Electric spindle CNC machine are advanced CNC machine that integrate electric spindle technology by combining the motor and spindle into one unit. This design achieves high-speed, high-precision, and highly efficient machining, making it essential equipment in modern manufacturing.

I. Working Principle

The electric spindle is the core component of the machine tool, integrating a high-performance AC or DC motor inside. The spindle speed and torque are controlled by a frequency converter or servo driver. Power is directly transmitted to the spindle without intermediate transmission devices, reducing energy loss and mechanical wear. The spindle is supported by precision bearings, enabling stable high-speed rotation with speeds reaching tens of thousands of revolutions per minute, driving cutting tools to perform turning, drilling, milling, and other machining operations. Efficient cooling and lubrication systems reduce temperature and friction, extending equipment life. Advanced CNC systems precisely control spindle speed, feed rate, and machining paths, while real-time monitoring and automatic adjustments improve machining accuracy and efficiency. Sensors and data acquisition systems monitor spindle parameters in real time to assist in optimizing the machining process.

II. Application Areas

Electric spindle CNC machine are widely used in aerospace, automotive manufacturing, mold making, precision instruments, and electronics industries, meeting the demands for high precision and high efficiency machining:

· Aerospace: Machining aircraft parts, engine blades, turbine disks, and other complex components.

· Automotive Manufacturing: Machining engine blocks, crankshafts, connecting rods, gears, and other critical parts.

· Mold Making: Producing injection molds, stamping dies, and die-casting molds to improve mold quality and production efficiency.

· Precision Instruments: Machining optical components, medical devices, and other micron-level high-precision parts.

· Electronics: Machining semiconductor chips, printed circuit boards, connectors, and other precision electronic components.

III. Features and Advantages

· High-Speed Machining: Spindle speeds up to tens of thousands of RPM increase material removal rates and production efficiency.

· High-Precision Machining: Micron-level machining accuracy ensures part dimensions and surface quality.

· High Efficiency: Equipped with automatic tool changers and automatic loading/unloading systems for continuous unattended machining.

· Low Noise and Vibration: Optimized design reduces noise and vibration, improving the working environment and equipment lifespan.

· Easy Maintenance: Modular design and intelligent diagnostic systems reduce maintenance costs and downtime.

IV. Development Trends

· Higher Speeds: Increasing spindle speeds to further shorten machining cycles.

· Greater Precision: Combining advanced sensors and control technologies to enhance machining accuracy.

· Intelligent Manufacturing: Applying AI and IoT technologies for automatic programming, adjustment, and optimization.

· Green Manufacturing: Using energy-efficient motors and cooling systems to promote environmentally friendly production.

Summary

With its advantages of high speed, high precision, and high efficiency, electric spindle machine tools have become key equipment for machining complex parts in modern manufacturing. As a professional distributor, OTURN Machinery offers a range of high-performance CNC machine tools equipped with electric spindle technology, including:

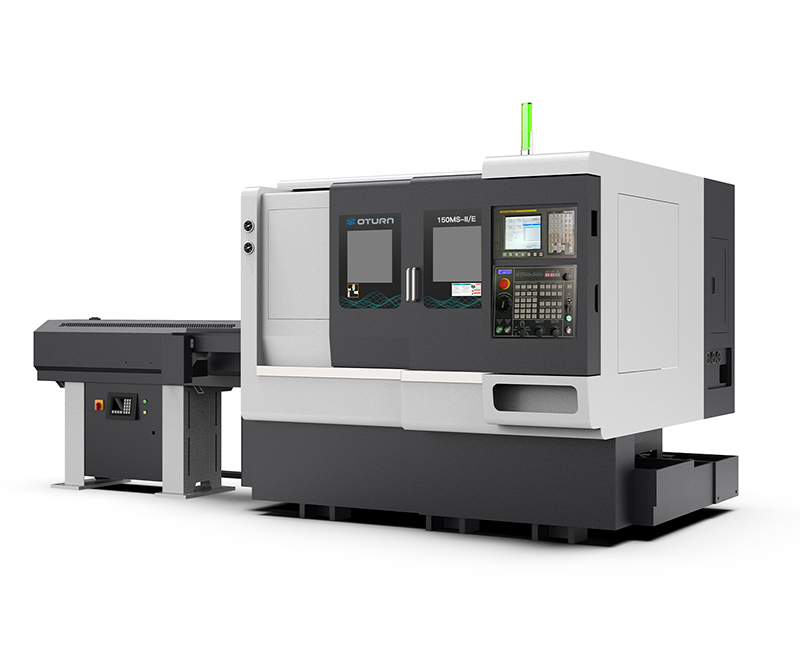

150MS Series Double Spindle CNC Turning Center

600/800/1200/1600/2000/3000 Series High-Performance Main Spindle Machine Tools

208 Series Double Spindle CNC Lathe

With rich industry experience and a comprehensive service system, OTURN is committed to providing professional technical support and customized solutions to help manufacturers improve machining efficiency and product quality, achieving intelligent manufacturing transformation and upgrading. Contact us to learn more about the electric spindle machine and related products.

Post time: Jul-08-2025