Leading CNC machining center manufacturers play a vital role in the precision engineering landscape. Choosing the right manufacturer, such as those specializing in double spindle CNC turning centers, ensures optimal performance and efficiency in production processes. Key criteria for ranking these manufacturers include precision, productivity, operational reliability, and manufacturing efficiency. Recent market data highlights that the CNC machining center market size is projected to grow significantly, indicating the increasing demand for high precision CNC machines and advanced technologies like high precision 5-axis machining centers and 5-axis CNC machining.

Key Takeaways

- Choosing the right CNC machining center manufacturer is crucial for achieving optimal performance and efficiency in production.

- Top manufacturers like Haas Automation and Mazak Corporation prioritize innovation, offering advanced technologies that enhance productivity.

- Customer support and service are key differentiators among manufacturers, with robust training and 24/7 support being essential for client satisfaction.

- Customization options, such as 5-axis systems and AI-enabled monitoring, allow manufacturers to meet diverse client needs effectively.

- Sustainability practices are increasingly important, with manufacturers adopting energy-efficient operations and eco-friendly materials to minimize environmental impact.

Leading CNC Machining Center Manufacturers

Haas Automation

Haas Automation stands as a prominent player in the CNC machining center market. Founded in 1983, the company has grown to become the largest CNC machine tool manufacturer in the United States, boasting annual revenues exceeding $1 billion. Haas specializes in producing a wide range of CNC machines, including CNC lathes and milling machines. Their focus on mid-market solutions caters to various sectors, such as mold-making, education, and general manufacturing.

Haas Automation is recognized for its commitment to innovation. The company has introduced several technological advancements, including:

- Advanced Control Systems: The Haas Next Generation Control (NGC) features a user-friendly interface and real-time performance monitoring.

- High-Speed and High-Precision Machining: Their machines utilize advanced spindle designs, enabling high-speed operations essential for industries like aerospace and automotive.

- Integrated Automation Solutions: Options such as robotic loading systems enhance productivity and reduce human error.

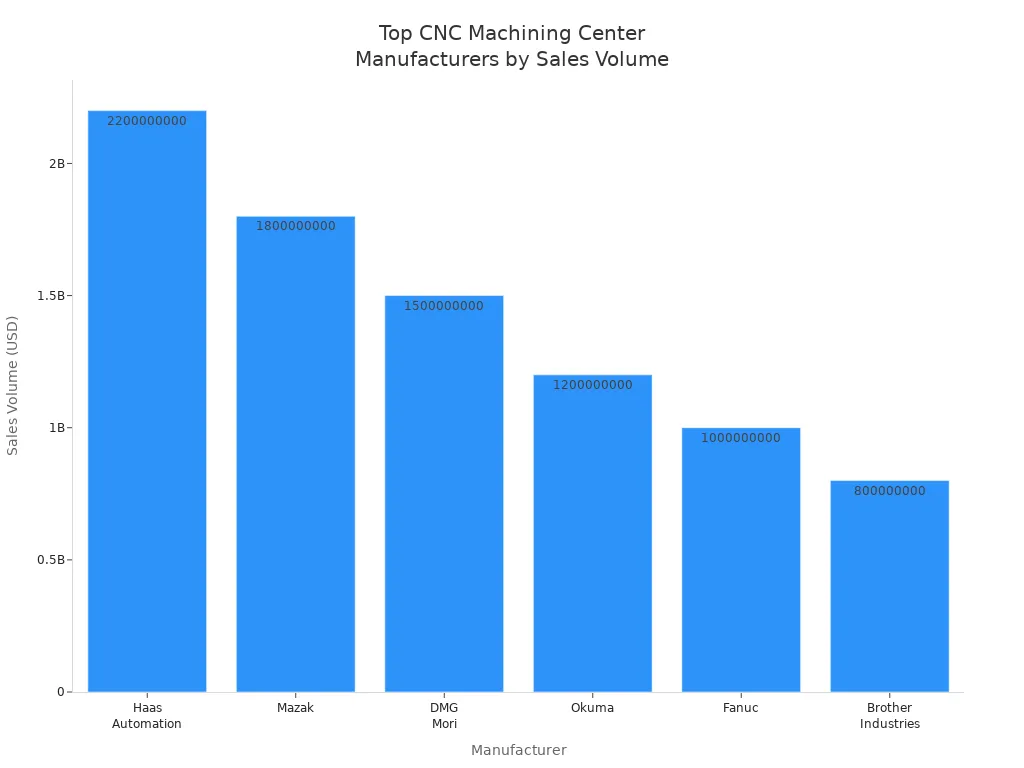

The following table highlights Haas Automation’s sales volume and product offerings compared to other leading manufacturers:

| Brand | Sales Volume | Types of CNC Machines | Distribution Areas |

|---|---|---|---|

| Haas Automation | $2.2 billion | CNC Lathes, CNC Mills | Global, strong in North America |

| Mazak | $1.8 billion | Multi-Tasking Machines, CNC Lathes | Worldwide, focus on Asia and Europe |

| DMG Mori | $1.5 billion | CNC Lathes, CNC Milling Machines | Global, strong in Europe and North America |

| Okuma | $1.2 billion | CNC Lathes, CNC Mills | Global, strong in Asia and North America |

| Fanuc | $1 billion | CNC Milling Machines, CNC Lathes | Worldwide, strong in automotive sector |

| Brother Industries | $800 million | CNC Tapping Machines, Machining Centers | Global, strong in Asia and North America |

Mazak Corporation

Mazak Corporation, founded in 1919, is a pioneer in the CNC machining center industry. The company is well-known for its multi-tasking CNC machines and has established a strong global presence, particularly in the U.S. and Europe. With annual revenues of approximately $1.8 billion, Mazak focuses on providing innovative solutions that enhance productivity and efficiency.

Mazak’s commitment to customer support is noteworthy. The company offers robust training options and extensive after-sales service, ensuring that clients maximize their machine potential. Their product line includes multi-tasking machines, 5-axis machining centers, and turning centers, catering to a diverse range of industries.

Mazak has received several accolades for its contributions to manufacturing innovation, including recognition for 50 years of excellence in the field. The following table compares Mazak’s global presence and product offerings with its competitors:

| Feature | Mazak Corporation | Competitors (Haas, DMG Mori) |

|---|---|---|

| Global Presence | Strong in the U.S. and Europe | Varies by manufacturer |

| Product Line | Multi-tasking, 5-axis, turning centers | Similar offerings |

| Customer Support | Robust support and training options | Generally less comprehensive |

| Manufacturing Location | Expansive plant in Kentucky | Varies by manufacturer |

DMG Mori

DMG Mori is another leading manufacturer in the CNC machining center market, holding approximately 14% of the global market share as of October 2023. The company aims to increase its market share to around 25%. DMG Mori offers a diverse range of products, including turning and milling machines, with a focus on high precision and advanced technology.

Their product lines include:

- Turning: Featuring around 20 series, including universal lathes and innovative turning and milling centers.

- Milling: Offering vertical milling machines and horizontal machining centers.

- ULTRASONIC: Utilizing ultrasound-assisted cutting for machining strong materials.

- LASERTEC: Focusing on laser precision machining for various applications.

- Additive Manufacturing: Involving metallic 3D printing techniques.

DMG Mori’s commitment to innovation and quality positions it as a formidable competitor in the CNC machining center industry.

Okuma Corporation

Okuma Corporation is recognized for its innovative technology and high-precision equipment, making it a prominent player in the CNC machining sector. The company distinguishes itself through its advanced OSP control system, which offers features such as graphical programming and real-time diagnostics. This system enhances user experience and operational efficiency.

Key features of Okuma’s CNC machining centers include:

- Machining Navi: This feature reduces chatter during machining, ensuring smoother operations.

- Servo Navi: This technology optimizes feed rates, improving overall performance.

- High Tool Capacity: Okuma machines can accommodate up to 120 tools, allowing for versatile machining options.

- High Torque Spindles: These spindles enable the machining of complex geometries with precision.

Customer satisfaction ratings for Okuma’s CNC machining centers reflect their quality. Users have praised models like the MCV4020 for their precision and reliability. For instance, one user stated, “The Okuma MCV4020 is simply incredible. Its precision and reliability are unparalleled. Definitely a solid investment for our production line.” Another user noted, “We have been using the MCV4020 for a year now. Great machine, but it does have a steep learning curve. Initial setup took some time.”

Amada

Amada is recognized as an integrated provider of CNC sheet-metal machines and automation cells, which positions it strongly in the CNC machining center market. The company reported a revenue of approximately $1.60 billion in 2024, showcasing its robust market presence. Amada’s flagship products include the ENSIS-AJ laser cutting machine, the HG ARs press brake, and the VENTIS AJ, which are well-regarded for their efficiency and precision.

The following table outlines Amada’s main strengths and opportunities in the CNC machining center market:

| Strengths | Weaknesses | Opportunities/Threats |

|---|---|---|

| Turnkey lines | Lower software stack | Construction steel demand cycles |

Amada’s focus on turnkey solutions allows customers to streamline their operations, enhancing productivity. Their commitment to innovation and customer service further solidifies their reputation in the industry.

Key Features of Top CNC Machining Center Manufacturers

Innovation and Technology

Top CNC machining center manufacturers prioritize innovation and technology to enhance their product offerings. They invest significantly in research and development to stay ahead in a competitive market. For instance, companies like DMG MORI focus on smart manufacturing capabilities, integrating advanced automation and precision engineering into their machines. This commitment to innovation results in features such as:

- Advanced Automation: Many manufacturers implement automation in CNC operations, improving efficiency and reducing human error.

- AI and Machine Learning: Integration of artificial intelligence allows for process optimization, enabling machines to adapt to varying production demands.

- IoT Integration: Manufacturers utilize the Internet of Things (IoT) for real-time data insights, facilitating predictive maintenance and minimizing downtime.

The following table highlights some of the technological features found in leading manufacturers’ products:

| Manufacturer | Technological Features |

|---|---|

| Mikron | Outstanding thermal stability, Machine Spindle Protection (MSP) technology, integrated automation solutions |

| Makino | High precision, high efficiency, user-centered design, exceptional performance |

| CHIRON | Fastest tool change system, advanced automation technologies, efficient production solutions |

Customer Support and Service

Customer support and service are critical aspects that distinguish top CNC machining center manufacturers. They understand that maintaining strong relationships with clients enhances satisfaction and loyalty. Leading manufacturers offer various service levels to address customer needs effectively. These services include:

- Installation: Professional installation of CNC machines ensures optimal setup and performance.

- Maintenance Training: Manufacturers provide training for customers on how to maintain their machines, promoting longevity and efficiency.

- 24/7 Technical Support: Many companies offer around-the-clock support, ensuring that customers receive timely assistance whenever issues arise.

The following table outlines the different service levels provided by manufacturers:

| Service Level | Description |

|---|---|

| Level 1 | Basic preventive maintenance services. |

| Level 2 | Intermediate services including alignment and tuning. |

| Level 3 | Comprehensive services for extensive maintenance needs. |

Additionally, manufacturers emphasize friendly relationships with customers, ensuring timely support and a deep understanding of their issues. This commitment to service fosters long-term partnerships.

Customization Options

Customization options play a vital role in meeting the diverse needs of clients in various industries. Leading CNC machining center manufacturers offer tailored solutions to enhance productivity and efficiency. Some common customization options include:

- 5-axis CNC Systems: These systems provide advanced machining capabilities for complex parts, allowing for greater design flexibility.

- High-Torque Spindle Options: Enhanced performance for demanding applications is achieved through high-torque spindles, which enable efficient machining of tough materials.

- AI-Enabled Toolpath Monitoring: Intelligent oversight improves efficiency by optimizing toolpaths based on real-time data.

- Integrated Robotic Automation: Streamlined processes increase productivity by automating repetitive tasks.

The following table summarizes some of the customization options available from leading manufacturers:

| Customization Option | Description |

|---|---|

| 5-axis CNC systems | Advanced machining capabilities for complex parts |

| High-torque spindle options | Enhanced performance for demanding applications |

| AI-enabled toolpath monitoring | Intelligent oversight for improved efficiency |

| Integrated robotic automation | Streamlined processes for increased productivity |

These features allow manufacturers to cater to specific client requirements, ensuring that their CNC machining centers deliver optimal performance in various applications.

Quality and Precision

Quality and precision are paramount in the CNC machining center industry. Manufacturers implement rigorous standards to ensure their products meet the highest specifications. They recognize that even minor deviations can lead to significant issues in production. To maintain quality and precision, manufacturers adopt several key practices:

- Quality Assurance Management Program: Each project undergoes a systematic approach to quality assurance. This program outlines the steps necessary to meet quality standards throughout the manufacturing process.

- Advanced Measurement Technologies: Manufacturers utilize cutting-edge technologies in their Quality Assurance Labs. These tools allow for precise measurement and inspection of components.

- Process Monitoring: Continuous monitoring occurs at every phase of the machining process. This ensures compliance with specifications and helps identify potential issues early.

The following table summarizes the quality control processes employed by leading manufacturers:

| Quality Control Process | Description |

|---|---|

| Preemptive Analysis | Engineers use advanced software to simulate machining processes and identify potential issues before production begins. |

| Real-time Monitoring | Machines are equipped with sensors that check tool performance and workpiece accuracy during production. |

| Regular Inspections | Techniques like coordinate measuring machines (CMM) evaluate finished parts against specifications. |

| Quality Management System | Integrates planning, control, assurance, and improvement to ensure team alignment on quality. |

| Staff Training | Regular training on quality standards fosters a culture of excellence. |

Manufacturers also invest in dedicated Quality Assurance Labs. These labs feature advanced measuring and inspection technologies. They monitor every phase of the machining program to ensure specifications and tolerances are met. A commitment to 100% accuracy and consistency drives these efforts.

Comparison of Top CNC Machining Center Manufacturers

Overview of Features

Leading CNC machining center manufacturers offer a variety of features tailored to meet diverse industry needs. For instance, DMG Mori excels with its DMU 50, a versatile 5-axis machining center ideal for complex geometries. Okuma stands out with its Genos M Series, emphasizing efficiency and precision. The following table summarizes key features across different machine types:

| Machine Type | Max Working Area (mm) | Spindle Speed (RPM) | Tool Change Type | Price Range (USD) | Materials Compatible |

|---|---|---|---|---|---|

| CNC Milling Machine | 1200 x 800 x 600 | 24000 | Automatic | 50,000 – 100,000 | Aluminium, Plastic, Wood |

| CNC Laser Cutter | 3000 x 1500 | 20000 | Manual | 30,000 – 70,000 | Metal, Acrylic, Wood |

| CNC Router | 2400 x 1200 | 18000 | Automatic | 25,000 – 60,000 | Wood, Composite, Plastic |

| CNC Plasma Cutter | 4000 x 2000 | 15000 | Automatic | 20,000 – 50,000 | Metal |

Pricing and Value

The pricing strategies of leading CNC machining center manufacturers are evolving towards value-based models. This approach emphasizes the total cost of ownership and long-term support rather than just the initial purchase price. The CNC machine market features intense competition, with various manufacturers offering a wide range of products at different price points. Each company has distinct features and pricing strategies that reflect its unique market positioning.

Market Reputation

Industry experts consistently rate the reputation of top CNC machining center manufacturers highly. The following table highlights their standings based on various criteria:

| Rank | Manufacturer | HQ / Region | Best-known for | Typical industries |

|---|---|---|---|---|

| 1 | DMG MORI | Germany / Japan | Premium 5-axis, mill-turn, digital integration | Aerospace, medical, automotive, molds |

| 2 | MAZAK | Japan | Multi-tasking, high productivity | General machining, aerospace, energy |

| 3 | HAAS Automation | USA | Value + availability, job-shop friendly | Job shops, education, automotive |

| 4 | Okuma | Japan | Rigid machines + in-house controls | Aerospace, energy, heavy industry |

| 5 | Makino | Japan | High-speed precision machining | Molds, aerospace, medical |

This reputation reflects their commitment to quality, innovation, and customer satisfaction, making them leaders in the CNC machining center industry.

Industry Trends Influencing CNC Machining Center Manufacturers

Automation and Smart Technology

The rise of automation and robotics significantly influences CNC machining center manufacturers. Companies increasingly adopt these technologies to enhance production efficiency. Automation allows for 24-hour uninterrupted production, which boosts productivity. Additionally, it improves processing accuracy and consistency by reducing human error. As manufacturers face a labor shortage, automation not only replaces skilled labor but also enhances operational capabilities.

Artificial Intelligence (AI) plays a crucial role in this transformation. AI optimizes machining processes, automates setup procedures, and enables predictive maintenance. With AI, inspection becomes proactive, allowing machines to recognize geometry and auto-assign toolpaths. This integration streamlines operations and enhances the accuracy of machining tasks.

Sustainability Practices

Sustainability has become a priority for leading CNC machining center manufacturers. They adopt various practices to minimize environmental impact. Key initiatives include:

- Energy-efficient operations

- Material recycling

- Integration of smart technologies

- Predictive maintenance

- Real-time monitoring

- Lean manufacturing principles

Manufacturers implement energy-efficient machinery and optimized servo motors to conserve power. They also utilize eco-friendly coolants and lubricants, along with closed-loop systems for coolant recycling. These practices not only reduce waste but also promote a more sustainable manufacturing process.

Global Market Dynamics

Global market dynamics significantly affect CNC machining center manufacturers. The rapid growth in Asian markets, particularly in China and Japan, drives the demand for automation and customized solutions. Manufacturers must adapt their strategies to remain competitive in this fragmented market, characterized by established players and emerging startups. This adaptation is crucial for meeting the increasing demand for advanced technologies and maintaining a strong market presence.

In summary, leading CNC machining center manufacturers such as Haas Automation, DMG Mori, and Mazak Corporation offer a range of advanced features and capabilities. Selecting the right manufacturer is crucial for meeting specific machining needs. A deep understanding of CNC capabilities enhances part manufacturing, leading to higher quality and innovative products.

Readers should explore these manufacturers to find solutions that align with their requirements. Resources like CNC Machining Blogs and Insight Series provide valuable information for further exploration.

FAQ

What is a CNC machining center?

A CNC machining center is a versatile machine tool that automates the machining process. It combines multiple operations, such as milling, drilling, and tapping, into one setup, enhancing efficiency and precision in manufacturing.

How do I choose the right CNC machining center?

Selecting the right CNC machining center depends on factors like production volume, material type, and required precision. Assessing specific machining needs and consulting with manufacturers can help identify the best fit.

What industries use CNC machining centers?

CNC machining centers serve various industries, including aerospace, automotive, medical, and electronics. They are essential for producing complex parts with high precision and efficiency.

What maintenance is required for CNC machining centers?

Regular maintenance for CNC machining centers includes cleaning, lubrication, and calibration. Scheduled inspections help ensure optimal performance and extend the machine’s lifespan.

How can I improve productivity with CNC machining centers?

Improving productivity involves optimizing tool paths, implementing automation, and utilizing advanced features like 5-axis machining. Continuous training for operators also enhances efficiency and reduces downtime.

Post time: Feb-03-2026