Large parts demand specialized machining. Understanding the core distinctions between Vertical CNC Turning and Horizontal CNC Turning is crucial for success. Manufacturers must evaluate several primary factors when choosing an Industrial CNC lathe for heavy and oversized workpieces. These factors include part geometry, weight, and the precise CNC turning machine specifications required for optimal performance. A robust CNC Turning Machine ensures quality.

Key Takeaways

- Vertical CNC machines hold heavy, short parts well. Gravity helps keep the part steady, which makes machining more accurate.

- Horizontal CNC machines are good for long, thin parts. They support the part at both ends, which stops it from bending.

- Vertical machines handle heavy loads better because gravity pushes the weight into the machine. This means less clamping is needed.

- Horizontal machines clear chips better. Chips fall away easily, which helps tools last longer and makes surfaces smoother.

- Choosing the right machine depends on the part’s size, weight, and shape. This choice helps make the best parts.

Key Differences in CNC Turning Machine Design and Workpiece Orientation

Vertical Spindle Configuration for Large Parts

Vertical CNC turning machines stand tall. They position the workpiece vertically. This design uses gravity to stabilize heavy items. Manufacturers often choose these machines for large, heavy, and bulky workpieces. A sturdy frame supports these massive parts. The vertical design includes large-diameter rotating tables. These tables easily hold substantial workpieces. This configuration ensures high precision and accuracy. It minimizes vibrations during machining. Gravity helps clamp the workpiece firmly on the rotating table. This means less clamping force is needed. This is a huge benefit for very large or heavy parts. Double Column VTLs offer even more stability. They use two columns for enhanced rigidity. This makes them perfect for the largest, most precise jobs. These machines integrate CNC technology. This allows for complex tasks with high accuracy. Multi-axis movement further expands their capabilities.

Horizontal Spindle Configuration for Large Parts

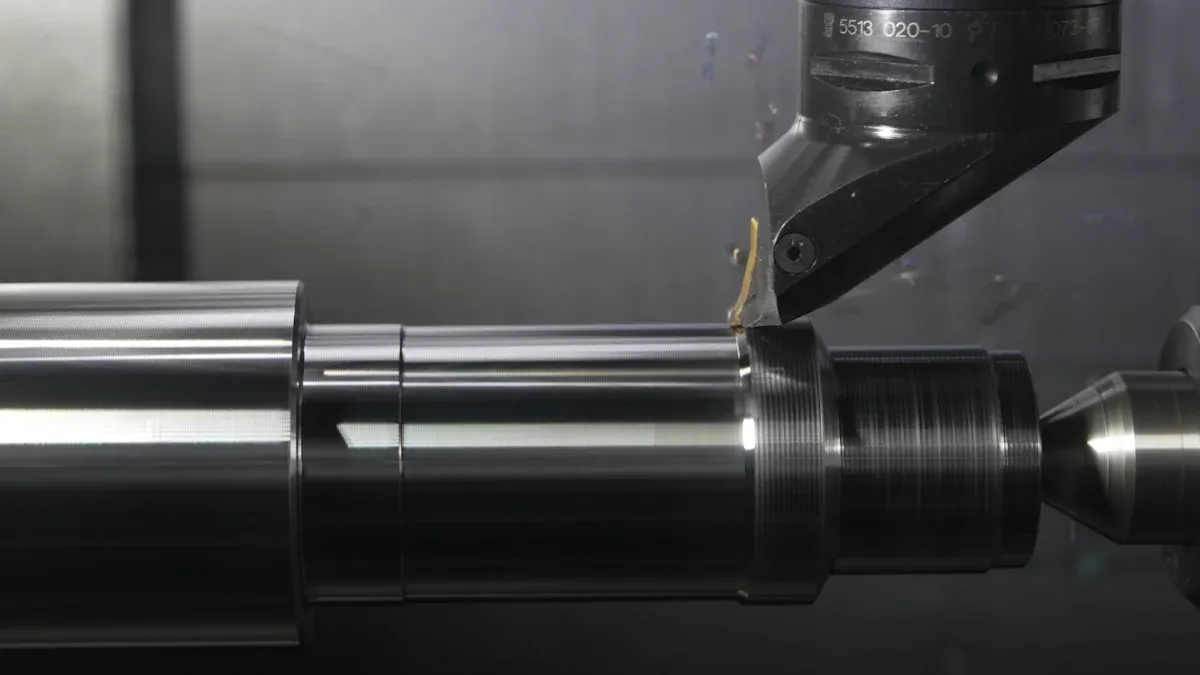

Horizontal CNC turning machines orient the workpiece horizontally. The spindle lies parallel to the floor. Operators load the workpiece onto a chuck. This chuck rotates the part along a horizontal axis. This setup works well for long, slender parts. It also handles parts that require support at both ends. For very large parts, horizontal machines need robust support systems. They must counteract gravity’s pull. Workpiece stability relies heavily on clamping force and steady rests. These components prevent sagging or deflection. These machines offer excellent visibility for the operator. They also provide easy chip removal.

Impact on Workpiece Stability and Support

Workpiece stability is a critical factor. It directly impacts machining accuracy. Vertical machines excel here. Gravity assists in stabilizing the workpiece. It holds the part firmly on the rotating table. This reduces the need for excessive clamping. This design minimizes vibrations. It ensures better dimensional accuracy. Horizontal machines face a different challenge. Gravity pulls the workpiece downwards. This requires strong clamping and additional support. Steady rests become essential for long or heavy parts. Without proper support, deflection can occur. This affects precision. The choice depends on the part’s geometry and weight. Vertical machines offer inherent stability for heavy, short parts. Horizontal machines provide good support for long, slender components. Each CNC Turning Machine design offers unique advantages for specific applications.

Performance and Precision for Heavy-Duty CNC Turning Machine Operations

Gravitational Load Management and Rigidity

Managing gravitational loads is paramount for large parts. Vertical turning centers master this challenge. They leverage gravity to enhance workpiece stability. This design directs the weight into the machine’s foundation. This minimizes inaccuracies. It also reduces the clamping force required. This allows for a greater workpiece weight capacity. For instance, MetalTech’s Doosan Puma vertical CNC turning machines skillfully handle components weighing up to 2 tonnes. Kent CNC’s large heavy-duty VTL series, designed for demanding sectors like aerospace, defense, and energy, emphasizes rigidity, stability, and precision. This commitment to robust construction suggests a high load capacity. Horizontal machines, however, must actively counteract gravity. They require robust clamping and steady rests to prevent sagging. This ensures the part remains stable throughout the machining process.

Chip Evacuation Efficiency in CNC Turning Machines

Efficient chip evacuation significantly impacts tool life and surface finish. Horizontal CNC machines excel in this area. Their horizontal spindle orientation allows chips to naturally fall away from the cutting area. This natural chip removal reduces recutting. It enhances surface finish. It also prolongs tool life. Horizontal machining centers are well-suited for large and heavy parts. Here, efficient chip evacuation is critical for deep and heavy cuts. Chips fall due to gravitational pull, leading to efficient material removal.

| Feature | Vertical CNC Machine | Horizontal CNC Machine |

|---|---|---|

| Chip Evacuation | Poorer (chips fall on part) | Excellent (chips fall away by gravity) |

| Tool Life | Shorter due to chip accumulation | Longer, thanks to better cooling and clearance |

| Best Use Cases | Smaller parts, flat surfacing, prototyping | Heavy-duty, large production runs |

Vertical machining centers face a different challenge. Chips tend to accumulate on the workpiece and tooling. This negatively impacts surface finish and tool life. Chips gather on the bed or table. This often requires additional cleaning methods. Chip congestion can occur during deep pocket machining. This affects tool life and surface finish.

Vibration Dampening and Achievable Tolerances

Vibration dampening is crucial for achieving tight tolerances. Vertical CNC turning machines inherently offer superior vibration dampening. Their robust, vertical structure and the way they manage gravitational loads contribute to this. The workpiece’s weight presses down into the machine’s foundation. This creates a stable machining environment. This design minimizes vibrations. It allows for exceptional dimensional accuracy and surface finish. Horizontal machines, especially with long or heavy workpieces, can be more susceptible to vibrations. The workpiece extends horizontally. This can create leverage points for vibration. Manufacturers must employ advanced dampening technologies and careful setup procedures. This ensures precision. The choice of CNC Turning Machine directly influences the achievable tolerances. Vertical machines often provide an advantage for the most demanding precision requirements on heavy, large-diameter parts.

Operational Considerations for Large Part CNC Turning Machines

Footprint and Space Requirements

Manufacturers must carefully consider the physical space a large CNC Turning Machine occupies. Vertical machines often rise tall. They require significant overhead clearance. However, their floor footprint can be surprisingly compact. This makes them suitable for facilities with limited floor area but ample vertical space. Horizontal machines, especially those designed for very long workpieces, demand extensive floor space. They stretch out horizontally. This requires a longer, wider area in the workshop. Planning the factory layout becomes crucial. It ensures efficient workflow and safe operation around these powerful machines.

Workpiece Loading and Unloading Challenges

Moving massive workpieces presents unique challenges. Vertical machines use gravity to their advantage during machining. Yet, loading and unloading these extremely heavy parts can be challenging. Crane access might be blocked by the machine’s bridge-like structure. This requires careful planning and specialized rigging. Horizontal machines often offer easier crane access. Operators can position the crane directly over the workpiece. However, they must ensure robust support for the part during transfer. This prevents sagging or damage. Safety protocols are vital for both machine types. They protect both the workpiece and the operators.

Tooling Access and Changeover Efficiency

Efficient tooling access and quick changeovers boost productivity. Vertical machines often feature large tool magazines. These hold many tools. However, accessing and changing tools can sometimes be more complex due to the machine’s vertical orientation. Horizontal machines generally provide more straightforward access to the tool turret. This allows for faster tool changes. Operators can quickly swap tools. This minimizes downtime. The choice depends on the complexity of the part and the frequency of tool changes required for the job.

Ideal Applications and Industry Suitability for CNC Turning Machines

Vertical CNC Turning Machines for Specific Large Part Geometries

Vertical CNC turning machines excel with specific large part geometries. They handle larger, heavier workpieces with ease. These machines are ideal for short, wide components. Consider large gears, turbine disks, or heavy flanges. The vertical orientation uses gravity to stabilize these massive parts. This ensures superior accuracy during machining. Manufacturers achieve precise results on complex, heavy items. This design minimizes vibration, leading to exceptional surface finishes. It empowers producers to tackle the most challenging, oversized parts.

Horizontal CNC Turning Machines for Specific Large Part Geometries

Horizontal CNC turning machines shine with different part shapes. They are perfect for long, slender workpieces. Examples include shafts, rollers, or long pipes. These machines provide support at both ends of the part. This prevents sagging and maintains concentricity. They also manage parts requiring extensive drilling or boring along their length. This setup offers excellent visibility for operators. It facilitates easy chip removal, which is vital for long, continuous cuts. Manufacturers choose horizontal machines for their versatility with elongated components.

Industries Benefiting from Vertical CNC Turning Machines

Many industries rely on vertical CNC turning machines for their demanding needs. These machines are crucial for sectors producing large, heavy components. Industries like aerospace, automotive, and medical devices frequently use them. Heavy machinery manufacturers also benefit greatly. Power generation, mining, and military applications depend on their capabilities. Machine tool makers, marine, and OEM (Original Equipment Manufacturer) sectors also find them indispensable. Aerospace manufacturing, in particular, utilizes these robust machines for critical components. A reliable CNC Turning Machine is essential for these high-stakes environments. These powerful machines enable the creation of vital parts for infrastructure and transportation. They drive innovation across diverse industrial landscapes, proving the versatility of this advanced CNC Turning Machine technology.

Industries Benefiting from Horizontal CNC Turning Machines

Horizontal CNC turning machines empower many industries. They excel in manufacturing long, slender components. These machines provide crucial support for extended workpieces. This prevents sagging and ensures precision.

Consider the automotive industry. Manufacturers produce countless crankshafts, camshafts, and axles. These parts demand consistent quality and high production rates. Horizontal machines deliver this efficiency. They handle the length of these components with ease.

The oil and gas sector also relies heavily on these robust machines. They create drill pipes, shafts, and various tubular goods. These components operate in harsh environments. Their integrity is paramount. Horizontal turning ensures the necessary strength and accuracy.

Aerospace manufacturers utilize horizontal machines for specific structural elements. They machine long spars and engine shafts. These parts require exceptional precision and surface finish. Horizontal machines meet these stringent demands.

Furthermore, the heavy equipment industry benefits immensely. They produce hydraulic cylinders, long pins, and large shafts. These components form the backbone of construction and mining machinery. Horizontal CNC turning machines build these essential parts with unwavering reliability.

- Key Advantages for These Industries:

- Superior support for long workpieces.

- Efficient chip evacuation, boosting productivity.

- High-volume production capabilities.

- Consistent precision for critical components.

These machines drive innovation and success across diverse manufacturing landscapes. They enable companies to create vital parts that power our world. Businesses choose horizontal CNC turning machines for their unmatched ability to handle elongated workpieces and maintain high production standards. This choice leads to remarkable achievements in manufacturing.

Choosing the right CNC turning machine empowers manufacturing success. Critical decision-making factors include workpiece size, weight, and geometry. Vertical machines excel with large-diameter, heavy, and short parts, using gravity for stability and easy mounting. Horizontal machines are ideal for long, slender components like shafts, offering superior support and efficient chip evacuation. The optimal choice always depends on specific part characteristics, desired production volume, and unique operational priorities. Aligning these elements unlocks peak performance.

FAQ

Which CNC turning machine best handles extremely heavy workpieces?

Vertical CNC turning machines excel with heavy parts. They use gravity for stability. This design minimizes clamping needs. It ensures superior accuracy for massive components. Manufacturers achieve great success with these robust machines.

How do vertical and horizontal machines manage chip removal?

Horizontal machines offer excellent chip evacuation. Gravity helps chips fall away from the cutting area. This boosts tool life. Vertical machines may accumulate chips. This requires additional cleaning methods. Operators find success with efficient chip management.

What are the space considerations for each machine type?

Vertical machines require significant overhead clearance. Their floor footprint is often compact. Horizontal machines demand extensive floor space. They stretch out horizontally for long workpieces. Planning your workshop space carefully leads to success.

Which machine offers superior precision for large parts?

Vertical CNC turning machines often provide superior precision. Their robust structure dampens vibrations effectively. This leads to exceptional dimensional accuracy. Horizontal machines require careful setup for similar precision. Achieving high precision empowers manufacturers.

Post time: Dec-03-2025