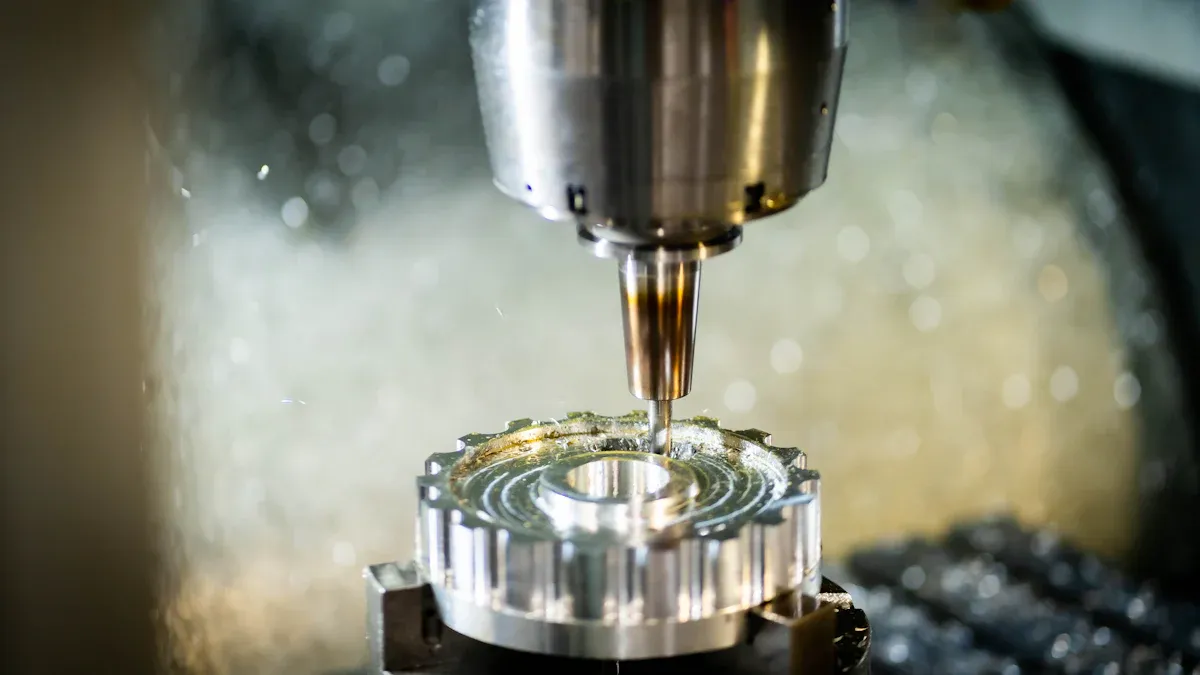

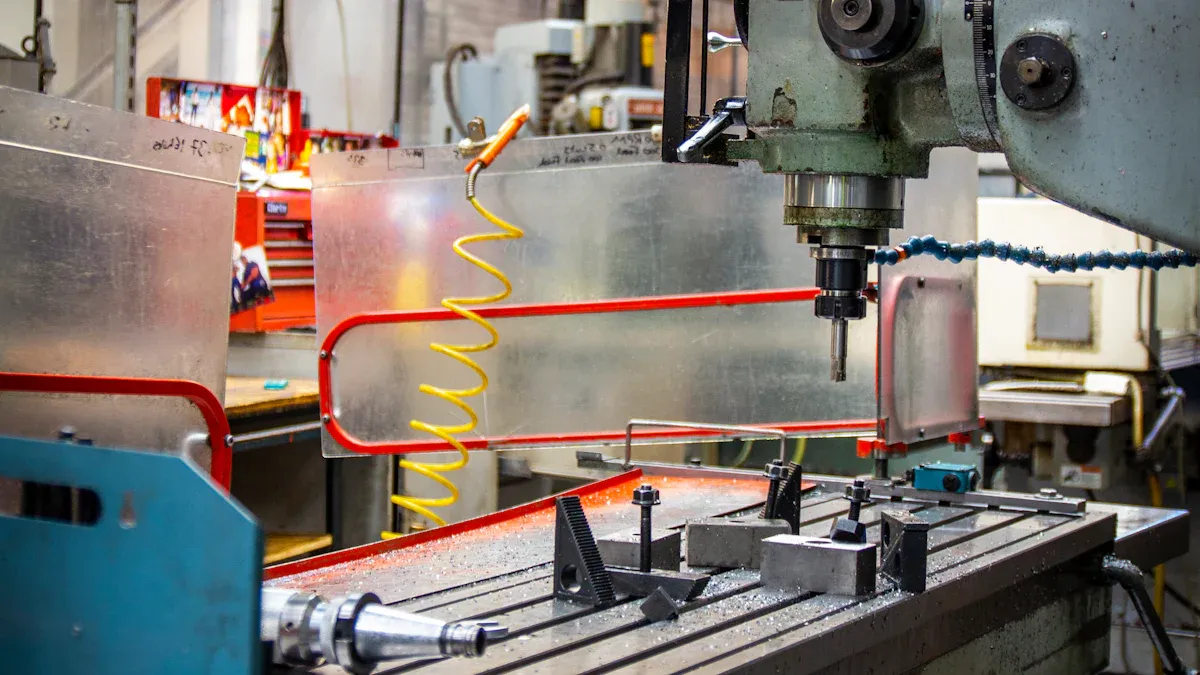

Selecting the right CNC Turning Center is crucial for achieving high precision in metalworking. The accuracy of these machines directly affects the quality of the final product. For instance, environmental conditions, equipment design, operator skill, and regular maintenance all play significant roles in ensuring precise outcomes.

When considering the best CNC turning center, one must evaluate various factors, including industrial turning machine features and operational requirements. A precision CNC lathe guide can be invaluable in this process. Understanding these elements, along with high rigidity turning center options, will lead to better decision-making and ultimately enhance project success. Additionally, keep in mind some turning center buying tips to ensure you make the most informed choice.

Key Takeaways

- Define your project requirements clearly. Consider complexity, production volume, and precision needs to select the right CNC Turning Center.

- Establish a realistic budget. Factor in initial costs, long-term maintenance, and energy consumption to avoid unexpected expenses.

- Analyze machine specifications carefully. Focus on spindle speed, axis count, and tooling options to ensure the machine meets your specific tasks.

- Evaluate support and service options. Choose manufacturers that offer training, local service centers, and strong warranty agreements for better machine performance.

- Prioritize precision in your selection. Investing in the right CNC Turning Center enhances product quality and can lead to long-term cost savings.

Define Your Project Requirements

When selecting a CNC Turning Center, defining project requirements is essential. This process involves understanding various factors that influence machine selection. Here are key considerations:

- Project Complexity:

- Assess the complexity of your designs. Simple designs may not require advanced machines, while intricate designs necessitate sophisticated CNC capabilities.

- Production Volume:

- Estimate your production volume. High-volume projects demand durable machines for continuous operation. In contrast, smaller jobs benefit from machines optimized for quick changeovers.

- Machine Specifications:

- Key specifications include spindle speed, power, and work area dimensions. Machines must balance speed and power according to the materials and tasks anticipated.

- Precision and Accuracy:

- High precision is vital for producing quality parts. Machines vary in tolerance levels. Selecting one with excellent precision is crucial for projects requiring tight tolerances. The typical tolerances for precision metalworking include:

Tolerance Type Value Diameter ±0.001″ (0.025 mm) to ±0.002″ (0.051 mm) Quick ±0.0005″ (0.013 mm) Precision Length ±0.005″ (0.127 mm) Roundness ±0.002″ (0.051 mm) Surface Finish Ranges from rough to highly polished, with smooth finishes achievable up to 16 RMS. - Software Compatibility:

- Ensure the machine supports the right software for design and execution. Compatibility with existing CAD/CAM systems is crucial for a smooth workflow.

- Budgeting and Cost Analysis:

- Consider both initial investment and long-term costs, including maintenance and consumables. High-quality machines may have higher upfront costs but can be more cost-effective over time due to durability and efficiency.

- Material Considerations:

- Different materials impact machining characteristics. For example:

Material Type Properties Impacting Machining Machining Characteristics Stainless Steel High strength, hardness, wear resistance Difficult to machine, requires slower speeds Carbon Steel High strength, hardness Causes tool wear, needs special tools Aluminum Alloys Lower hardness, good machinability Easier to machine, allows faster cutting speeds Brass Good electrical conductivity, moderate strength Generally easy to machine, less tool wear - Harder materials like stainless steel and carbon steel require special tools and slower cutting speeds due to increased tool wear. Softer materials such as aluminum alloys allow for faster machining and produce less heat, reducing the risk of warping.

By thoroughly defining these project requirements, individuals can make informed decisions regarding CNC Turning Center selection. This approach ensures that the chosen machine aligns with specific project needs, ultimately enhancing precision in metalworking.

Establish Your Budget

Establishing a budget for a CNC Turning Center is a critical step in the selection process. The costs associated with these machines can vary significantly based on several factors. Understanding these factors helps businesses make informed decisions that align with their financial capabilities.

- Initial Purchase Costs:

- The price of CNC Turning Centers can range widely. For small to medium-sized metalworking businesses, the average price range is as follows:

Type of CNC Lathe Machine Price Range Entry-level $10,000 – $30,000 Mid-range $30,000 – $100,000 Investing in a machine that meets specific project requirements is essential. While entry-level machines may suffice for basic tasks, mid-range options often provide enhanced features and capabilities.

- Financing Options:

- Many businesses explore financing options to ease the burden of upfront costs. These options can significantly impact purchasing decisions. Consider the following benefits of financing:

- Customized financing options match business cycles and growth objectives.

- Financing can cover equipment purchases, refinances, and working capital needs.

- CNC machine loans help companies acquire necessary equipment to enhance productivity.

Understanding the total cost of ownership (TCO) is crucial. Investing in high-quality equipment can lead to long-term savings by reducing errors and increasing efficiency. A thorough cost analysis helps avoid unexpected budget issues and supports investment justification.

- Long-term Maintenance Costs:

- Maintenance costs can accumulate over time, affecting overall budgets. Key factors include:

Maintenance Factor Description Spindle and Bearing Systems High-quality tools can extend spindle life, reducing costs associated with spindle rebuilds ($5,000-$25,000). Preventive Maintenance Complexity Unpredictable tool performance increases maintenance frequency and costs due to conservative scheduling. Secondary System Impact Poor tooling affects filtration and chip handling systems, increasing maintenance labor and costs. Regular maintenance ensures optimal performance and longevity of the CNC Turning Center. Businesses should factor these costs into their budgets to avoid surprises.

- Energy Consumption:

- Energy costs also play a significant role in operational budgets. Higher energy consumption increases costs, straining budgets in high-volume production environments. Inefficiencies in energy use lead to longer machining times, escalating operational costs. Longer machining times result in fewer parts produced, reducing machine efficiency and increasing labor costs per part.

By carefully considering these aspects, businesses can establish a realistic budget that accommodates both initial and ongoing expenses. This approach ensures that the CNC Turning Center selection aligns with financial capabilities while meeting project demands.

Analyze Machine Specifications

When selecting a CNC Turning Center, analyzing machine specifications is vital. These specifications determine the machine’s capabilities and suitability for specific tasks. Here are the key specifications to consider:

| Specification | Description |

|---|---|

| Axis Count | Determines machining complexity. |

| Spindle Speed & Power | Higher power is better for tough alloys. |

| Chuck Size & Bar Capacity | Defines maximum workpiece size. |

| Travel Range (X, Z, Y) | Determines machining envelope. |

| Tooling Options | Includes live tooling, automatic tool changers, and sub-spindles. |

| Automation Features | Bar feeders, part catchers, and robotic integration enhance efficiency. |

| CNC Controller | User interface and programming compatibility are crucial for ease of use. |

Spindle speed plays a significant role in machining performance. The right RPM ensures stable cutting and accurate surface finishes. However, too high RPM can cause vibration and premature tool failure, while too low RPM reduces cutting efficiency. Proper spindle speed balances these factors, enhancing overall productivity.

Axis configuration also impacts the CNC Turning Center selection. A machine with multiple axes, such as a 5-axis configuration, allows for complex geometries and multi-surface machining. This capability is essential in industries like aerospace and medical devices, where precision is paramount. The addition of a fourth axis enables rotation of the workpiece, allowing for machining on multiple sides without manual repositioning. This feature significantly enhances precision and reduces setup time.

Evaluate Support and Service Options

When selecting a CNC Turning Center, evaluating support and service options is essential. Reliable support can significantly impact machine performance and overall productivity. Here are key factors to consider:

- Manufacturer Support:

- Investigate the level of support offered by the manufacturer. Look for companies that provide comprehensive training programs. For example, Midmark Corp. developed a customized CNC machinist training program with Edison State Community College. This initiative reduced operator training time from 12 months to just 6 months. Such programs enhance operator proficiency and ensure that staff can effectively utilize the CNC Turning Center.

- Local Service Centers:

- The availability of local service centers can greatly reduce downtime. These centers offer immediate and personalized support, which is crucial for maintaining operational efficiency. Quick technical assistance, onsite repairs, and preventive maintenance services help keep machines running smoothly. This local presence can be a game-changer for businesses that rely on continuous production.

- Warranty and Service Agreements:

- Review warranty options and service agreements. A robust warranty can protect against unexpected repair costs. Service agreements often include regular maintenance checks, which can prevent issues before they arise. Understanding the terms of these agreements helps businesses plan for long-term support.

- Customer Reviews and Testimonials:

- Research customer feedback regarding support services. Positive reviews can indicate a manufacturer’s reliability and responsiveness. Engaging with current users can provide insights into their experiences with support and service.

- Technical Documentation and Resources:

- Ensure that the manufacturer provides comprehensive technical documentation. Access to manuals, troubleshooting guides, and online resources can empower operators to resolve minor issues independently. This self-sufficiency can enhance productivity and reduce reliance on external support.

By thoroughly evaluating these support and service options, businesses can make informed decisions during the CNC Turning Center selection process. A strong support system not only enhances machine performance but also contributes to the overall success of metalworking projects.

Selecting the right CNC Turning Center involves careful consideration of several key factors. These include bar capacity, swing over bed, maximum machining diameter, and tool options. Each factor plays a crucial role in ensuring the machine meets specific project requirements.

Businesses should assess their unique needs before making a decision. This structured evaluation can lead to improved outcomes in CNC Turning Center selection.

Prioritizing precision in metalworking not only enhances product quality but also contributes to long-term cost savings. By investing in the right technology, companies can achieve operational efficiency and maintain a competitive edge in the industry.

FAQ

What is a CNC Turning Center?

A CNC Turning Center is a computer-controlled machine that shapes materials by rotating them against cutting tools. It allows for high precision and efficiency in producing complex parts.

How do I determine the right size for my CNC Turning Center?

Consider the maximum workpiece dimensions and weight. Evaluate your typical project requirements to ensure the machine can accommodate your largest parts comfortably.

What materials can I machine with a CNC Turning Center?

CNC Turning Centers can machine various materials, including metals like aluminum, brass, stainless steel, and plastics. The choice depends on the machine’s specifications and tooling options.

How often should I perform maintenance on my CNC Turning Center?

Regular maintenance is crucial for optimal performance. Schedule preventive maintenance every 500 hours of operation or as recommended by the manufacturer to ensure longevity and reliability.

Can I upgrade my CNC Turning Center later?

Yes, many CNC Turning Centers allow for upgrades. Options may include adding new tooling, software enhancements, or automation features to improve efficiency and capabilities.

Post time: Jan-29-2026