilization.

What is Total Cost of Ownership (TCO)?

TCO includes a machine’s full financial impact. It covers the purchase price, installation, and maintenance. It also includes energy use and training. Businesses consider TCO for a complete financial picture. This helps make informed investment decisions.

Post time: Jan-08-2026