The advantages of 5-axis vertical machining center in the aerospace field lie in their ability to complete complex multi-faceted machining in a single setup, significantly improving machining accuracy and efficiency. This meets the manufacturing requirements of complex geometries and high-performance materials, effectively reducing production costs and ensuring the quality stability of key components.

With the rapid development of the aerospace industry, the requirements for machining accuracy and efficiency of aircraft parts are increasing. As a high-precision, high-efficiency CNC machine tool, the five-axis vertical machining center is finding increasingly widespread application in the aerospace field. This machine tool integrates three linear axes (X, Y, Z) and two rotary axes (A, B, or C), achieving complex simultaneous motion in five degrees of freedom, suitable for the precise machining of complex curved surfaces and three-dimensional parts. This article will discuss its characteristics, aerospace applications, and advantages in detail.

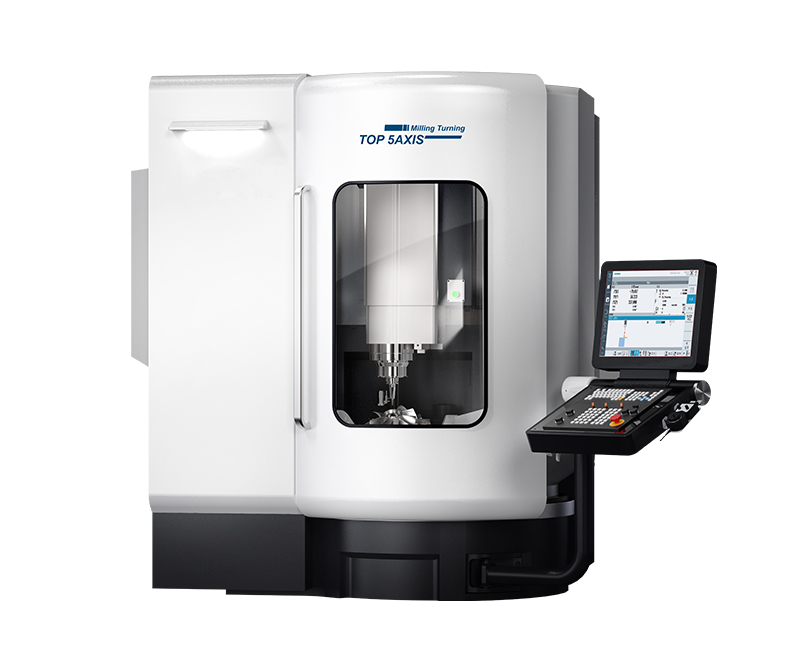

Core Features of Five-Axis Vertical Machining Centers

Five-axis vertical machining centers employ a multi-axis simultaneous design, enabling the workpiece to achieve continuous trajectory motion in five directions, avoiding the multiple positional errors of three-axis machine tools. A high-rigidity cast iron bed, precision ball screws, and linear guides ensure high-speed turning stability. Spindle speeds can reach 24,000 RPM, supporting difficult-to-machine materials such as titanium alloys, with micron-level repeatability.

Advanced CNC systems such as Siemens or Fanuc support complex CAM programming and real-time error compensation, maintaining optimal turning angles, improving surface finish Ra to 0.4μm, and reducing tool wear. Compared to three-axis machine tools, it completes multi-face machining in a single setup, significantly improving efficiency.

Specific Applications in the Aerospace Industry

· Blade Machining

Aircraft engine blades have complex shapes and thin-walled structures, requiring extremely high precision. 5-axis vertical machining centers achieve integrated roughing and finishing of the blade back, blade base, and blade tip, completing multi-face milling in a single setup, ensuring a contour error of less than 0.01mm. They are widely used in turbine blade projects for the Aero Engine Corporation of China.

· Fuselage Structural Component Machining

Spallations, panels, and frame parts are large and made of aluminum or titanium alloys. Five-axis machine tools provide a large stroke and a high-rigidity bridge structure, supporting deep hole machining on long shafts. In the C919 large passenger aircraft project, it is used for precision frame panel surface machining, improving assembly accuracy and cycle time.

· Other complex parts machining

Suitable for deflectors, shock absorbers, and integral bladed disks (Blisks). The machine tool handles flow channel milling of Inconel materials, with a roundness error of less than 0.005mm, and is also used in missile and UAV component production.

Significant advantages of the five-axis vertical machining center

High precision through multi-axis synchronization to eliminate errors, meeting aerospace IT5 tolerance levels. High efficiency is reflected in a 30%-50% reduction in machining cycle time, reducing non-turning time by performing multiple operations in a single setup.

High flexibility, supporting rapid tool changes (<2 seconds) and program switching, adapting to small-batch, multi-variety production. Automated integration of robotic loading/unloading and online inspection enhances the level of unmanned production lines.

The 5-axis vertical machining center significantly improves the machining capabilities of complex aerospace parts with its high precision, high efficiency, and flexibility. It completes multi-faceted machining of blades, fuselage structural components, etc., in a single setup, promoting the independent control of domestically produced large passenger aircraft.

OTURN offers high-performance five-axis vertical machining centers equipped with a precision multi-axis simultaneous system and advanced CNC control to meet the high-precision requirements of aerospace blades, structural components, and other products. It also supports difficult-to-machine materials such as titanium alloys, helping companies achieve efficient and flexible production.

Post time: Dec-09-2025