As summer temperatures continue to rise, many manufacturing companies have noticed fluctuations in the machining accuracy of their CNC machining center. Part dimensions frequently deviate from tolerances, and occasional equipment alarms and shutdowns occur. Customers often ask, “How can we ensure the stability and machining quality of CNC machines in high-temperature environments? Are there effective solutions to address the challenges posed by summer heat?” This has become a widespread concern in the industry.

Summer heat not only affects the comfort of operators but also directly impacts key components of CNC machines. Regardless of how advanced or expensive the machine is, temperature changes cause thermal deformation of the machine structure and core components, leading to machining errors. Thermal elongation of the spindle, thermal expansion of the ball screws, and overall thermal deformation of the machine structure can all cause deviations in part dimensions and positioning, sometimes resulting in scrapped parts. Understanding the root causes of these thermal deformations is the critical first step in developing effective control strategies.

I. Specific Effects of Summer Heat on Key Components of CNC Machining Centers

CNC machining centers consist of multiple precision components, and high temperatures affect these components to varying degrees, mainly including:

1. Electrical Cabinet and Control System

The electrical cabinet houses core electronic components such as PLC, servo drives, and main control boards. High temperatures increase the temperature inside the cabinet, affecting the stability and lifespan of electronic components. Overheating can trigger system alarms, automatic protective shutdowns, and in severe cases, equipment failures.

2. Spindle and Bearings

The spindle is the core component of the CNC machine. Temperature rise causes thermal expansion of the spindle, leading to reduced machining accuracy. High temperatures also degrade bearing lubrication, increasing wear risk and shortening bearing life.

3. Transmission System (Ball Screws and Linear Guides)

Thermal expansion of ball screws and linear guides causes clearance changes, resulting in positioning errors and reduced repeatability. High temperatures can also impair lubricant performance, increasing mechanical friction and wear.

4. Cooling System

Elevated coolant temperatures reduce cooling efficiency, affecting the spindle and motors’ heat dissipation, which in turn impacts overall machine stability.

5. Machine Structural Components

Thermal expansion of the machine bed, columns, and other structural parts can alter machine geometry, affecting machining accuracy.

II. Solutions to Address Summer Heat Challenges

1. Optimize Electrical Cabinet Cooling

Keep the electrical cabinet sealed to prevent dust and coolant mist ingress, avoiding component damage.

Regularly clean fans and filters to ensure unobstructed airflow.

Add air conditioning or cooling devices if necessary to maintain stable cabinet temperatures.

2. Spindle and Bearing Temperature Control

Spindle cooling systems are used to maintain coolant levels and temperatures within appropriate ranges.

Regularly check bearing lubrication and use high-temperature lubricants.

Monitor spindle temperature to prevent overheating.

3. Transmission System Maintenance

Use preloaded ball screws and high-precision guides to reduce errors caused by thermal expansion.

Regularly replace lubricants to ensure effective lubrication.

Monitor ball screw temperature and install cooling devices if needed.

4. Workshop Environment Control

Equip the workshop with air conditioning and dehumidifiers to maintain stable temperature and humidity.

Ensure good ventilation to prevent heat accumulation.

Avoid exposing machines to direct sunlight.

5. Software and Operation Optimization

Utilize built-in machine compensation functions to automatically adjust machining parameters for thermal expansion.

Backup programs and data regularly to prevent loss due to battery failure.

Provide operator training to master operation and maintenance under high-temperature conditions.

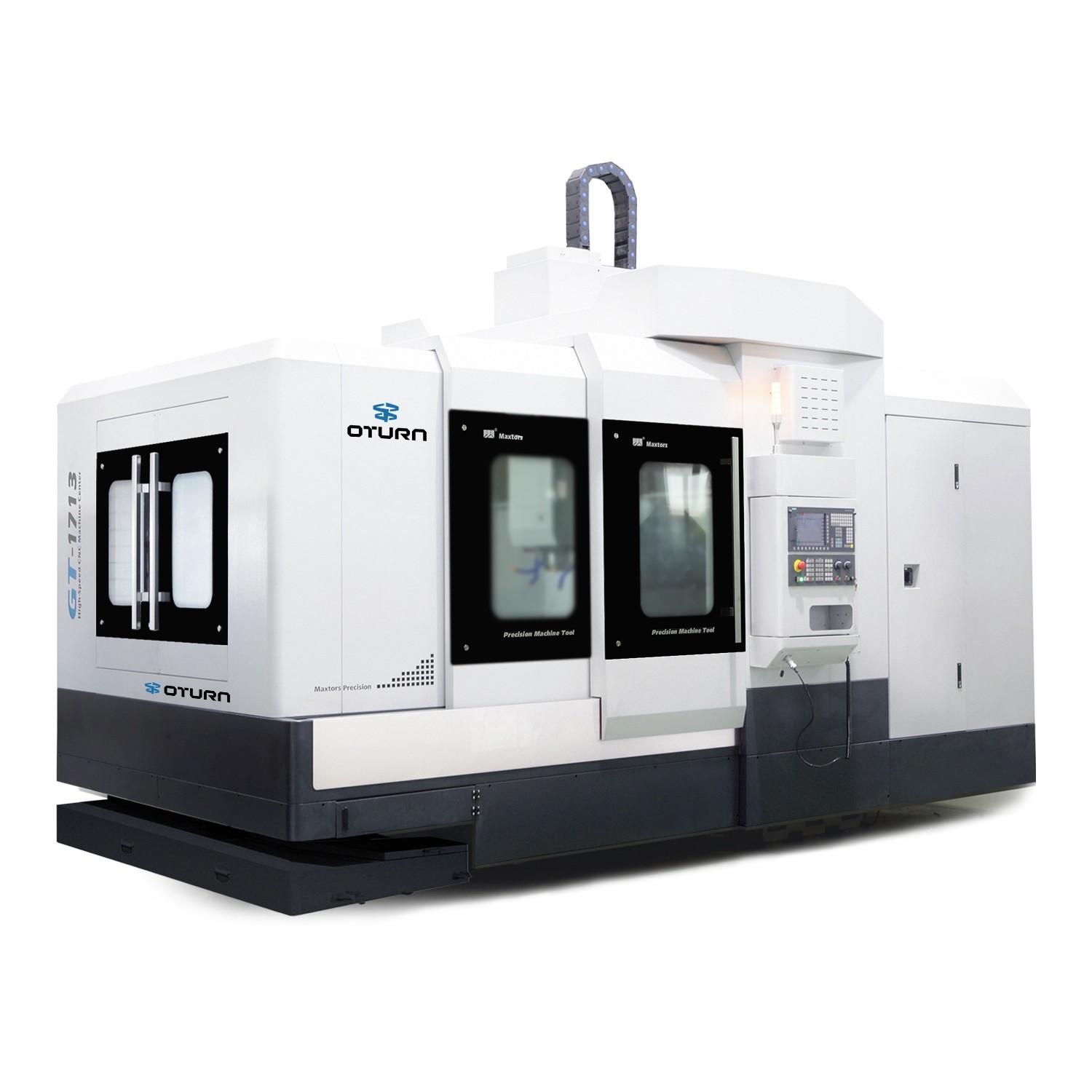

The impact of summer heat on CNC milling machine cannot be ignored. However, through scientific equipment maintenance, environmental control, and operational management, machine precision and stability can be ensured. As a professional CNC equipment service provider, OTURN offers comprehensive technical support and customized maintenance solutions:

· Professional Team: Experienced engineers tailor heat management strategies for your needs.

· Rapid Response: 24/7 customer service ensures prompt handling of equipment issues.

· Preventive Maintenance: Regular inspections and servicing minimize heat-related risks.

· Technical Training: Operator training on high-temperature operation and maintenance.

Choose OTURN to keep your CNC machining centers performing at peak levels all summer long, helping your business maintain stable and efficient production.

Post time: May-23-2025