Yes, the Horizontal Machining Center is unequivocally the key to maximizing ROI in 2025 high-volume production. Industry experts project a Compound Annual Growth Rate (CAGR) of 4.9% for horizontal CNC machining centers from 2025 to 2035. This significant growth highlights their increasing importance. A forward-thinking machine tool manufacturer understands this trend. They see the value these machines bring to high-volume operations. Every CNC equipment supplier also recognizes their efficiency. For example, they offer excellent Automotive Parts CNC Machining Solutions. This type of Cnc Machining Center excels in demanding environments.

Key Takeaways

- Horizontal Machining Centers (HMCs) are very good for making many parts quickly. They can work on different sides of a part at the same time.

- HMCs save money by using less labor and energy. They also make fewer mistakes, which means less wasted material.

- HMCs have smart systems that change tools fast and keep the machine running. This helps make more parts without stopping.

- Even though HMCs cost more at first, they help businesses earn more money over time. They make production faster and cheaper.

- Vertical Machining Centers (VMCs) are still good for making a few parts or for businesses with less money to spend.

HMC vs. VMC: Core Operational Differences for High-Volume CNC Machining Center Production

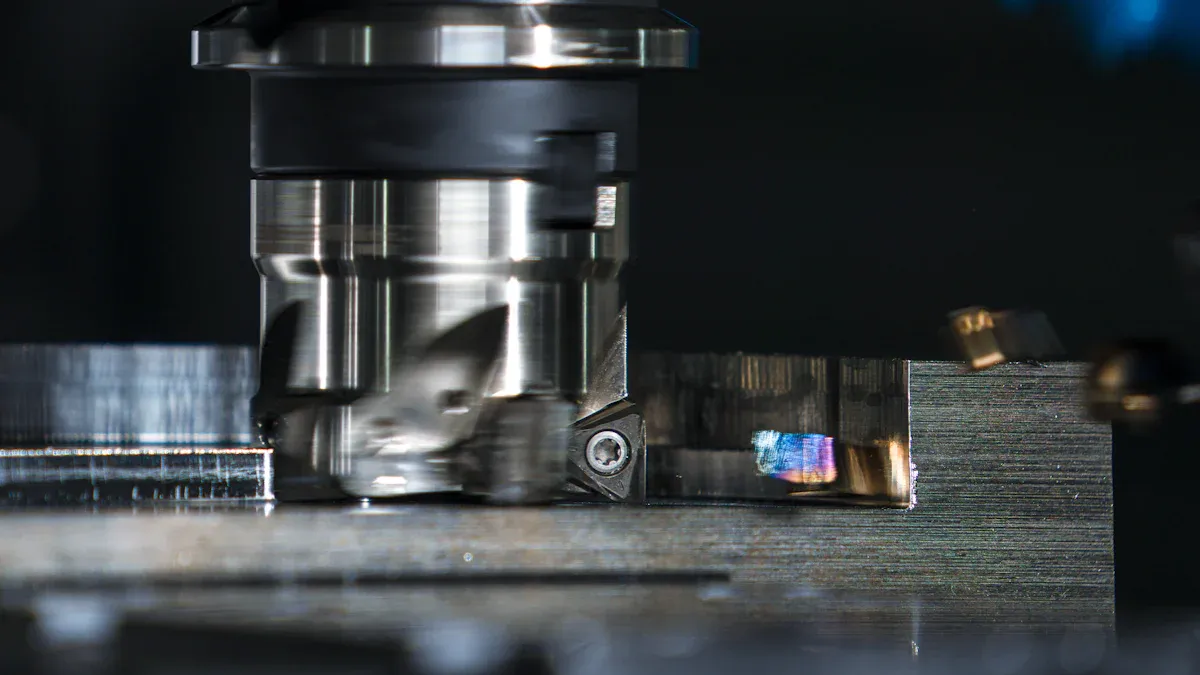

Spindle Orientation and Workpiece Access

The most apparent difference between vertical and horizontal CNC machining centers is their spindle orientation. Vertical machining centers utilize a vertical spindle. Horizontal machining centers, however, employ a horizontal spindle. This orientation directly impacts how the cutting tool engages the workpiece. It also influences the types of parts you can machine efficiently. In horizontal CNC milling machines, the spindle axis is positioned parallel to the worktable. This setup allows for greater access to multiple sides of a workpiece in a single clamping.

Chip Evacuation Efficiency in CNC Machining Centers

Chip evacuation efficiency is another critical distinction. Horizontal machining centers (HMCs) offer more efficient chip removal. Gravity helps chips fall away from the cutting zone. This improves surface finish and extends tool life. In contrast, vertical machining centers (VMCs) often struggle with chip accumulation. Chips can build up due to gravity, potentially affecting surface finish and tool life if you do not manage them properly. Great chip control and coolant flow are hallmarks of horizontal CNC milling machines.

Pallet Systems and Automation Readiness

Horizontal machining centers excel in automation readiness, largely due to their integrated pallet systems. These systems significantly boost productivity. For example, rotary-type pallet changers quickly exchange heavy workpieces. This allows you to set up the next workpiece while the current one is being machined. Multi-pallet automation integrates with CNC equipment. This enables unmanned machining, offering efficiency and scalability. Systems like the Okuma Pallet Pool System or the Automated Modular Pallet System (AMPS) connect machining centers. They facilitate automatic part handling and pallet changes. This is especially beneficial for shops with limited floor space. The PALLETECH system also automatically transports pallets with fixtures and workpieces. This improves machine and fixture utilization.

Unlocking HMC Advantages for High-Volume CNC Machining Center Throughput

Horizontal machining centers offer significant advantages for high-volume production. They unlock greater throughput and efficiency. Manufacturers can achieve impressive results by leveraging their unique capabilities. A Horizontal Cnc Machining Center truly transforms production.

Multi-Sided Machining in a Single Setup

Horizontal machining centers excel at multi-sided machining. Their horizontal spindle orientation, often combined with a rotary B-axis, allows the machine to access multiple faces of a workpiece. This means a single setup can complete complex parts. Operators do not need to re-clamp the part repeatedly. This capability drastically reduces overall cycle times. It also improves part accuracy by eliminating errors from multiple setups.

Reduced Part Handling and Setup Times

Reducing part handling is crucial for high-volume efficiency. Horizontal CNC milling allows for machining multiple sides of a component in a single setup. This inherently reduces the need for repeated part handling. Other machining centers often require operators to reset the workpiece multiple times to machine different sides of a single part. This increases handling. HMCs offer faster production cycles and the ability to perform multiple cuts in one pass. This improves efficiency for large batches and further minimizes handling. Horizontal mills are particularly well-suited for high-volume jobs. Minimizing part handling per piece contributes significantly to overall efficiency.

Superior Thermal Stability and Accuracy

Maintaining accuracy over long production runs is a key challenge. Horizontal machining centers are engineered for superior thermal stability. This design helps them maintain precision even during continuous, high-speed operation. They use materials with high thermal conductivity and low thermal expansion coefficients. This significantly reduces deformation. Advanced cooling systems are also implemented. These sophisticated coolant delivery and water-cooling cycles effectively dissipate heat. Thermal barrier coatings prevent excessive heat buildup within machine components. Continuous temperature monitoring systems proactively manage thermal effects. These features ensure consistent part quality and reduce scrap rates.

Enhanced Tool Management and Capacity

Horizontal machining centers truly shine in tool management and capacity. They often come equipped with significantly larger tool magazines. This means manufacturers can load many more tools into the machine at one time. A larger tool capacity allows for greater flexibility. It also supports machining more complex parts without manual tool changes. This reduces interruptions during long production runs. It also enables lights-out manufacturing.

HMCs also boast faster tool change times. The machine quickly swaps tools. This minimizes the time the spindle sits idle. Reduced tool change time directly contributes to shorter overall cycle times. For high-volume production, every second saved adds up. This efficiency boosts throughput significantly. It means more parts produced per shift.

Modern horizontal Cnc Machining Center models include advanced tool management systems. These systems monitor tool wear in real-time. They can even automatically switch to a redundant tool if one breaks or wears out. This capability ensures continuous operation. It prevents costly downtime. Manufacturers can load duplicate tools for critical operations. This provides an extra layer of reliability. Such features are vital for maintaining high production rates. They also help in achieving consistent part quality. This proactive approach to tool management minimizes scrap. It also maximizes machine uptime. Ultimately, this directly translates into a higher return on investment.

The Financial Impact: HMC ROI in High-Volume CNC Machining Center Settings

Calculating Throughput and Cycle Time Savings

Horizontal machining centers significantly boost production throughput. They also drastically cut cycle times. This leads to substantial financial benefits. For example, switching from vertical to horizontal CNC Machining Centers can increase throughput by an average of 45%. This impressive gain happens for several reasons. Chips fall away from the cutting surface. This prevents them from interfering with coolant. It also stops them from slowing down metal removal rates.

HMCs offer increased spindle utilization. They also reduce setup time. You can cut all five sides of a part in one operation. This keeps the machine spindle running continuously. Sharing tool changes across multiple parts also saves valuable time. Machine time is a critical cost factor in CNC machining. Longer machining times directly increase expenses. They also impact production capacity. Reducing cycle times through improved cutting processes directly lowers production costs.

Consider a customer example: they cut 16 stainless steel parts in one cycle. They used shared tools. The cycle time was under 45 minutes. This led to a return on investment in just three months. HMCs are operations where costs can accumulate. So, efficiency gains in these machines lead to significant cost reductions.

Labor Cost Reduction Through Automation

Horizontal machining centers also reduce labor costs. They need fewer operator touches. One HMC can replace four vertical machining centers. This means one operator can manage the work of four. Operators can comfortably tend more than one machine. This boosts productivity without increasing staff.

Implementing work cells further enhances labor savings. These cells run processes in parallel. They handle value-added tasks during the machining cycle. This reduces total process time. It also saves labor costs. This strategic approach maximizes human resources.

Material Waste Minimization

HMCs help minimize material waste. Reduced part handling means fewer errors. This helps maintain product quality. When you cut all sides of a part in one operation, you reduce the chance of mistakes from re-clamping. Mistakes often lead to scrapped parts.

Using combination tools also helps. These tools cut multiple features at once. This decreases cycle times. It also reduces the chance of errors that could lead to material waste. The superior thermal stability and accuracy of HMCs (as discussed earlier) also contribute to less scrap. They ensure consistent part quality throughout long production runs.

Energy Efficiency Considerations

Manufacturers often overlook energy consumption. However, it significantly impacts the bottom line. Horizontal machining centers offer notable energy efficiencies. These efficiencies contribute to a higher return on investment. They help reduce operational costs over time.

Think about the reduced cycle times. HMCs complete parts faster. This means the machine runs for less time per part. Less run time directly translates to lower electricity usage. Every minute saved on the machine adds up. This becomes a substantial energy saving in high-volume production.

Modern HMCs also feature advanced energy-saving technologies. They often include intelligent power management systems. These systems can automatically shut down non-essential components during idle periods. For example, they might turn off coolant pumps or auxiliary motors when not in use. Some machines even have variable speed drives for their main motors. These drives adjust motor speed based on the load. This prevents motors from running at full power unnecessarily. This smart power usage reduces overall energy demand.

Consider the chip evacuation process. Gravity helps chips fall away from the cutting zone in an HMC. This natural process requires less energy. Vertical machining centers, on the other hand, often need more powerful coolant pumps or chip conveyors. These systems actively fight gravity to remove chips. This uses more electricity. The efficient chip removal in HMCs also prevents chip re-cutting. Re-cutting chips wastes energy and wears out tools faster.

Automation also plays a role in energy efficiency. HMCs are highly compatible with lights-out manufacturing. This means they can run unattended for long periods. Manufacturers can schedule these runs during off-peak electricity hours. Electricity rates are often lower during these times. This strategy significantly reduces energy costs. It also maximizes machine utilization without increasing the energy bill during peak hours.

Finally, the overall efficiency of HMCs minimizes wasted energy. Their ability to machine multiple sides in one setup reduces errors and scrap. Producing fewer defective parts means less energy wasted on materials that end up in the trash. Superior thermal stability also ensures consistent part quality. This prevents energy-intensive reworks. All these factors combine to make HMCs a more energy-efficient choice for high-volume manufacturing.

Strategic Investment: Initial Cost vs. Long-Term Gains for CNC Machining Centers

Amortizing Higher Upfront Investment

Horizontal machining centers often come with a higher initial price tag than their vertical counterparts. However, manufacturers should view this as a strategic investment. The advanced capabilities of HMCs, such as multi-sided machining and superior chip evacuation, lead to significantly higher throughput and reduced cycle times. These efficiencies quickly translate into increased production volume and lower per-part costs. This allows businesses to amortize the initial investment much faster through greater profitability and operational savings.

Maintenance and Downtime Cost Analysis

While HMCs are complex machines, their robust design and integrated automation often lead to lower effective maintenance costs and reduced downtime. Their efficient chip management systems prevent issues that can plague VMCs, like chip re-cutting or tool wear from debris. Many modern HMCs also incorporate predictive maintenance features. These systems monitor machine health in real-time, allowing teams to address potential problems before they cause costly breakdowns. This proactive approach minimizes unexpected downtime, keeping production lines running smoothly and maximizing machine uptime.

Scalability and Future Production Needs

Investing in HMCs prepares a company for future growth. Automated pallet systems, for instance, provide a foundation for flexible automation. They allow continuous production by letting one pallet be machined while another is loaded. This setup supports extended unattended operation, including during off-shifts, significantly increasing available production time. Automation systems can boost machine utilization from 30-40% to 70-85% or higher. This minimizes downtime during setup and changeover. Horizontal machining centers offer high scalability through various worktable sizes, like single or double pallet options. This design helps them meet diverse product processing needs across different industries. It also effectively handles the demands of large-scale automated product lines. Future scalability will also benefit from the increased integration of HMCs with Industry 4.0 technologies by 2025. This includes IoT connectivity and real-time data analytics.

When VMCs Still Make Sense: Niche CNC Machining Center Applications

While Horizontal Machining Centers (HMCs) offer significant advantages for high-volume production, Vertical Machining Centers (VMCs) still hold a crucial place in many workshops. They excel in specific applications where their design and cost structure provide a better fit.

Prototyping and Low-Volume Runs

VMCs are often the go-to choice for prototyping and low-volume production. Their simpler setup and programming make them ideal for quickly bringing new designs to life. Manufacturers find them versatile for testing new concepts without a large initial investment.

- Part Geometries: VMCs handle flat, simple parts very well. They also excel with parts needing detailed contouring.

- Production Volumes: They are perfect for low to medium production volumes or creating prototypes.

Their versatility makes them excellent for prototyping new designs. This allows for scaling up to production without changing processes.

Large, Flat Part Machining

VMCs shine when machining large, flat parts. The vertical spindle allows gravity to assist in holding the workpiece firmly on the table. This setup provides excellent stability for wide, thin components. Operators can easily load and secure these parts. The open work envelope of a VMC also offers better visibility of the cutting process. This helps with inspection and adjustments during machining.

Budgetary Constraints and Entry-Level Operations

For businesses just starting out or those with tighter budgets, VMCs present a more accessible entry point into CNC machining. Their lower initial cost makes them an attractive option.

| Machining Center Type | Entry-Level Price Range |

|---|---|

| Vertical | $20,000 – $55,000 |

| Horizontal | $63,000 – $82,000 |

This significant price difference allows smaller shops to acquire reliable machining capabilities. They can begin production without the substantial capital outlay required for an HMC. VMCs offer a cost-effective solution for many manufacturing needs.

Horizontal CNC Machining Centers clearly provide a significant and measurable ROI advantage for high-volume production in 2025. Their inherent efficiencies directly translate into substantial cost savings and increased profitability for businesses. Therefore, investing in HMC technology represents a strategic move for manufacturers. It helps them achieve peak performance and gain a competitive edge in the market, especially when considering a high-volume Cnc Machining Center setup.

FAQ

Why do HMCs excel in high-volume production?

HMCs machine multiple sides in one setup. They also remove chips efficiently. This reduces handling and cycle times. These features significantly boost throughput for large batches.

How do HMCs contribute to a higher ROI?

HMCs reduce labor costs through automation. They minimize material waste and improve energy efficiency. Their faster production cycles mean more parts per hour. This directly increases profitability.

When is a VMC a better choice for a manufacturing operation?

VMCs are ideal for prototyping and low-volume runs. They also suit large, flat parts. Companies with tighter budgets often find VMCs a more accessible entry point into CNC machining.

What role does automation play in HMC efficiency?

Automation, like pallet systems, allows HMCs to run unattended. This enables “lights-out” manufacturing. It significantly increases machine utilization and reduces labor needs. This boosts overall productivity.

Post time: Dec-08-2025