High-volume engine part production demands exceptional throughput and consistent repeatability. Manufacturers must understand automation’s profound impact on production efficiency. Selecting the right CNC machine is critical for achieving optimal cost-effectiveness and quality. This involves considering factors like whether 5-Axis CNC Machining is necessary for complex components. Evaluating “How does a 4-axis machining center improve automotive part precision?” helps assess efficiency gains. For specific materials, one might ask, “Which CNC machine is best for aluminum alloy auto parts?” Multi-axis Simultaneous Milling solutions also play a key role in advanced CNC machine operations.

Key Takeaways

- Define your production needs. Look at the part’s shape, material, and how many you need to make. This helps you pick the right CNC machine.

- Horizontal Machining Centers (HMCs) are good for big engine parts. They can work on many sides of a part without moving it much. This saves time and makes fewer mistakes.

- Multi-axis CNC machines are best for complex engine parts. They can make tricky shapes with high accuracy. This reduces how many times you need to set up the machine.

- Automation and robots help make many parts quickly. They load and unload parts and move materials. This makes machines work longer and faster.

- A strong and stable machine is important for making precise parts. It helps avoid vibrations and makes sure parts are made correctly. Good cooling systems also help tools last longer.

Defining Production Needs for Your CNC Machine

Manufacturers must clearly define production needs before selecting a CNC machine. This foundational step ensures the chosen equipment aligns perfectly with operational goals.

Analyzing Engine Part Geometry and Material

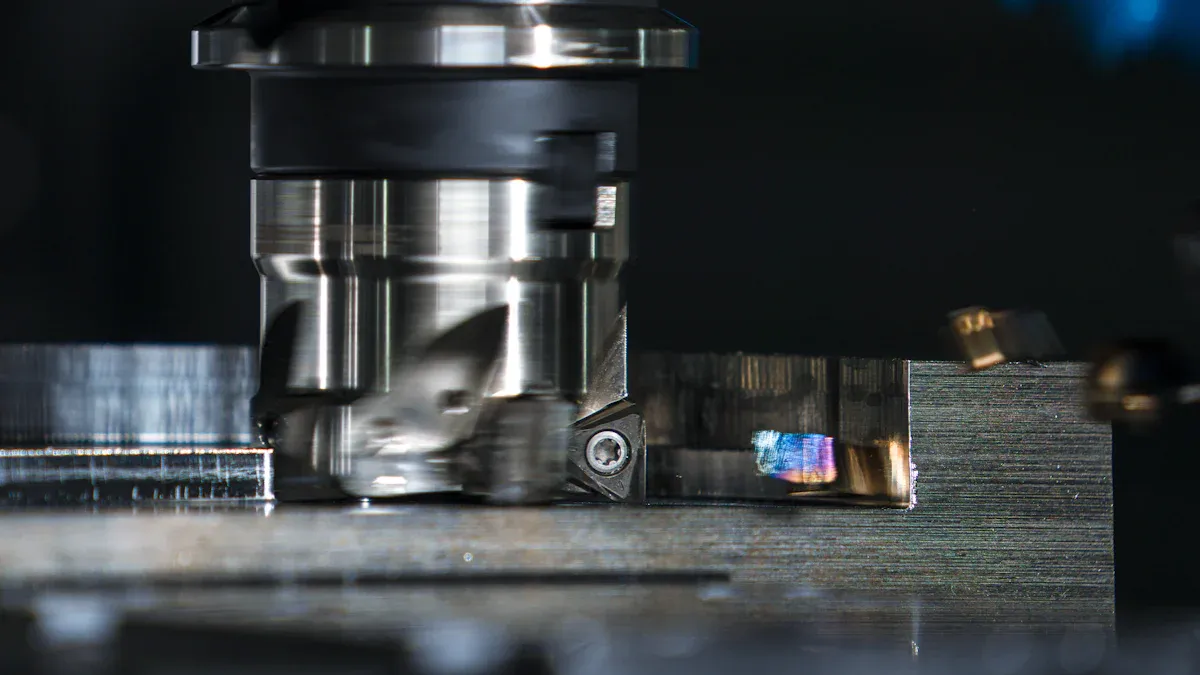

Engine part geometry significantly influences machine selection. Parts with perfect or near-perfect rotational symmetry, such as shafts or rods, are ideal for CNC turning. Conversely, complex curves, sharp corners, or non-symmetrical features require CNC milling. For intricate 3D shapes, cavities, or contoured surfaces, multi-axis milling is essential. Consider specific features like:

- Porting and Polishing: Reshaping ports, smoothing rough spots, and blending edges to maximize airflow.

- Valve and Seat Machining: Cutting precise angles on valve seats and performing bowl cutting for smoother transitions.

- Combustion Chamber Shaping: Optimizing chamber shape for efficient airflow and fuel combustion.

- Deck Resurfacing: Achieving specific deck heights and ensuring parallelism on V-type blocks.

- Cylinder Overboring/Honing: Correcting bore centerlines to exact specifications.

Material properties also dictate machining processes. Aluminum machines easily at higher speeds and lower forces, offering good tooling life. Cast iron, however, machines differently. Gray iron is relatively easy due to graphite acting as a chip breaker. Ductile iron is harder and requires different tooling. The table below highlights key differences:

| Property | Cast Aluminum | Cast Iron |

|---|---|---|

| Machinability | Easy to machine, reduced cutting forces, less tool wear. | Challenging, higher hardness, rapid tool wear. |

| Tool Wear | Less tool wear, extended tool life. | Rapid tool wear, increased tooling costs. |

| Cutting Forces | Reduced cutting forces. | Higher cutting forces. |

| Production Efficiency | Faster machining speeds. | Slower machining speeds may be required. |

Determining Required Production Volume and Cycle Times

Production volume and desired cycle times directly impact machine capacity and automation levels. High-volume production necessitates machines capable of continuous operation with minimal downtime. Manufacturers must calculate the number of parts needed per shift, day, or week. This calculation helps determine the required machine speed, tool change efficiency, and potential for automated loading/unloading systems. Efficient cycle times are crucial for meeting production targets and optimizing throughput.

Specifying Precision and Surface Finish Requirements

Engine components demand high precision and specific surface finishes for optimal performance and longevity. Critical parts like crankshafts require exceptional surface quality. For crankshafts, the surface roughness (Ra) typically aims for values below 0.2 µm during the polishing process. This level of finish minimizes friction, reduces wear, and ensures proper sealing. Specifying these requirements guides the selection of a CNC machine with the necessary rigidity, spindle accuracy, and tooling capabilities to achieve the desired tolerances and surface quality.

Key CNC Machine Types for High-Volume Engine Parts

Selecting the appropriate CNC machine type is paramount for efficient high-volume engine part production. Different machine configurations offer distinct advantages for specific component geometries and production requirements.

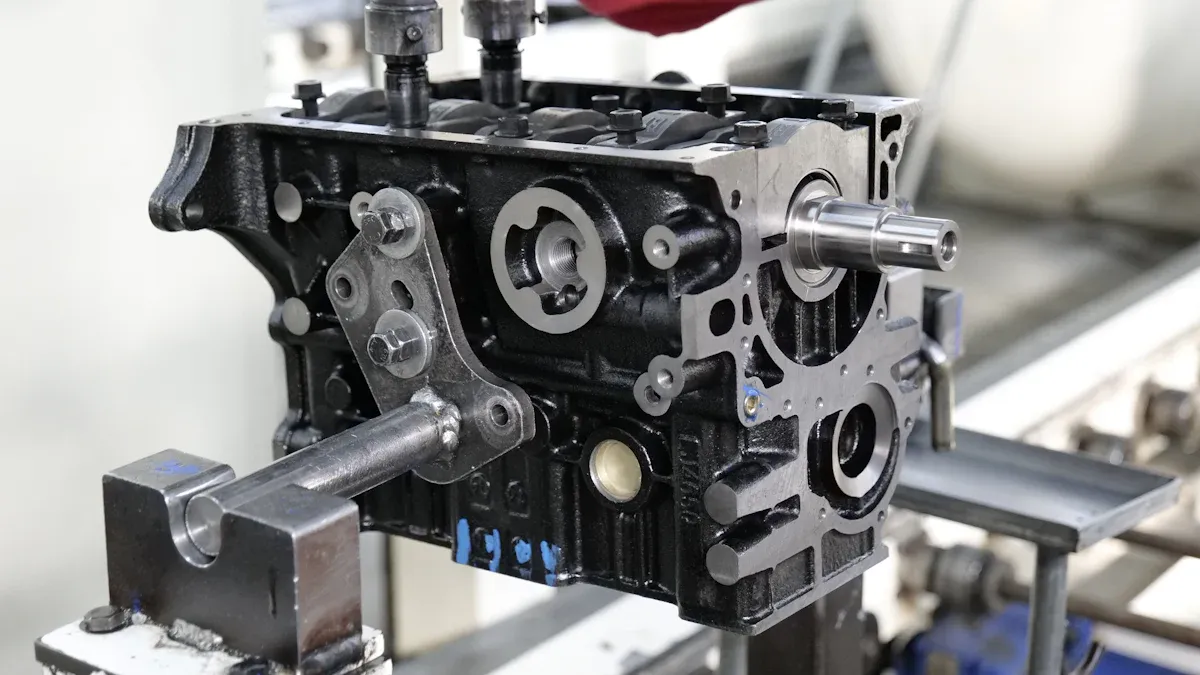

Horizontal Machining Centers for Engine Blocks and Heads

Horizontal Machining Centers (HMCs) are indispensable for machining large, complex engine components like blocks and heads. These machines excel at multi-sided machining, a critical capability for such parts. A Vertical Machining Center (VMC) typically requires an operator to move a multi-sided part seven or more times. This increases labor costs, causes considerable spindle downtime, and raises the potential for errors. In contrast, an HMC handles a six-sided part with no more than three operator touches. This significantly reduces part handling, minimizes spindle downtime, and decreases the risk of mechanical or human error, which contributes to increased efficiency and profitability.

HMCs offer several key advantages:

- Multi-sided Machining: HMCs typically feature numerous axes (3-5), enabling machining operations on multiple faces. This is crucial for complex parts like engine blocks.

- Enhanced Productivity: Dual pallet HMCs allow for simultaneous and continuous handling of multiple workpieces, improving efficiency.

- Improved Chip Management: The distinct orientation and impressive chip evacuation mechanisms of HMCs ensure efficient removal of accumulated fragments. This prevents interference during machining.

- Improved Firmness: The unique configuration of HMCs provides firmness. This allows them to securely hold weighty pieces like engine blocks, with force evenly distributed during machining.

- Improved Precision: HMCs contain a rigid spindle. This enables them to perform distinct machining operations with unrivaled accuracy.

HMCs also accommodate larger and heavy-duty workpieces, unlike VMCs which favor comparatively smaller and lighter workpieces. For workholding, tombstone fixtures, also known as tooling blocks, are commonly employed. They facilitate mounting multiple workpieces on different faces of a vertical block, allowing for simultaneous or sequential machining. This method effectively minimizes downtime and boosts productivity, making them suitable for high-volume production. Pallet changers represent an advanced workholding solution often found on HMCs. They function as power-operated tooling plates, enabling operators to set up new pallets while the machine actively works on another. This system minimizes machine downtime by cycling pallets in and out of the machining area, allowing setup to occur in parallel with machining operations. Some systems include ‘Pallet Pools’ for extended unattended operation, contributing to higher automation levels. The integration of a 4th axis, typically a rotary axis, is a valuable workholding strategy for HMCs. This axis, often standing upright and parallel to the X or Y axis, provides increased clearance. It allows for new part orientations, enabling access to more sides of a workpiece for continuous mass production without manual flipping. Additionally, it facilitates machining multiple parts arrayed around the 4th axis.

Multi-Axis CNC Machines for Complex Components

Multi-axis CNC machines, particularly 5-axis systems, are essential for producing complex engine components with intricate geometries. These machines offer significant productivity gains over traditional 3-axis machines. For example, they can reduce machining processes from 13 to 5 for an engine casing. They also shorten the production cycle from 72 hours to 28 hours for the same part.

Complex engine components benefit greatly from 5-axis machining:

- Turbine blades: These parts have complex airfoil geometries requiring continuous surface transitions. Traditional methods cannot achieve proper cutting angles, leading to compromised surface finishes and dimensional accuracy.

- Engine components: Intake manifolds, cylinder heads, and turbocharger housings utilize 5-axis capabilities for their compound curves and multiple machined surfaces. These demand sophisticated machining approaches.

- Turbocharger wheels: These components require perfect airflow paths and light, strong parts.

- Custom manifolds: High-performance engines need custom manifolds to achieve perfect airflow paths.

Multi-axis machines offer numerous advantages:

- Single setup machining reduces setups for complex parts, improving production time and quality.

- Less fixturing eliminates or reduces the need for special fixturing, saving time and manpower.

- The ability to machine more complex shapes allows for unique tool paths and greater accuracy for intricate geometries.

- Shorter cutting tools enable higher cutting speeds, less tool vibration, better surface finish, and reduced tool deflection.

- Better surface finish is achieved through less vibration from shorter tools and consistent cuts from rotating tables/spindles.

- Quicker material removal occurs because the cutting tool is perpendicular to the surface, allowing more material removal per pass and lower cycle times.

- Reduced labor cost per part results from fewer setups and fixturing, allowing one machinist to operate multiple machines with limited attention.

- Shorter lead times produce parts in a fraction of the time due to fewer setups.

- Higher part accuracy is achieved by eliminating the need to move the part for multiple setups or across different machines.

- Improved floor space results because one 5-axis machine can replace several 3-axis machines.

- Increased cost savings and faster ROI come from improved tool life, less scrap, reduced fixturing, and better floor space utilization.

Turning Centers and Mill-Turn Machines for Rotational Parts

For engine parts with rotational symmetry, manufacturers choose between turning centers and mill-turn machines. Each offers distinct capabilities for high-volume production.

| Feature/Capability | Turning Center | Mill-Turn Machine |

|---|---|---|

| Primary Function | Specializes in rotational symmetry, producing precise diameters, tapers, and threads. | Combines turning and full milling capabilities. |

| Key Processes | Turning (facing, contouring, straight turning), boring, threading. | All turning processes plus milling operations (contour milling, pocketing, off-center drilling). |

| Off-Center Features | Cannot easily produce features offset from the rotational centerline (unless equipped with live tooling and Y-axis). | Can produce off-center features using live tooling and Y-axis capabilities. |

| Tooling | Standard turning tools. | Live tooling (rotating spindles for end mills and drills). |

| Axes | Typically 2 dimensions (X and Z); advanced models may add C-axis and Y-axis. | Includes X, Z, C-axis, and Y-axis for off-center machining. |

| Setup Efficiency | Quicker setups for simple cylindrical parts; excels at high-volume production of simple rotational components. | Reduced setups as parts requiring both turning and milling can be finished in one clamping. |

| Part Complexity | Ideal for standard, symmetric components like bushings, shafts, bolts, engine pistons, and connectors. | Ideal for complex parts requiring both turning and milling, often for aerospace, medical, and specialized machinery. |

| Error Reduction | Lower risk for simple parts. | Significantly reduces errors by eliminating part transfers and re-chucking inconsistencies. |

| Throughput | High for simple, high-volume parts. | Increased throughput for complex parts due to multitasking and reduced cycle times. |

| Cost | Generally lower initial cost. | Significantly higher initial cost, but justified by efficiency gains for high-value components. |

| Engine Parts Suitability | Excellent for basic rotational engine parts like pistons (mass production of standard, symmetric components). | Beneficial for complex rotational engine parts that might require both turning and milling features, completing them in a single setup. |

Turning centers specialize in producing precise diameters, tapers, and threads for parts like engine pistons. They excel at high-volume production of simple rotational components. Mill-turn machines combine turning and full milling capabilities. They perform all turning processes plus milling operations such as contour milling, pocketing, and off-center drilling. This allows them to produce off-center features using live tooling and Y-axis capabilities. Mill-turn machines significantly reduce errors by eliminating part transfers and re-chucking inconsistencies. They offer increased throughput for complex parts due to multitasking and reduced cycle times. While a mill-turn machine has a significantly higher initial cost, its efficiency gains for high-value components often justify the investment.

Dedicated Production Lines and Pallet Systems

Dedicated production lines and integrated pallet systems represent the pinnacle of efficiency for high-volume engine part manufacturing. These systems are specifically engineered for continuous, uninterrupted production of a single product or a family of similar products. They streamline the entire manufacturing process from raw material input to finished part output. Pallet systems, a crucial component of these lines, automatically transport workpieces between different machining stations. This eliminates manual handling and significantly reduces non-productive time.

Integrating dedicated production lines with advanced pallet systems offers significant advantages for manufacturers. These systems combine multiple processes into one cohesive unit. This dramatically reduces the overall footprint, saving a lot of floor space. Such integration also eliminates bottlenecks that occur when moving pallets between separate stations. This directly leads to increased throughput. Furthermore, these systems ensure enhanced load integrity. They create secure, stable, and weather-resistant shipping units in one smooth process.

Manufacturers also see lower material costs. Stretch hood technology, for example, can use up to 10% less film than older wrapping methods. This results in real savings. Beyond material savings, these systems reduce labor costs. Companies can reassign employees from physically demanding stacking jobs to more valuable roles within the facility. They also minimize product damage. Expertly formed, stable loads do not shift or get crushed. This protects goods all the way to their final destination. Optimized material use is another benefit. Integrated wrapping and hooding systems apply exactly the right amount of film. This cuts out waste and lowers spending on consumables.

The real game-changer is throughput consistency. By automating the palletizing process, you create a predictable and dependable workflow. You’re essentially eliminating one of the most common sources of operational delays, making sure your entire supply chain runs like a well-oiled machine.

Dedicated production lines, often leveraging features similar to conventional layer palletizers, are highly effective for specific production scenarios. These systems are best for high-volume, low-mix environments and dedicated production lines. They offer very high and consistent speeds. While their flexibility is lower, requiring mechanical changeovers for different parts, they provide robust, methodical handling for durable products. They also require standard mechanical and electrical maintenance. This comprehensive approach ensures maximum output and consistent quality for engine components.

Essential Features of a High-Volume CNC Machine

High-volume engine part production relies on machines with specific features. These features ensure efficiency, precision, and continuous operation. Manufacturers must carefully evaluate these capabilities when selecting equipment.

Automation and Robotics Integration

Automation and robotics integration are crucial for maximizing throughput in high-volume engine part manufacturing. These technologies reduce manual labor, increase speed, and improve consistency. Robots handle repetitive tasks like loading and unloading workpieces. This frees human operators for more complex roles.

Different types of robotic systems serve various purposes in a manufacturing environment:

| Type of CNC Robot | Key Features | Typical Applications (relevant to loading/unloading) |

|---|---|---|

| Articulated Robots | Multiple joints (6 or more axes), High flexibility | Complex trajectory machining, Material handling |

| Cartesian (Gantry) Robots | Linear movement in X/Y/Z axes, High rigidity, Strong payload capacity | Large workpiece handling, Loading/unloading |

| Collaborative Robots (Cobots) | Safe human-robot collaboration, Integrated force/torque sensors, Simple programming | Machine tending (loading/unloading CNC machines) |

| Cylindrical Robots | Cylindrical coordinate system, Rotary and vertical movement, Compact footprint | Vertical loading/unloading, Material handling |

Manufacturers often use specific robot types for machine tending:

- Collaborative Robots (Cobots): These robots work safely alongside humans. They are suitable for machine tending, which includes loading and unloading CNC machines.

- Cylindrical Robots: These robots manipulate components. They handle parts during production, implying loading and unloading tasks.

- Cartesian Robots (Gantry Robots): These robots load and unload materials into and out of machines. They also handle bulky items on production lines.

Automated Guided Vehicles (AGVs) and conveyor systems further enhance material flow. They integrate seamlessly with CNC machines. These systems offer significant benefits:

- Enhanced Movement Efficiency: AGVs transport materials precisely. They optimize workflows and reduce downtime.

- Reduced Physical Strain on Workers: AGVs handle repetitive tasks. This improves employee well-being. It also allows staff to focus on complex tasks.

- Improved Precision and Safety: AGVs offer greater accuracy and safety compared to manual transport or forklifts.

Conveyor systems are also vital for automating material flow:

- Automating Material Flow: Conveyors move parts into and out of CNC machines. They prevent bottlenecks.

- Belt Conveyors: These are ideal for small to medium parts. They are especially useful when surface protection is important.

- Roller Conveyors: These suit heavier components or fixtures. They can be easily rolled.

- Chain Conveyors: These work best for bulkier or high-temperature parts.

- Cleated or Incline Conveyors: Manufacturers use these for orientation control or elevation changes.

- Magnetic or Chip Conveyors: Some CNC applications deploy these to remove scrap or residual materials.

Integrating these systems leads to several operational advantages:

- Reduced Labor Needs: Automation replaces manual loading and unloading. This cuts costs and injury risks.

- Increased Machine Uptime: Machines operate continuously with predictable cycles. This eliminates idle time between parts.

- Increased Output: Throughput boosts by embedding preparatory work within machine cycles. This does not require new machines.

- Safety Improvements: Automation eliminates repetitive bending, lifting, and reaching. This enhances workplace safety.

- Scalability: Modular and portable solutions allow for phased investment across facilities.

Spindle Speed, Power, and Tooling Capacity

Spindle speed, power, and tooling capacity are critical for high-volume engine part production. High spindle speeds allow for faster material removal rates. This reduces cycle times. Powerful spindles maintain consistent cutting forces. They handle tough materials without bogging down. This ensures stable machining and prevents tool deflection.

Tooling capacity refers to the number of tools a machine can hold in its automatic tool changer. A larger capacity means less manual intervention for tool changes. This increases machine uptime. Rapid tool change mechanisms also contribute to efficiency. They minimize the time the spindle remains idle between operations. For complex engine parts requiring many different tools, a machine with ample tooling capacity and quick changeovers is essential.

Chip Management and Coolant Systems

Effective chip management and advanced coolant systems are indispensable for continuous, high-volume machining. Chips, or metal shavings, must evacuate from the cutting zone efficiently. Poor chip evacuation leads to several problems. It can cause tool wear, surface finish degradation, and even machine damage.

High-pressure through-spindle coolant systems offer significant advantages:

Significantly reducing heat and chips at the cutting area always equates to longer tool life and reduced downtime.

High-pressure coolant quickly penetrates the ‘vapor barrier’. This layer of steam forms on the cutting tool and workpiece. It acts as a heat insulator. By cooling the ‘hot zone’ where the tool contacts the workpiece, it quenches metal chips. This makes them brittle and easy to snap away. This process immediately flushes chips from the cutting zone. It prevents re-machining. This leads to better parts, increased speeds and feeds, and significantly extended tool life, often by five times or more.

These systems provide multiple benefits:

- Reduced Tool Wear: High-pressure coolant systems direct coolant precisely to the cutting zone. They effectively dissipate heat. This prevents the tool from reaching excessive temperatures. Thus, they extend tool life.

- Improved Heat Management: These systems maintain consistent temperatures at the cutting edge. They minimize thermal damage. This allows for faster cutting speeds.

- Increased Cutting Speeds and Productivity: With better cooling and chip removal, high-pressure coolant systems enable higher cutting speeds and faster machining cycles.

A high-pressure coolant system helps remove chips more effectively by flushing them away from the cutting area. This prevents chip buildup that could otherwise cause damage to the tool or workpiece. In addition to keeping the cutting area clear, the efficient removal of chips reduces the likelihood of chip re-cutting—a process where leftover chips are re-engaged by the tool, leading to unnecessary wear and surface imperfections. With high-pressure coolant systems, the chips are quickly ejected, leaving the cutting area clean for more efficient machining.

Proper chip conveyors and filtration systems complement high-pressure coolant. They ensure continuous operation without manual chip removal. This maintains a clean machining environment.

Machine Rigidity and Stability for Precision

Machine rigidity and stability are paramount for achieving high precision and superior surface finishes in high-volume engine part production. A rigid machine minimizes vibrations and deformation. This ensures tight tolerances and dimensional accuracy. For instance, a rigid machine base reduces deflection, allowing manufacturers to meet specifications with minimal errors. Furthermore, a rigid machine is crucial for producing high-quality surface finishes. It prevents tool chatter and ensures smooth tool movement. Achieving a mirror-like finish often requires specific parameters. These include feed rates below 0.05 mm/rev, cutting speeds exceeding 300 SFM, and spindle speed stability within ±1% variation.

Machine builders achieve foundational rigidity through careful material selection and structural design. Common materials for machine frames include cast iron, mineral composites, or welded steel. Cast iron is often favored for its excellent vibration-damping properties and thermal stability. Structural designs incorporate features like ribbed reinforcements, box-type structures, and symmetrical layouts. These designs enhance stiffness and reduce thermal deformation. Modern machine design utilizes Finite Element Analysis (FEA) to simulate stress and strain. This ensures the structure resists bending and twisting under dynamic loads.

Beyond the core structure, dampening systems further enhance stability. Passive dampening involves embedding materials like polymer concrete or damping pads into the machine structure. These materials absorb vibrations. More advanced machines use active dampening systems. These systems employ sensors and actuators to detect and counteract vibrations in real-time. This leads to smoother operation and better surface finish.

The spindle assembly is another critical component for precision. High-quality spindles incorporate precision bearings, such as ceramic hybrid bearings. These bearings provide both rigidity and speed. Thermal stability is also crucial. Cooling systems and thermal compensation mechanisms maintain dimensional accuracy. They counteract heat-induced spindle elongation. Low runout, typically less than 1 micron, ensures minimal tool deviation. This is essential for tight-tolerance applications. Spindle power directly influences the rigidity of a machine. High-power spindles generate greater cutting forces. This necessitates a rigid structure to prevent deflection. A well-designed spindle assembly ensures tool stability even under high-speed or high-force conditions. This is vital for achieving tighter tolerances and superior surface finishes, particularly for complex automotive parts.

Other components also contribute to overall machine rigidity. The machine base and structure serve as the foundation. They reduce vibrations and provide stability. Guideways and ball screws enable precise motion without unnecessary play or movement. Tool holders and fixtures minimize flex under load. They maintain consistent tool positioning. This comprehensive approach to rigidity allows the CNC machine to effectively process diverse materials used in engine parts, such as lightweight aluminum, durable stainless steel, or high-strength titanium, each requiring stable cutting conditions.

Operational Considerations for Your CNC Machine Investment

Investing in high-volume production equipment requires careful consideration of long-term operational factors. Manufacturers must evaluate aspects beyond the initial purchase price. These considerations ensure sustained efficiency and profitability.

Maintenance Requirements and Service Support

Effective maintenance is crucial for maximizing the lifespan and uptime of high-volume production machinery. A robust preventive maintenance schedule minimizes unexpected breakdowns and ensures consistent performance. For instance, yearly maintenance includes replacing all guideway wipers to prevent contamination and maintain smooth movement. Manufacturers also inspect and replace any worn or damaged belts.

Regular maintenance tasks span various frequencies:

- Daily: Verify fluid levels, remove metal shavings, and inspect the spindle area.

- Weekly: Clean or replace control cabinet filters and inspect belts for tension.

- Monthly: Evaluate coolant quality and check motor performance.

- Quarterly/Semi-Annually: Perform extensive cleaning, alignment checks, and inspect safety devices.

- Annually: Evaluate spindle play, replace hydraulic fluids, and calibrate the machine.

Manufacturers must keep essential spare parts on hand. These include components that undergo regular wear, such as belts, filters, seals, and sensors. Reliable service support from the machine vendor also proves invaluable for complex repairs and technical assistance.

Total Cost of Ownership and ROI

Manufacturers must analyze the total cost of ownership (TCO) to understand the true investment in a high-volume production machine. TCO extends beyond the initial purchase price. It encompasses all expenses incurred throughout the machine’s lifecycle. This comprehensive view helps assess the return on investment (ROI).

TCO includes several categories:

- Direct Costs: These cover material costs, manufacturing costs (machining time, labor, tooling, maintenance, energy), quality control, and packaging.

- Indirect Costs: This category includes design and engineering, administrative overhead, and warranty expenses.

- Hidden Costs: Manufacturers often overlook inventory holding costs, opportunity costs from lost sales, and risks associated with supply chain disruptions.

Evaluating these factors provides a realistic financial picture. It allows manufacturers to make informed decisions about equipment acquisition.

Operator Training and Skill Requirements

Skilled operators are essential for maximizing the efficiency and precision of high-volume production equipment. Manufacturers must invest in comprehensive training programs. Operators need familiarity with software and essential programming languages. They must follow technical instructions and specifications, determining ideal product setup. Proficiency in reading and comprehending blueprints, including fabrication tolerances, is also critical.

Operators require a strong mathematics foundation, particularly geometry and trigonometry. Understanding CAD/CAM technology is also important. They must possess problem-solving skills to evaluate product quality and make necessary machine or programming adjustments. Knowledge of various machine subtleties due to different machine types and setup requirements is also vital. Educational paths often begin with high school science and math courses. Secondary education from trade and vocational schools provides courses like blueprint reading and machine tooling. Certifications, such as a CNC Operator certificate or a CNC Production Technician diploma, offer industry-recognized skills and cover topics like machining processes, safe operation methods, and offsets calculation. Continuous learning and external certifications are crucial for career advancement.

Scalability and Future Production Demands

Manufacturers must design production systems with future growth in mind. A scalable production setup adapts to changing market demands and increased output requirements. Planning for scalability ensures long-term operational success and maximizes the return on investment. Businesses can implement several strategies to create a machining cell that allows for future expansion and increased production capacity.

These strategies include:

- Upgrade Machinery: Enhance speed, precision, and efficiency. Manufacturers can upgrade to multi-axis machines or integrate two-axis tables with three-axis machines for five-sided integration. This allows for more efficient part production and shorter turnaround times. It directly supports increased capacity.

- Improve Production Floor Organization: Maintain a clean and organized manufacturing facility. Proper coordination, high-quality tool drawers, shadow boards, and enhanced labeling schemes reduce wasted time and resources. This contributes to overall efficiency. It also helps handle higher production volumes.

- Consistent Improvements in CNC Programming: Continuously refine CNC programming. This minimizes errors, optimizes machine programs, and boosts machining productivity. Expert programming ensures consistent processing and limits accumulated errors. This is crucial for scalable and efficient operations.

- Augment the Machining Process: Invest in staff training for new CAM systems. Consider upgrading travel guidance systems for greater accuracy and efficiency. Well-trained staff and precise guidance systems reduce errors and improve operational speed. This supports increased production.

- Invest in Enhancing Tool Life and Maintenance: Implement preventative and predictive maintenance for tools, filters, and spindles. Use high-quality replacement parts and harder tools when feasible. This extends tool life, prevents frequent replacements, and minimizes downtime. It ensures continuous and high-capacity production.

These proactive measures allow manufacturers to meet evolving production demands efficiently. They ensure the production line remains agile and responsive to market changes.

Selecting the ideal CNC machine requires careful alignment of its capabilities with specific production demands. Manufacturers must balance the initial investment against long-term operational efficiency. This strategic approach ensures optimal performance and cost-effectiveness. An informed decision ultimately leads to sustainable high-volume engine part production.

FAQ

What is the main advantage of Horizontal Machining Centers (HMCs) for engine blocks?

HMCs excel at multi-sided machining. They significantly reduce part handling and spindle downtime. This increases efficiency and profitability. HMCs also offer superior chip management and rigidity for heavy workpieces.

Why are multi-axis CNC machines important for complex engine components?

Multi-axis machines, especially 5-axis systems, produce intricate geometries. They reduce setups and shorten production cycles. This leads to higher accuracy and better surface finishes for parts like turbine blades and cylinder heads.

How do high-pressure coolant systems improve machining efficiency?

High-pressure coolant systems reduce heat and effectively remove chips from the cutting zone. This extends tool life, prevents re-machining, and allows for faster cutting speeds. They significantly boost productivity and part quality.

What role does automation play in high-volume engine part production?

Automation, through robotics and conveyor systems, maximizes throughput. It reduces manual labor, increases speed, and improves consistency. Automated systems handle repetitive tasks, enhance material flow, and increase machine uptime.

How does machine rigidity impact precision in engine part manufacturing?

Machine rigidity minimizes vibrations and deformation. This ensures tight tolerances and dimensional accuracy. A rigid machine prevents tool chatter, leading to superior surface finishes. It is crucial for high-quality engine components.

Post time: Dec-28-2025