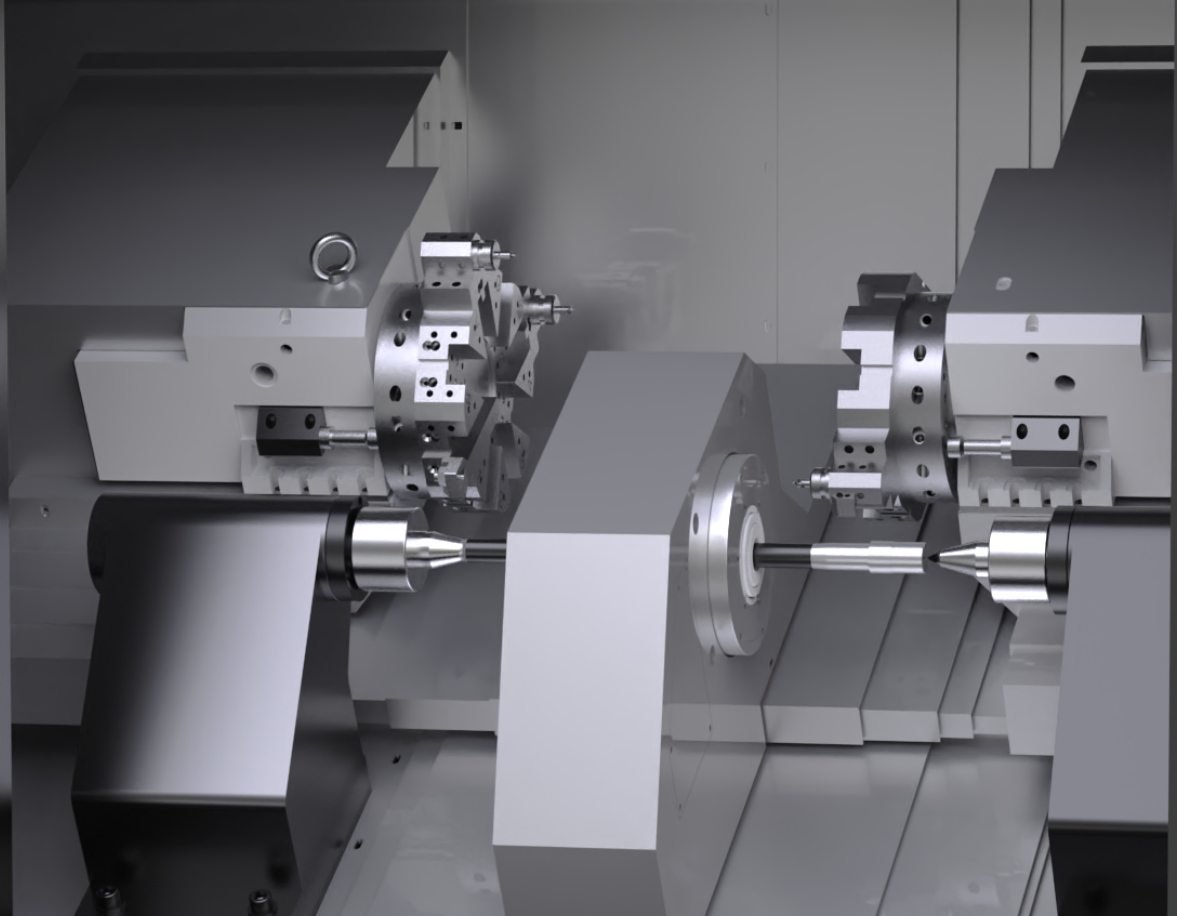

Due to its unique dual-spindle symmetrical machining characteristics, the double-spindle CNC lathe exhibits significant differences in turning principles when machining different workpiece materials. These differences primarily stem from the material’s physical properties and the mechanical reactions during the turning process, including the distribution of turning forces, energy conversion patterns, and the tool-material interaction mechanism. A thorough understanding of these differences is crucial for optimizing machining parameters, improving machining efficiency, and enhancing product quality.

I. Turning Principles in Metal Machining

The machining process of metal materials is primarily centered around plastic deformation. For materials with high plasticity, such as mild steel, significant compression and slippage occur in the contact area between the tool’s rake face and the chip, resulting in a continuous and stable chip. During this process, the turning force is dominated by the material’s yield strength. Leveraging the technological advantages of dual-spindle simultaneous turning, symmetrical force distribution is achieved, effectively offsetting radial forces, reducing workpiece deformation caused by turning, and improving machining accuracy and surface quality.

For brittle materials, such as cast iron, the machining process is primarily characterized by fracture separation, resulting in chip fragmentation. Peak turning forces are high but short-lived. The machining of these materials requires lower turning speeds to minimize tool damage from impact loads and extend tool life.

Due to their low thermal conductivity, it is difficult to CNC machine materials such as high-temperature alloys can easily cause localized temperature increases in the turning area, resulting in a temporary increase in material hardness and work hardening. In these cases, the turning process relies more heavily on the tool material’s high-temperature wear resistance to maintain machining continuity and stability.

II. Turning Principles in Non-Metallic Material Machining

Non-metallic material machining exhibits a more diverse range of turning mechanisms. For example, the core of ceramic machining is a combination of brittle fracture and abrasive wear. The tool edge must withstand high-frequency impacts, resulting in significant fluctuations in turning forces. Using ultrafine-grained tool materials can effectively improve tool chipping resistance and ensure machining continuity.

Due to the different mechanical properties of the fibers and matrix, composite materials often experience fiber pullout and matrix tearing during turning. During machining, the removal mechanisms of different components must be considered, and the tool angle design must be optimized to minimize damage at the material interface and improve surface quality.

III. Dynamic Adjustment and Optimization of Turning Parameters

Turning parameters on a dual-end CNC lathe must be dynamically adjusted based on material properties. When machining metal materials, the key is to properly match turning speed and feed rate to ensure turning stability and workpiece accuracy. When machining non-metallic materials, prioritizing turning temperature and tool wear rate is crucial to avoiding quality degradation due to overheating or excessive wear.

Understanding the turning principles and process characteristics of different materials is fundamental to achieving efficient and precise machining and is key to enabling double-spindle CNC lathes to leverage the dual-spindle symmetrical machining advantages. Scientifically and rationally combining turning parameters and tool selection can help improve machining efficiency, extend tool life, and ensure consistent product quality.

To experience the superior performance of double-spindle CNC lathes and learn more about turning principles and process optimization for multi-material machining, please visit us at EMO 2025 in Hall 15, Booth B54. Our on-site technical experts will provide detailed answers and look forward to exploring the future of efficient and intelligent manufacturing with you.

Post time: Aug-15-2025