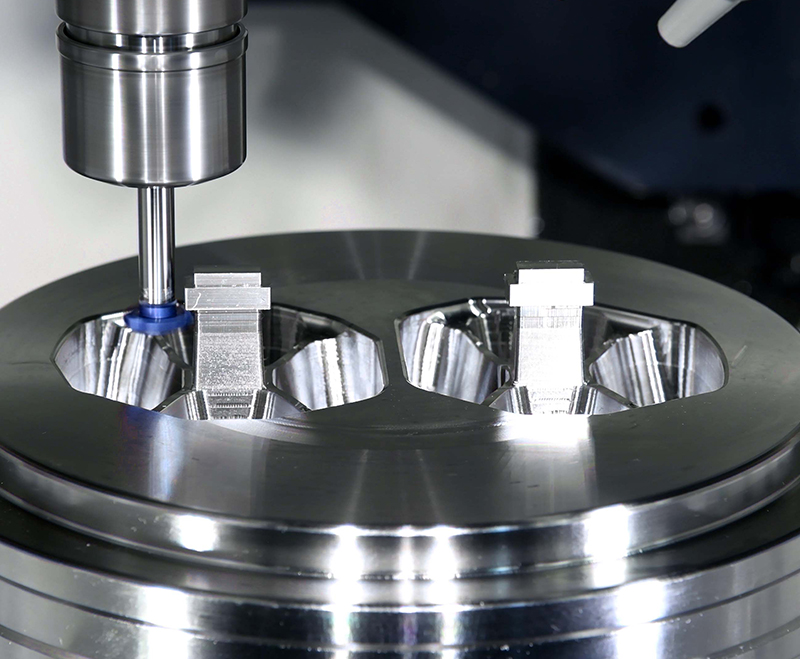

You achieve advanced precision machining with a CNC metal lathe. Its automated, computer-controlled processes ensure micron-level accuracy and consistency. Digital control and robust mechanics in the CNC metal lathe are fundamental. They produce components with superior precision. These machines create complex geometries and tight tolerances, essential for high-performance applications.

Key Takeaways

- CNC metal lathes use computers to control movements. This makes parts very accurate and consistent.

- Special software helps design parts and plan how the machine cuts. This prevents mistakes and makes the process efficient.

- These machines can make complex shapes and smooth surfaces. They are used in many industries like aerospace and medical devices.

The Core Mechanisms of Precision in CNC Metal Lathe Operations

Computer Numerical Control for Exact Movements

Your CNC metal lathe achieves exact movements through Computer Numerical Control (CNC). This system translates digital instructions into precise physical actions. The CNC controller interprets G-code and M-code commands. G-code acts like a GPS for the machine’s toolpaths. It tells the machine how to move. G-code focuses on the geometry and motion of the machine. It directs the tool’s path along different axes to create specific shapes. For example, G01 commands linear movement. M-code manages other machine operations. These include starting and stopping functions, activating the spindle, or turning on coolant. M08, for instance, activates the coolant.

The CNC machine reads these commands line by line. This precise control guides tool movement and machine functions. To ensure these movements are exact, your machine relies on robust mechanical components. The lathe bed forms the foundational platform. It absorbs turning forces and keeps everything aligned. High-quality materials like Meehanite-grade cast iron help dampen vibrations and maintain stability. This ensures alignment even with temperature changes. The headstock controls rotational accuracy. It features a high-torque spindle with very low runout, often less than 0.003mm. Precision bearings, like P4-class angular contact bearings, maintain concentricity. They keep the spindle rotating smoothly and accurately.

The carriage system moves the turning tool along the X and Z axes. It uses ball screws to convert rotary motion into precise linear motion. Ball screws have recirculating ball bearings. These reduce friction and allow for smooth, accurate linear movement. Linear guides also play a crucial role. They use bearings to facilitate smooth, precise straight-line movement, even for heavy parts. This combination of digital control and robust mechanics ensures your machine makes exact movements.

Automated Tool Path Generation and Optimization

You achieve advanced precision through automated tool path generation and optimization. This process starts with specialized software. CAM (Computer-Aided Manufacturing) software is essential here. It helps you select the best machining strategies. These strategies include contouring, pocketing, drilling, and finishing. CAM software also applies advanced techniques like trochoidal milling or high-speed machining. These methods generate and optimize the tool paths.

Simulation software, often a feature within CAM, verifies these tool paths. It checks for errors, collisions, or deviations before you start machining. This step saves time and material. It also measures important parameters like tool path length and machining time. Optimization software then refines these paths. It can reduce machining time, minimize tool wear, or improve surface roughness. For complex geometries, methods like Automated Off-Line Programming (AOLP) use Scalable Vector Graphics (SVG) to extract intricate paths. A Genetic Algorithm (GA) then optimizes these paths. This minimizes the total path length for the robot end effector. This entire automated process ensures your machine follows the most efficient and precise route.

Real-time Feedback Systems for Accuracy

Your CNC system uses real-time feedback to maintain accuracy. This is a “closed-loop system.” In this system, feedback constantly goes from the control system back to the planned input. Sensors monitor the tool’s position in real-time. They immediately adjust for any deviations. This continuous feedback corrects errors. It ensures your products meet design specifications. This is vital for complex parts where precision is critical.

The controller continuously compares the planned position with the actual position. It uses data from encoders. Encoders convert mechanical motion into electrical signals. These signals provide crucial data on position, speed, and direction. Your machine uses various types of encoders. Linear encoders, like the FORTiS™ linear encoder, are sealed to protect against contamination. Rotary encoders, such as the SpinCo™ incremental magnetic encoder, provide high-resolution feedback for spindles. Absolute encoders, like the RESOLUTE™ absolute encoder, offer precise angular positioning for rotary tables.

When the controller detects a difference, it generates a control output. This output goes to the servo driver. This enables real-time closed-loop motor control. Adjustments happen in microseconds. This enhances operational efficiency and maintains accuracy. Error detection is key. Any discrepancies in movement are immediately corrected. This continuous adjustment ensures precision and makes your system resilient against inconsistencies. High-precision bearings, like ISO P4 grade, also significantly enhance stability and accuracy. They support the spindle shaft, allowing rotation with minimal friction. Spindle runout, the deviation from the perfect centerline, is kept extremely low, often +/- .0001″ in top-quality spindles. This level of accuracy ensures consistent dimensions in your turning operations.

Operational Processes for Advanced Precision with CNC Metal Lathe

CAD/CAM Software Integration for Design and Programming

You begin your precision machining journey with robust CAD/CAM software integration. This powerful combination streamlines your entire process. CAD (Computer-Aided Design) software allows you to create detailed 2D drawings and complex 3D models. You can accurately capture all dimensions and tolerances within these models. This digital design creation reduces manual work and eliminates many steps. It also improves efficiency, saving time and boosting productivity. You can easily reuse designs and make quick modifications. CAD facilitates intricate digital designs that are difficult to achieve with physical drawings. This gives you better visualization and greater accuracy.

CAM (Computer-Aided Manufacturing) software then takes these precise CAD models. It translates them into machining instructions, known as G-code, for your CNC machines. CAM systems calculate optimal turning paths, speeds, and feeds. They base these calculations on your material and tool specifications. This process ensures accuracy, especially for tight tolerances. The software helps you define machining strategies. These include tool selection, turning parameters, and the sequence of operations. Simulations within CAM software are crucial. They help you detect potential collisions and inefficiencies before machining begins. This step ensures accuracy and reduces errors. Post-processors then convert the toolpath data into G-code. This G-code is specifically tailored for your CNC metal lathe. This minimizes operator input and ensures consistent results.

Meticulous Machine Setup and Calibration

Achieving advanced precision demands meticulous machine setup and calibration. You must first verify all documentation and materials. Confirm that drawings and specifications are complete. Ensure your raw material meets all requirements. Thoroughly review all documentation, including fixture usage and operational methods. Next, inspect your equipment. Check the lathe, prepare necessary accessories, and lubricate the machine according to guidelines. Always perform a trial run.

You select the appropriate CNC metal lathe based on your part’s material, size, shape, and required machining accuracy. Different lathes offer varying processing capacities and precision ranges. You then securely install the turning tool on the tool post. Precisely clamp the workpiece on the spindle. Ensure its center aligns perfectly with the spindle’s rotation center. Proper workholding is critical. It securely holds workpieces against machining forces. It also aligns them to the machine’s coordinate axes and locates their origin relative to the machine’s origin. Precision-engineered chucks and collets provide rigidity. Optimizing clamping pressure and using tailstock support or steady rests prevent vibration and deflection.

Tool setting is another vital operation. You determine the relative positional relationship between the tool and the workpiece using a tool setter. Measure and input the tool’s offset values (e.g., X-axis and Z-axis for an external cylindrical turning tool) into the lathe’s control system. This ensures accurate tool movement control. You precisely measure turning tool length and diameter using tool presetters or machine-mounted probes. Establish each tool’s position relative to the workpiece coordinate system with high accuracy, often 0.0001″, for dimensional control.

You must also establish the coordinate system alignment. This defines the relationship between CAD model dimensions and the physical workpiece position. Operators use edge finders, probe systems, or reference surfaces to set work offsets. This translates programmed coordinates to actual machine positions for accurate geometry reproduction.

Environmental factors significantly influence precision. Fluctuations in ambient temperature cause machine components and workpieces to expand or contract. This leads to dimensional inaccuracies. Vibrations, from external sources like nearby machinery or internal sources such as unbalanced spindles, induce errors. They cause the tool or workpiece to oscillate, compromising surface finish and dimensional accuracy. You can mitigate these issues. Mount CNC machines on vibration-damping foundations or active isolation systems. These systems use pneumatic or piezoelectric actuators to counteract external vibrations in real-time. Balancing spindles and tools also minimizes internal vibrations, improving surface finish and accuracy.

Regular calibration is essential for sustaining precision. You implement scheduled realignment checks for spindles and axes. Use ballbar tests and laser calibration tools semi-annually or annually. Manage workshop temperature and humidity to prevent thermal expansion or dust accumulation. For calibration, you can use various tools:

- Ballbar Calibration: Employs a specialized ballbar device to assess deviations in circularity and accuracy during circular movements.

- Laser Interferometer Calibration: Uses laser beams to precisely measure the positioning accuracy of machine axes, detecting minute deviations.

- Probing System Calibration: Involves touch probes to measure tool offsets and workpiece positions, automating setup and reducing human error.

- Dial Indicators and Micrometers: Standard tools for measuring small linear distances with high precision, used for spindle alignment and detecting deviations.

Automated Machining Cycles and In-process Adjustments

Your CNC metal lathe executes automated machining cycles with minimal human intervention. This automation is key to consistent precision. During these cycles, in-process measurement systems continuously monitor the machining process. These systems provide real-time feedback, allowing for automatic adjustments.

You can integrate various measuring devices:

- Measuring devices for the tool:

- Contact tool setters: These are typically mounted on the machine table. They offer an economical, contact-based solution for tool setting. They measure tool length, radius offset, wear, and breakage. These systems connect to the machine’s control, allowing for automatic adjustments and alarming if wear tolerances are exceeded.

- Non-contact tool setters (laser measuring systems): These are usually table-mounted. They provide a non-contact method for tool setting and monitoring. They analyze tools of various shapes and sizes by continuously measuring the shading of a laser beam. These systems can compensate for spindle drift and runout errors. They also provide tool identification, wear detection, and preventative maintenance information.

- Measuring devices for the workpiece:

- Workpiece touch probes: You use these to set workpiece origin and measure features on machined parts. They verify dimensions against tolerances. They inspect the workpiece by touching it at predetermined locations, triggering a value recording. These probes enable part setup, workpiece measurement, and thermal and tool wear compensation.

- Scanning probes: These verify shape dimensions by continuously scanning the part. They record a constant stream of data to create a comparative measurement between a master part and the workpiece. They provide pass or fail feedback directly to the machine’s control.

- Roughness gauges: These inspect the surface finish of a workpiece inside the machine tool. They provide feedback directly to the machine’s control.

- Bore gauges: You use these to measure bore diameters during mass production. They provide diameter, position, roundness, cylindricity, and concentricity measurements.

These integrated systems allow your CNC metal lathe to make immediate, precise adjustments. This ensures that every part meets the exact specifications, even during long production runs.

Advantages and Applications of Advanced Precision CNC Metal Lathe Machining

Achieving Unparalleled Dimensional Accuracy and Repeatability

You achieve unparalleled dimensional accuracy and repeatability with advanced CNC metal lathes. These machines virtually eliminate human error. They use digital templates, enabling flawless, repetitive actions. Every part precisely matches the prototype’s specifications. This guarantees uniformity across all outputs. Unlike traditional methods, where even skilled engineers produce slight variations, CNC machines ensure consistent quality.

CNC machining utilizes computerized systems for unparalleled accuracy. This capability is crucial in modern manufacturing. It enables the production of parts with tight tolerances and high consistency. You will see increased production efficiency and reduced waste. CNC systems operate based on software programming. This reduces human input and the potential for errors. It ensures consistent accuracy across all units, even in multi-shift production. You can achieve a standard tolerance of ±0.13 mm (±0.005″) for turning operations. Advanced CNC machines can achieve ISO 2768 Fine tolerance class specifications, reaching ±0.05 mm for materials like aluminum and brass/copper alloys.

You must monitor and control the temperature of both the machine tool and its environment. Temperature fluctuations cause thermal expansion or contraction of machine components. This alters dimensions and alignment, leading to errors. Maintaining a stable temperature is essential. You can achieve this through thermal sensors, cooling systems, and insulation. Minimizing vibration also improves repeatability. Vibration and noise induce mechanical stress and distortion. They negatively impact the machine tool’s accuracy. You should isolate machine tools from external vibration sources. Utilize anti-vibration mounts, pads, or mats.

Producing Complex Geometries and Superior Surface Finishes

You produce complex geometries and superior surface finishes with advanced CNC metal lathes. Mill-Turning CNC Centers combine high-speed production with 5-axis milling flexibility. This integration creates more complex geometries. You can produce parts with rotational symmetry, like impellers. These centers reduce the need for multiple machines and decrease setup time. They streamline production, offering a cost-effective solution for intricate designs.

You can perform various operations. Drilling and boring create perfectly centered holes. Threading produces precise threads on bolts, rods, or nuts. Slotting and grooving create keyways or grooves for O-rings. Facing removes material from workpiece edges to create flat surfaces. Taper turning shapes angled profiles for snug fits. These capabilities allow you to achieve intricate internal and external features.

Industry Applications Benefiting from CNC Metal Lathe Precision

Many industries benefit from CNC metal lathe precision. In aerospace, you manufacture critical components. These include turbines, gears, shafts, fasteners, pins, bushings, and threaded components. These parts demand extreme accuracy for safety and performance.

Medical device manufacturers leverage this precision for critical implants and instruments. Precision is paramount here. Even slight deviations can lead to serious consequences for patient safety. CNC ensures exact specifications. It aligns with regulatory standards and optimal performance. You produce custom prosthetics and dental components. You also create highly precise surgical tools and components. These include biopsy tubes, surgical scissors, and scalpels. CNC technology is instrumental in producing these specialized tools. It achieves intricate geometries and exacting tolerances. You can produce medical machined components with a very tight tolerance of +/- 0.025mm. This is repeatable and necessary for volume production.

You rely on CNC metal lathes for advanced precision manufacturing. They combine automation, digital control, and robust design, ensuring exceptional accuracy and consistency in component production. The continuous evolution of CNC metal lathe technology, featuring advanced control systems and multi-axis capabilities, empowers you to meet stringent quality demands and innovate product design.

FAQ

How does a CNC metal lathe ensure such high precision?

A CNC metal lathe uses computer numerical control for exact movements. Real-time feedback systems constantly monitor and adjust tool paths. This ensures micron-level accuracy and consistency in every part you produce.

What role does software play in CNC metal lathe precision?

CAD/CAM software is crucial. You use it to design parts and generate optimized tool paths. This software simulates machining, preventing errors and ensuring your machine follows the most efficient and precise route.

Can a CNC metal lathe produce complex shapes?

Yes, you can produce complex geometries with a CNC metal lathe. Mill-Turning CNC Centers combine milling and turning capabilities. This allows you to create intricate internal and external features with superior surface finishes.

Post time: Oct-15-2025