CNC Horizontal Machining Centers are essential equipment in modern manufacturing, widely used in mold making, aerospace, automotive, and other industries due to their high precision, efficiency, and stability. Below are the detailed steps for installation and commissioning of a CNC Horizontal Machining Center:

1. Installation

1.1 Selecting the Installation Site

Choose a location that avoids direct sunlight, heat sources, and areas with high dust concentrations. The foundation must be solid and stable. If there are strong vibration sources nearby, appropriate vibration isolation measures should be taken to protect the machine’s accuracy.

1.2 Securing the Machine

The machine can be placed directly on the foundation or concrete floor, or fixed firmly with anchor bolts to ensure stability and prevent movement during operation.

1.3 Cleaning and Lubrication

After installation, use cotton yarn soaked in gasoline or clean kerosene to carefully remove rust-preventive oil from the machine surfaces, then apply a layer of machine oil to protect the parts from corrosion.

2. Commissioning

2.1 Lubrication and Air Supply

Fill all lubrication points with the appropriate oil, fill the hydraulic oil tank with specified hydraulic oil, and connect the air supply to the machine.

2.2 Power-On Test

Power on the machine and supply electricity to each component individually or perform a full power-on test. Check for any alarms, manually operate components to verify normal function, and confirm all safety devices are working properly. Ensure all machine axes and mechanisms operate smoothly.

2.3 Rough Adjustment of Machine Accuracy

After the initial operation, perform rough geometric accuracy adjustments by aligning the main moving parts and the relative positions of the main unit. Correct the positioning of the robot arm, tool magazine, and pallet changer.

2.4 Grouting

After rough adjustment, use fast-setting cement to grout the anchor bolts of the main machine and accessories, filling the bolt holes to secure the machine firmly to the foundation.

2.5 Preparation of Measuring Tools

Prepare precision instruments such as a precision level, standard square, and parallel square tube to assist with fine adjustments.

2.6 Fine Leveling of the Machine Bed

Adjust the CNC machine bed to be level in a free state, ensuring geometric accuracy falls within allowable error limits and maintain the stability of the bed after adjustment.

2.7 Adjustment of Robot Arm and Tool Magazine

Manually adjust the robot arm relative to the spindle using a dial gauge. When installing heavy tool holders, perform multiple automatic tool changes between the tool magazine and spindle to ensure accurate, collision-free operation.

2.8 Adjustment of the Pallet Table

Move the pallet table to the exchange position and adjust the relative position between the pallet station and the exchange table. Ensure smooth automatic pallet exchange and test multiple exchanges under heavy load conditions.

2.9 Parameter Verification

Check that the CNC system and Programmable Logic Controller (PLC) parameters conform to the specifications provided in the machine’s documentation.

2.10 Functional Testing

Test all main operational functions, safety features, and commonly used commands to verify correct execution and machine readiness.

Scientific and standardized installation and commissioning are key to ensuring the stable operation and high-precision machining capability of the Horizontal CNC Machining Center. It is strongly recommended to follow the machine’s operation manual strictly to achieve optimal performance.

Advantages of Choosing CNC Horizontal Machining Centers

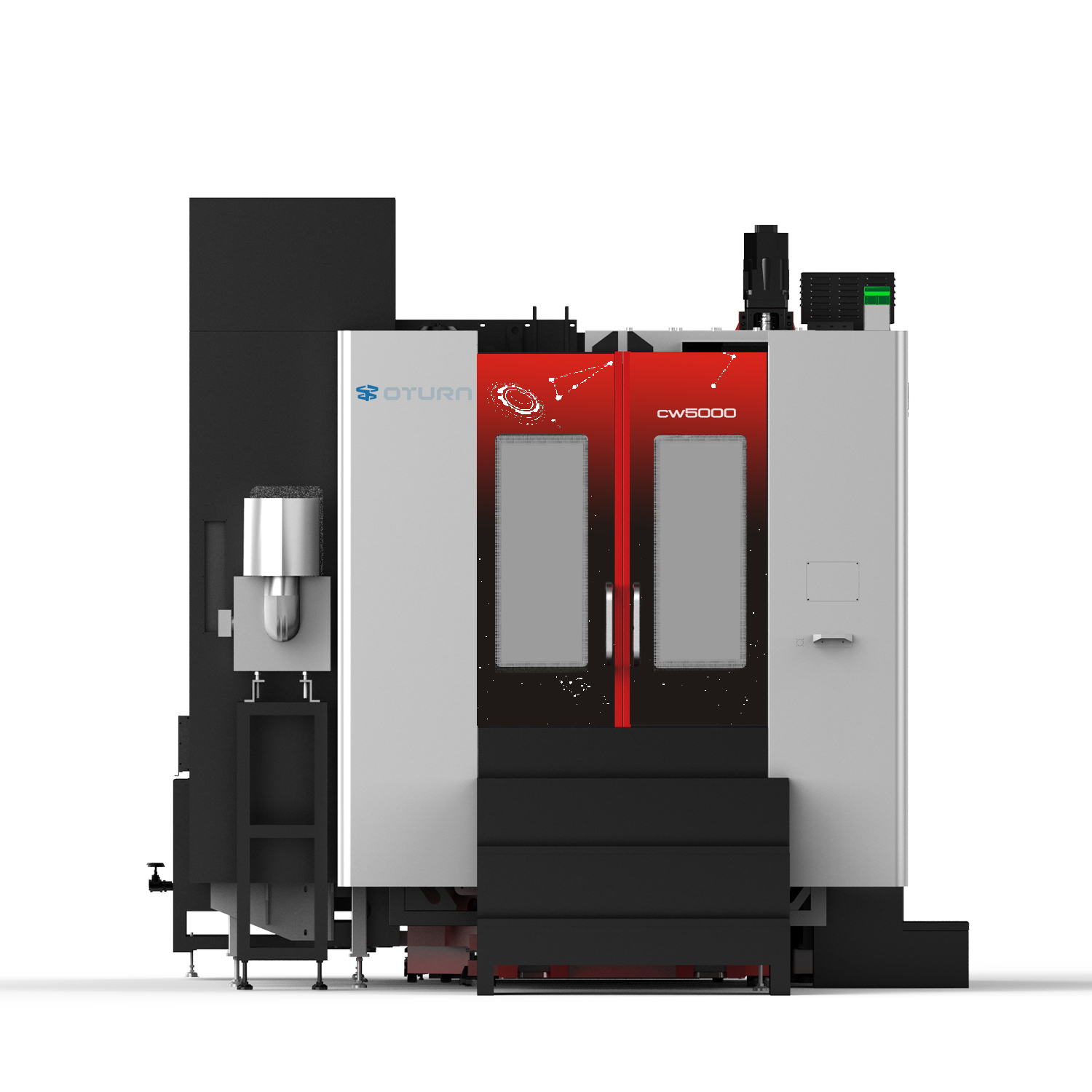

Taking the OTURN CW Series CNC Horizontal Machining Center as an example, this model features a high-rigidity structure and precise temperature control system, ensuring the machine remains stable and deformation-free during heavy-load, high-speed cutting, thereby guaranteeing machining accuracy and workpiece quality. Equipped with a large worktable and a powerful spindle, it is well-suited for efficient machining of complex parts in industries such as aerospace, automotive manufacturing, and mold making. Intelligent configurations like automatic tool changers, hydraulic clamping, and multi-station pallet changers significantly enhance production efficiency and automation levels.

Moreover, OTURN leverages extensive technical experience and comprehensive after-sales service to assist customers in smoothly completing equipment installation and commissioning, ensuring stable and efficient CNC machine operation. Our professional team provides on-site guidance, remote technical support, and regular maintenance services to quickly resolve any installation and commissioning issues, maximizing equipment performance and production efficiency. Choosing OTURN helps customers achieve high precision, high efficiency, and high stability in modern manufacturing. Contact us to learn more about our professional solutions and join us in advancing intelligent manufacturing.

Post time: May-16-2025