Structural Design Advantages

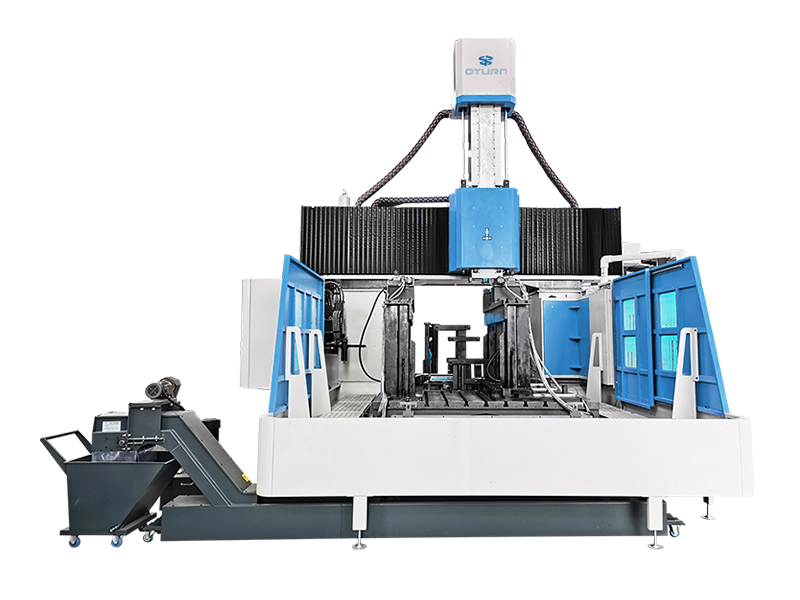

Core components in energy equipment manufacturing, such as steam turbine cylinders, wind turbine flanges, and nuclear power pressure vessels, are large, complex, and require extremely high precision. The fixed-beam, moving-column CNC gantry machining center utilizes a “fixed crossbeam, movable column” design. The fixed crossbeam provides stable support for the milling head and other actuators, eliminating inertia errors caused by crossbeam movement and ensuring stable and accurate machining. The column moves along guide rails, enabling the milling head to move over a wide range of motion in the X-axis. Combined with multi-axis linkage in the Z and Y axes, it can cover the machining range of large workpieces and meet the machining requirements of large, high-precision components in energy equipment.

Efficient Machining Capabilities

This CNC machine is equipped with a high-power spindle that supports high-speed turning, significantly improving turning efficiency. The multi-tool magazine automatic tool changing system reduces process changeover time and improves production continuity. Some models feature a dual-table design for alternating operation, allowing one table to process while the other is clamping a workpiece, significantly reducing equipment idle time. These features are particularly well-suited for the mass production needs of new energy equipment, ensuring efficient production.

Ensuring Machining Accuracy

The fixed-beam, moving-column structure reduces the weight and inertia of moving parts. Combined with high-precision linear encoder feedback and a closed-loop control system, machining errors are kept within micron limits. The machine bed utilizes integral casting and undergoes a time-consuming processing to enhance rigidity and stability, effectively resisting deformation caused by turning forces and fluctuations in ambient temperature. This ensures the dimensional accuracy and form and position tolerances of easily deformable components, such as turbine cylinders, meeting stringent manufacturing standards.

Adaptability to Complex Processes

Energy equipment parts often feature deep cavities, curved surfaces, and specially shaped holes. The CNC machine with specialized accessories such as universal milling heads and right-angle milling heads, the fixed-beam, moving-column gantry machining center enables multi-angle and multi-directional turning. Compatible with complex machining functions such as milling, drilling, boring, and tapping, it reduces part transfers between multiple machines, effectively reduces clamping errors, and improves machining quality and efficiency.

Development Prospects and Application Value

With the growing demand for large, complex, and high-precision components in energy equipment manufacturing, fixed-beam, dynamic-column gantry machining centers, with their structural advantages and efficient machining capabilities, have become key technical equipment driving the industry’s efficient and high-precision development. They not only improve machining efficiency and product quality, but also, due to their adaptability to complex processes, are becoming a key support for intelligent and green manufacturing, helping energy equipment manufacturing reach new heights.

In summary, fixed-beam, dynamic-column gantry machining centers have significantly improved the manufacturing of large, complex components in the energy equipment manufacturing sector through their innovative structural design, efficient and high-precision machining capabilities, and integrated multi-process capabilities, injecting strong impetus into the high-quality development of the industry.

FAQ

What types of workpieces are suitable for fixed-beam, dynamic-column gantry machining centers?

This CNC machine is particularly well-suited for machining large, heavy-loaded, and complex components, such as turbine cylinders, wind turbine flanges, and nuclear power pressure vessels. It is particularly well-suited for manufacturing tasks requiring high precision and multi-process integration.

How can I ensure the machining accuracy of a fixed-beam, dynamic-column gantry machining center?

By fixing the crossbeam to reduce inertia errors, combined with a precision linear encoder feedback system, closed-loop control, and a highly rigid bed structure, deviations caused by thermal deformation and turning forces are effectively suppressed, ensuring micron-level machining accuracy.

What should I do if a tool is stuck in the tool magazine system of a gantry machining center?

Common causes include insufficient air pressure, abnormal spindle orientation angle, or offset tool change origin position. To address this, first shut down the power supply for protection, then manually or programmatically reset the machine to correct the tool jam. If necessary, consult a professional maintenance technician.

How does the machine’s dual-table design affect production efficiency?

Dual tables allow one table to process while the other is clamping parts, enabling simultaneous machining and clamping, significantly reducing equipment idle time and improving overall production efficiency.

What is the typical service life of a fixed-beam, moving-column gantry machining center?

The CNC machine structure is integrally cast and aged, typically with a service life of over 10 years, provided it maintains high stability and precision over time with proper maintenance and care.

Post time: Sep-11-2025