China’s manufacturing sector features several prominent producers of advanced machine tools. OPMT Laser provides cost-efficient 5 Axis CNC Machining Center solutions. Dalian Machine Tool Group (DMTG) delivers proven value in Cnc Machining Center production. Shenyang Machine Tool Co., Ltd. (SMTCL) showcases large-scale innovation. Beijing Jingdiao Group offers precision at competitive prices. Haitian Precision manufactures robust machines for diverse applications. These companies exemplify a Professional CNC Machining Center Manufacturer China. They provide excellent choices for those considering how to choose a CNC machining center manufacturer in China, including advanced Five Axis Cnc Milling Machine and reliable Vertical Cnc Machine options.

Key Takeaways

- Cost-efficient 5-axis CNC machines balance the initial price with long-term savings. They save money through better productivity and higher quality parts.

- Chinese manufacturers like OPMT Laser, DMTG, SMTCL, Jingdiao, and Haitian Precision offer good value. They provide advanced technology and reliable machines.

- When choosing a supplier, look at their technical skills, quality checks, and after-sales help. Also, check their reputation and the total cost of owning the machine.

- Always define your exact needs for the machine. Make sure the supplier has the right certifications. Also, negotiate terms carefully before buying.

Defining Cost-Efficiency for 5 Axis CNC Machining Center Procurement

Balancing Initial Investment with Long-Term Value

Procuring a 5 Axis CNC Machining Center involves a significant financial commitment. The initial purchase price of these advanced machines is substantial, representing a high capital expenditure for any manufacturing operation. However, a truly cost-efficient approach balances this upfront investment with the long-term value the equipment delivers. Companies must look beyond the sticker price and consider the total cost of ownership, including operational savings, increased productivity, and enhanced product quality over the machine’s lifespan. This holistic view ensures a strategic investment rather than a mere purchase.

Key Performance Indicators for 5 Axis CNC Machining Center Value

Several key performance indicators (KPIs) help assess the value of a 5-axis CNC machining center. These machines significantly improve overall part accuracy by minimizing setup transitions, which reduces cumulative tolerance stack-up and potential misalignments. This leads to higher quality parts. They also offer superior surface finish because optimal cutting angles reduce tool marks, often eliminating or significantly reducing the need for secondary finishing processes. This lowers downstream processing costs. Furthermore, the equipment reduces the need for fixtures, as it can complete a part in a single setup, eliminating associated costs and maintenance.

The Role of Technology in 5 Axis CNC Machining Center Cost Performance

Advanced technology plays a crucial role in the cost performance of 5-axis CNC machining centers. These machines offer reduced production time and increased efficiency through automation, automatic tool changes, optimized tool paths, and single-setup machining. This significantly decreases setup time, material waste, and lead times, leading to predictable costs and increased efficiency across production volumes. They also facilitate faster revision cycles and reduce engineering change costs; digital programs are easily stored, recalled, and modified, making design revisions quicker and less expensive. The comprehensive capabilities of 5-axis CNC machines streamline the production process, simplifying management, planning, and scheduling, especially for complex workpieces. While 5-axis CNC equipment demands a higher initial investment and more complex programming, these costs are frequently justified by significant reductions in setup time, extended tool life, and enhanced part quality for appropriate applications.

OPMT Laser: Advanced 5 Axis CNC Machining Center Technology

Core Strengths in 5 Axis CNC Machining Center Manufacturing

OPMT Laser establishes itself as a leader in advanced manufacturing through significant innovation. The company holds an extensive patent portfolio, including 302 total patents, with 62 invention patents and 147 utility model patents. This demonstrates their commitment to technological advancement. OPMT Laser also maintains a high production capacity, manufacturing 1,000 sets annually. They operate five dedicated research centers, including a Provincial Manufacturing Innovation Center and an Ultrafast Laser Processing Joint Laboratory, which drives their cutting-edge research and development. Their hybrid systems achieve material removal rates 200% faster than conventional EDM processes. These systems also reduce operating costs by 50% due to the elimination of consumable tooling. Optimized beam delivery and precise thermal control lead to improved surface finish quality. Furthermore, eliminating cutting fluid requirements enhances environmental compliance. OPMT Laser’s 5-axis CNC systems integrate advanced NUM universal CNC systems, supporting up to 32 axes/spindles for complex multi-tasking operations with seamless RTCP compatibility. GTR software integration simplifies migration from EDM to laser processes, reducing programming complexity by 75% and minimizing operator training. The company maintains comprehensive quality management systems with ISO 9001:2015, ISO 14001, and ISO 45001 certifications. For medical device manufacturing, OPMT systems offer validated cleaning procedures and traceability documentation supporting FDA 21 CFR Part 820 compliance.

Why OPMT Laser Offers Superior Cost Performance

OPMT Laser delivers superior cost performance through several key technological advantages. Their technology achieves 200-300% faster processing times compared to conventional EDM methods, significantly boosting productivity. The absence of consumable electrodes and cutting tools reduces ongoing operational costs by approximately 50%. Femtosecond laser systems consume 44% less energy than traditional thermal processing, contributing to lower energy bills and environmental benefits. A modular design architecture allows for function expansion and software upgrades, extending equipment lifecycle and adaptability. The direct drive indexing structure ensures high angular accuracy and excellent dynamic response across all rotational axes. Natural marble machine beds provide superior thermal stability and vibration damping, enhancing precision. Linear motor drives offer zero backlash and high dynamic response for all linear axes. High-precision torque motors enable direct drive rotational axes with exceptional accuracy. Full closed-loop control utilizes grating scale feedback on all axes for maximum precision. Modular optical systems include CCD positioning cameras and high-precision probes for enhanced functionality, making their 5 Axis CNC Machining Center a cost-effective choice.

Dalian Machine Tool Group (DMTG): A Legacy of 5 Axis CNC Machining Center Excellence

DMTG’s Comprehensive 5 Axis CNC Machining Center Offerings

Dalian Machine Tool Group (DMTG) has a long-standing reputation in the machine tool industry. The company offers a comprehensive range of advanced machining solutions. Their product line includes various 5 Axis CNC Machining Center models designed for diverse industrial applications. Customers can find options such as the Vmc850 4 & 5 Axis Vertical CNC Machining Center. DMTG also provides the GT DMTG VMC650 Machining Center 5 Axis Cnc. Other notable models include the 5 Axis VMC650 VDF650 Metal CNC Milling Machine VMC Vertical Machining Center. Furthermore, DMTG offers customizable solutions like the VMC650 Taiwan 5 Axis Cnc Milling Cutter Metal Machining Center. These machines cater to different production needs, from general machining to highly specialized tasks.

Achieving Cost-Efficiency with DMTG 5 Axis CNC Machining Centers

DMTG helps manufacturers achieve cost-efficiency through robust machine design and reliable performance. Their machines are built for durability, which reduces maintenance costs and extends operational life. This long lifespan contributes to a lower total cost of ownership. DMTG also focuses on integrating user-friendly controls and automation features. These features streamline operations and minimize the need for extensive manual intervention. Reduced labor costs and increased throughput directly translate into economic benefits for users. The company’s extensive experience in machine tool manufacturing ensures consistent quality and precision. This reliability minimizes scrap rates and rework, further enhancing cost-efficiency. DMTG’s global presence also provides accessible support and spare parts, ensuring minimal downtime. This comprehensive approach makes DMTG a strong contender for cost-effective 5-axis machining solutions.

Shenyang Machine Tool Co., Ltd. (SMTCL): Global Scale 5 Axis CNC Machining Center Production

SMTCL’s Technological Edge in 5 Axis CNC Machining Centers

Shenyang Machine Tool Co., Ltd. (SMTCL) stands as a global leader in machine tool manufacturing. The company consistently invests in research and development. This commitment drives their technological advancements across their product lines. SMTCL integrates advanced control systems and precision components into their machines. They focus on developing intelligent manufacturing solutions. Their engineering teams work to enhance machine performance and reliability. SMTCL’s large-scale production capabilities allow for extensive testing and refinement of their designs. This ensures their machines meet rigorous industry standards. They offer a wide range of sophisticated machine tools, including advanced multi-axis solutions.

Market Impact and Cost Advantages of SMTCL 5 Axis CNC Machining Centers

SMTCL’s immense production scale significantly impacts the global machine tool market. Their ability to manufacture a high volume of machines allows for competitive pricing. This makes advanced technology more accessible to a broader range of businesses. Customers benefit from SMTCL’s established global distribution and service networks. These networks provide reliable support and spare parts, minimizing downtime. The company’s focus on standardized components also contributes to cost-efficiency. This simplifies maintenance and reduces the overall cost of ownership. SMTCL’s 5 Axis CNC Machining Center offerings provide a strong value proposition. They combine advanced features with an attractive price point. This makes them a compelling choice for manufacturers seeking high performance without excessive capital expenditure.

Beijing Jingdiao Group: High-Precision 5 Axis CNC Machining Center Solutions

Jingdiao’s R&D and Application of 5 Axis CNC Machining Centers

Beijing Jingdiao Group commits significant resources to research and development. The company focuses on several core technological areas. These include precision machinery, advanced control technology, and key component development. Jingdiao also innovates in motor drive systems and CAD/CAM software, specifically for multi-axis machining. Their R&D efforts extend to information management and intelligent manufacturing solutions. A notable achievement is the development of the JD50 CNC system, which features robust 5-axis machining capabilities. Jingdiao continuously works on strategies to improve and stabilize machining accuracy. They also develop high-speed motorized spindles to enhance machine performance.

Value Proposition of Jingdiao 5 Axis CNC Machining Centers

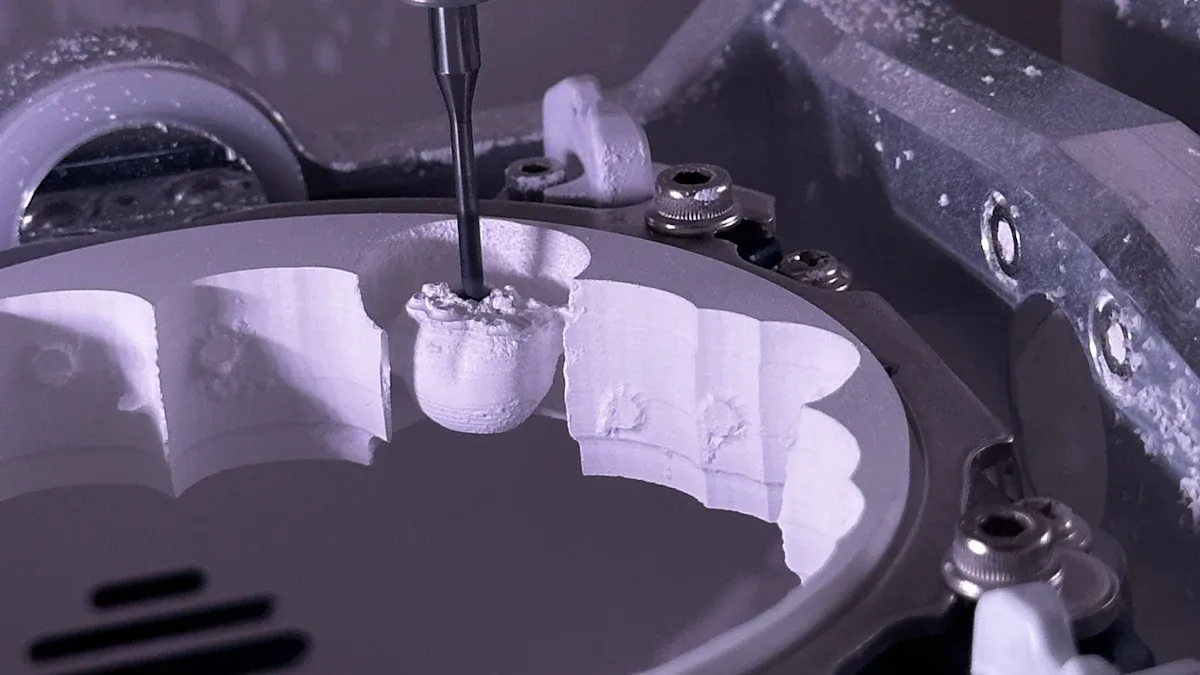

Jingdiao’s 5-axis CNC machining centers offer distinct advantages for precision industries. These machines achieve micron dimensional accuracy in part machining. They also produce mirror-finishes with nano surface roughness. The equipment is suitable for efficient composite machining of metal parts. Jingdiao offers specific models for various applications:

- Machining die mold parts with 2-5μm accuracy.

- Efficiently machining complex-shaped parts with 10-20μm accuracy.

- Grinding complex-shaped brittle-hard parts with 2-5μm accuracy.

Jingdiao machines excel in precision machining of small products for medical, clock, and jewelry industries. They can drill small holes, such as D0.002 inch. The machines offer a high space utilization rate. For example, a machine weighing 1.65 tons covers only 2.25㎡. This allows for efficient use of production space. It even permits upstairs installation. Jingdiao ensures stable processing quality, achieving “0.1 μ feed, 1 μ cutting, nanoscale surface roughness.” This stability comes from optional JINGDIAO spindles (up to 36000rpm) and an on-machine inspection system. For precious metal parts, the machines feature a high protection structure to prevent chip entry. Stainless steel protective sheet metal allows for easy waste disposal. An in-machine flushing device and recovery filter bag improve precious metal chip recovery. Jingdiao’s proprietary JD50 CNC system, with over 120,000 units installed, offers high reliability and advanced functions. These include integrated measurement for workpiece verification and intelligent modification simulation. Their proprietary CAD/CAM software, JDSoft SurfMill, further enhances machining quality.

Haitian Precision: Durable 5 Axis CNC Machining Center for Industrial Use

Haitian’s Robust 5 Axis CNC Machining Center Designs

Haitian Precision engineers their 5 Axis CNC Machining Center for exceptional durability and industrial performance. They focus on creating robust machine structures. These designs ensure stability and precision even under demanding operational conditions. Haitian machines feature heavy-duty components. These components contribute to a longer operational lifespan. The company prioritizes reliability in its manufacturing processes. This commitment results in machines that withstand continuous use in various industrial settings. Their design philosophy emphasizes minimizing downtime. This approach helps manufacturers maintain consistent production schedules. Haitian’s machines are known for their strong build quality. This quality makes them suitable for diverse and challenging applications.

Global Support and Economic Benefits of Haitian 5 Axis CNC Machining Centers

Haitian Precision offers extensive global support, which enhances the economic benefits for its customers. Hision (Haitian Precision) products serve diverse industries worldwide. CNCmarket.ca Inc. has represented Hision (Haitian Precision) in Canada since 2025. They provide CNC machine tool technology and support to Canadian manufacturers. Haitian Precision USA supports customers across North America. Its headquarters are in Moncks Corner, SC. Additional regional offices and technical centers are located throughout the U.S. and Canada. This widespread network ensures prompt service and technical assistance. Reliable support minimizes machine downtime. This directly translates into increased productivity and cost savings for businesses. The durability of Haitian machines also reduces maintenance costs over time. Their robust construction means fewer repairs and replacements. This long-term reliability contributes to a lower total cost of ownership. Haitian Precision’s global presence and durable machines offer significant economic advantages to industrial users.

Our Methodology for Selecting Top 5 Axis CNC Machining Center Suppliers

Technical Capabilities and Innovation in 5 Axis CNC Machining Centers

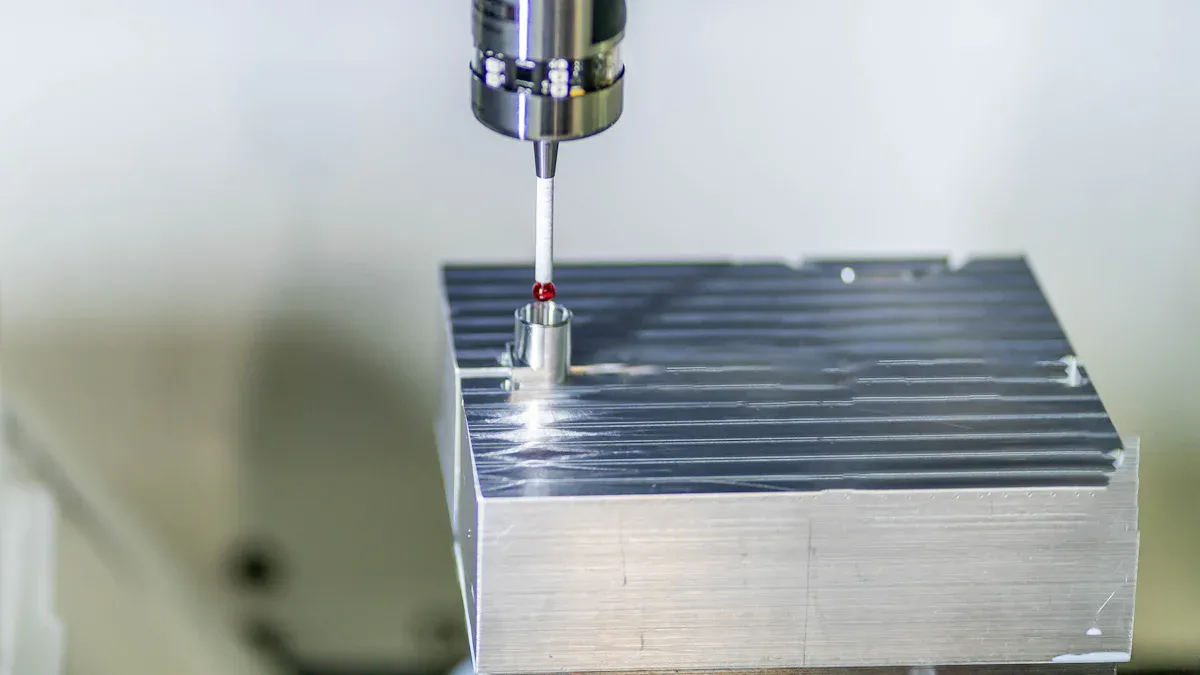

Companies must evaluate a supplier’s technical capabilities and innovation when selecting a 5 Axis CNC Machining Center. A strong supplier holds valid ISO 9001 certification and maintains a well-equipped inventory with documented maintenance records. They employ a qualified technical team. Modern manufacturers integrate AI to optimize tool paths and use predictive maintenance to prevent downtime. Smart factories with real-time monitoring improve efficiency. Suppliers offer customization and OEM/ODM services, providing tailored solutions for global clients. They demonstrate flexibility in small-batch production and rapid prototyping. Expertise in machining challenging materials like titanium, using specialized tooling and cooling techniques, is crucial. Advanced technologies, such as 11-axis CNC Swiss screw machining and multi-axis turning centers, indicate innovation. Precision measurement tools like Coordinate Measuring Machines (CMM) and advanced laser scanning systems ensure accuracy.

Quality Control and Reliability of 5 Axis CNC Machining Centers

Quality control and reliability are paramount for any machine tool investment. Suppliers should maintain robust quality control documentation and procedures. They perform regular maintenance, including spindle alignment and backlash compensation, for consistent performance. In-process inspection uses probes or laser systems to detect deviations during machining. Final inspection involves post-machining checks with Coordinate Measuring Machines (CMMs) or optical scanners. CMM accuracy of ±0.002 mm or better verifies dimensions and surface quality. Statistical Process Control (SPC) monitors process stability; providers should show control charts with Cpk values of 1.33 or higher. Traceability ensures each part links to its production batch, including material certifications. ISO 9001:2015 certification indicates adherence to international quality standards. Machine rigidity, build quality, and thermal stability are essential for consistent precision.

After-Sales Service and Support for 5 Axis CNC Machining Centers

Comprehensive after-sales service and support are critical for long-term operational success. A reliable supplier offers rapid response times for technical issues. They ensure a consistent supply of spare parts, minimizing downtime. Remote diagnostics capabilities allow for quick troubleshooting and problem resolution. Many leading brands provide 24/7 support, ensuring assistance is always available. This level of service protects the investment and maintains productivity.

Market Reputation and Customer Feedback on 5 Axis CNC Machining Centers

A manufacturer’s market reputation significantly influences purchasing decisions. Companies build strong reputations through consistent product quality and reliable customer service. Positive customer feedback often highlights machine performance, durability, and the effectiveness of after-sales support. Industry awards, certifications, and long-term client relationships also indicate a supplier’s standing. Prospective buyers often review testimonials and case studies. They also consider peer recommendations. A strong reputation suggests a manufacturer delivers on its promises. This builds trust among potential customers.

Pricing Models and Total Cost of Ownership for 5 Axis CNC Machining Centers

The initial purchase price of a 5 Axis CNC Machining Center represents only one part of the overall investment. Buyers must consider the Total Cost of Ownership (TCO). TCO includes installation, training, maintenance, energy consumption, and spare parts. It also accounts for potential downtime and the machine’s resale value. Different pricing models exist. Some manufacturers offer base models with optional features. Others provide comprehensive packages including service contracts. Evaluating TCO helps companies make informed financial decisions. It ensures they select a machine that offers long-term economic benefits, not just a low upfront cost.

Engaging with Chinese 5 Axis CNC Machining Center Manufacturers

Defining Specific Requirements for Your 5 Axis CNC Machining Center

Defining precise requirements is crucial before engaging with manufacturers. Buyers must understand project needs like part size, complexity, and desired accuracy. This helps identify essential machine features such as spindle type, table size, and software. For instance, the 5 Axis CNC Machining Center, especially trunnion-style machines, requires specific sizing for the intended part family. This prevents issues from using an improperly sized machine. For small-to-medium parts (e.g., 3” to 6” cubes), avoid large machines with large rotary tables (e.g., 24” diameter). A medium-sized machine (e.g., 10” or 12” diameter table) suits such parts better. Oversizing can cause problems like chatter and interference. When considering trunnion machines, pay close attention to Y-axis travel. Insufficient Y-axis travel can lead to “out of travel” alarms if the part and fixture height are significant. For swivel-head configurations, X-axis travel is a key limitation. Longer tools and larger parts demand greater X-axis travel.

Verifying Certifications and Standards for 5 Axis CNC Machining Centers

Verifying certifications and standards ensures quality and compliance. CE Marking is a mandatory requirement for products sold within the European Economic Area (EEA). It indicates conformity with health, safety, and environmental protection standards. For 5-axis CNC machines, obtaining CE Certification is vital. It assures customers of the machine’s compatibility with stringent regulations. Key directives for CE Certification include the Machinery Directive 2006/42/EC, Low Voltage Directive 2014/35/EU, and Electromagnetic Compatibility (EMC) Directive 2014/30/EU. Other crucial standards include ISO 9001 for quality management, ISO 14001 for environmental management, and ISO 45001 for occupational health and safety. Industry-specific standards like AS9100 for aerospace, IATF 16949 for automotive, and ISO 13485 for medical devices are also important. Nadcap Accreditation is a global program for aerospace and defense industries.

Conducting Due Diligence on 5 Axis CNC Machining Center Suppliers

Thorough due diligence is essential when evaluating potential suppliers. First, define technical specifications. Then, research machine configurations, exploring options like 3+2 versus full simultaneous machining. Evaluate potential suppliers by requesting company profiles, customer references, and case studies. Verify certifications and compliance, checking for ISO 9001 and other relevant safety/environmental certifications. Request demonstrations or trials to assess machine capabilities and performance firsthand. Analyze the Total Cost of Ownership (TCO), considering maintenance, tooling, software, training, warranty, and after-sales support. Negotiate terms and conditions regarding payment, delivery, and installation support. Prepare detailed 3D CAD models and 2D technical drawings for accurate quotes. Request a Quote (RFQ) and evaluate the professionalism of the response. Look for suppliers offering Design for Manufacturability (DFM) feedback. Review case studies of similar parts and verify quality certifications. Finally, place a sample or prototype order to inspect quality, accuracy, and finish.

Negotiating Terms for 5 Axis CNC Machining Center Purchases

Successful procurement of a 5 Axis CNC Machining Center requires careful negotiation. Buyers must clearly define payment schedules, including down payments and final installments. They should also discuss warranty terms extensively. This includes coverage duration, parts, and labor. Service level agreements are crucial. These agreements outline response times for technical support and maintenance. Delivery timelines and installation support also require clear understanding. Manufacturers often provide training packages for machine operators and programmers. Buyers should negotiate these training details. Furthermore, consider any potential discounts for bulk purchases or long-term contracts. A well-negotiated agreement protects the buyer’s investment and ensures smooth operations.

Logistics and Installation of 5 Axis CNC Machining Centers

After securing the purchase, logistics and installation represent critical phases. Proper setup ensures the optimal performance of a 5 Axis CNC Machining Center. The configuration process involves several key steps:

- Prepare Holding Equipment: Securely mount the workpiece at the machine table center. Use appropriate clamps, such as a zero clamp vice, hydraulic clamp, or a securely mounted block. The workpiece must remain secure and accessible from all five sides.

- Prepare Cutting Tools: Measure, prepare, and load cutting tools and their holders into the machine’s Automatic Tool Changer (ATC) magazine.

- Perform Calibration: Calibrate the machine using specific software and an automatic measuring probe before production begins. This ensures accuracy across all axes and minimizes tolerance accumulation.

- Check for Potential Collisions: Thoroughly check for any potential collision areas before starting the machining cycle. Verify the correctness of each position and the accuracy of every tool change.

- Run Pre-Program Check: Execute the entire program step-by-step. This confirms the correctness of each position and tool change. It helps prevent crashes and ensures smooth operation.

These meticulous steps guarantee the machine operates efficiently and safely from day one.

China’s manufacturers offer a strategic advantage for sourcing a 5 Axis CNC Machining Center. They provide unbeatable cost-efficiency and mature technical capabilities. Their strong supply chain resilience and increasingly high quality standards also benefit buyers. Informed decision-making is crucial for optimal procurement. Buyers should evaluate equipment lists, technical prowess, and quality control. They should also assess communication skills and industry experience. Investing in these top suppliers offers long-term value. This includes scalability from prototype to mass production and a world-class manufacturing ecosystem.

FAQ

What defines cost-efficiency in a 5-axis CNC machining center?

Cost-efficiency balances initial investment with long-term value. It considers operational savings, increased productivity, and enhanced product quality. Advanced technology, reduced production time, and lower maintenance contribute to overall value.

How do Chinese manufacturers ensure the quality of their 5-axis CNC machines?

Chinese manufacturers implement robust quality control. They adhere to international standards like ISO 9001. They also conduct rigorous in-process and final inspections. This ensures precision and reliability in their 5-axis CNC machines.

What role does after-sales support play in the value of a 5-axis CNC machine?

After-sales support is crucial for operational success. Reliable suppliers offer rapid technical assistance and consistent spare parts. Remote diagnostics and 24/7 support minimize downtime. This protects the investment and maintains productivity.

Why should businesses consider Chinese suppliers for 5-axis CNC technology?

Chinese suppliers offer competitive pricing due to large-scale production. They provide advanced technology and robust designs. Their extensive global support networks ensure accessibility and reliable service. This delivers significant economic advantages.

Post time: Dec-16-2025