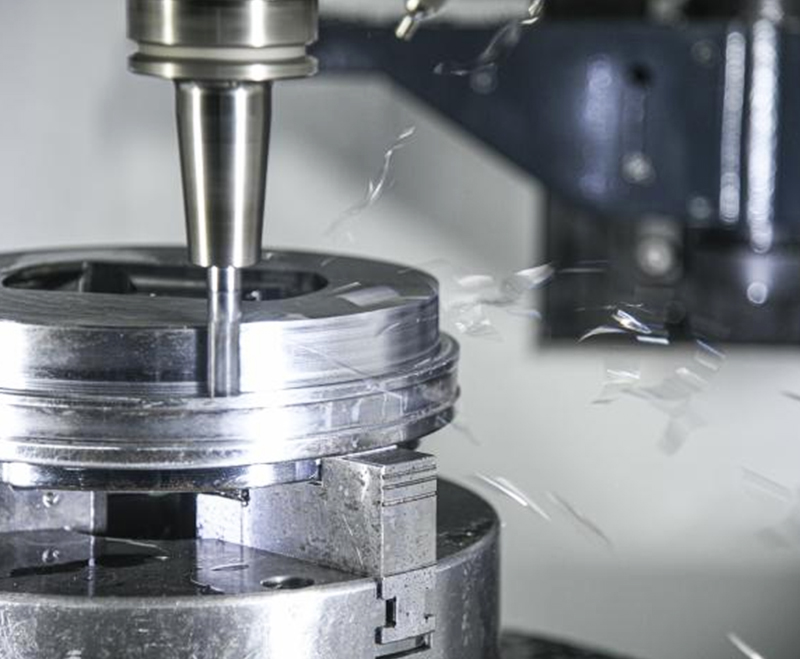

A CNC machining center is an intelligent machine tool that integrates multiple functions such as milling, drilling, and tapping, achieving high-precision automated machining through a computer numerical control (CNC) system.

The structure of a CNC machining center mainly includes basic components, spindle components, a CNC system, an automatic tool changer, and auxiliary systems.

I. Basic Components: Composed of the bed, worktable, and column, providing high-rigidity support to withstand turning loads.

The bed typically uses a one-piece high-strength cast iron structure with internal reinforcing ribs and heat-aging treatment to ensure high precision and stability during long-term heavy-load operation. Strong rigidity is key to ensuring turning quality and extending tool life.

The worktable is the workpiece support platform, responsible for precise movement. High-precision guideways, combined with a servo drive system, ensure precise control over every minute displacement. Some high-end models also offer vacuum adsorption or multi-point clamping designs to adapt to different workpiece shapes.

The column connects the bed and the spindle head, bearing the main load of the spindle throughout the machining process. To enhance overall rigidity, medium and large-sized machining centers generally employ a dual-column design to ensure stability during high-torque turning.

II. The spindle assembly, including the spindle box, spindle motor, and bearings, directly determines the turning capability and stability of the machining center.

High-performance spindle motors support wide-frequency constant power output, maintaining stable speed and power regardless of whether it’s low-speed, high-torque turning or high-speed, light turning. The bearings generally use imported high-speed angular contact bearings, with some high-end models using ceramic ball bearings, significantly reducing friction and thermal deformation.

Combined with a constant-temperature cooling system and an automatic lubrication system, the spindle maintains excellent dynamic balance even under continuous high-speed conditions, providing reliable assurance for high-precision mold and precision parts machining.

III. The CNC system, as the control core, includes the CNC unit, PLC, and servo drives to ensure accurate interpolation movements.

The CNC unit handles trajectory interpolation and motion control, achieving coordinated operation of the X, Y, and Z axes through preset programs. The PLC module manages auxiliary CNC machine tool actions such as tool changing, cooling, lubrication, and door lock detection. The servo system ensures smooth movement, sensitive response, and error control within the micrometer range.

Currently, mainstream control systems include brands such as FANUC, Siemens, Huazhong CNC, and KND. They offer open communication interfaces, seamlessly integrating with MES or ERP systems to easily achieve data interconnection and remote monitoring in smart workshops.

IV. The automatic tool changer system consists of a tool magazine and a robotic arm, supporting rapid tool changes.

Disc, chain, or umbrella-shaped tool magazines can hold 20 to 200 tools depending on the model. The robotic arm, through precise extension and retraction, completes the process of retracting the old tool and loading the new tool within seconds. The entire switching process is smooth and reliable, minimizing non-turning time.

For companies pursuing takt time production, automatic tool changers can directly bring considerable productivity increases.

V. Auxiliary systems encompass lubrication, cooling, and chip removal, improving the reliability, efficiency, and maintenance costs of CNC machining centers.

* Lubrication System: Provides metered oil supply to guideways and lead screws, reducing friction and wear.

* Cooling System: Utilizes high-pressure coolant to remove processing heat, preventing workpiece thermal deformation.

* Chip Removal System: Spiral or chain-plate chip conveyors ensure a clean working area, improving processing efficiency.

* Protective System: Fully enclosed protective covers and oil mist collection devices protect operators and the workshop environment.

VI. Summary

In summary, the core competitiveness of CNC machining centers stems from four aspects: structural rigidity, spindle performance, control system accuracy, and auxiliary system stability. Different working conditions and product requirements necessitate the selection of matching configuration combinations.

If your company is planning to expand production capacity, implement automated production lines, or seek to improve machining accuracy in fields such as mold making, automotive parts, and precision electronics, choosing a high-quality CNC machining center will be a worthwhile investment.

OTURN offers a complete one-stop solution—from selection and trial turning to after-sales training—helping you quickly achieve efficient and stable production.

Post time: Dec-16-2025