The LTC80-500-T2 dual-turret vertical turning machine is an advanced device designed to meet the multi-process, high-efficiency machining demands of modern manufacturing. It integrates turning, milling, and drilling, enabling multiple processes on complex parts to be completed in a single setup. This not only improves production efficiency but also significantly shortens manufacturing cycles.

Dual-Turret Design Enables Simultaneous Machining Of Both Ends

The LTC80-500-T2 features a dual-turret structure, enabling simultaneous machining of both ends, increasing machining efficiency by up to 200%. Furthermore, the machine utilizes a dual-channel CNC system, coupled with a centered spindle and high-speed spindle design, ensuring stable and reliable machining.

The Vertical Structure Reduces Floor Space By 50% For Smoother Machining

The vertical layout design effectively saves workshop space. The vertical structure facilitates efficient chip removal, reduces the impact of thermal deformation on machining quality, and ensures long-term stable operation.

The Superior Machine Foundation Ensures High Precision

The machine base is constructed of a mineral casting, which offers far superior vibration-damping properties than traditional cast iron, effectively suppressing machining errors caused by vibration. Bidirectional turning technology further mitigates the risk of deformation during machining, improving product quality consistency.

Technical Parameters and Customization Advantages

The LTC80-500-T2 vertical CNC lathe can process parts with a maximum outer diameter of 150 mm and a machining length of up to 500 mm. It features a spindle speed of up to 6000 rpm and a maximum X- and Z-axis traverse speed of 25 m/min. Feed rates range from 0.1 to 0.4 mm/rev, and turning speeds from 150 to 300 m/min, meeting diverse machining needs while ensuring production efficiency and process quality.

Notably, all technical parameters can be customized to meet customer needs, providing tailored solutions to ensure the machine is optimally suited to your production environment and process requirements.

Smart Manufacturing, More Flexible Machining

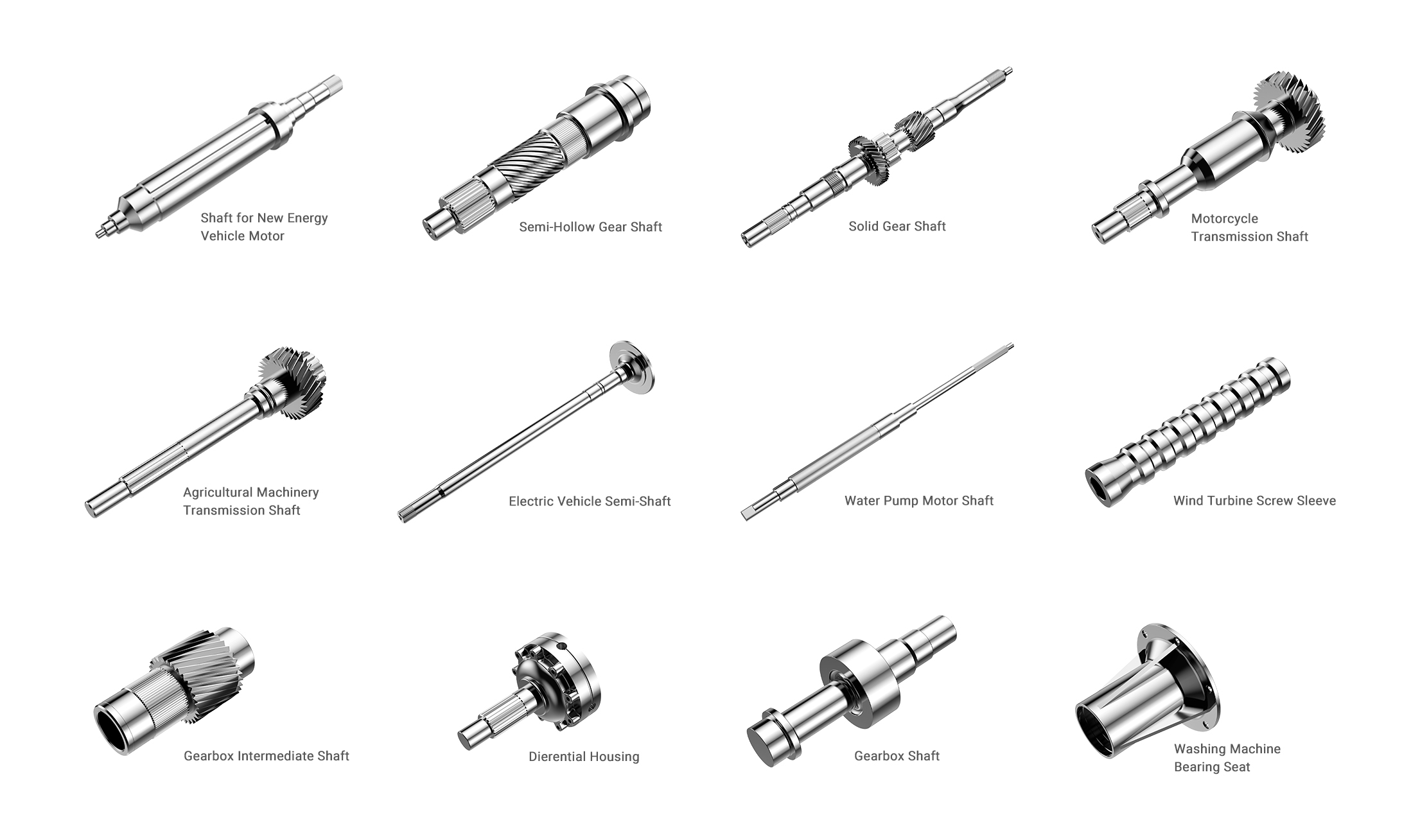

The CNC machine is equipped with a servo-powered turret that supports multi-tool switching, enabling faster tool changes and more flexible machining. Optional automatic loading and unloading and in-line inspection functions facilitate the development of intelligent production lines, reduce operator workload, and enhance automation and quality control. The LTC80-500-T2′s design focuses on integrating energy efficiency with intelligent manufacturing, fully aligning with the current trends of Industry 4.0. It is an ideal machining tool for industries such as automotive parts, wind power, agricultural machinery, and motor manufacturing. By integrating turning, milling, drilling, and tapping processes, it truly achieves multi-process integration, significantly improving workshop automation and production efficiency.

Emo 2025 is About to Begin

We sincerely invite you to experience the exceptional performance of the LTC80-500-T2 dual-turret vertical CNC machine at the upcoming EMO International Machine Tool Show. Additional advanced CNC machine and automation solutions will also be on display. We look forward to in-depth discussions with you as we embrace the future of intelligent manufacturing together!

· Exhibition Dates: September 22-27, 2025

· Venue: Hannover Exhibition Center, Germany

· Booth Number: Hall 15, Booth B54

FAQ

What is a dual-turret vertical lathe?

A dual-turret vertical lathe is a CNC lathe with a vertically mounted spindle and equipped with two turrets. It enables simultaneous machining of multiple workpiece parts or multiple processes, making it ideal for complex parts requiring a single clamping setup to perform multiple machining operations.

What are the advantages of a dual-turret design over a single turret?

Dual turrets can simultaneously machine both ends of a workpiece or different parts, significantly improving machining efficiency and shortening cycle times. It is particularly well-suited for mass production and machining complex parts.

Can a variety of tool materials be used during machining?

It supports switching between a variety of tool materials, including carbide and ceramic, allowing tool configuration based on workpiece material and process requirements to ensure machining quality and efficiency.

What production scales are dual-turret vertical lathes suitable for?

It is suitable for batch and medium-to-large-volume production, especially for efficient machining of complex parts. It is particularly suitable for manufacturers seeking high production capacity and precision.

Can you customize the machine based on our drawings and process requirements?

Of course! We customize the CNC machine based on our customers’ drawings and process requirements to ensure that machining requirements are met and production efficiency and quality are improved.

Post time: Sep-12-2025