A CNC vertical machining center (VMC) is a CNC machine tool with a spindle axis perpendicular to the worktable. It is automatically controlled by a computer program, enabling efficient machining of high-precision, multi-faceted, and multi-process parts. With the continuous upgrading of the automotive industry, high-precision and high-efficiency parts manufacturing has become a key competitive advantage for companies. CNC vertical machining centers, with their superior technological advantages, have become a vital tool for automotive parts processing.

Key Points:

· Key technologies ensure high precision and stability, meeting the demands of complex parts.

· Widely used in engines, chassis, and new energy vehicles, they improve efficiency and quality.

· Intelligent automation shortens cycle times, reduces costs, and accommodates diversified production.

I. Core Technology Highlights of CNC Vertical Machining Centers

· High-Precision CNC System and Intelligent Control

Advanced CNC systems, combined with artificial intelligence and real-time monitoring, enable precise positioning and dynamic parameter adjustment, ensuring stable and reliable machining processes and meeting the complex geometries and tight tolerances required of automotive parts.

· High-rigidity Machine Structure

The CNC machine tool is constructed of high-strength cast iron or steel, and its structural design is optimized through finite element analysis. This significantly reduces machining vibration and thermal deformation, improving machining accuracy and tool life, thereby ensuring the dimensional stability and surface quality of automotive parts.

· Multi-process, multi-tool automatic tool-changing system

Supports the completion of multiple processes in a single clamping, reducing clamping errors and production cycle time, meeting the requirements of combining mass production with flexible manufacturing in automotive manufacturing.

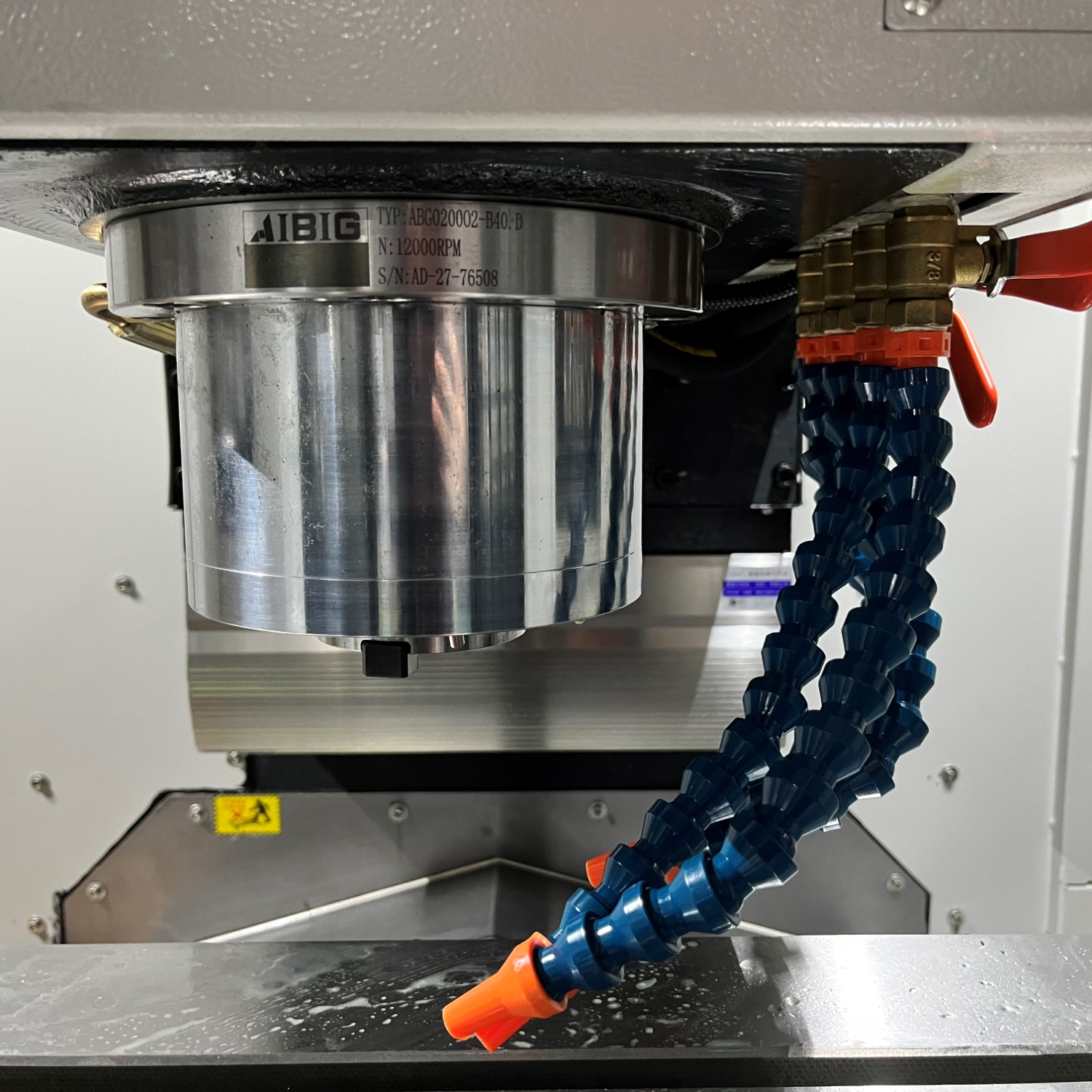

· Efficient Cooling and Lubrication System

Optimized cooling channel design reduces heat buildup, and the automatic lubrication system ensures long-term stable operation of tools and machine components, extending equipment life and addressing the complex thermal conditions associated with machining diverse materials.

These four technical features are highly compatible with the diverse materials, high-precision machining, batch and flexible requirements, and quality and durability standards of automotive manufacturing, and are key to ensuring efficient and stable automotive parts manufacturing.

II. Typical Applications of CNC Vertical Machining Centers in Automotive Parts

· Engine assembly parts: These key components, including cylinder blocks, crankshafts, and camshafts, require extremely high dimensional and surface accuracy. Vertical machining centers, with their high rigidity and intelligent control, meet these precision machining needs.

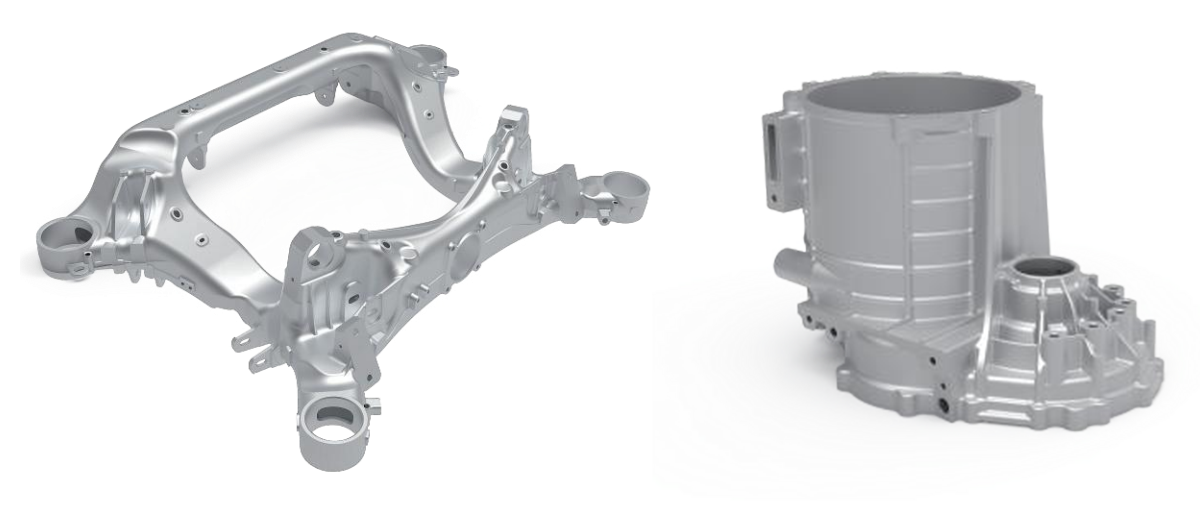

· Chassis system parts machining: Components such as suspension walls and subframes require mechanical strength and machining stability. Vertical machining centers ensure structural stability with their high dynamic rigidity and efficient turning capabilities.

· New energy vehicle parts: Parts such as battery trays and modules emphasize lightweighting and consistency. CNC vertical milling machine offer high precision and flexible machining to meet the industry’s upgrading needs.

· Other automotive parts and fixtures: Processing a variety of parts, including precision brackets and connectors, enables integrated production and significantly improves assembly accuracy.

III. Advantages of CNC vertical machining centers in automotive manufacturing

· Improves machining accuracy and part quality, meeting the stringent standards for automotive parts.

· Shortened production cycles, increased production efficiency, and the ability to effectively meet the demands of high-volume manufacturing.

· Reduced manual operation risks, enabling automated and intelligent production.

· Reduced material waste, significantly reducing production costs.

· Flexible adjustment capabilities accommodate small-batch, high-mix production requirements.

· Stable equipment operation ensures long-term, continuous production.

· High-quality customer support drives continuous process optimization and technological upgrades.

IV. Summary

In the future, CNC vertical machining centers will deeply integrate the concepts of Industry 4.0, enabling intelligent manufacturing and digital factories. Multi-axis machining, automated loading and unloading, and in-line inspection will become the norm, significantly improving machining efficiency and quality.

Overall, the technical advantages and application value of CNC vertical machining centers are closely linked. They are irreplaceable core equipment in modern automotive parts manufacturing, contributing to industrial upgrading and enhancing market competitiveness.

Post time: Oct-06-2025