In the rail transit industry, the machining quality of components directly determines the safety, reliability, and operational efficiency of trains. As essential processing equipment, gantry machining centers have become the key tools for manufacturing large rail transit components, thanks to their high rigidity, long travel, and multi-axis simultaneous technology. By integrating advanced processes and innovative methods, gantry machining centers are driving high-quality development and intelligent manufacturing upgrades in the rail transit sector.

The Ideal Choice for Large Component Machining

Large components in rail transit, such as car body frames and bogies, are massive in size, making them difficult to process with traditional machine tools. Gantry machining centers feature a wide-span gantry structure and long-travel guideways, enabling single-setup, multi-face machining of large workpieces. This greatly reduces positioning errors caused by multiple setups and significantly improves machining accuracy and surface quality.

· Single-setup, multi-face machining: Effectively avoids repeated positioning errors and ensures dimensional consistency of parts.

· Five-axis simultaneous technology: Precisely mills complex surfaces, ensuring that critical components like bogies meet strict geometric tolerance standards.

Precision Control Technologies Ensure Machining Quality

The high precision of CNC gantry machining center is achieved through multiple technical safeguards:

· High-rigidity machine structure: Made from high-strength cast iron or welded steel, stress-relieved to eliminate internal stresses, enhancing overall rigidity and reducing machining deformation.

· High-precision transmission system: Equipped with ball screws and linear guideways, combined with high-performance servo motors, achieving positioning accuracy up to ±0.005mm.

· In-process measurement technology: Machine-mounted probes measure workpiece dimensions in real time, feeding data back to the CNC system for automatic correction of machining deviations, ensuring parts meet the strict standards of the rail transit industry.

Efficient Mass Production Technologies

To meet the mass production demands of rail transit components, gantry machining centers employ several technologies to boost efficiency:

· Optimized tool paths and turning processes: Use of high-speed turning and micro-turning techniques increases material removal rates while maintaining machining accuracy.

· Automatic tool changers and pallet changers: Enable rapid tool replacement and automatic loading and unloading of workpieces, reducing auxiliary time and improving production efficiency.

· Intelligent CNC systems: Real-time adaptive adjustment of turning parameters based on workpiece material and tool condition further enhances efficiency and shortens production cycles.

Core Advantages of Gantry Machining Centers in Rail Transit

· High precision and stability: Ensures the machining quality of safety-critical components.

· Multi-functionality and flexibility: Adapts to the processing needs of various complex parts.

· Reduced labor and operational costs: High automation reduces human error and labor intensity.

· Excellent surface quality: Minimizes secondary processing and improves overall part performance.

As rail transit technology continues to advance, gantry machining centers will continue to integrate more intelligent, multi-axis, and digital technologies, propelling the industry toward higher precision, efficiency, and smart manufacturing. For rail transit manufacturers, investing in advanced CNC gantry machining center is a strategic move to improve product quality, optimize production processes, and enhance market competitiveness.

Gantry machining centers, with their outstanding processing capabilities and technical advantages, have become irreplaceable core equipment in the field of rail transit component manufacturing.

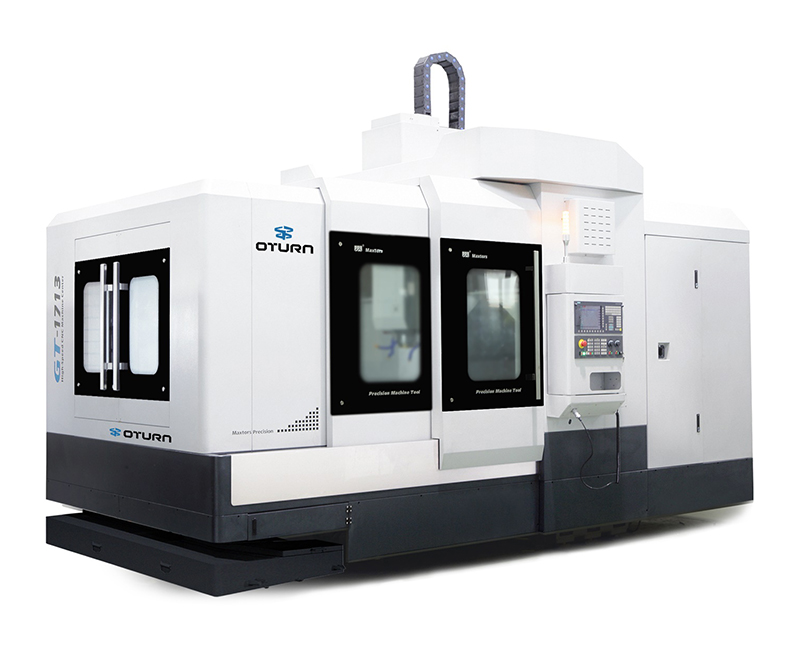

With years of extensive experience, OTURN is dedicated to providing customized machining solutions and one-stop services for rail transit, aerospace, energy, engineering machinery, and other industries, helping clients improve machining efficiency and product quality and achieve intelligent manufacturing upgrades. Feel free to contact us for more information about our products and solutions.

Post time: Sep-29-2025