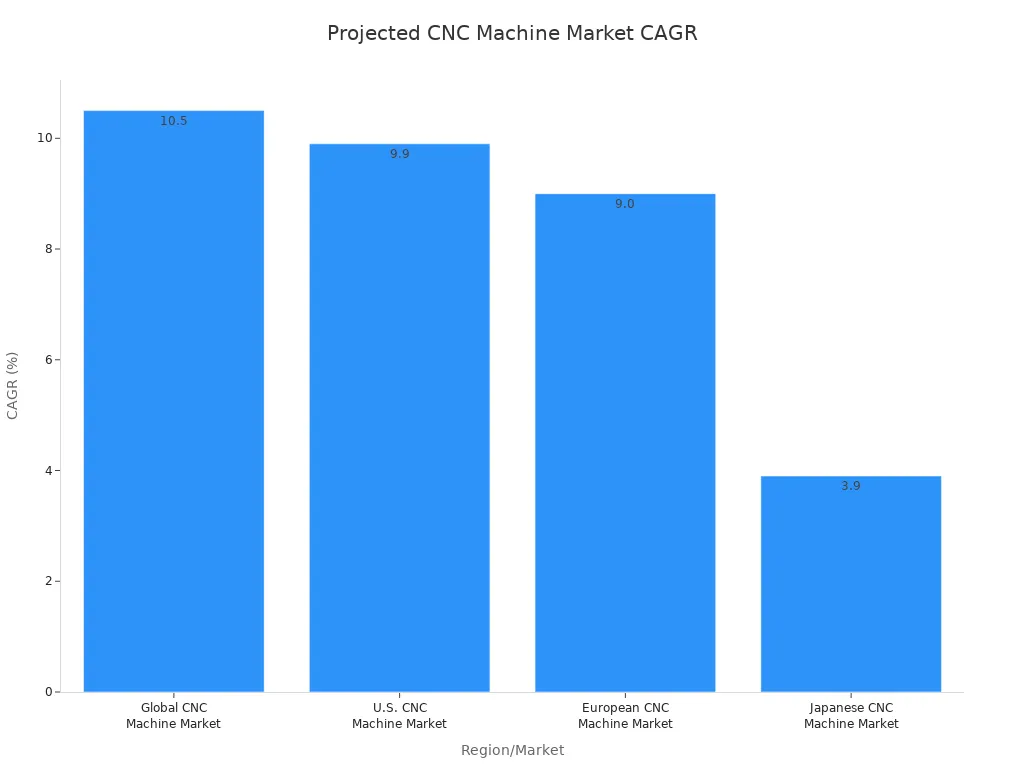

A CNC Machine, or Computer Numerical Control machine, automates manufacturing tools through pre-programmed computer software. This technology directs tools like lathes and mills with high precision. The global CNC machine tools market size was approximately USD 97.20 billion in 2024. It projects to reach USD 196.00 billion by 2034, indicating a strong Compound Annual Growth Rate (CAGR) of roughly 7.50%. A CNC Machining Center offers versatile operations. Advanced options include a 5-Axis Machining Center, a Gantry Machining Center, or a Double Spindle Turning Center.

Understanding how to choose the right CNC Lathe is crucial for specific applications.

Key Takeaways

- CNC machines use computers to control tools. This makes manufacturing precise and consistent.

- CAD and CAM software help design parts and tell the CNC machine how to make them.

- CNC technology makes things faster and reduces mistakes. It saves money over time.

- Many types of CNC machines exist. They work with different materials like metal, wood, and plastic.

- CNC is important in many industries. These include cars, airplanes, and medical tools.

Understanding the CNC Machine

Computer Numerical Control Explained

Computer Numerical Control (CNC) represents a significant advancement in manufacturing. It involves using computers to automate and control machine tools. This system interprets digital instructions to guide the movements of cutting tools, ensuring high precision and consistency. At its core, a CNC Machine operates through a sophisticated interplay of various components. These components work together to transform digital designs into physical products.

A typical CNC system includes several fundamental parts:

| Feature | Use |

|---|---|

| Machine Bed and Frame | Provides stability and absorbs vibrations for precision. |

| Machine Control Unit (MCU) | Processes instructions and precisely moves tools. |

| Controller and Software | Interprets designs into smooth tool movements. |

| Motors and Drives | Powers motion and ensures steady, accurate movements. |

| Feedback System | Checks performance and ensures everything stays on track. |

| Coolant System | Keeps tools cool and reduces friction. |

| Display Unit and Control Panel | Shows real-time information and allows setting adjustments. |

| Spindle and Cutting Tools | Rotates tools to cut or shape materials precisely. |

| Chip Management | Clears chips and debris for clean operation. |

| Workholding | Holds the part steady during machining. |

The Machine Control Unit acts as the brain, processing the programmed instructions. The drive system, comprising motors and ball screws, facilitates precise linear movement of the cutting tool along multiple axes (X, Y, Z). A feedback system continuously monitors the tool’s position and movement. It uses sensors like encoders to provide real-time data to the MCU, allowing for immediate accuracy adjustments. The tooling system includes the cutting tool itself and often an automated tool changer for efficiency. A robust work-holding device, such as a vise or chuck, secures the raw material, ensuring stability during the machining process. Furthermore, a coolant system prevents overheating of both the machine tool and the workpiece, dissipating heat and lubricating the cutting process.

Beyond Manual Operation with a CNC Machine

Traditional manual machining relies heavily on an operator’s skill and physical manipulation of machine controls. This method often introduces variability and limits the complexity of parts produced. CNC technology moves manufacturing beyond these manual limitations, offering unparalleled advantages in precision, speed, and consistency.

Consider the operational differences between manual and CNC machining:

| Feature | CNC Machining | Manual Machining |

|---|---|---|

| Precision and Accuracy | High, repeatable accuracy due to computer control; ideal for complex geometries and tight tolerances. | Relies on operator skill; precision can vary, suitable for simpler designs and less stringent tolerances. |

| Speed and Efficiency | Faster for mass production; consistent output; reduced cycle times. | Slower, especially for repetitive tasks; production rate depends on operator’s pace. |

| Cost | Higher initial investment for machinery and software; lower labor costs per unit in high-volume production. | Lower initial investment; higher labor costs due to time-intensive operations. |

| Flexibility | High flexibility for design changes through programming; can switch between tasks quickly. | Limited by tooling and operator’s ability to adapt; less efficient for frequent design changes. |

| Skill Requirement | Requires programming and operational knowledge; less direct physical skill. | Requires extensive hands-on skill, experience, and craftsmanship. |

| Safety | Generally safer due to automated processes; reduced direct human interaction with cutting tools. | Higher risk of accidents due to direct human involvement with machinery. |

| Volume Suitability | Best for high-volume production and repetitive tasks. | Ideal for low-volume, custom, or prototype work. |

CNC machines excel at producing complex, multi-axis parts with intricate details. They achieve this through programmed instructions, eliminating the inconsistencies inherent in human operation. This automation leads to significantly reduced cycle times and higher production rates, especially for repetitive tasks. While the initial investment for a CNC Machine and its associated software is higher, the technology often results in lower labor costs per unit in high-volume production. It also offers greater flexibility for design changes, as engineers can quickly modify programs rather than retooling a manual setup. The automated nature of CNC machining also enhances safety by minimizing direct human interaction with cutting tools.

How a CNC Machine Works

A CNC machine operates through a sophisticated digital workflow. This process transforms a digital design into a physical product with remarkable precision. It relies on specialized software and precise programming to guide the machine’s actions.

CAD and CAM Software in CNC Machining

CAD and CAM software form the backbone of modern CNC machining. These powerful tools bridge the gap between a designer’s vision and a physical product. They are essential for preparing designs for automated manufacturing.

Computer-Aided Design (CAD) software allows engineers and designers to create detailed 2D or 3D computer models. These models are based on common geometric patterns. Designers use CAD to test an object through simulations before manufacturing it. This virtual environment allows for rapid iteration and refinement. Modern CAD software features parametric modeling, creating adaptable models that respond dynamically to changes in dimensions or materials. It also integrates with simulation software. This integration allows engineers to perform virtual testing and validate designs under various conditions. CAD facilitates seamless collaboration among multidisciplinary teams through cloud-based platforms. It serves as the cornerstone of digital manufacturing, integrating with advanced techniques like multi-axis machining. Ultimately, CAD software outputs a G-code program. This program instructs the CNC Machine on its actions and movements. It requires precise specification of the origin point (0,0,0) to match the 3D CAD software.

Computer-Aided Manufacturing (CAM) software takes the CAD model and translates it into machine-readable instructions. CAM includes path planning for precise cutting and milling. It facilitates tool selection and offers simulation capabilities. CAM also provides optimization features to improve machining quality and productivity. Built-in libraries store tool information, such as geometry and cutting parameters. They also assist with job planning and estimating time, material, and cost. CAM software can create digital twins for virtual simulation and testing of the machining process. Integrated artificial intelligence (AI) suggests optimal cutting speeds, tool paths, and machining strategies. This automation of complex programming tasks generates efficient toolpaths, ensuring consistent quality, faster programming, and reduced errors.

G-Code and M-Code Programming

G-code and M-code are the fundamental languages that control a CNC machine. These codes tell the machine exactly what to do, where to move, and how to perform specific functions.

G-code, or Geometric Code, primarily dictates tool movements and operations. For example, G00 commands rapid positioning, moving the machine at maximum travel speed to a specified point without cutting. This is a non-cutting movement used for quick positioning. G01 instructs the machine to move in a straight line at a set feed rate. This command is used for cutting or extruding material in a straight line, specifying the end position with X, Y, Z, and speed with F. G02 and G03 define circular movements, clockwise and counterclockwise, respectively. Other G-codes set units (G20 for inches, G21 for millimeters) or select the working plane (G17 for XY plane). G28 sends the tool to its reference or home position. G90 and G91 determine how the machine interprets coordinates, either from a fixed zero point (absolute) or incrementally from the last position (relative). G40, G41, and G42 manage cutter diameter compensation, allowing the machine to position its tool to the left or right of a defined path. G43 handles tool length compensation, defining the length of individual tools using a Z-axis height. G54 defines work offsets, determining the distance from the machine’s internal coordinates to the datum on a workpiece.

M-code, or Miscellaneous Code, controls auxiliary machine functions. These commands manage actions beyond simple tool movement. For instance, M00 stops the program temporarily, requiring operator intervention. M01 provides an optional pause for inspections. M02 and M30 mark the end of a program. Spindle control M-codes include M03 for clockwise rotation and M05 to stop the spindle. M06 triggers a tool change. Coolant control uses M08 to turn coolant on and M09 to turn it off. Other M-codes manage feed rate and speed overrides (M50, M51, M52, M53), select work coordinate systems (M54 to M59), or choose gear ranges (M61 to M68) to adjust the machine’s speed capabilities.

The CNC Machining Process

The CNC machining process transforms a digital design into a physical part through a series of precise steps. This systematic approach ensures accuracy and efficiency.

- Designing the Part: Engineers create a detailed digital model using CAD software. This model specifies exact dimensions, geometry, and other specifications. It forms the basis for manufacturing.

- Programming the Machine: The CAD file then moves into CAM software. This software converts the design into machine instructions, including tool selection, speeds, feeds, and cutting depth. CAM software generates optimal toolpaths and simulates the cutting process. This simulation identifies potential issues before actual machining begins.

- Setting Up the Machine: An operator prepares the CNC machine. This involves installing the correct cutting tools and securing the raw material, also known as the workpiece. Operators establish coordinate systems and verify program accuracy through test runs.

- Executing the Program: The CNC machine reads the programmed instructions. It automatically performs cutting, drilling, milling, turning, or grinding operations. The machine removes material from the workpiece according to the G-code. The control system manages spindle rotation, tool changes, coolant flow, and axis movements. Operators monitor the process for any errors.

- Quality Inspection and Finishing: After machining completes, the part undergoes inspection. This ensures it meets required tolerances, specifications, and surface finish. Quality control measures use instruments like micrometers and gauges. The component is then cleaned, polished, and may undergo other finishing processes like plating or powder coating. This prepares the part for use or assembly.

Types of CNC Machines

CNC technology encompasses a diverse range of machines, each designed for specific manufacturing tasks. These machines leverage computer control to achieve unparalleled precision and efficiency across various industries.

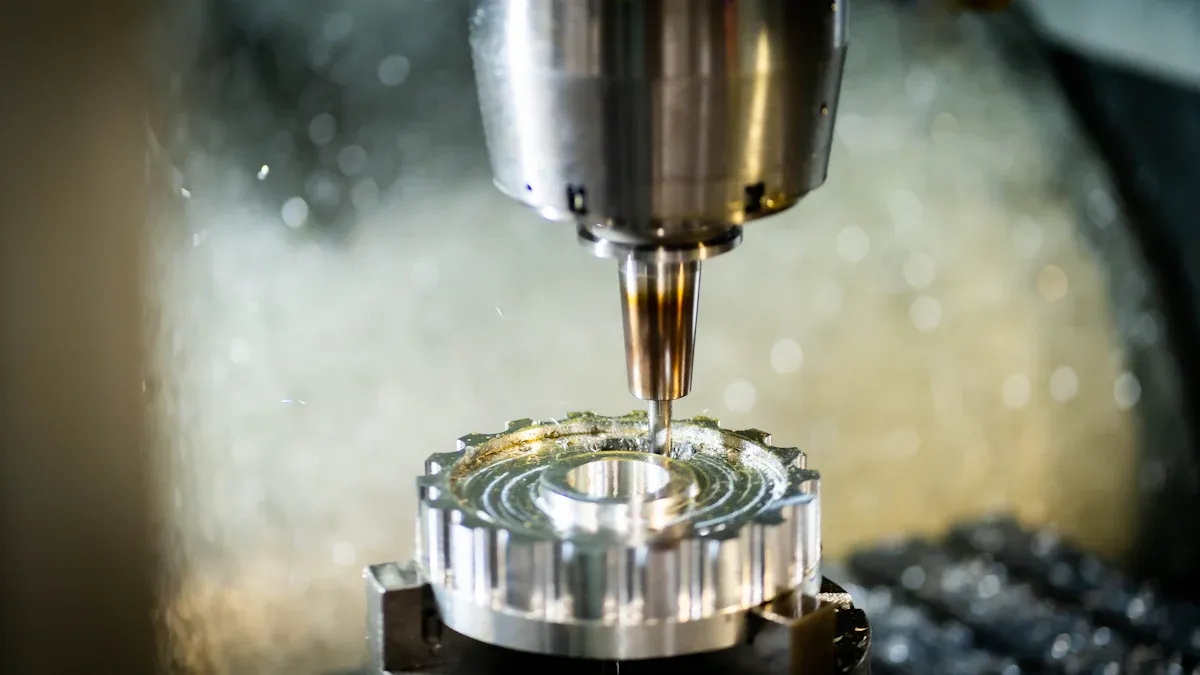

CNC Mills and Lathes

CNC mills and lathes are fundamental to subtractive manufacturing. CNC mills offer remarkable versatility, producing a wide range of parts, shapes, features, and complex geometries. They replicate designs with minimal deviation from the 3D model, ensuring high accuracy and precision. Mills efficiently produce complex geometries, which benefits rapid prototyping. They are scalable for both one-off prototypes and medium-scale production batches. These machines work with various materials, including metals, glass, plastic, stone, and wood.

CNC mills find applications in:

- Rapid Prototyping: Quickly manufacturing new parts for feasibility or functionality testing.

- Custom One-Off Productions: Creating unique parts like custom medical implants or spare parts.

- Batch Production: Mass producing custom or existing parts.

Mills come in various configurations:

- 3-axis CNC Milling Machines: Move in three axes (X, Y, Z), executing motion with the cutting tool, worktable, or both.

- 4-axis CNC Milling Machines: Include three lateral axes plus an additional rotational axis for more complex parts.

- 5-axis CNC Milling Machines: Feature three lateral axes and two rotational axes, rapidly producing highly complex geometries.

CNC lathes, conversely, excel at creating cylindrical parts. They reduce production time through full automation and enable quicker tool changes. Lathes generate less scrap, saving material costs, and offer high precision for tight tolerances. They manufacture conical shafts, discs, gaskets, gears, rods, and shafts.

Lathe configurations include:

- 2-Axis CNC Lathe: Operates on X (diameter) and Z (length) axes, ideal for simple, symmetrical parts.

- 3-Axis CNC Lathe: Adds a Y-axis for off-center milling, suitable for complex shapes.

- 4-Axis CNC Lathe: Introduces a C-axis for spindle rotation, enhancing complexity.

- 5-Axis CNC Lathe: Adds A and B axes for tool approach from virtually any direction, paramount for complex geometries.

- 6 or More Axis CNC Lathes: Offer the pinnacle of machining flexibility, manipulating the workpiece and tool simultaneously.

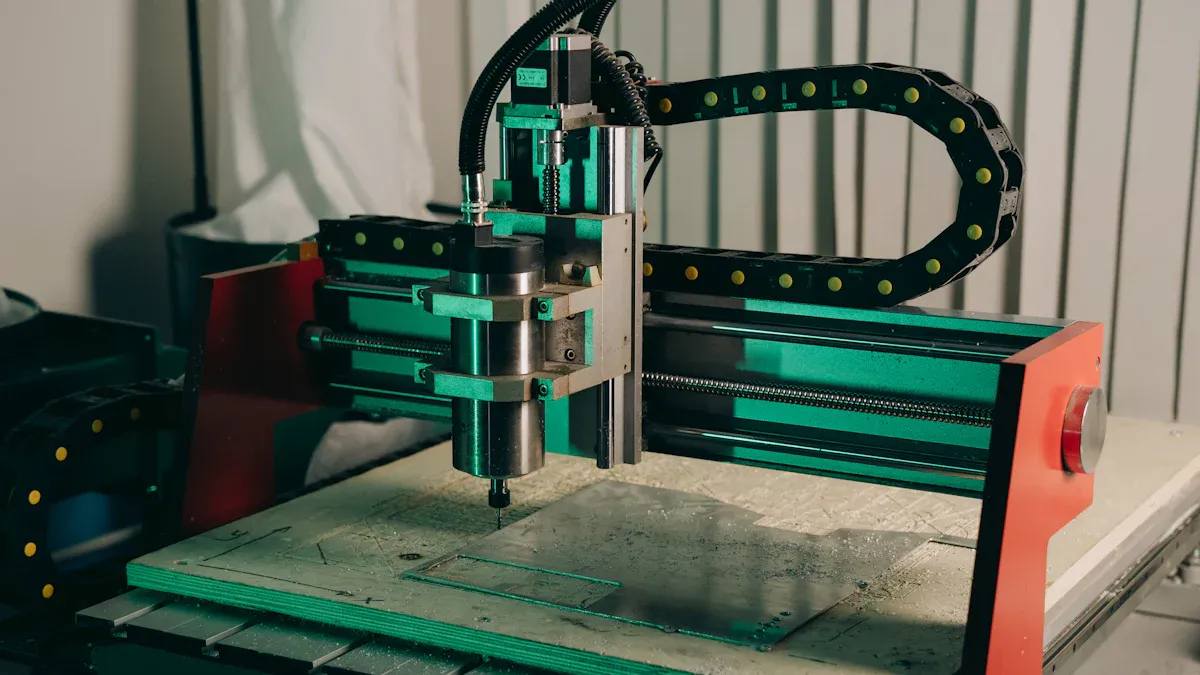

CNC Routers and Grinders

CNC routers provide increased productivity and efficiency compared to manual routers. They produce a wide variety of customized parts with high precision, including three-dimensional cutting tasks. Automation reduces time and labor, increasing production capacity and ensuring repeatability. Routers process a diverse range of materials, including plastics, wood, foams, fiberglass, and softer metals like brass and aluminum. They are cost-effective, making them accessible for small businesses.

CNC grinders typically apply finishing touches to parts initially shaped by mills or lathes. They abrade rough surfaces to achieve precise dimensional specifications. Grinders are crucial for industries like aerospace and high-end automotive, producing ultra-precise components with micron-level tolerances. They integrate into automated production lines for continuous operation and on-the-fly tool sharpening.

Grinders offer several advantages:

- Automation: Reduces manual labor and increases throughput.

- Precision: Achieves micron-level tolerances and consistent results.

- Efficiency: Minimizes errors and waste through real-time monitoring.

- Flexibility: Adapts to complex geometries and various manufacturing demands.

Plasma and Laser CNC Cutters

Plasma and laser CNC cutters specialize in cutting materials with high accuracy. CNC plasma cutters generate a high-temperature plasma arc that melts through various metals, creating precise and smooth cuts. This process minimizes post-cut processing. Advanced control systems ensure consistent and repeatable results, suitable for high-volume production.

Plasma cutters work with:

- Mild Steel: The plasma arc easily melts through.

- Stainless Steel: High-definition capabilities for clean edges.

- Aluminum: Requires higher power output due to thermal properties.

- Carbon Steel: Plasma arcs easily penetrate high-carbon content.

- Copper & Brass: Requires proper settings and consumables.

Laser cutting involves two main types:

- Laser fusion cutting: Melts material in a column and uses a high-pressure gas stream to shear away molten material.

- Ablative laser cutting: Removes material layer by layer using a pulsed laser, evaporating the material.

The operational principles of laser CNC cutters involve:

- Laser Source: Generates a high-energy laser beam.

- Optical System: Focuses this beam into a high-energy-density spot.

- Laser Beam Exposure: This intense spot melts or vaporizes the material.

- Assist Gas: A gas system blows away molten material.

- CNC Control System: Directs the laser head along a pre-set path.

Laser cutters process a wide range of materials, including sheet metal, wood, diamond, glass, plastics, silicon, and ceramics.

Waterjet Cutting CNC Machines

Waterjet cutting CNC machines use a high-pressure stream of water, often mixed with abrasive particles, to cut through materials. This method offers a precise and versatile cutting solution for many industries. It stands apart from thermal cutting processes because it does not generate heat. This cold cutting process prevents material distortion, burning, or melting.

Waterjet cutting provides several advantages:

- It works well for tight tolerances and intricate designs. It delivers precise cutting with minimal rough edges or burrs. This reduces the need for additional finishing.

- The process suits both single-part production and scaled manufacturing. It has lower setup costs compared to traditional CNC machining.

- It is a cold process. This means it causes no structural changes to the material. It prevents burning, melting, warping, surface hardness, or cracks. This differs from thermal cutting methods.

- It offers high machining accuracy and surface quality. Various edge qualities are available to balance speed and finish.

Waterjet cutters can cut virtually any material. This includes metal, composites, tile, glass, and soft materials like plastic, rubber, and foam. The same tool can cut diverse materials such as meat, tool steel, textiles, ceramics, and superalloys. This versatility makes waterjet technology highly adaptable.

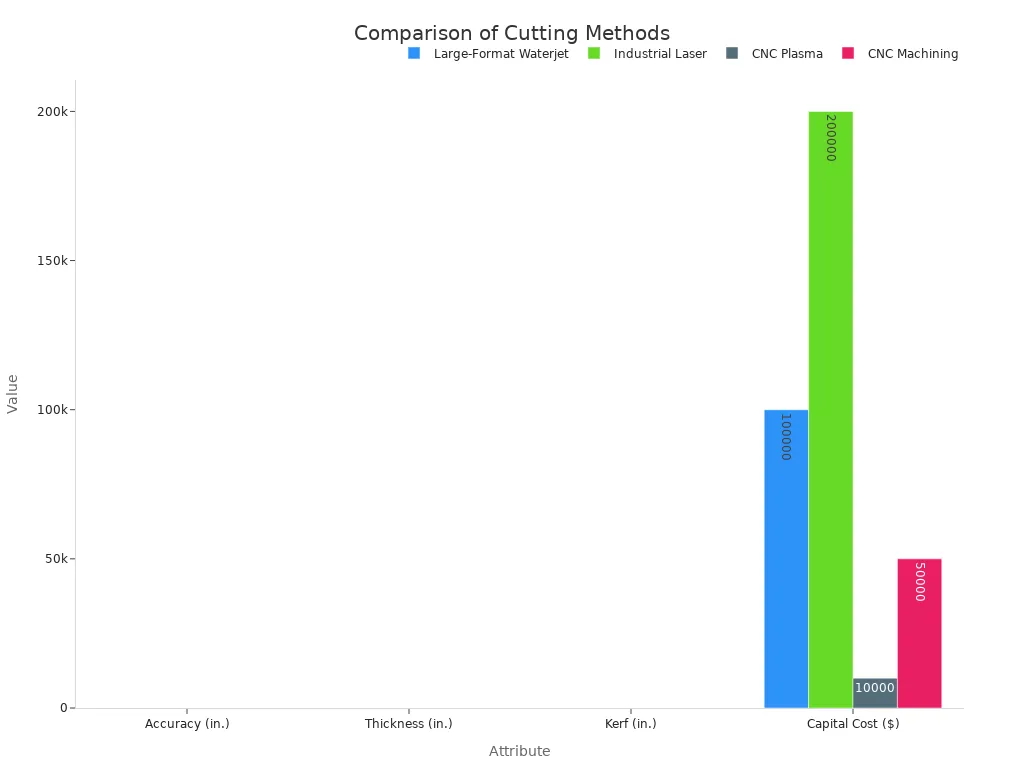

Compared to other cutting methods, waterjet cutting offers distinct benefits.

| Large-Format Waterjet | Industrial Laser | CNC Plasma | CNC Machining | |

|---|---|---|---|---|

| Materials | Any Material | Non-reflective Metal | Conductive Metal | Metal, Plastic |

| Accuracy | ±0.003” | ±0.001” | Up to ±0.010” | ±0.0005” |

| Thickness | Up to 12” | Up to 0.25” | Up to 1” | Above 0.25” |

| Cutting Speed | Slow | Medium | Fast | Slow |

| Edge Quality | Excellent | Good | Poor | Excellent |

| Material Distortion | None | Heat affected zone | Heat affected zone. Warping on thin material. | None |

| Kerf (width of cut) | 0.030” | 0.007” | 0.1” | Varies with tool |

| Taper | Minimal | Minimal | 2° | None (parallel edges) |

| Capital Cost | >$100,000 | >$200,000 | $10,000 | >$50,000 |

Waterjet cutting also improves safety compared to other processes. It is less dangerous and toxic. It produces no heat-affected zone or edge hardening. This benefits subsequent machining processes.

Applications of CNC Machines

CNC in Manufacturing and Automotive

CNC technology significantly transforms manufacturing and the automotive industry. It enables faster production cycles by executing programs at high speeds with minimal downtime. This allows for continuous operation and automated tool changes. The technology also reduces labor costs per part, as one skilled operator can oversee multiple machines. CNC enhances quality and consistency, executing cuts with incredible precision, often within 0.001 inches. This automated nature reduces human error, ensuring consistent, high-quality parts. Computer-Aided Manufacturing (CAM) software streamlines programming, converting 3D CAD models into CNC code. This reduces lead times, optimizes toolpaths, and boosts overall machining efficiency.

In the automotive sector, CNC milling machines are crucial for prototyping and producing parts like cylinder blocks, gearboxes, valves, and shafts from extruded metal. They also process plastics for components such as dashboards and gas meters. CNC machining produces intricate parts with minimal setup time, reduced material waste, and high accuracy. CNC lathes provide precise turning for cylindrical parts like shafts and gears. CNC routers cut and shape softer materials for interior components. CNC grinding machines offer fine surface finishes for critical parts, while laser and plasma cutters handle sheet metal and thicker chassis components. Multi-axis CNC machines provide enhanced flexibility for complex engine blocks and molds.

Aerospace and Medical CNC Applications

CNC technology is indispensable in aerospace and medical fields, where precision is paramount. Aerospace uses CNC for crafting precise components like turbine blades and intricate parts of cockpit control systems. Absolute precision is critical for these applications. CNC also supports rapid prototyping in aerospace, aiding in evaluating structural integrity.

In the medical device industry, CNC machining creates custom drawer systems, telescoping support arms, mobile workstation frames, and precision-fit joints using biocompatible materials like stainless steel and aluminum. It produces load-bearing brackets and mounts with complex geometries for critical medical equipment. CNC-machined enclosures and housings protect sensitive electronics and medical instruments. Furthermore, CNC machines create personalized implants and prosthetics, such as titanium hip replacements, with exact specifications to match a patient’s unique anatomy. They also produce complex components for minimally invasive surgical instruments, leading to less scarring and faster patient recovery.

Woodworking and Prototyping with CNC

CNC machines significantly enhance woodworking processes. They perform cutting, turning, and carving across multiple axes, adding value while saving time and resources. Once configured with design software, they ensure consistent and reliable results, producing hundreds to thousands of identical pieces. This bypasses manual intervention, reducing human error and maintaining quality assurance. CNC machines efficiently produce larger pieces like stair risers or large doors, ideal for mass production. They reduce waste by optimizing material layout and streamline workflows. Popular woodworking applications include furniture, boat building, musical instruments, and cabinetry.

CNC rapid prototyping offers numerous advantages that enhance product development. It produces prototypes with tight tolerances and intricate details, closely matching the final design for effective testing. CNC accommodates a broad spectrum of materials, including metals, plastics, and composites. This allows engineers to select materials that best represent the final product’s properties. Automation and efficiency enable quick prototype production, significantly reducing development timelines. This process identifies design flaws early, avoiding costly modifications during mass production. It also minimizes material waste. CNC prototyping is crucial for industries like automotive, medical, and aerospace, allowing for the production of functional models and highly customized, complex prototypes.

Advantages of CNC Machining

Precision and Repeatability of CNC

CNC machining offers exceptional precision and repeatability. This technology ensures parts meet exact specifications consistently. Default CNC tolerances are generally around ±0.005″ (0.13 mm). Manufacturers often control these tolerances to ISO 2768-1 medium (m) for milled and turned parts. For high-precision applications, such as aerospace or high-performance automotive components, tolerances can be as tight as ±0.001″ (0.025 mm) or even better. Highly specialized parts, like surgical equipment, may require tolerances ranging from ±0.0002″ (0.00508 mm) to ±0.0005″ (0.0127 mm). However, this extreme precision is rarely necessary for most applications.

| Manufacturing Process | Standard Tolerance |

|---|---|

| CNC Milling | ±0.010" (±0.25 mm) |

| CNC Turning | ±0.010" (±0.25 mm) |

| Multi-axis Machining | ±0.010" (±0.25 mm) |

Repeatability in CNC machining refers to how precisely a commanded motion can be duplicated consistently over time. A machine’s ability to return to the same position repeatedly is crucial. For instance, if a machine receives instructions to move to X = 500.000 mm ten times, repeatability measures how closely those ten positions cluster together. This holds true even if they are slightly offset from the ideal target. Typical repeatability ranges from ±0.001 mm to ±0.01 mm. Statistical analysis of repeated trials measures this metric.

Efficiency and Speed of a CNC Machine

A CNC Machine significantly boosts manufacturing efficiency and speed. These machines operate continuously, often with minimal human intervention. This capability leads to faster production cycles and higher output rates. Automated tool changes further reduce downtime, allowing for uninterrupted operation. The precise control offered by CNC technology also optimizes material usage. It minimizes waste and reduces the need for rework. This streamlined process translates into quicker turnaround times for parts and products.

Reduced Human Error and Waste in CNC

CNC technology significantly reduces human error by automating the manufacturing process. This automation minimizes mistakes common in manual operations. Precise computer programming controls production, eliminating variability and inconsistencies. Manual handling often introduces measurement inaccuracies, tool misalignment, or operator fatigue. CNC machining relies on sophisticated software and highly accurate machinery. This ensures consistent quality and repeatability, leading to fewer defects and higher overall reliability of manufactured parts. CNC machines produce parts with high precision and accuracy. This results in better performance and durability. Consistent programming ensures consistent results, improving overall quality and consistency by producing products to tight tolerances.

Cost-Effectiveness of CNC Technology

CNC technology offers significant cost-effectiveness for manufacturing operations. It provides substantial long-term savings through various mechanisms. Automation reduces labor costs by streamlining production processes. This allows for efficient material usage, which minimizes waste and enhances sustainability. Increased productivity enables faster manufacturing, boosting overall revenue for businesses.

CNC machining significantly reduces material waste. It uses CAD software for precise cutting paths, minimizing production mistakes. This process eliminates human error, ensuring consistent results. This precision also allows for close monitoring of production. Manufacturers can make immediate adjustments to prevent larger issues. Furthermore, CNC technology enhances efficiency and precision. It automates complex tasks with accuracy surpassing manual methods. This leads to reduced waste, fewer reworks, and accelerated production timelines.

The technology also lowers labor costs. It automates manufacturing and finishing processes. This reduces the need for manual post-processing and skilled labor. CNC machines improve setup and cycle times, leading to higher output and faster turnaround. These combined factors contribute to a more economical production model. Businesses achieve greater profitability and competitiveness in the market. The initial investment in CNC equipment pays off through these sustained operational efficiencies and reduced expenditures.

Key Takeaways of CNC Technology

CNC technology transforms manufacturing. It offers unparalleled precision, efficiency, and repeatability. This automation reduces human error and waste. It also provides significant cost-effectiveness. CNC machines are essential across diverse industries, from automotive to medical.

The Future of Automated Manufacturing with CNC

The future of automated manufacturing with CNC looks promising. It involves higher levels of automation and robotics collaboration. Robots will perform intricate tasks, reducing cycle times. Artificial intelligence (AI) and machine learning (ML) will optimize parameters in real-time. This improves cutting speeds and extends tool life. Enhanced connectivity and cloud-based solutions will enable remote monitoring and flexible production. Hybrid manufacturing systems will combine CNC machining with 3D printing. These systems will create complex geometries and reduce material waste.

FAQ

What is the primary difference between CNC and manual machining?

CNC machining uses computer programs to automate tool movements, ensuring high precision and consistency. Manual machining relies on an operator’s skill and physical control. This method can introduce variability.

How do CAD and CAM software contribute to CNC machining?

CAD software creates detailed 2D or 3D digital models of parts. CAM software then translates these CAD models into machine-readable instructions. These instructions include toolpaths and cutting parameters for the CNC machine.

What is G-code, and what does it do?

G-code is the primary programming language for CNC machines. It dictates tool movements and operations. For example, it commands rapid positioning, linear cuts, and circular motions, guiding the machine’s actions precisely.

What materials can CNC machines process?

CNC machines are highly versatile. They can process a wide range of materials. These include metals (steel, aluminum), plastics, wood, composites, glass, and even foam, depending on the specific machine type.

What are the main benefits of using CNC technology?

CNC technology offers exceptional precision, repeatability, and efficiency. It reduces human error and material waste. This leads to significant cost-effectiveness and faster production cycles in manufacturing.

Tip: Understanding these fundamental aspects helps you appreciate the power and versatility of CNC technology in modern manufacturing.

Post time: Jan-15-2026