CNC turning machines fundamentally transform manufacturing. They enable unparalleled precision, efficiency, and versatility, producing complex components across various industries. These machines meet stringent Precision CNC Turning Requirements. They deliver high-quality output for many applications. For example, CNC Machined Components for Hardware rely on this technology. This advanced Precision CNC Turning capability sets new industry standards. Meeting strict CNC Turning Tolerances is crucial for product integrity. Furthermore, ISO 13485 compliant CNC turning is vital for specialized sectors. A CNC Turning Machine truly shapes the future of production.

Key Takeaways

- CNC turning machines make parts with great accuracy for cars, planes, and medical devices. This helps these products work better and be safer.

- These machines help create new electric car parts and lighter airplane components. This pushes forward how we travel and move.

- CNC turning machines make small, precise parts for medical tools and implants. This helps doctors give better care to patients.

- These machines help make many different hardware items, from simple screws to parts for smart home devices. They support new inventions.

- CNC turning machines work with robots to make factories more automated. They also help create custom products quickly and efficiently.

1. Automotive Industry: How CNC Turning Machine Ensures Performance and Safety

Requirements for Automotive Components

The automotive industry demands extreme precision and reliability from every component. Each part, from the smallest fastener to the largest engine block, must perform flawlessly under harsh conditions. For instance, automotive fasteners often require tight tolerances, ranging from ±0.01 mm to ±0.1 mm. Critical engine assembly components need even tighter specifications, sometimes as low as ±0.005 mm. Threads must meet precise standards to prevent stripping, and surface finishes, like Ra 1.6 to Ra 3.2 µm, are crucial for minimizing friction and wear. Consider the cylinder head and block; they need a flatness of ≤0.02 mm and precise cylinder bore concentricity. Camshaft lobes, vital for valve timing, demand an accuracy of ±5 μm. These exacting standards ensure vehicle performance and safety.

Impact on Future Vehicle Manufacturing

CNC turning machines are vital for the automotive industry’s future, especially with the rise of electric vehicles (EVs). They help create lightweight, durable, and complex parts. For example, CNC machining reduces EV weight by creating innovative dies for body panels and pocketing internal components. It also machines lightweight aerospace materials for vehicles. Within EV battery packs, extremely precise CNC machining produces components like rotary shafts and configurable plates. This ensures tight seals, protecting against vibration, extreme temperatures, and moisture.

Tip: CNC machining ensures flawless manufacturing, meeting expectations for less maintenance and perfect surface finishes. This is critical for quiet EVs, where precise components eliminate rattles and squeaks.

While traditional engine components require less machining in EVs, there is high demand for machined parts like motor housings, precision shafts, and bearings, all needing tight tolerances. CNC turning machines enable the production of these high-precision components, optimizing EV performance, efficiency, and safety. They support breakthroughs in electric mobility, boosting vehicle range and maintaining superior reliability.

2. Aerospace Industry: Uncompromising Accuracy with CNC Turning Machine for Critical Components

Aerospace Manufacturing Demands

The aerospace industry operates under extreme conditions. This demands components with unmatched precision and reliability. Parts like jet engines, fuel systems, and flight-critical components need very tight tolerances. These can be as precise as ±0.005 mm to ±0.01 mm. Such exact specifications ensure optimal thrust, reduce vibration, and guarantee long-term safety during high-altitude and high-speed operations.

Manufacturers also use advanced materials for these parts. These include titanium alloys and nickel-based superalloys. These materials offer exceptional strength and can handle very high temperatures. For example, turbine blades often use superalloys like Rene 77, CMSX-4, or Inconel. These alloys were developed over decades, with new processing methods like vacuum induction melting and single crystal production improving their strength. Ceramic matrix composites (CMCs) are also emerging. They can withstand even higher temperatures, making them crucial for future engine designs.

Advancing Future Air and Space Travel

CNC turning machines are essential for meeting these strict aerospace requirements. They produce lightweight, high-strength parts. These parts have the necessary precision and surface finish for safe flight. CNC turning creates critical cylindrical components. These include shafts, threaded fasteners, pins, and bushings.

For larger structural parts like fuselage frames and wing ribs, CNC machining mills aluminum or titanium billets. This creates pocketed geometries. It minimizes mass while keeping rigidity. This “integral machining” method reduces the number of fasteners. It also improves how well parts resist fatigue. As aerospace moves towards more composites, titanium, and next-generation alloys, CNC turning provides the precise interfaces these materials need. This technology helps advance future air and space travel by ensuring every component performs perfectly.

3. Medical Industry: CNC Turning Machine for Miniaturization and Biocompatibility

Precision for Medical Devices and Implants

The medical industry demands incredible precision for devices and implants. These components often need to be very small. This miniaturization presents unique challenges. For example, smaller devices can have decreased power transfer efficiency. This limits how deep doctors can implant them. It also means they need more power. Smaller microdevices also have reduced energy harvesting and supply voltage. This is especially critical for stimulating implants. Aligning these tiny devices to their power source for optimal efficiency is also difficult. Controlling their orientation during or after injection is a big hurdle.

The internal body environment adds more challenges. Electrical connectivity and communication become complex. Implants can corrode inside the body. Manufacturers must ensure devices are robust and hermetic. This means they must be completely sealed. Reducing device size without losing quality is key. They also need to ensure application-specific qualities, like flexible guidewires, remain reliable. Maintaining biocompatibility is crucial. This means the body will not reject the device. Manufacturing smaller, finer medical wires requires great precision and expertise. This includes knowledge of metallurgy and process development.

Shaping Future Healthcare Solutions

CNC turning machines are vital for shaping future healthcare solutions. They help create personalized medical devices. These machines produce implants specifically for an individual’s body. This customization makes implants more compatible and effective. It leads to better patient outcomes. Using advanced materials and precise machining, these custom implants integrate well with the body. They offer highly individualized solutions. For example, doctors can create cranial implants for a trauma patient’s skull. They use medical-grade titanium and precise models. Tailored dental implants, hip replacements, and hearing aid housings are also possible.

Many biocompatible materials are machined using CNC turning. Titanium alloys are a top choice for orthopedic implants. They have excellent strength, low density, and a high strength-to-weight ratio. This allows them to handle body loads while staying light. CNC turning precisely carves complex shapes in titanium. This helps implants fit human skeletal contours. It improves stability and biocompatibility. Stainless steel is also important for surgical tools and some implants. It resists corrosion and is very durable. CNC turning provides high accuracy for stainless steel. This ensures sharp cutting edges for tools. It also makes implants more durable and resistant to fatigue. This ensures consistency and accuracy. It also allows for delicate designs, like microfluidic channels. These channels improve how medical devices work.

4. Hardware Industry: Versatility of CNC Turning Machine for Everyday and Specialized Components

Diverse Needs of Hardware Production

The hardware industry makes many different parts. These range from simple screws to complex industrial components. Each part needs specific materials and precise shapes. Manufacturers use various metals like steel, aluminum, titanium, brass, copper, and stainless steel. For example, stainless steel is strong and resists rust, making it great for shafts and bolts in tough environments. Aluminum is light, strong, and easy to machine, so it appears in many consumer products. Brass is durable and good for plumbing fittings. A CNC Turning Machine handles all these materials with great accuracy.

Powering Future Consumer and Industrial Tech

CNC turning plays a big role in creating new hardware. It helps with rapid prototyping, which means making quick test versions of new designs. For example, engineers use CNC turning to create precise shafts or pins for new products. This process ensures high accuracy, often within ±0.005 mm, and a smooth surface finish. This makes it perfect for testing new gears or other rotating parts. Beyond prototyping, CNC turning also makes parts for smart home devices. It produces precise housings, sensor brackets, and control modules. These parts need tight tolerances for electronics to fit perfectly and for the devices to look good. This technology supports both making a few custom items and producing many items at once. It helps power the next generation of consumer gadgets and industrial equipment.

5. Cross-Industry Impact: CNC Turning Machine Driving Automation and Customization

Integration with Advanced Manufacturing Systems

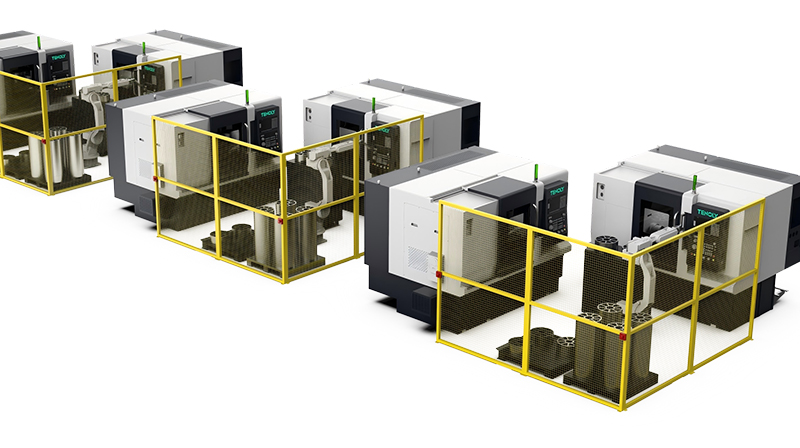

CNC turning machines are not standalone tools. They integrate seamlessly with advanced manufacturing systems. This integration drives automation across industries. For example, combining them with robotic systems brings many benefits. Robots can load and unload parts, inspect them, and transfer materials. This reduces downtime and increases productivity. Robots also ensure precise part placement, which minimizes human error and improves product quality. They can handle dangerous tasks, making the workplace safer for humans. While robots have initial costs, they offer long-term savings. They operate 24/7, reduce labor costs, and can even extend the life of CNC machines.

Our CNC Swiss screw machines already have 12-foot bar feeders on them. These allow us to run parts when no one is at the machine.

This capability is key for “lights-out” manufacturing. Bar feeders make lathes ready for automated workpiece loading. This means factories can run production even without human operators present. This level of automation is a core principle of Industry 4.0. CNC turning machines support intelligent CNC systems with smart diagnostics. They use real-time data to optimize production. They also connect to other systems through IIoT platforms and cloud integration. This creates flexible manufacturing networks.

Enabling Future Production Paradigms

CNC turning machines are crucial for future production. They enable mass customization. This means manufacturers can produce custom parts in large quantities. Computer controls ensure high accuracy and repeatability. This makes CNC turning perfect for mass manufacturing custom items. The automated process reduces labor and setup times. This offers an economical way to bring customized products to market quickly.

CNC custom machining provides great flexibility. It allows for diverse shapes, materials, and surface finishes. This is very different from traditional mass production, which focuses on uniformity. Manufacturers can create single prototypes, small batches, or custom parts for specific designs. This flexibility speeds up product development. Companies can test and refine designs in days, not weeks or months. On-demand CNC machining services also make world-class machining accessible. Businesses can reduce overhead and scale production based on real-time demand. This aligns perfectly with agile product development, where flexibility is essential for customization.

CNC turning machines are more than just tools; they are foundational pillars. They shape manufacturing’s future by meeting diverse industries’ stringent demands. Their continuous evolution in precision, automation, and material handling drives innovation. This efficiency creates increasingly sophisticated products. The CNC Turning Machine plays an indispensable role in global production across automotive, aerospace, medical, and hardware sectors. It truly solidifies its position.

FAQ

What is a CNC turning machine?

A CNC turning machine uses computer control to shape materials. It rotates a workpiece against a cutting tool. This creates precise cylindrical parts. Manufacturers use it for high accuracy and efficiency in production.

How does CNC turning improve manufacturing?

CNC turning boosts precision, efficiency, and versatility. It makes complex components with tight tolerances. This reduces errors and waste. It also speeds up production times for many industries.

Which industries rely on CNC turning machines?

Many industries use CNC turning. These include automotive, aerospace, medical, and hardware. It produces critical parts for cars, planes, medical devices, and everyday items.

Can CNC turning create custom parts?

Yes, CNC turning excels at customization. It allows manufacturers to produce unique parts in various shapes and materials. This supports rapid prototyping and mass customization for specific designs.

How does CNC turning contribute to automation?

CNC turning integrates with robots and advanced systems. This enables automated loading, unloading, and inspection. It supports “lights-out” manufacturing and Industry 4.0 principles, increasing productivity and safety.

Post time: Dec-04-2025