Haas Automation, Mazak, DMG Mori, Okuma, Makino, Doosan Machine Tools, FANUC, Hurco, Brother Industries, Hyundai WIA, Toyoda, and BORUI CNC are top Cnc Machining Center Manufacturers. They provide diverse solutions. The U.S. market for these machines reached $1.6 billion in 2024. China’s market will hit $1.8 billion by 2030. The ‘less than 5-axis segment’ of the Vertical Machining Center market was valued at USD 2.05 billion in 2023. The Cnc Vertical Machining Center market projects a 5.36% CAGR from 2025-2035, growing from USD 10.23 billion to USD 17.24 billion. This market will also increase by USD 1.09 billion at a 5% CAGR between 2024 and 2029. A Cnc Horizontal Machining Center offers different capabilities. A 5 Axis Gantry Type Machining Center handles complex parts. A Cnc Vertical Milling Machine also serves various industries.

Key Takeaways

- Top companies like Haas, Mazak, and DMG Mori make CNC Vertical Machining Centers. These machines help create precise parts for many industries.

- Modern CNC machines use new technology like AI. This makes them work faster and more accurately. It also helps them last longer.

- Choosing the right CNC machine means looking at what you need to make. Think about the materials, part size, and how many parts you need. This helps you pick the best machine.

- Five-axis CNC machines can make very complex parts in one go. This saves time and makes the parts more accurate. They are good for detailed work.

Leading CNC Vertical Machining Center Manufacturers

Haas Automation: Versatile CNC Vertical Machining Center Solutions

Haas Automation stands as a prominent name in the manufacturing industry. The company offers a wide range of versatile CNC Vertical Machining Center solutions. These machines cater to various needs, from small job shops to large production facilities. Haas machines are known for their ease of use and reliability. They provide a cost-effective entry point for many businesses looking to automate their machining processes. Haas Automation focuses on delivering practical and efficient solutions for diverse manufacturing applications.

Mazak: Innovative CNC Vertical Machining Center Technology

Mazak consistently introduces innovative technology into its CNC Vertical Machining Centers. The company aims to improve efficiency and precision for its users. One key innovation is the MAZATROL SmoothAi CNC system. This system uses artificial intelligence to reduce setup and programming time. It also shortens cycle times and improves machining accuracy. Another advancement is the MAZATROL SmoothEz CNC. This technology makes operation, setup, and machining easier for Ez Series machines. It supports both EIA/G-code and conversational programming. The system features a 15-inch touch screen and a full keyboard for better functionality.

Mazak also offers automation solutions like the Ez LOADER. This compact system includes a robot arm, a vision sensor, and special software. It works with Mazak’s small and medium-sized machines. The PALLETECH High-Rise System (PHS) is another automated pallet transfer system. It significantly boosts productivity by automatically moving palletized workpieces.

Mazak’s machine lineup includes advanced models. The VARIAXIS C-700 Vertical Machining Center offers full 5-axis machining capabilities. It has different spindle options for various materials, from heavy steel to light aluminum. This machine can also integrate automation options like pallet changers. The VC-Ez 20 Vertical Machining Center provides reliable performance at an affordable price. It features a 25 HP, 12,000-rpm spindle and a standard 30-tool automatic tool changer. It also includes Thermal Displacement Control to maintain stable accuracy during long operations.

DMG Mori: Precision CNC Vertical Machining Center Engineering

DMG Mori engineers its CNC Vertical Machining Centers for maximum precision. These machines help produce high-quality components. Their robust construction ensures the highest levels of accuracy. The DMV, NVX, and NVD series, for example, offer enhanced precision and dynamics. They feature rapid feeds of up to 62 meters per minute. These series also come with a diverse range of spindles to suit different machining tasks. DMG Mori’s commitment to precision engineering makes their machines suitable for demanding industries.

Okuma: Reliable CNC Vertical Machining Center Performance

Okuma builds its CNC Vertical Machining Centers for reliable performance. These machines consistently deliver precision and efficiency. Manufacturers trust Okuma for stable operations and long-term durability. Okuma’s advanced thermal compensation systems maintain accuracy during extended production runs. Their OSP control system offers intuitive operation and powerful processing capabilities. This ensures consistent part quality and reduced downtime. Okuma machines support a wide range of applications, from general machining to complex aerospace components.

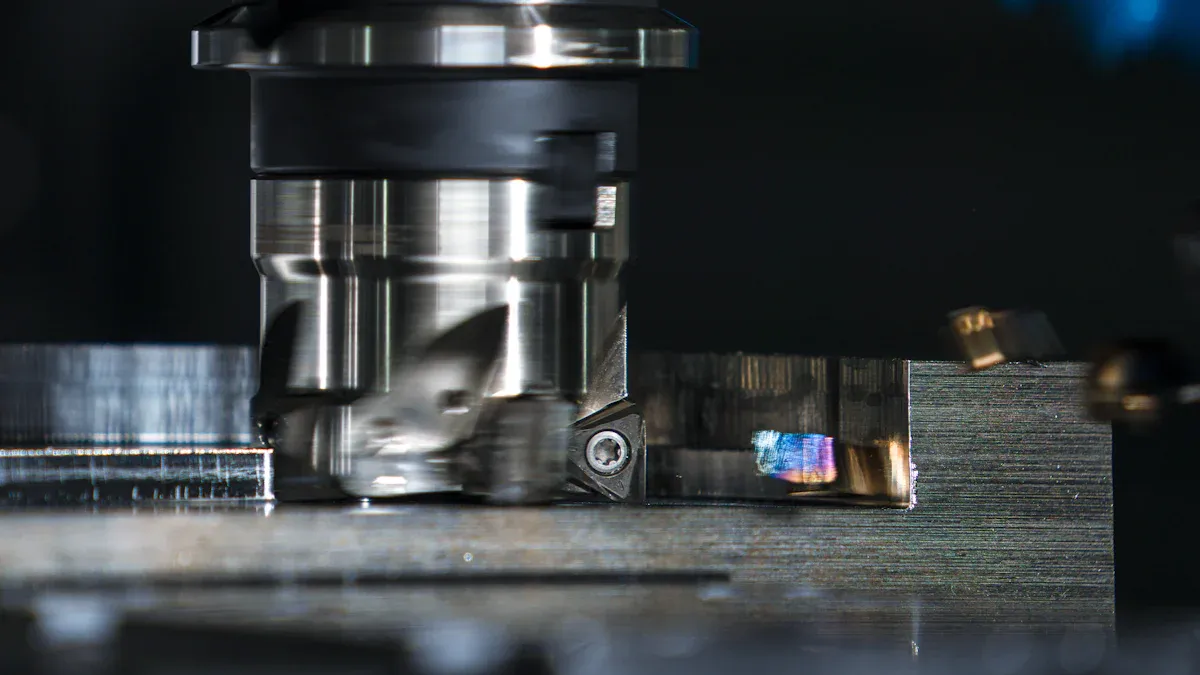

Makino: High-Performance CNC Vertical Machining Center Applications

Makino designs its CNC Vertical Machining Centers for high-performance applications. These machines excel in demanding manufacturing environments. They significantly reduce cycle times in small batch production runs. Makino VMCs enable faster feed rates and heavier cuts in drilling operations. This leads to 10 to 15 percent cycle time savings compared to previous VMCs. Makino machines are ideal for high-performance contour machining. They handle complex 3D contoured geometry in modern die/mold applications. They also perform tight-tolerance hard milling with exceptional accuracy. Makino VMCs ensure continuous, tight-tolerance machining. They produce complex, 3D contoured shapes, including dies, complex cavities and cores, and medical parts. These machines achieve vibration and chatter-free production of small details and fine features. They use small tools at high RPMs. Makino VMCs also machine large parts and multi-sided components. They produce complex 3D parts with greater accuracy. This results in a higher quality surface finish and chatter-free cutting.

Doosan Machine Tools: Robust CNC Vertical Machining Center Offerings

Doosan Machine Tools offers robust machining solutions. These machines are built to withstand rigorous manufacturing demands. They ensure reliability in high-volume production. The Doosan MV4020D model features a robust build. This design handles high-volume production demands effectively. Doosan VMCs incorporate advanced thermal management systems. These systems maintain consistent accuracy during operation. Their designs feature robust C-frame and double column structures. This provides exceptional stability. The Mynx Series offers heavy-duty cutting capabilities. It includes customizable features like box-type guideways and two-step gearboxes. The VC Series provides unsurpassed rigidity for precise machining. The DMP Series achieves superior rigidity through roller-type LM Guides. These features collectively contribute to the durability and consistent performance of Doosan’s offerings.

FANUC: Advanced CNC Vertical Machining Center Control Systems

FANUC provides advanced control systems for CNC Vertical Machining Centers. These systems enhance precision and efficiency in manufacturing. They help machine shops produce complex parts with greater ease.

The FANUC Series 500i-A CNC represents a significant advancement. This new control system uses optimized 5-axis integrated technology. It works with the new FANUC Alpha i-D Servo System. This combination supports easier operation, enhanced security, and optimized efficiency. It also helps reduce cycle times with faster speeds and improved productivity. Jon Heddleson, General Manager of the Factory Automation Division for FANUC America, states that the 500i-A CNC addresses the market need. It helps make parts quicker, better, and easier. It does this by providing optimized 5-axis integrated technology. It also simplifies operation and maintenance.

FANUC’s new generation servo system, the α i-D Series, delivers high speed and high precision. John Horn, National Sales Manager for FANUC America’s Factory Automation Division, highlights its ability to reduce energy loss. These servo motors offer increased speed-torque characteristics. They also feature IP67 protection. Customers can order them with battery-less encoders. The drive systems have a smaller footprint. This saves cabinet space and enhances overall system efficiency.

The 500i-A CNC also features a modern iHMI2 interface. This interface has a simplified 1-1 task-to-screen display. A battery-less system makes maintenance easier. Furthermore, FANUC CNC systems, including the 500i-A CNC, advance IoT efforts. They use centralized data collection and management software. They also guard against cybersecurity issues. Features like FOCAS3, user authentication, and data access protection are included. The 500i-A CNC offers digital twin technology. This assists in complex machine design. It also allows builders to customize user interfaces. The new control series has a dual engine architecture. It boasts 2.7 times higher CPU processing power than previous models. Updated hardware and graphically enhanced software improve block processing time. Macro program processing also sees improvement. This leads to faster cycle times and improved productivity.

FANUC also offers other powerful control series. The 30 Plus Series enhances 5-axis operations and faster cycle times. This premium class of controls (30i/31i/32i-B Plus) maximizes and simplifies advanced machine tool operations. The 0iM-F Plus Series helps machine shops achieve more efficient operations. It optimizes spindle performance and reduces sequencing processing time. It also offers a customizable, user-friendly interface.

The ROBODRILL α-D28LiB5ADV Plus Y500 Vertical Machining Center showcases these advancements. This VMC offers a larger table. It provides shorter drilling and tapping cycles. It also has increased tool storage capacity with faster tool changes. This gives more advantages for production machine shops. It features an extended Y-axis stroke of 500 mm. It also has an increased table size without increasing its footprint. It speeds up drilling and tapping with rapid Z-axis acceleration (2.2 G) and a traverse rate of 60m/min. It has an expanded tool capacity of 28 tools.

Hurco: User-Friendly CNC Vertical Machining Center Programming

Hurco focuses on user-friendly CNC Vertical Machining Center programming. The company designs its machines to simplify complex machining tasks. This approach benefits job shops and manufacturers who need quick setup and efficient production.

Hurco’s conversational programming system, WinMax, allows operators to program parts directly at the machine. This eliminates the need for extensive G-code knowledge. Operators can input part dimensions and machining operations using a graphical interface. The system then generates the necessary tool paths. This significantly reduces programming time. It also lowers the skill barrier for new operators.

The UltiMotion control system further enhances Hurco’s user-friendliness. UltiMotion provides smooth, high-speed contouring. It maintains accuracy even during rapid movements. This technology optimizes tool paths. It also reduces cycle times without sacrificing part quality. Operators experience less chatter and better surface finishes.

Hurco machines are ideal for small to medium-sized businesses. These businesses often handle diverse, short-run jobs. The intuitive programming allows for quick changeovers between different parts. This maximizes machine uptime and overall productivity. Hurco’s commitment to ease of use makes their machines accessible and efficient for a wide range of manufacturing applications.

Key Strengths of Top CNC Vertical Machining Center Suppliers

Innovation and Technology in CNC Vertical Machining Centers

Leading suppliers constantly push the boundaries of technology. They integrate AI-powered control systems into new CNC machines. This allows for faster programming and reduces vibration. It also improves thermal stability. Machine learning helps prevent errors, which can reduce scrap by up to 22%. These innovations reshape Cnc Vertical Machining Center operations for better efficiency and precision. They use data analytics and smart algorithms to optimize processes. This reduces downtime and enables real-time monitoring. Advanced materials also play a role. New stereolithography (SLA) materials mimic traditional plastics. This expands the capabilities of CNC-related additive manufacturing. Waterjet technology offers versatile and precise cutting solutions. Automated bending cells deliver precise bending with fast cycle times. They feature new vision systems for better part detection. Redesigned press brakes offer faster, more precise operations and use less energy.

Reliability and Durability of CNC Vertical Machining Centers

Top manufacturers build their machines for long-term reliability. The initial construction quality of a CNC machine determines its durability. Reputable brands often provide machines designed to withstand heavy use. Regular and proactive maintenance is crucial for sustained performance. This includes proper lubrication, routine inspections, and timely replacement of worn parts. A controlled environment also helps. Factors like temperature and humidity affect components. Machines used within recommended limits last longer. Heavy, continuous use leads to faster wear. Upgradability also extends machine life. Machines designed for new features avoid complete replacement. Knowledgeable operators who use the machine correctly prevent damage.

Customer Support and Service for CNC Vertical Machining Centers

Excellent customer support is a hallmark of top suppliers. They offer comprehensive technical assistance. This helps users troubleshoot issues quickly. Many suppliers provide training programs for operators and maintenance staff. These programs ensure users maximize machine potential. Availability of spare parts is also critical. A good inventory of parts minimizes downtime during repairs. Strong customer service builds trust and ensures long-term satisfaction.

Global Reach and Market Presence of CNC Vertical Machining Center Brands

Leading manufacturers of machining centers establish strong global presences. They build extensive networks to support customers worldwide. These companies ensure their machines and services reach diverse markets. This global reach helps manufacturers provide timely support and technical assistance.

Many top brands have a significant international footprint.

| Manufacturer | Headquarters/Origin | Global Presence/Network Details |

|---|---|---|

| BORUI CNC | China | Strong global presence |

| Haas Automation | American | Large distributor network with over 2,000 sales, service, and engineering personnel across the Americas |

| DMG MORI | Germany and Japan | Presence in over 40 countries, 17 production facilities worldwide, 120+ sales and service locations |

| Mazak Corporation | Japanese (with American presence) | Multiple production plants globally, supports customers through 80+ technology centers and a well-established service network |

| Okuma Corporation | Japanese | Huge distributor network in the Americas with nearly 2,000 sales, service, application engineering, and support personnel |

| SYIL Machine Tools | Operates in more than 20 countries | |

| Makino | Japanese | Supports customers in 41+ countries through a strong global sales and service network |

| JTEKT Machinery | Strong global presence | |

| Methods Machine Tools | Major VMC manufacturer in North America | |

| Yangsen CNC | Chinese | Exports to 20+ countries |

Haas Automation, for example, maintains a large distributor network. Over 2,000 sales, service, and engineering personnel work across the Americas. DMG MORI operates in more than 40 countries. It has 17 production facilities and over 120 sales and service locations. Mazak Corporation supports customers through more than 80 technology centers. It also has a well-established service network globally. Okuma Corporation boasts a huge distributor network in the Americas. Nearly 2,000 sales, service, and application engineering staff support their customers. Makino reaches customers in over 41 countries. It uses a strong global sales and service network.

This widespread presence ensures customers receive prompt service. It also guarantees access to spare parts and expert advice. A strong global network helps manufacturers understand local market needs. They can then tailor their products and services accordingly. This global strategy strengthens their market position. It also builds customer loyalty across different regions.

Popular CNC Vertical Machining Center Models and Their Applications

Entry-Level CNC Vertical Machining Centers for Job Shops

Entry-level vertical machining centers serve small businesses, job shops, and educational institutions. They offer compact designs and basic functionalities. These machines typically feature a lower-power spindle and a simple control system. Their price generally ranges from $10,000 to $50,000. This makes them an excellent choice for those with limited budgets or those just starting operations. These small industrial units provide significant power without being overly expensive. They offer enhanced durability and precision. This makes them ideal for serious production without requiring a very large investment.

High-Production CNC Vertical Machining Centers for Manufacturing

High-production vertical machining centers meet the demands of large-scale manufacturing. These machines prioritize speed, efficiency, and automation. They often include features like fast automatic tool changers and integrated pallet changers. This minimizes downtime and maximizes throughput. Manufacturers design them for continuous operation, handling high volumes of parts with consistent quality. Industries such as automotive, aerospace, and general manufacturing rely on these robust machines. They produce components quickly and efficiently.

High-Precision CNC Vertical Machining Centers for Specialized Industries

High-precision vertical machining centers cater to industries requiring extreme accuracy and tight tolerances. These machines feature advanced control systems, superior thermal stability, and robust construction. They minimize vibration and ensure exceptional surface finishes.

| Industry | Specific Applications |

|---|---|

| Mold and Die Manufacturing | Creating complex 3D contours, cavities, and cooling channels for plastic injection molds, die-casting dies, and stamping tools. Requires exceptional precision and fine surface finishes. |

| Automotive Components | Manufacturing engine parts, transmission housings, brake components, and structural frames. Demands a balance of strength, weight reduction, and dimensional precision, including complex parts like cylinder heads or EV motor housings. |

| Aerospace and Defense | Producing turbine blades, landing gear parts, and engine housings from hard-to-cut materials like titanium and Inconel, meeting strict quality standards and requiring precise contoured aerodynamic surfaces. |

| Precision Tool and Equipment Manufacturing | Fabricating ultra-precise jigs, molds, and tooling components for industries such as semiconductor production, medical device fabrication, and optical component machining. |

| General Metalworking and Custom Parts Production | Used by job shops and contract manufacturers for prototypes, small-batch parts, and repair components, offering flexibility for diverse customer needs. |

These specialized machines ensure the production of intricate components with the highest quality standards.

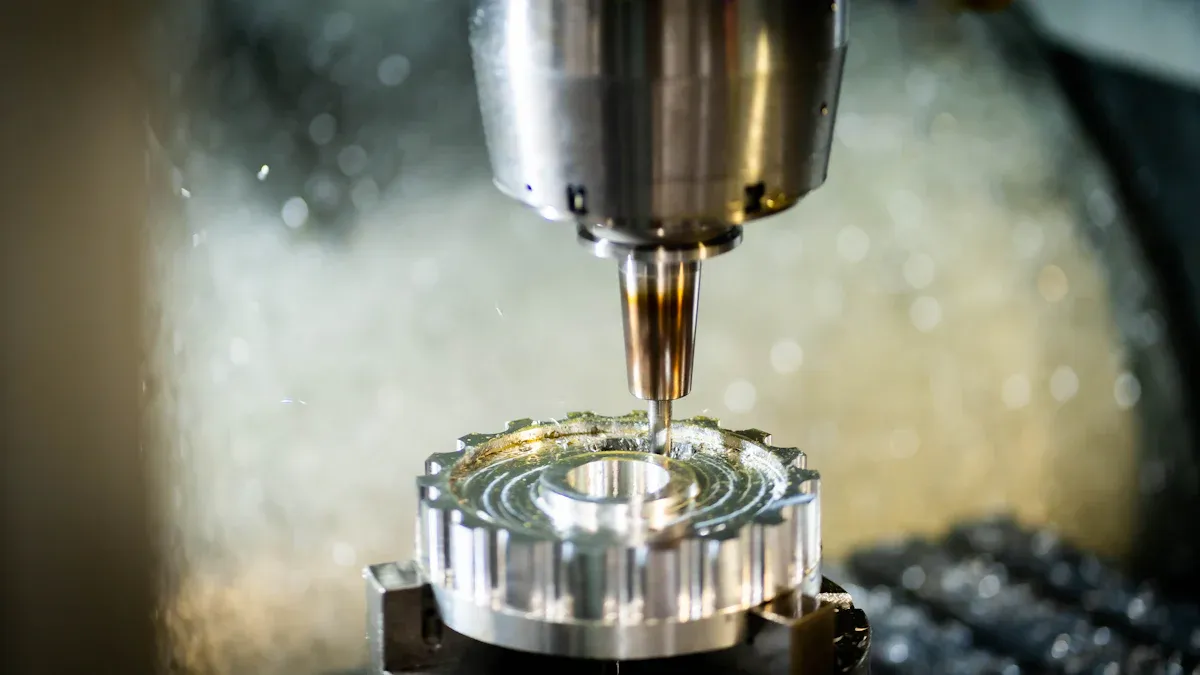

5-Axis CNC Vertical Machining Centers for Complex Parts

Five-axis vertical machining centers offer significant advantages for creating complex parts. These machines move workpieces across more dimensions without needing repositioning. This capability allows manufacturers to create intricate angles and geometries. They achieve premium finishes and tighter tolerances on these complex shapes.

Compared to 3-axis machines, 5-axis VMCs provide several benefits. They produce more complex part geometries. The additional A-axis and B-axis bring the work material closer to the cutting tool. This allows for shorter cutting tools. Shorter tools are less prone to machining vibration, which results in better surface finishes. The extra axes also improve drilling capabilities. They reach tighter and more complex angles for drilling applications, producing parts with finer finishes.

Five-axis machines also boost efficiency. Multi-side access in a single setup reduces the number of fixtures needed. It also lowers operator interventions. This shortens the overall cycle time for complex parts. Fewer reclampings mean fewer accumulated errors, which supports tighter tolerances and enhances precision.

These machines handle complex geometries with ease. Simultaneous motion on X, Y, Z, and two rotary axes allows machining of free-form surfaces. They create deep cavities and compound-angle features. These tasks are impractical on 3-axis equipment. The ability to keep the tool oriented normal to the surface improves chip evacuation and cutter engagement. This yields smoother transitions and finer surface finishes on sculpted areas.

Five-axis devices offer great versatility. They produce a wide variety of parts and geometries. They are particularly effective for aerospace blisks, medical implants, and precision molds. They also excel in other parts where both geometry and surface integrity are critical. These machines speed up production and improve efficiency by performing continuous milling operations. They create smoother surfaces and more accurate parts. Continuous milling operations also reduce tool changes, saving time and manual effort.

Choosing the Right CNC Vertical Machining Center for Your Needs

Factors to Consider When Selecting a CNC Vertical Machining Center

Businesses must carefully evaluate several factors when selecting a vertical machining center. First, consider machining requirements. Different materials, like steel or aluminum, need specific machine capabilities. The required precision level, especially for industries such as aerospace, dictates the machine’s accuracy. Part size and shape determine the necessary table size, travel range, and spindle configuration. Second, assess machine performance. Spindle power and speed are crucial for various materials and machining conditions. High power handles heavy cutting, while high speed suits fine machining. Rapid traverse and feed rates affect cycle time and production efficiency. Tool magazine capacity and tool change speed are important for continuous operation. Third, examine the control system. It should offer ease of use, precision, and automation. It also needs programmability, data tracking, and diagnostic functions. Finally, machine rigidity and stability impact accuracy and tool life. A robust structure and damping technologies are key.

Matching CNC Vertical Machining Center Features to Business Requirements

Aligning machine features with production needs is essential. Businesses first understand their manufacturing needs. Consider part complexity; simple parts may need basic 3-axis machining, while intricate geometries might require multi-axis machines. Material type also matters. Different materials demand varying power levels and specific cutting tools. The machine must be compatible with chosen materials. Production volume guides choices; high-volume production benefits from faster, automated machines. Smaller-batch production suits more versatile options. Key features impact performance and efficiency. A robust frame ensures precision and reduces vibrations. The machine’s axis travel range must align with project sizes. An intuitive control system reduces the learning curve. Advanced options like touchscreens enhance productivity. A wider range of tooling options increases utility and adaptability.

Cost-Benefit Analysis of Different CNC Vertical Machining Center Options

Businesses perform a cost-benefit analysis for different machine options. This analysis helps make an informed decision. The total cost of ownership (TCO) includes the purchase price, operating costs, energy consumption, tool wear, and potential downtime. High performance and durability can reduce TCO over time. They also increase the return on investment. Investing in a machine that meets specific production needs avoids unnecessary expenses. It also ensures efficient operation.

Future Trends in CNC Vertical Machining Center Manufacturing

Automation and Robotics Integration in CNC Vertical Machining Centers

Modern CNC centers increasingly integrate robotics and automated material handling systems. This reduces manual intervention. It also increases production speed and improves manufacturing consistency. Robotic arms and collaborative robots (cobots) handle tasks like loading and unloading parts. They manage repetitive operations. These robots work safely alongside humans, especially in high-mix, low-volume environments. Robotic CNC integration advances. Robots not only load and unload but also assist in complex tasks. These tasks include part inspection, quality control, and tool-changing operations. This enhances flexibility and efficiency in mixed-product environments. Automated Cnc Vertical Machining Center can operate continuously with minimal human intervention. Robotics and smart tooling reduce setup times. They accelerate production cycles. Real-time monitoring via IoT ensures machines operate at peak efficiency. This contributes to increased productivity.

AI and Machine Learning for Optimized CNC Vertical Machining Centers

AI and machine learning optimize CNC operations. AI systems use historical data. They recommend optimal tooling options for specific tasks. This ensures efficient production. AI-driven software adapts CNC programs in real-time based on machine feedback. It automatically adjusts parameters if a tool underperforms. It also adjusts if material behaves unexpectedly. AI continuously monitors machine performance. It makes real-time adjustments to optimize speed, feed rates, and tooling conditions. This minimizes downtime and maximizes productivity. AI systems analyze operational data. They predict maintenance needs. This reduces unexpected breakdowns. It ensures machines are production-ready. Advanced sensors and AI algorithms monitor machines. They detect slight deviations for immediate adjustments. AI predictive analytics forecast tool wear. This guides proactive maintenance schedules. It prevents unexpected tool failure. Machine learning systems predict cutting forces and tool wear. This extends cutting tool life. They also optimize machining parameters to enhance efficiency.

Sustainable Practices in CNC Vertical Machining Center Production

Leading manufacturers adopt sustainable practices in production. They implement strategies for material recycling. This includes metal chip recycling and coolant recovery systems. These efforts minimize waste and conserve resources. Companies upgrade to modern, energy-saving machinery. They optimize machining processes to reduce energy usage. Some integrate renewable energy sources like solar or wind power. Smart technologies play a role. Predictive maintenance uses sensors and data analytics. Real-time monitoring allows for process adjustments. AI integration identifies patterns and recommends improvements. Lean manufacturing focuses on process optimization. It eliminates unnecessary steps. Efficient inventory management prevents overproduction. Employee training fosters environmental responsibility. These practices aim for a more environmentally friendly manufacturing future.

Advanced Materials Processing with CNC Vertical Machining Centers

Modern manufacturing often requires working with advanced materials. These materials include superalloys, composites, and ceramics. They offer unique properties like high strength, heat resistance, or lightweight characteristics. Processing these materials presents significant challenges for traditional machining methods. However, advanced CNC Vertical Machining Centers meet these demands effectively.

These specialized machines feature robust construction. They minimize vibration during cutting, which is crucial for hard materials. High-speed spindles deliver the necessary power and rotational velocity. This allows for efficient material removal without damaging the workpiece or tool. Many machines also incorporate advanced cooling systems. These systems manage the extreme heat generated when cutting tough alloys. Specialized tooling, often made from diamond or ceramic composites, withstands the abrasive nature of these materials.

Manufacturers use these advanced VMCs in various industries. Aerospace companies machine turbine blades from nickel-based superalloys. Medical device makers create implants from titanium or specialized ceramics. Automotive manufacturers produce lightweight components from carbon fiber composites. The precision and control offered by these machines ensure high-quality parts. They also achieve tight tolerances and excellent surface finishes. This capability allows industries to develop innovative products with superior performance.

The integration of advanced sensors and adaptive control systems further enhances material processing. These systems monitor cutting conditions in real-time. They adjust parameters automatically to optimize performance and prevent tool wear. This leads to longer tool life and reduced production costs. Ultimately, these advanced VMCs enable the creation of complex parts from challenging materials. They support innovation across many high-tech sectors.

The top 12 CNC Vertical Machining Center suppliers offer diverse solutions for various manufacturing needs. They cater to different industries and production scales. Businesses must understand each manufacturer’s unique strengths. This knowledge is crucial for making an informed decision. Selecting the right machine directly impacts a company’s productivity and long-term success in the market.

FAQ

What is a CNC Vertical Machining Center?

A CNC Vertical Machining Center (VMC) is a machine tool. It uses computer numerical control to perform various machining operations. The spindle axis is vertically oriented. VMCs cut materials like metal, plastic, and wood. They create precise parts for many industries.

Who are the leading CNC Vertical Machining Center suppliers?

Top suppliers include Haas Automation, Mazak, DMG Mori, Okuma, Makino, Doosan Machine Tools, FANUC, and Hurco. Other notable brands are Brother Industries, Hyundai WIA, Toyoda, and BORUI CNC. These companies offer diverse solutions for manufacturing needs.

What are the advantages of 5-axis CNC Vertical Machining Centers?

Five-axis VMCs machine complex parts in a single setup. They reduce repositioning and improve accuracy. These machines use shorter tools, which reduces vibration. This results in better surface finishes and tighter tolerances. They also increase efficiency for intricate geometries.

How does AI optimize CNC Vertical Machining Centers?

AI and machine learning optimize VMC operations. They recommend optimal tooling and adjust parameters in real-time. AI monitors performance and predicts maintenance needs. This minimizes downtime and maximizes productivity. It also extends tool life and enhances efficiency.

Post time: Dec-23-2025