China holds a pivotal role in global CNC manufacturing. The country projects a 16.4% Compound Annual Growth Rate (CAGR) for generative CNC technology from 2025 to 2035, positioning it as the fastest-growing nation in this segment. By 2025, the CNC rate for key processes in China’s machine tool industry is expected to reach 64%. This robust growth makes Chinese manufacturers a leading choice for global buyers seeking a Cnc Machine For Sale. They offer advanced solutions, from a precise Horizontal Machining Center to a versatile Cnc Vertical Machining system. Many ask, “Which companies are the top CNC machine manufacturers in China?” These manufacturers consistently deliver high-quality 5 Axis Cnc Machine options and other specialized equipment.

Key Takeaways

- China is a major leader in making CNC machines. It shows fast growth and new technology.

- Chinese CNC makers offer good prices. They use advanced technology and can make many products.

- When choosing a Chinese maker, check their quality. Look for good customer service and new ideas.

- Top Chinese CNC companies include SMTCL, DMTG, and Beijing Jingdiao. They make many different machines.

- The CNC industry in China is changing. It uses more robots, smart factories, and green methods.

Key Advantages of Partnering with Chinese CNC Manufacturers

Cost-Effectiveness and High Value Proposition

Chinese CNC manufacturers offer significant cost advantages. Their manufacturing costs are often much lower compared to regions like the United States. This primarily results from competitive labor and material expenses. Businesses can expect substantial savings when choosing CNC manufacturing in China. For example, labor costs in China range from $6 to $12 per hour, significantly less than the $35 to $50 per hour in the United States. China also benefits from affordable raw materials due to its extensive manufacturing infrastructure. This allows for efficient equipment and maintenance practices.

| Region | Cost Advantage | Cost Disadvantage |

|---|---|---|

| China | Labor costs are $6 – $12 / hour; Large-scale manufacturing advantage with 37% of factories having over 100 CNC machines. | 13% – 17% VAT (export refundable); Rising environmental protection and land costs. |

| United States | Natural gas prices are 30% lower than in China; Automation helps reduce overall costs for non-core tasks. | High labor costs; Industrial chain fragmentation leads to high logistics costs. |

Integration of Advanced Manufacturing Technologies

Chinese manufacturers actively integrate advanced technologies into their CNC processes. They utilize automation with robotic arms and Automated Guided Vehicles (AGVs). For instance, BYD’s Shenzhen facility implemented fully automated CNC lines. This led to a 30% reduction in labor costs and a 25% increase in throughput. Manufacturers also employ closed-loop control systems and real-time feedback loops. These systems enhance precision, achieving tolerances as tight as ±0.001 mm in high-end applications. Advanced CNC processes include high-speed 5-axis milling and turning with live tooling. They also use Electrical Discharge Machining (EDM) with 0.1 µm resolution and fiber laser cutting. Hybrid manufacturing systems combine additive and subtractive processes. Firms like Xi’an Bright Laser Technologies pioneered these systems. They achieve material efficiencies up to 30%.

Extensive Production Capacity and Scalability

China possesses vast production capacity and offers excellent scalability. Its manufacturing sector includes numerous large factories. Many of these factories operate over 100 CNC machines. This extensive infrastructure allows Chinese manufacturers to handle large-volume orders efficiently. They can also scale production quickly to meet fluctuating demands. This capability makes them ideal partners for global buyers needing consistent supply and flexible production solutions. Their robust supply chains further support this capacity, ensuring timely delivery and efficient resource management.

Customization Capabilities and Design Flexibility

Chinese CNC manufacturers excel in offering extensive customization capabilities. They provide significant design flexibility for various industrial applications. These manufacturers deliver comprehensive solutions. This includes design optimization, material sourcing, and precision finishing like anodizing or powder coating. They also handle final assembly. Their advanced technological capabilities are notable. These include five-axis machining and micron-level tolerance control, often achieving ±5μm. Some even use hybrid CNC-3D printing for highly complex designs.

Manufacturers offer flexibility for production runs. They accommodate both one-off prototyping and large-scale production. They also provide Design for Manufacturing (DFM) support. This optimizes designs for efficient production. Chinese manufacturers work with a wide range of materials. These include various metals like aluminum, copper, titanium, and stainless steel. They also process non-metal materials such as plastics like ABS, PEEK, polycarbonate, and POM. Their diverse machining services include CNC milling, turning, EDM, and wire EDM. They also offer various surface treatments. These include anodizing, plating, and powder coating. Manufacturers achieve high precision with tight tolerance control, often as precise as ±0.005 mm or ±0.001 inches.

Robust and Efficient Supply Chain Networks

Chinese CNC manufacturers benefit from robust and efficient supply chain networks. These networks are a significant advantage. China’s vast industrial ecosystem supports these manufacturers. This ensures a steady and diverse supply of raw materials and components. The country’s well-developed logistics infrastructure further enhances efficiency. This includes extensive road, rail, and port systems. These systems facilitate quick movement of goods. Manufacturers can source materials rapidly. They can also deliver finished products on time. This efficiency reduces lead times for global buyers. It also helps maintain competitive pricing. The integrated nature of these supply chains allows for seamless production. This minimizes disruptions and ensures consistent output quality.

Critical Factors for Selecting the Right Chinese CNC Manufacturer

Selecting the right Chinese CNC manufacturer requires careful consideration of several critical factors. These elements ensure a successful partnership and high-quality outcomes.

Adherence to Quality and Precision Standards

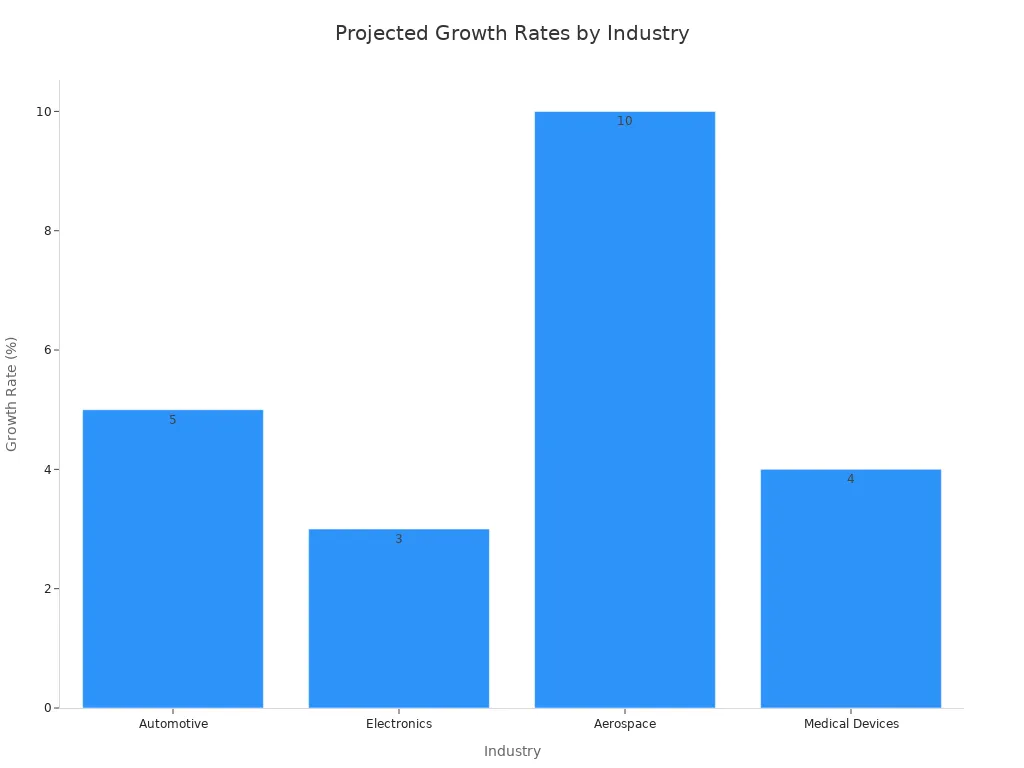

Manufacturers must demonstrate a strong commitment to quality and precision. Top Chinese CNC machine manufacturers commonly meet international standards such as ISO 9001. They also adhere to industry-specific certifications like IATF 16949 for automotive applications and ISO 13485 for medical devices. Precision is a cornerstone of their operations. They achieve tolerances as tight as ±0.001 mm for high-end applications. For example, GENSUN adheres to ISO 9001:2015 and achieves precision up to ±0.001mm. Runsom Precision meets ISO standards, including ISO 9001, with tolerances of ±0.0005 inches and ±0.01 mm. Tik Precision also holds ISO 9001 certification, indicating high-precision machining capabilities.

Comprehensive After-Sales Service and Technical Support

Reliable after-sales service and technical support are essential. Leading Chinese CNC manufacturers offer extensive support packages. These often include a one-year or more warranty for different CNC machines, often with lifetime maintenance. They provide 24/7 technical support through various channels like phone, email, Skype, WhatsApp, and online live chat. Manufacturers also offer free training for basic CNC machine operation. They supply user-friendly multi-language user manuals and instructional documents. Their professional after-sales teams provide comprehensive solutions, including product installation, commissioning, and maintenance services. They ensure quick responses to customer problems and offer personalized customization services, even upgrading robot arms. Many maintain 24-hour after-sales service hotlines and tracking systems, conducting regular satisfaction surveys.

Industry Certifications and Regulatory Compliance

Manufacturers must hold relevant industry certifications and comply with regulations, especially for international markets. For European markets, CE certification is mandatory. It ensures compliance with safety, health, and environmental standards. UKCA certification is necessary for the UK market, similar in scope to CE. GS certification, though voluntary, holds high recognition for electrical products. BSCI factory inspection is important for social responsibility audits. For the United States, UL Certification ensures product safety. FCC Certification is mandatory for electronic products, focusing on EMC and RF radiation. ETL Certification indicates testing to relevant industry standards. ISO 9001, a quality management system, is fundamental for market entry. ISO/TS 16949 is crucial for the automotive supply chain.

Investment in Innovation and Research & Development

Leading Chinese CNC manufacturers prioritize innovation. They invest heavily in research and development (R&D). This commitment drives technological advancements and improves machine performance. Many top manufacturers allocate a significant portion of their revenue to R&D.

| Metric | 2021 | 2022 |

|---|---|---|

| R&D Investment (% of Revenue) | 8% | 8% |

For example, Shenzhen Han’s CNC Technology Co., Ltd. invests approximately 5% of its total revenue in R&D. This dedication leads to new product development and enhanced existing models. Manufacturers focus on areas like automation, smart manufacturing, and advanced materials. Their R&D efforts ensure they remain competitive globally. They also meet the evolving demands of various industries.

Manufacturer Reputation and Customer Testimonials

A manufacturer’s reputation offers crucial insights into their reliability and product quality. Buyers should research a company’s history and market standing. Online reviews, industry awards, and case studies provide valuable information. Positive customer testimonials often highlight consistent performance and excellent support.

Reputable manufacturers build long-term relationships with clients. They demonstrate a commitment to customer satisfaction. Direct communication with past clients can also confirm a manufacturer’s claims. A strong reputation indicates a trustworthy partner for CNC machine procurement. It assures buyers of quality products and dependable service.

Identifying the Top CNC Machine Manufacturers in China for 2025

China’s manufacturing sector continues to lead globally, with several companies standing out as the top CNC machine manufacturers. These firms demonstrate innovation, extensive product ranges, and significant market influence. They cater to diverse industrial needs, from heavy-duty applications to high-precision tasks.

Shenyang Machine Tool Group (SMTCL)

Shenyang Machine Tool Group (SMTCL) stands as a prominent global player in the CNC machine industry. The company offers a comprehensive range of CNC machines. This includes advanced lathes and complex machining centers. SMTCL demonstrates a significant global presence in the industry.

| Category | Details |

|---|---|

| Main Product | Five-axis CNC machining centers |

| Diverse Portfolio | 5-axis CNC machining centers, horizontal and vertical machining centers, CNC lathes, specialized automation technologies |

| Main Markets | Aerospace, automotive, defense, and precision engineering industries globally |

| Key Sectors | Aerospace, automotive, precision engineering, energy sectors |

| Proprietary Technology | i5 platform control systems |

| Business Type | Manufacturer of CNC machine tools and industrial solutions |

SMTCL’s product portfolio is notably diverse. It includes five-axis CNC machining centers, which represent a main product offering. The company also manufactures horizontal and vertical machining centers, alongside various CNC lathes. SMTCL integrates specialized automation technologies into its solutions. Its primary markets span critical sectors such as aerospace, automotive, defense, and precision engineering industries worldwide. The company also serves the energy sector. SMTCL distinguishes itself with proprietary technology, specifically its i5 platform control systems. As a manufacturer of CNC machine tools and industrial solutions, SMTCL consistently delivers advanced machinery to a global clientele.

Dalian Machine Tool Group (DMTG)

Dalian Machine Tool Group (DMTG) is a major manufacturer known for its robust and diverse range of machine tools. The company provides heavy-duty and specialized industrial solutions. DMTG’s offerings cater to a wide array of manufacturing requirements.

DMTG’s primary heavy-duty machine tool offerings for industrial clients include:

- CNC Lathes

- Machining Centers

- Five Axis CNC Milling Machines

- Turning And Milling Machining Centers

- Manual Lathes

- Intelligent Manufacturing Production lines

The company also specializes in:

- CNC Turning Centers

- Vertical Machining Centers

- Horizontal Machining Centers

- Gantry Machining Centers

- Boring & Milling Machines

- Conventional Lathes

- 5 Axis Vertical Machining Centers

DMTG’s extensive product line highlights its capability to support various industrial applications. From precision CNC turning to complex five-axis milling, DMTG provides reliable and efficient machinery. Its intelligent manufacturing production lines also offer integrated solutions for modern factories.

Qinchuan Machine Tool & Tool Group (QCMT&T)

Qinchuan Machine Tool & Tool Group (QCMT&T) specializes in precision grinding and gear manufacturing technologies. The company offers a comprehensive range of machines designed for high accuracy and efficiency in these specialized fields.

QCMT&T utilizes specific precision grinding and gear manufacturing technologies, including:

- CNC & Manual Gear Grinders: These include worm, cone, and form wheel types, suitable for various applications.

- CNC & Manual Shaving Cutter Grinders.

- CNC & Manual OD/Cylindrical Grinders: These cater to standard, universal, high-speed, camshaft, crankshaft, bearing, and specialty markets.

The company’s product range further encompasses:

- Cylindrical grinding machines

- Gear cutting machines

- Thread grinding machines

- Precision gears

QCMT&T also produces gear grinders, thread grinders, and various cylindrical grinders, including those for crankshafts, spherical components, and axles. They manufacture gear hobbing machines and precision, high-efficiency broaching machines. The company also produces precision gears.

Qinchuan Machine Tool Factory notably produces an eleven-axis five-linkage gear grinding machine, model YKZ7230 CNC worm wheel gear grinding machine. This advanced machine processes gears with a modulus of 1-6mm and an outer diameter of 300mm. It features high automation, including automatic workpiece clamping and pressure angle adjustment. The machine utilizes multiple grinding heads to enhance machining efficiency. It also employs same-phase dressing technology to improve grinding wheel dressing accuracy.

Beijing Jingdiao Group

Beijing Jingdiao Group establishes itself as a leader in high-precision engraving and milling solutions. The company specializes in machines that deliver exceptional accuracy for intricate tasks. Jingdiao’s technology supports industries requiring fine detail and superior surface finishes.

Jingdiao offers a comprehensive range of high-precision machines. These include:

- JINGDIAO High-Speed Machining Centers

- 3-Axis Series

- 5-Axis Series

- Series for Special Use

- JINGDIAO CNC Machining Centers

- CTA Series

- VTA Series

These machines cater to diverse applications, from mold making to aerospace components. Jingdiao’s focus on innovation ensures its position among the top CNC machine manufacturers. They consistently provide advanced solutions for complex machining challenges.

Haitian Precision

Haitian Precision stands out for its large-scale and high-performance CNC machines. The company designs its equipment for maximum productivity and stability. Haitian Precision serves industries that process oversized and complex workpieces.

Haitian Precision’s product lines include:

- DGM-Series: This series focuses on high-efficiency double column gantry machining. It provides maximum productivity, stability, power, and accuracy. It handles large-scale, high-precision, complex, and oversized workpieces.

- DP-Series: This series offers precision power in large-scale machining. It provides exceptional accuracy and stability for heavy-duty and oversized components. Its double column design contributes to this performance.

Other notable series from Haitian Precision include:

- DA Series: Compact Double Column Machining Center (Fixed Crossrail).

- DB Series: Medium Size Double Column Machining Center (Fixed Crossrail).

- DD Series: Large Size Double Column Machining Center (Fixed Crossrail).

- DG Series: Ultra Large Size Double Column Machining Center (Fixed Crossrail).

- DGM Series: Heavy Cutting Double Column Machining Center (Moving Crossrail).

- DP Series: High Speed Double Column Machining Center (Moving Crossrail).

- DDE Series: High Production Double Column Machining Center (Moving Crossrail).

- VQ-Series: High Precision & Production Vertical Machining Center.

Haitian Precision’s extensive portfolio demonstrates its capability to meet demanding industrial requirements. They deliver robust and reliable solutions for heavy-duty machining.

Jinan No.1 Machine Tool Co., Ltd.

Jinan No.1 Machine Tool Co., Ltd. (JMTCL) holds a significant place in China’s machine tool industry. The company specializes in comprehensive lathe and machining centers. JMTCL has a long history of contributing to the development of machine tools in China.

JMTCL manufactures a wide array of products. These include various types of CNC lathes, vertical machining centers, and horizontal machining centers. The company’s machines serve general manufacturing, automotive, and other heavy industries. JMTCL focuses on producing reliable and efficient equipment. They aim to meet the diverse needs of their customers. Their commitment to quality and performance helps maintain their strong market presence.

Guangzhou CNC Equipment Co., Ltd. (GSK)

Guangzhou CNC Equipment Co., Ltd. (GSK) stands as a leading force in advanced CNC systems and control technologies. The company specializes in the research, development, and manufacturing of high-performance CNC controllers. GSK’s innovations significantly contribute to the intelligence and automation of machine tools across China. They provide critical components that empower many domestic machine tool builders.

GSK’s product portfolio extends beyond just controllers. They also offer a range of complete machine tools, including CNC lathes and milling machines, all integrated with their proprietary control systems. Their commitment to R&D ensures continuous improvement in precision, speed, and reliability. This focus helps manufacturers achieve higher productivity and better product quality. GSK plays a vital role in elevating the technological capabilities of the Chinese CNC industry.

Chongqing Machine Tool Group

Chongqing Machine Tool Group holds a significant position among China’s industrial machinery manufacturers. The group specializes in producing high-quality, specialized machine tools. They particularly excel in gear manufacturing equipment and precision machinery. Their products serve various heavy industries and precision engineering sectors.

Chongqing Machine Tool Group manufactures a diverse range of essential machinery. These include:

- CNC gear hobbing machines

- Precision lathes

The group’s expertise in gear hobbing machines allows for the production of highly accurate gears, crucial for automotive, aerospace, and wind power industries. Their precision lathes offer robust solutions for turning operations, meeting stringent tolerance requirements. Chongqing Machine Tool Group consistently delivers reliable and efficient solutions, supporting the backbone of industrial production.

Tongtai Machine Tool Co., Ltd.

Tongtai Machine Tool Co., Ltd. is a prominent manufacturer offering comprehensive machine tool solutions. The company provides a wide array of advanced machinery, catering to diverse industrial needs. Tongtai’s commitment to innovation and quality makes them a key player in the global market.

Tongtai’s extensive product offerings include:

- Horizontal Machining Centers (e.g., SH-4000(P))

- Horizontal CNC Lathes (e.g., TCS-2500[L]II)

- Multi-tasking Turning Centers (e.g., TD-2000Y[BC])

- Vertical Machining Centers

- 5-axis Machining Centers

- Tapping Centers

- Boring & Milling Machines

- Vertical CNC Lathes

The company’s market focus extends across several critical areas. These include:

- Machine Tools

- PCB Machines

- Laser Machines

- Additive Manufacturing

- Intelligent Manufacturing

Tongtai Machine Tool Co., Ltd. demonstrates a significant market focus in China. They operate two manufacturing facilities in Suzhou City, Jiangsu Province, under Shuzhou TongYu Machine & Tool Co., Ltd. The company also maintains a dedicated Chinese website (www.tongtai.com.tw/cn), further solidifying its commitment to the Chinese market. The establishment of the Suzhou factory fulfilled the company’s goal of having dual manufacturing centers, indicating a strategic investment in the region.

Tongtai provides comprehensive solutions, including turnkey projects. Their offerings encompass:

- Turnkey solutions

- Horizontal/Vertical machining centers

- Horizontal/Vertical CNC lathes

- PCB drilling/routing machines

- Horizontal boring and milling machines

This broad range of products and services positions Tongtai as a versatile and reliable partner for manufacturers seeking advanced CNC solutions. They are certainly among the top CNC machine manufacturers in the region.

Yamazaki Mazak China

Yamazaki Mazak China holds a prominent position among the top CNC machine manufacturers in the Chinese market. This company is a key player in providing advanced machine tools and comprehensive manufacturing solutions. Mazak’s global expertise translates into high-quality, innovative products tailored for the demanding Chinese industrial landscape. The company focuses on delivering precision, efficiency, and reliability across its diverse product range.

Yamazaki Mazak China offers a wide array of sophisticated CNC machine models. These machines cater to various industrial applications, from general manufacturing to high-tech sectors. Their product lineup includes:

- INTEGREX machines, known for their multi-tasking capabilities.

- Advanced 5-axis machining centers, providing complex part manufacturing.

- Versatile Vertical Machining Centers for diverse milling operations.

- High-precision CNC turning centers, ideal for rotational parts.

- Robust Horizontal Machining Centers, designed for heavy-duty production.

- State-of-the-art laser processing machines for cutting and welding.

Mazak’s commitment to innovation extends to its broader portfolio. They also distribute and support:

- Multi-Tasking Machines that combine multiple processes.

- Specialized 5-Axis Machining Centers for intricate geometries.

- Efficient CNC Turning Centers for various turning needs.

- Swiss-Style Production Turning Machines for small, precise components.

- Reliable Vertical Machining Centers for general-purpose milling.

- High-performance Horizontal Machining Centers for large-volume production.

- Additive Manufacturing (AM) solutions, integrating 3D printing capabilities.

- Friction Stir Welding (FSW) technology for advanced material joining.

The company emphasizes smart manufacturing solutions. They integrate automation and digital technologies into their machines. This approach helps customers achieve higher productivity and operational efficiency. Yamazaki Mazak China continues to invest in local research and development. This ensures their offerings meet the specific needs and evolving demands of Chinese industries. Their strong service network also provides excellent after-sales support and technical assistance to clients across the region.

Spotlight on Leading Chinese CNC Machine Manufacturers: Capabilities and Specializations

This section highlights the capabilities and specializations of some of the top CNC machine manufacturers in China. These companies demonstrate innovation, extensive product ranges, and significant market influence. They cater to diverse industrial needs, from heavy-duty applications to high-precision tasks.

SMTCL: Diverse Product Range and Global Market Reach

Shenyang Machine Tool Group (SMTCL) stands as a prominent global player in the CNC machine industry. The company offers a comprehensive range of CNC machines. These include advanced lathes and complex machining centers. SMTCL demonstrates a significant global presence. SMTCL exports its machine tools to more than 50 countries. These include key markets in Europe, North America, and Southeast Asia. The company also established strategic partnerships. These partnerships further enhance its market reach and technological capabilities. SMTCL’s products are utilized in over 80 countries worldwide. This demonstrates a significant global presence. A robust network of distributors and service centers facilitates this extensive reach. This network ensures international customer support.

DMTG: Heavy-Duty and Specialized Industrial Solutions

Dalian Machine Tool Group (DMTG) is a major manufacturer. It is known for its robust and diverse range of machine tools. The company provides heavy-duty and specialized industrial solutions. DMTG’s offerings cater to a wide array of manufacturing requirements. DMTG is identified as a ‘Metal Processing Industry Specialist‘. It provides optimum industrial solutions. Its heavy-duty solutions primarily serve several specific industrial sectors:

- Automobile industry

- Rail transit industry

- Engineering machinery industry

- Petroleum machinery industry

- Mining metallurgy industry

- Communication equipment industry

- Vocational education industry

DMTG’s extensive product line supports various industrial applications. From precision CNC turning to complex five-axis milling, DMTG provides reliable and efficient machinery. Its intelligent manufacturing production lines offer integrated solutions for modern factories.

QCMT&T: Expertise in Precision Grinding and Gear Manufacturing

Qinchuan Machine Tool & Tool Group (QCMT&T) specializes in precision grinding and gear manufacturing technologies. The company offers a comprehensive range of machines. These machines deliver high accuracy and efficiency in these specialized fields. QCMT&T utilizes specific precision grinding and gear manufacturing technologies. These include CNC and manual gear grinders. They also include worm, cone, and form wheel types. These are suitable for various applications. The company also produces CNC and manual shaving cutter grinders. Additionally, it manufactures CNC and manual OD/Cylindrical grinders. These cater to standard, universal, high-speed, camshaft, crankshaft, bearing, and specialty markets. QCMT&T’s product range further encompasses cylindrical grinding machines, gear cutting machines, thread grinding machines, and precision gears. The company also produces gear hobbing machines and precision, high-efficiency broaching machines. Qinchuan Machine Tool Factory notably produces an eleven-axis five-linkage gear grinding machine. This advanced machine processes gears with a modulus of 1-6mm and an outer diameter of 300mm. It features high automation. This includes automatic workpiece clamping and pressure angle adjustment. The machine uses multiple grinding heads. This enhances machining efficiency. It also employs same-phase dressing technology. This improves grinding wheel wheel dressing accuracy.

Beijing Jingdiao: High-Precision Engraving and Milling Solutions

Beijing Jingdiao Group leads the industry in high-precision engraving and milling solutions. The company specializes in machines that deliver exceptional accuracy for intricate tasks. Jingdiao’s technology supports industries requiring fine detail and superior surface finishes. Their advanced machines perform critical operations across various sectors. These include mold parts milling, where they achieve precise contours. They also excel in mirror-finished mold parts polishing, ensuring superior surface quality. Jingdiao machines handle precision holes grinding and small product parts precision milling with remarkable accuracy. Furthermore, they perform die casting parts composite processing and micro holes drilling on metals and special materials. Their capabilities extend to drilling, milling, and grinding, as well as hard brittle parts grinding.

Jingdiao offers a comprehensive range of high-precision machines. These include:

- JINGDIAO High-Speed Machining Centers

- 3-Axis Series

- 5-Axis Series

- Series for Special Use

- JINGDIAO CNC Machining Centers

- CTA Series

- VTA Series

These machines cater to diverse applications, from mold making to aerospace components. Jingdiao’s focus on innovation ensures its position among the top CNC machine manufacturers. They consistently provide advanced solutions for complex machining challenges.

Haitian Precision: Large-Scale and High-Performance CNC Machines

Haitian Precision stands out for its large-scale and high-performance CNC machines. The company designs its equipment for maximum productivity and stability. Haitian Precision serves industries that process oversized and complex workpieces. Their machines handle demanding tasks with exceptional reliability.

Haitian Precision’s product lines include:

- DGM-Series: This series focuses on high-efficiency double column gantry machining. It provides maximum productivity, stability, power, and accuracy. It handles large-scale, high-precision, complex, and oversized workpieces.

- DP-Series: This series offers precision power in large-scale machining. It provides exceptional accuracy and stability for heavy-duty and oversized components. Its double column design contributes to this performance.

Other notable series from Haitian Precision include:

- DA Series: Compact Double Column Machining Center (Fixed Crossrail).

- DB Series: Medium Size Double Column Machining Center (Fixed Crossrail).

- DD Series: Large Size Double Column Machining Center (Fixed Crossrail).

- DG Series: Ultra Large Size Double Column Machining Center (Fixed Crossrail).

- DGM Series: Heavy Cutting Double Column Machining Center (Moving Crossrail).

- DP Series: High Speed Double Column Machining Center (Moving Crossrail).

- DDE Series: High Production Double Column Machining Center (Moving Crossrail).

- VQ-Series: High Precision & Production Vertical Machining Center.

Haitian Precision’s extensive portfolio demonstrates its capability to meet demanding industrial requirements. They deliver robust and reliable solutions for heavy-duty machining.

GSK: Advanced CNC Systems and Control Technologies

Guangzhou CNC Equipment Co., Ltd. (GSK) leads in advanced CNC systems and control technologies. The company specializes in the research, development, and manufacturing of high-performance CNC controllers. GSK’s innovations significantly contribute to the intelligence and automation of machine tools across China. They provide critical components that empower many domestic machine tool builders.

GSK continuously advances its CNC systems. The GSK 25i Series represents a next-generation CNC controller. It offers unprecedented data processing speed, enhanced system stability, and robust control capabilities. This series integrates multi-axis linkage, bus control, and absolute encoders for high-speed precision. GSK also develops adaptive control of feed rate, specifically for 5-axis side-edge machining. Their pitch compensation features one-key operation for swift parameter settings and data writing, enabling precise correction and compensation. For complex multi-axis components, GSK offers 5-Axis machining with RTCP (optional). This supports up to 8-axis and 5-linkage. It includes features like inclined plane positioning, tool path fairing, and adaptive feed rate control.

GSK controllers boast impressive specifications:

| Feature | Specification |

|---|---|

| Control Axes | Up to 8 feed axes, 2 to 5 axes typically, with linear (up to 5) and circular (up to 2) interpolation. |

| Motion Control | Minimum moving unit: 0.1um (0.0001mm); Maximum moving speed: 100m/min. |

| G Functions | Up to 69 functions, including rapid positioning, various interpolations (linear, circular, cylindrical, polar coordinate), thread cutting, tool compensation, macro programming, and tilt axis control. |

| Feed Functions | Rapid Speed: 0-100,000mm/min; Cutting Feed Speed: 0-15,000mm/min; Configurable linear or S-type acceleration/deceleration. |

| Spindle Functions | Speed: 0-9999rpm; Override: 50%-120%; 2 channels of 0V-10V analog output; 2 channels of encoder feedback. |

| Tool Functions | Up to 32 groups for length and wear compensation; 32 groups for tool life management (8 tools/group); C-type tool nose radius compensation; various tool setting methods. |

| PLC Functions | Two-level program architecture (up to 5000 steps, 8ms refresh); 13 basic and 44 functional instructions; online display and monitoring; 48 input/38 output (expandable). |

| Program Storage & Editing | Up to 64MB capacity, 10,000 programs; full-screen editing; up to 4-fold macro/subprogram nesting. |

| Communication Interfaces | USB, RS232, LAN, GSK-LINK (Industrial Ethernet bus). |

| Safety Features | Emergency stop, hardware/software travel limits, data backup and recovery. |

GSK’s product portfolio extends beyond just controllers. They also offer a range of complete machine tools, including CNC lathes and milling machines, all integrated with their proprietary control systems. Their commitment to R&D ensures continuous improvement in precision, speed, and reliability. This focus helps manufacturers achieve higher productivity and better product quality. GSK plays a vital role in elevating the technological capabilities of the Chinese CNC industry.

The Chinese CNC manufacturing landscape sees a rise in retrofit solutions. Manufacturers upgrade legacy machines with modern GSK controllers, such as the 998T-MAX multi-axis retrofit kits. This enhances performance and extends lifespan, avoiding full system replacements. Newer models also support integration with IoT and cloud monitoring. They offer remote diagnostics and predictive maintenance via cloud platforms, including GSK-Link diagnostic functions, for improved operational oversight. Furthermore, GSK controllers increasingly focus on energy efficiency. They incorporate power-saving modes and optimized motion algorithms to reduce energy consumption and operational costs.

Jinan No.1 Machine Tool: Comprehensive Lathe and Machining Centers

Jinan No.1 Machine Tool Co., Ltd. (JMTCL) holds a significant place in China’s machine tool industry. The company specializes in comprehensive lathe and machining centers. JMTCL boasts a long history of contributing to machine tool development in China. It consistently delivers reliable and efficient equipment.

JMTCL manufactures a wide array of products. These include various types of CNC lathes, vertical machining centers, and horizontal machining centers. The company’s machines serve general manufacturing, automotive, and other heavy industries. JMTCL focuses on producing reliable and efficient equipment. They aim to meet the diverse needs of their customers. Their commitment to quality and performance helps maintain their strong market presence.

JMTCL’s product range includes:

- CNC Lathes: These machines offer precision turning capabilities for various materials.

- Vertical Machining Centers: They provide versatile milling, drilling, and tapping operations.

- Horizontal Machining Centers: These machines excel in high-volume production and complex part manufacturing.

The company’s dedication to robust design and manufacturing ensures their machines perform consistently in demanding industrial environments. JMTCL’s comprehensive offerings make them a key supplier for manufacturers seeking dependable and high-performance machine tools.

OTURN MACHINERY: Special Purpose Machine Manufacturing and Production Line Solutions

OTURN MACHINERY stands as a reliable special purpose machine manufacturer. It operates as an overseas marketing and sales center established by its group factories. OTURN MACHINERY focuses on the research and development (R&D) and manufacturing of high-quality, high-efficiency industrial special purpose machines for customers.

The company also designs complete production line solutions for clients, guiding them from initial concept to full implementation. OTURN MACHINERY prioritizes selecting the most efficient processing methods for its customers. This approach helps clients reasonably save equipment investment costs. It also ensures an earlier recovery of input costs.

OTURN MACHINERY’s core strengths include:

- Customized Solutions: They develop machines tailored to specific industrial needs, addressing unique manufacturing challenges.

- Production Line Integration: The company provides end-to-end solutions, designing and implementing entire manufacturing lines.

- Efficiency Focus: OTURN MACHINERY aims to optimize production processes, leading to higher output and reduced operational expenses.

- Cost-Effectiveness: They help customers achieve significant savings on equipment investment while ensuring quick returns.

OTURN MACHINERY’s mission centers on delivering innovative and practical solutions. They empower businesses to enhance their manufacturing capabilities and achieve greater operational efficiency. Their expertise in special purpose machines and production line design makes them a valuable partner for diverse industries.

Emerging Trends Shaping the Chinese CNC Manufacturing Landscape

The Chinese CNC manufacturing sector is rapidly evolving. Several key trends drive this transformation. These trends enhance efficiency, precision, and sustainability.

Accelerated Automation and Robotics Integration

Chinese CNC manufacturers increasingly integrate advanced robotics into their processes. This boosts automation capabilities and operational efficiency. Robots perform repetitive tasks, freeing human workers for more complex roles. China’s focus on innovation in CNC automation strengthens its position as a global manufacturing leader. With increased connectivity, robust cybersecurity measures become crucial. These measures protect data and ensure operational integrity. The demand for personalized products also drives the development of CNC machines. These machines produce highly customized solutions.

Smart Manufacturing and Industrial IoT Adoption

Chinese CNC factories widely adopt smart manufacturing and Industrial IoT (IIoT) technologies. Digital Twins allow remote factory audits. Purchasers monitor production progress, machine status, and quality inspection data in real-time. This improves cross-border collaboration efficiency by 40%. Big Data and AI optimize supplier matching. They analyze historical order data, reducing the supplier screening cycle by approximately 60%. AI also optimizes mass production strategies. It analyzes material utilization and energy consumption. It dynamically adjusts parameters like cutting speed and feed rate. This reduces tool consumption by 15%. Blockchain integrates with certification systems like ISO 9001. It encrypts and stores key process parameters and inspection reports. This ensures full lifecycle traceability for critical parts. Industrial Internet Platforms facilitate rapid responses for small-batch custom orders. Customers submit design requirements online. The system automatically generates process solutions and pricing. This compresses prototyping cycles from 14 days to within 72 hours. Generative AI for Design automatically creates part solutions. These solutions meet performance, weight, and cost constraints. This is particularly useful for aluminum CNC turning parts requiring lightweight designs.

Focus on Green and Sustainable Production Technologies

Chinese CNC manufacturers increasingly focus on green and sustainable production technologies. They aim to reduce their environmental footprint. This involves adopting energy-efficient machinery and optimizing production processes. Manufacturers also explore eco-friendly materials and waste reduction strategies. They implement advanced filtration systems to minimize emissions. This commitment to sustainability aligns with global environmental goals. It also enhances the industry’s long-term viability.

Expansion into High-End and Complex Applications

Chinese CNC manufacturers increasingly target high-end and complex applications. They move beyond traditional manufacturing sectors. This strategic shift reflects their growing technological capabilities. Manufacturers now focus on industries demanding extreme precision and intricate designs.

These advanced applications include:

- Aerospace

- Engine manufacturing

- Defense

- Consumer electronics

- New energy vehicles

These sectors require sophisticated machinery. For example, manufacturers develop advanced turn-milling composite machine tools. These tools represent the pinnacle of processing efficiency, precision, and complexity. They combine multiple operations into one machine. This reduces production time and improves accuracy. Chinese companies now produce machines capable of handling these demanding tasks. This expansion demonstrates their commitment to innovation. It also highlights their ability to meet global industry standards. This trend positions China as a leader in advanced manufacturing solutions.

Strategic Global Market Expansion and Partnerships

Chinese CNC manufacturers actively pursue strategic global market expansion. They form international partnerships. This approach helps them increase their global footprint. Manufacturers establish sales and service networks in key regions. They also collaborate with foreign companies. These partnerships facilitate technology exchange. They also open new distribution channels.

Companies invest in overseas research and development centers. This allows them to tailor products to specific market needs. They participate in international trade shows. This showcases their advanced machinery to a global audience. This outward-looking strategy strengthens their competitive position. It also enhances their brand recognition worldwide. Chinese manufacturers aim to become indispensable partners in the global supply chain. They offer reliable and technologically advanced CNC solutions.

China firmly establishes itself as a global CNC manufacturing powerhouse. Its rapid growth and technological advancements solidify this position. Thorough manufacturer selection remains crucial for buyers. They must consider quality, comprehensive support, and innovation. The Chinese CNC market will continue its trajectory of innovation. Smart manufacturing and sustainable practices will drive future growth and development.

FAQ

Why should global buyers consider Chinese CNC manufacturers?

Chinese CNC manufacturers offer cost-effectiveness and high value. They integrate advanced technologies and provide extensive production capacity. Their robust supply chains ensure efficient delivery. These advantages make them a leading choice for global buyers.

What critical factors guide the selection of a Chinese CNC manufacturer?

Buyers should prioritize adherence to quality standards and comprehensive after-sales service. Industry certifications and regulatory compliance are essential. Manufacturers’ investment in innovation and their reputation, supported by customer testimonials, also guide selection.

How do Chinese CNC manufacturers integrate advanced technologies?

Manufacturers actively integrate automation and robotics. They adopt smart manufacturing and Industrial IoT. This includes digital twins, AI for optimization, and blockchain for traceability. These technologies enhance precision, efficiency, and productivity.

What emerging trends are shaping China’s CNC manufacturing landscape?

Key trends include accelerated automation and smart manufacturing adoption. Manufacturers focus on green production technologies. They expand into high-end applications and pursue strategic global market expansion. These trends drive innovation and growth.

Post time: Dec-25-2025